Super-soft and super-cotton type hydrolysis-resistant wet polyurethane resin and preparation method thereof

A wet-process polyurethane and super cotton technology, which is applied in the field of polyurethane resin materials for synthetic leather and materials for synthetic leather, can solve the problems of short storage time, resin viscosity reduction, etc., achieve soft hand feeling, prevent resin viscosity reduction, and good hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

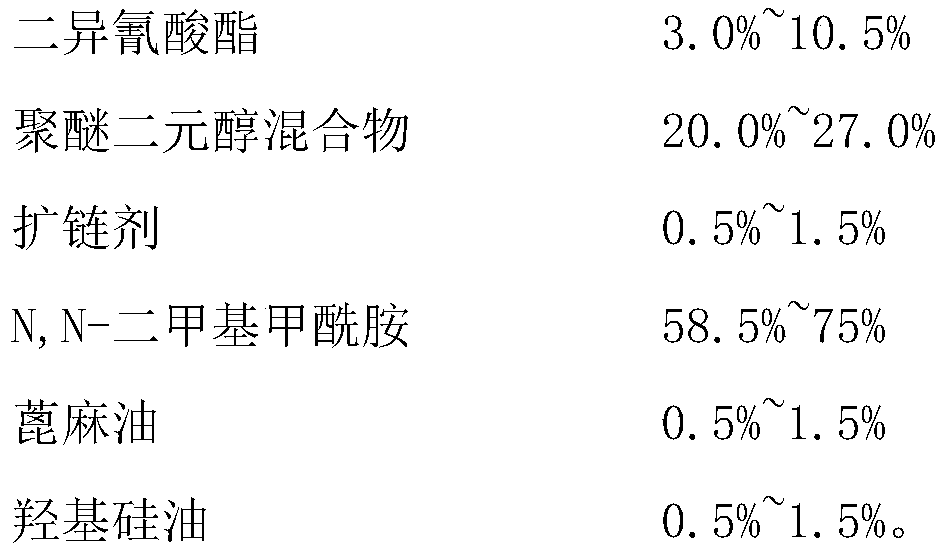

[0024] The weight percent of each component is as follows:

[0025]

[0026] Described hydroxy silicone oil adopts the 8858 model product of Guangzhou Siluoke Chemical Co., Ltd.;

[0027] The preparation method comprises the following steps:

[0028] 1) Prepolymerization reaction: Mix part of diisocyanate, polyether glycol mixture, castor oil, and part of N,N-dimethylformamide for reaction, control the solid content of the reaction solution to 50.3%, and react at 70°C 2 hours, the prepolymerization reaction finishes;

[0029] The part of diisocyanate is 60% of the total weight of diisocyanate;

[0030] The part of N,N-dimethylformamide is 30% of the total weight of N,N-dimethylformamide;

[0031] 2) Chain extension reaction: add chain extender and remaining N,N-dimethylformamide, react for 0.5 hours, add remaining diisocyanate to carry out chain extension reaction, reaction liquid viscosity reaches 190Pa·s / 25℃, add hydroxyl silicone oil Capped, the reaction ends.

Embodiment 2

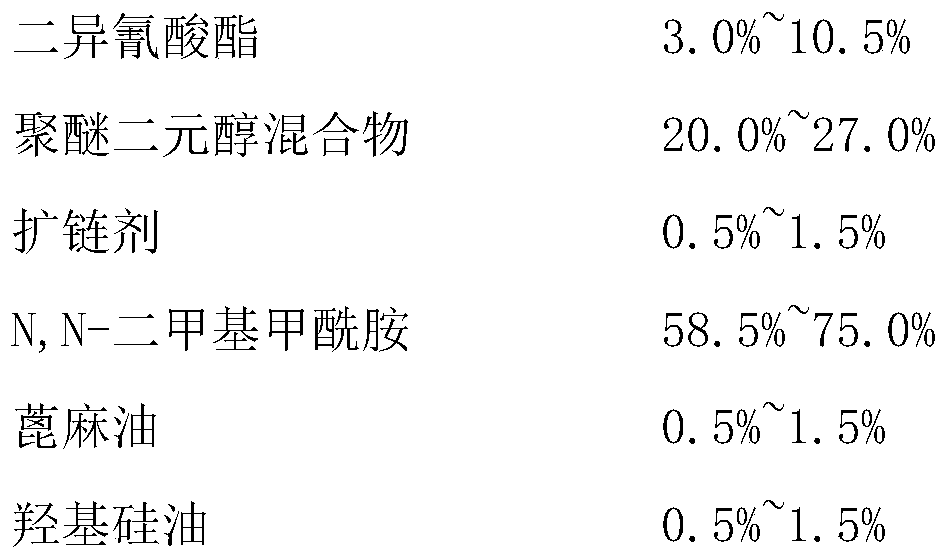

[0033] The weight percent of each component is as follows:

