Welding system for reducing aluminum alloy laser-arc hybrid welding air holes and method

A welding system and hybrid welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high porosity, uneven weld seam composition, and insufficient molten pool flow in laser-arc hybrid welding, and achieve The effect of reducing the risk of porosity, improving welding quality, and reducing welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

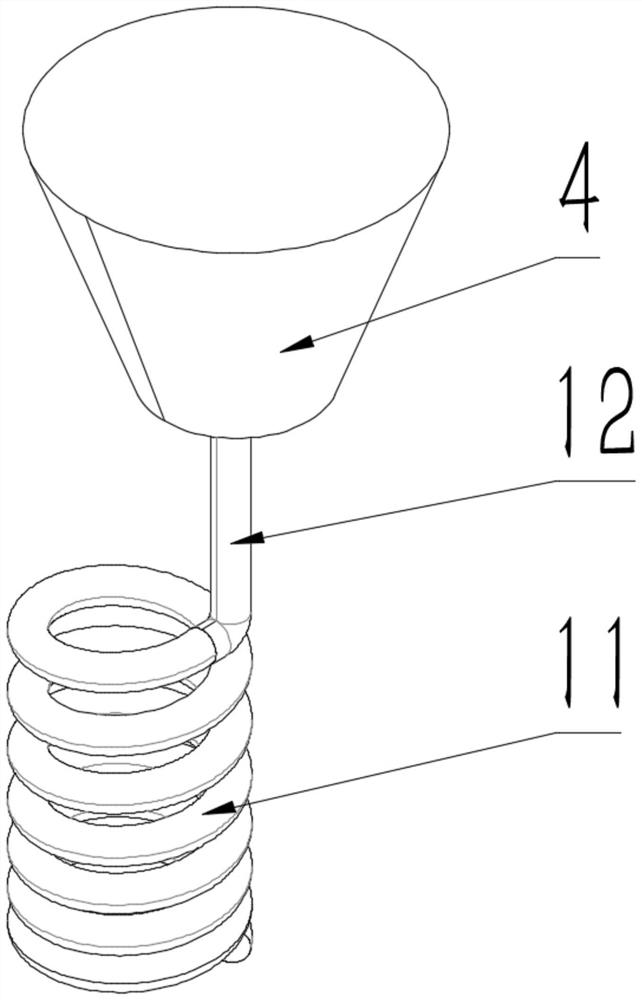

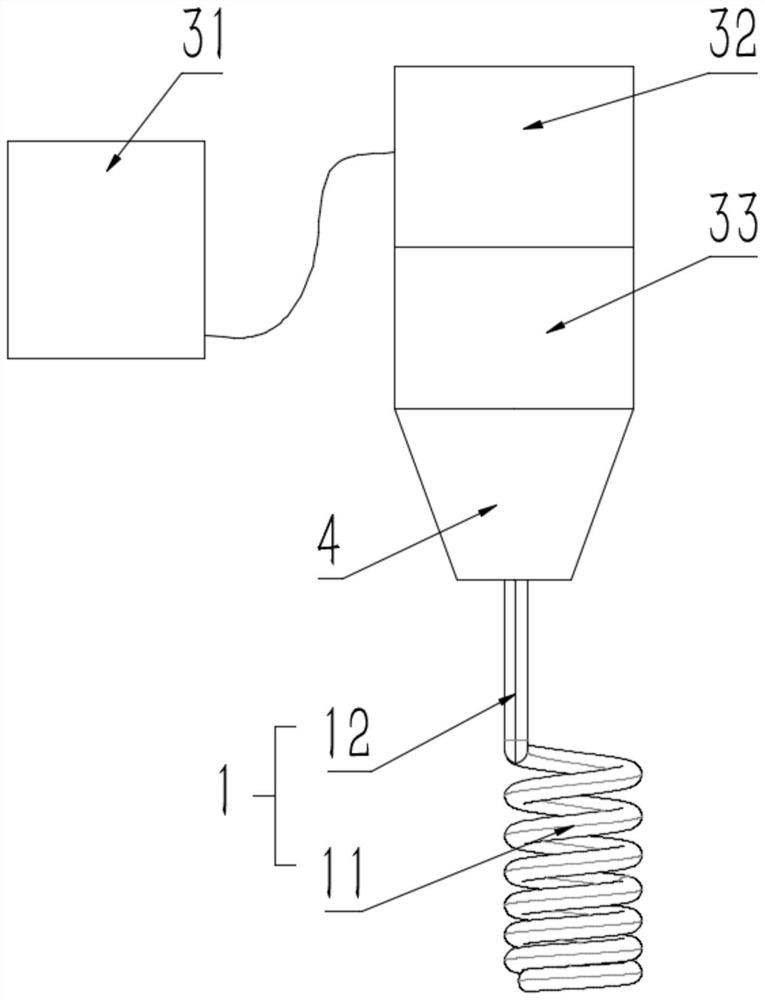

[0041] Such as figure 1 , figure 2 and Figure 6 As shown, this embodiment provides a welding system for reducing porosity in aluminum alloy laser-arc hybrid welding, including: a vibrating device and a probe, the vibrating device drives the probe 1 to vibrate, and the probe 1 includes a spiral Agitation section 11.

