Vacuum atomizing device and method for preparing 3D printing powder

An atomization device and vacuum technology, applied in the field of 3D printing, can solve the problem of difficulty in controlling the surface smoothness of powder particles, and achieve the effects of reducing the solidification speed, recycling resources, and increasing spherical similarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

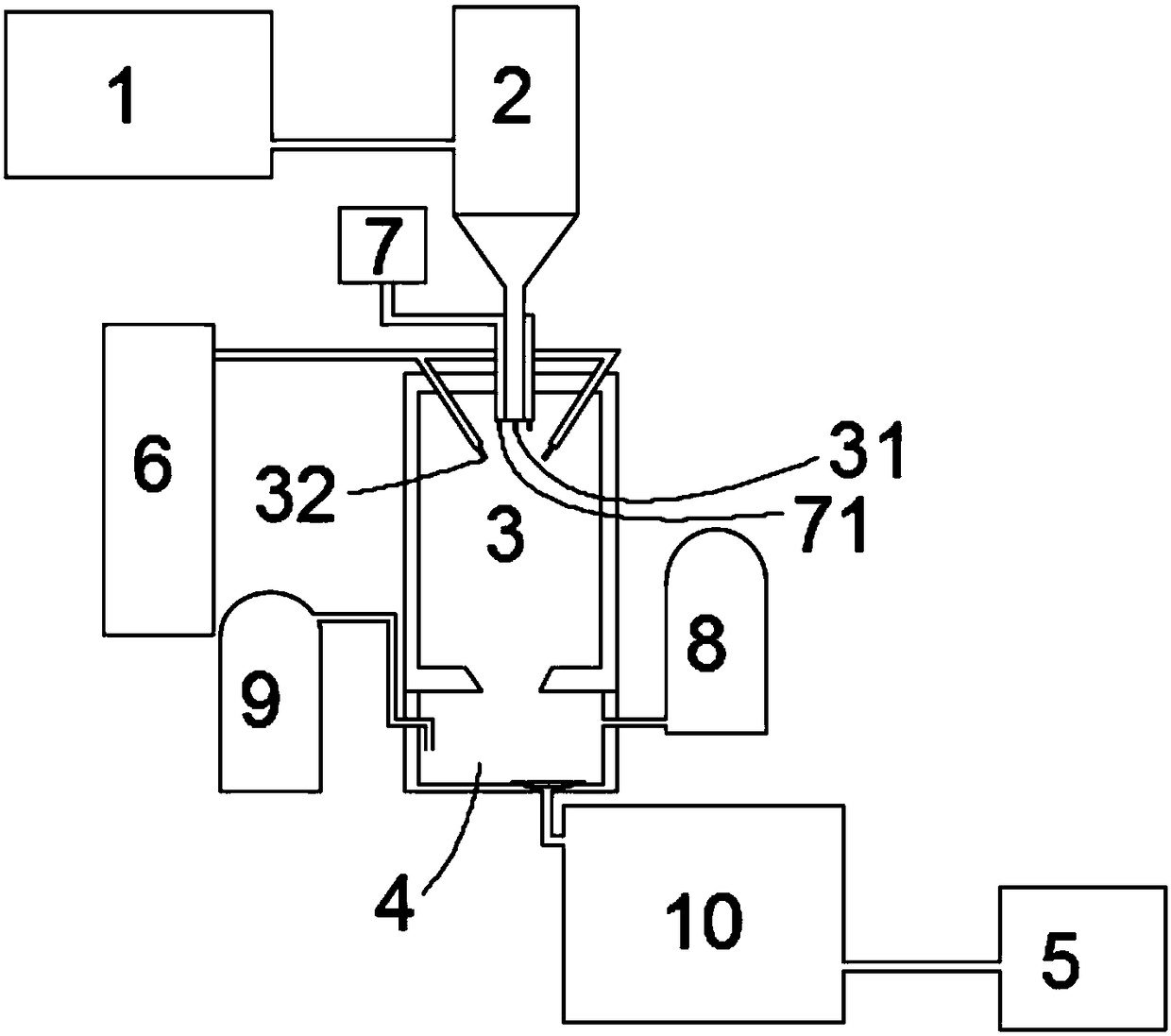

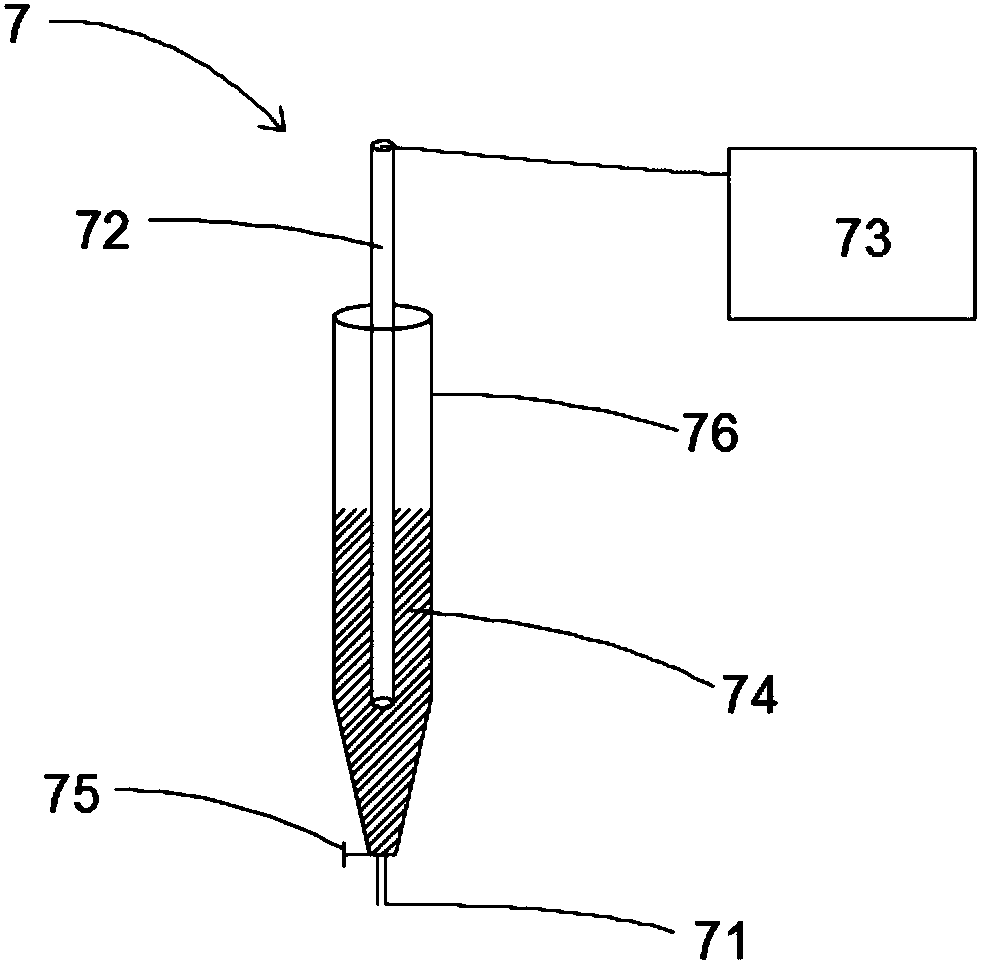

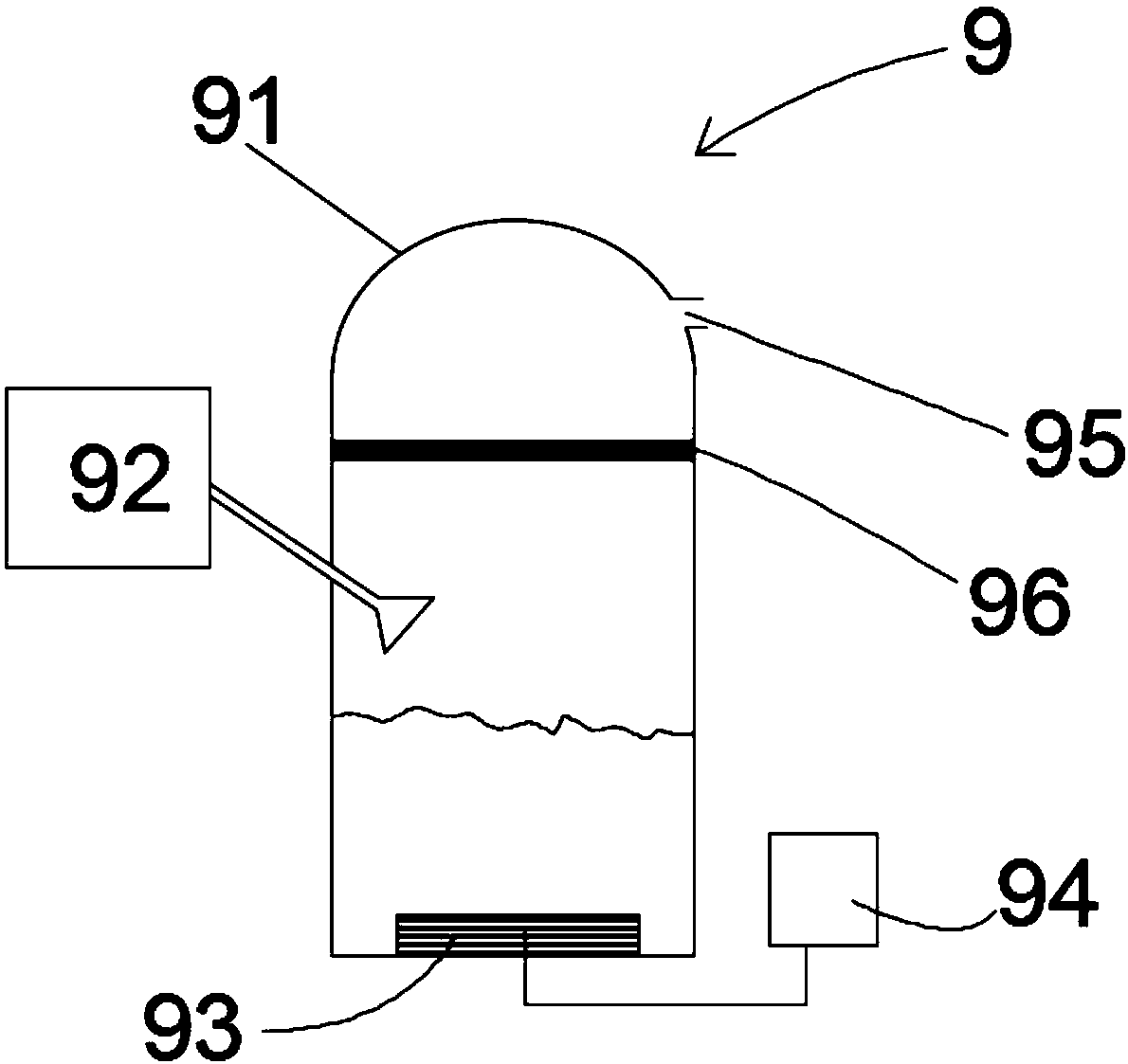

[0025] like figure 1 As shown, this embodiment provides a vacuum atomization device, which includes a vacuum induction furnace 1, a tundish 2, a gas atomization device 3, a cooling and dissolving tank 4, and a powder collection system 5 connected in sequence. The vacuum atomization device Also includes a high-pressure gas supply system 6, the gas atomization device 3 includes a metal liquid nozzle 31 communicated with the tundish 2 and a gas nozzle 32 communicated with the high-pressure gas supply system 6, the vacuum atomization device also Including a salt bath 7, the salt bath 7 is arranged above the gas atomization