[0034]

[0035] Described hydroxyl silicone oil adopts the BYK-16-201 model product of BYK chemical company;

[0036] The preparation method comprises the following steps:

[0037] 1) Prepolymerization reaction: Mix part of diisocyanate, polyether glycol mixture, castor oil, and part of N,N-dimethylformamide for reaction, control the solid content of the reaction solution to 54.1%, and react at 80°C 3 hours, the prepolymerization reaction finishes;

[0038] The part of diisocyanate is 60% of the total weight of diisocyanate;

[0039] The part of N,N-dimethylformamide is 50% of the total weight of N,N-dimethylformamide;

[0040] 2) Chain extension reaction: add chain extender and remaining N,N-dimethylformamide, react for 1 hour, add remaining diisocyanate for chain extension reaction, reaction liquid viscosity reaches 250Pa·s / 25℃, add hydroxyl silicone oil Capped, the reaction ends.

Embodiment 3

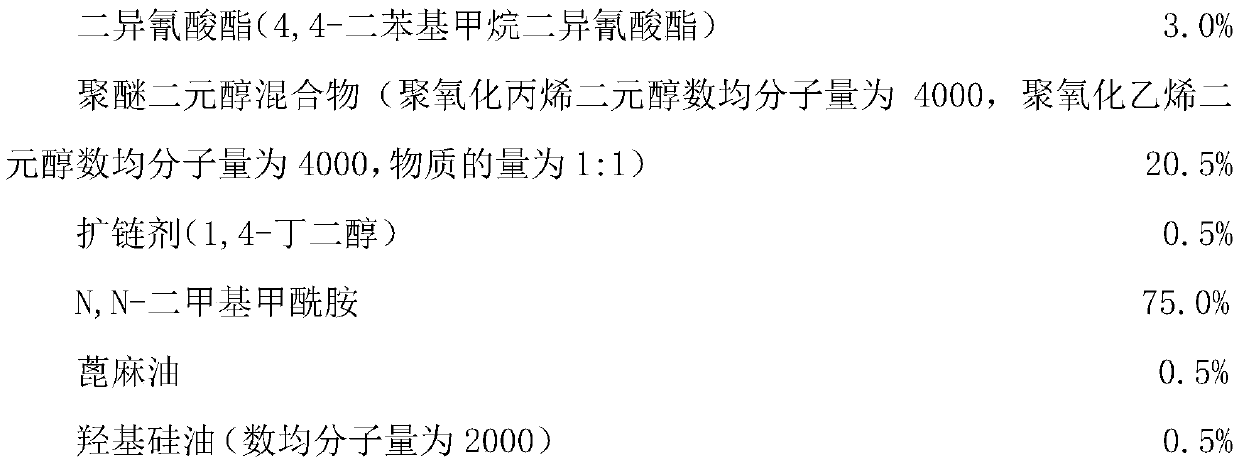

[0042] The weight percent of each component is as follows:

[0043]

[0044] Described hydroxyl silicone oil adopts the BYK-16-004 model product of BYK chemical company;

[0045] The preparation method comprises the following steps:

[0046] 1) Prepolymerization reaction: Mix part of diisocyanate, polyether glycol mixture, castor oil, and part of N,N-dimethylformamide for reaction, control the solid content of the reaction solution to 53.2%, and react at 75°C 2.5 hours, the prepolymerization reaction finishes;

[0047] The part of diisocyanate is 65% of the total weight of diisocyanate;

[0048] The part of N,N-dimethylformamide is 40% of the total weight of N,N-dimethylformamide;

[0049] 2) Chain extension reaction: add chain extender and remaining N,N-dimethylformamide, react for 1 hour, add remaining diisocyanate for chain extension reaction, reaction solution viscosity reaches 220Pa·s / 25℃, add hydroxyl silicone oil Capped, the reaction ends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com