[0042] Further, the probe 1 also includes a linear first connecting part 12, the agitating part 11 and the first connecting part 12 are integrally formed, and the vibrating device includes an ultrasonic generator 31, a transducer 32 and an amplitude Rod 33 , the ultrasonic generator 31 is electrically connected to the transducer 32 , the transducer 32 is fixedly connected to the horn 33 , and the horn 33 drives the stirring part 11 and the first connecting part 12 to vibrate.

[0043] Further, a first clamp 4 is further included, the first clamp 4 is fixedly connected with the horn 33 , and the first clamp 4 is detachably connected with the first connecting p...

Embodiment 2

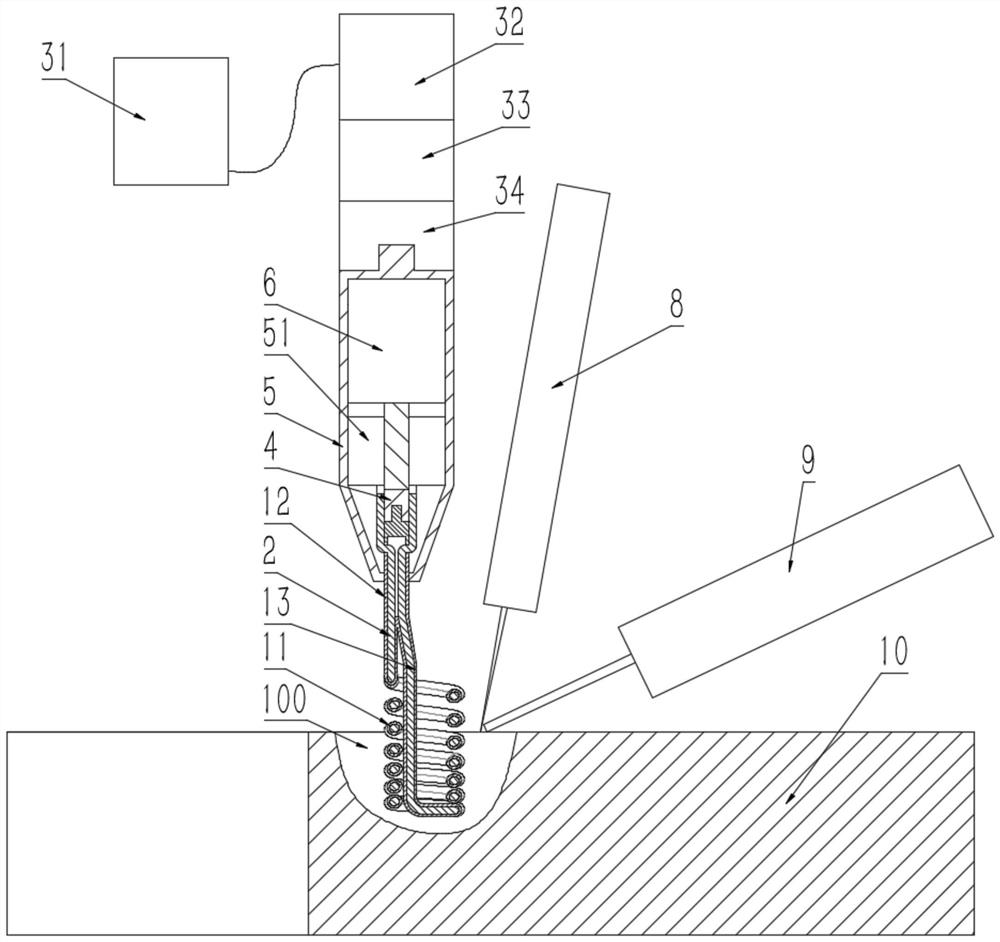

[0057] Such as image 3 and Figure 6 As shown, this embodiment provides a welding system for reducing porosity in aluminum alloy laser-arc hybrid welding, including: a vibrating device and a probe, the vibrating device drives the probe 1 to vibrate, and the probe 1 includes a spiral Agitation section 11.

[0058] Further, the probe 1 also includes a linear first connecting portion 12, the agitating portion 11 and the first connecting portion 12 are integrally formed, and the vibrating device includes an ultrasonic generator 31, a transducer 32 and an amplitude rod 33 , the ultrasonic generator 31 is electrically connected to the transducer 32 , the transducer 32 is fixedly connected to the horn 33 , and the horn 33 drives the stirring part 11 and the first connecting part 12 to vibrate.

[0059] Further, it also includes a first chuck 4, a first housing 5, a motor 6 and a second chuck 34, the horn 33 is fixedly connected to the second chuck 34, and the second chuck 34 is co...

Embodiment 3

[0076] Such as Figure 4 and Figure 6 As shown, this embodiment provides a welding system for reducing porosity in aluminum alloy laser-arc hybrid welding, including: a vibrating device and a probe, the vibrating device drives the probe 1 to vibrate, and the probe 1 includes a spiral Agitation section 11.

[0077] Further, the probe 1 also includes a linear first connecting portion 12, the agitating portion 11 and the first connecting portion 12 are integrally formed, and the vibrating device includes an ultrasonic generator 31, a transducer 32 and an amplitude rod 33 , the ultrasonic generator 31 is electrically connected to the transducer 32 , the transducer 32 is fixedly connected to the horn 33 , and the horn 33 drives the stirring part 11 and the first connecting part 12 to vibrate.

[0078] Further, it also includes a first chuck 4, a first housing 5, a motor 6, a second chuck 34, an electric push rod 52 and a second housing 53, and the horn 33 is fixed to the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com