device 3, the salt bath 7 includes a salt bath nozzle 71, and the opposite sides of the molten metal nozzle 31 are respectively provided with a Said salt bath nozzle 71, said gas nozzle 32 is respectively arranged on opposite sides of said metal liquid nozzle 31, said salt bath nozzle 71 is arranged between said gas nozzle 32 and said metal liquid nozzle 31;

...

Embodiment 2

[0036] In this implementation, the method of using tool steel to prepare 3D printing powder is tested:

[0037] Step 1: The tool steel raw material with the composition shown in Table 1 is removed by pickling or grinding to remove the surface oxide rust layer, and cut into small sections of 30-50 cm, and put into the vacuum in the vacuum device in Example 1. Smelt in the induction furnace 1, vacuumize, the vacuum degree is 100pa, set the power to 20kw, heat to ensure that the raw materials are completely melted, and open the sodium nitrate salt bath 7 at the same time to keep the temperature constant at 350°C;

[0038] Table 1 Chemical Composition of Raw Materials

[0039] C

Ti

mn

P

S

co

Mo

Ni

N

0.02

0.6

≤0.10

≤0.01

≤0.01

8.5

4.6

18.0

70ppm

[0040] Step 2: feed nitrogen into the gas atomization device 3, open the gas nozzle 32 of the high-pressure gas supply system 6, the pressure of the nozzle is 5MPa,...

Embodiment 3

[0046] In this implementation, the method of preparing 3D printing powder using rod-shaped Fe-Mn-Pt-based medical metal materials is tested:

[0047] Step 1: For tool steel raw materials with the composition shown in Table 1, use pickling or grinding to remove the oxide rust layer on the surface, cut into small sections of 30-50 cm, and put them into the vacuum induction furnace 1 in the vacuum device for melting , vacuum, the vacuum degree is 100pa, set the power to 20kw, heat to ensure that the raw materials are completely melted, and open the sodium nitrate salt bath 7 at the same time to keep the temperature constant at 350°C;

[0048] Table 2 Chemical Composition of Raw Materials

[0049] C

Al

mn

Pt

S

N

0.6

0.5

18

1

≤0.01

70ppm

[0050] Step 2: Pass nitrogen into the gas atomization device 3, open the gas nozzle 32 of the high-pressure gas supply system 6, the pressure of the nozzle is 5.5MPa, spray through the nozzle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com