Manual argon tungsten-arc welding and welding rod electric-arc welding combined welding method of G115 large-diameter pipe

A technology of argon tungsten arc welding and electrode arc welding, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of thermal crack penetration, poor, difficult to guarantee the mechanical properties of G115 large-diameter pipes, etc., and achieve forming The effect of beautiful appearance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode 1: This implementation mode is a welding method combining manual argon tungsten arc welding and electrode arc welding of G115 large-diameter tubes, which is completed according to the following steps:

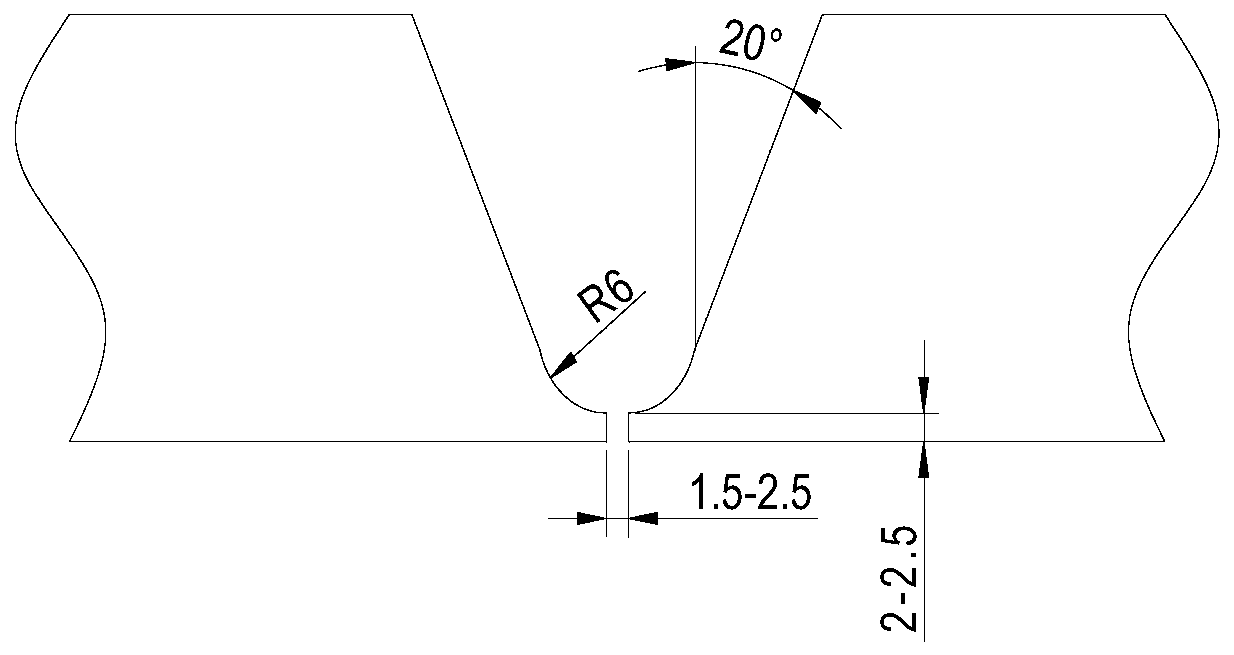

[0028] 1. Preparation before welding: Prepare the groove of the G115 large-diameter pipe, and then assemble it;

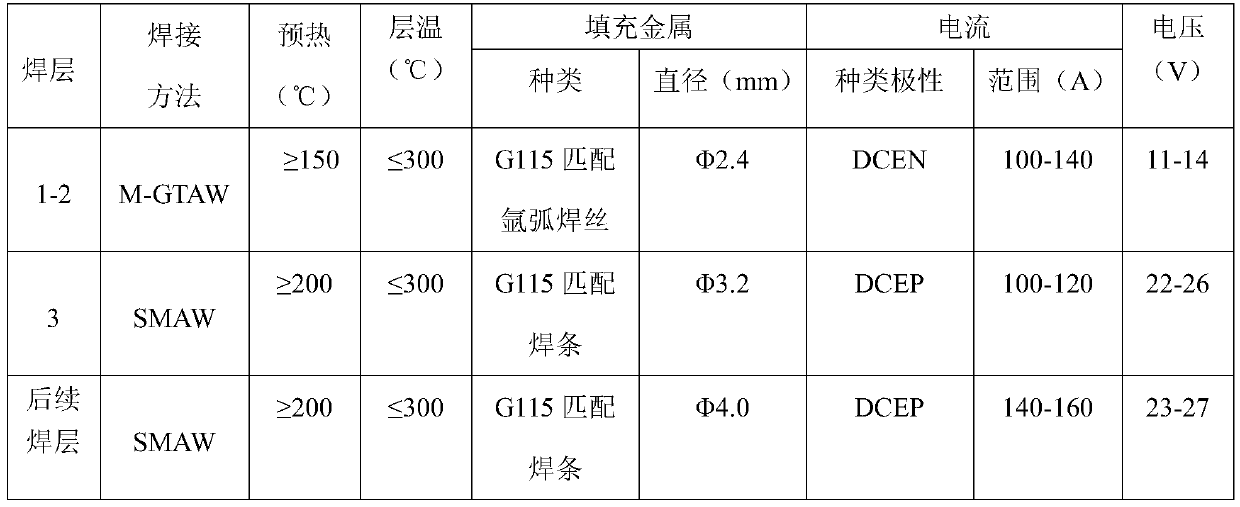

[0029] 2. Welding process: preheat the G115 large-diameter pipe, the first and second layers are manual tungsten argon arc welding, the layer temperature is ≤300 ℃, and the thickness of the deposited metal is 2mm to 3mm; the third layer is arc welding with electrodes. The layer temperature is ≤300℃, the thickness of the deposited metal is 2mm~3mm; the subsequent welding layer adopts electrode arc welding, the layer temperature is ≤300℃, and the thickness of the deposited metal is 3mm~4mm;

[0030] 3. Post-weld heat treatment: After welding, cool the G115 large-diameter pipe to 100°C-150°C, keep it warm for 1h, then raise the tempe...

specific Embodiment approach 2

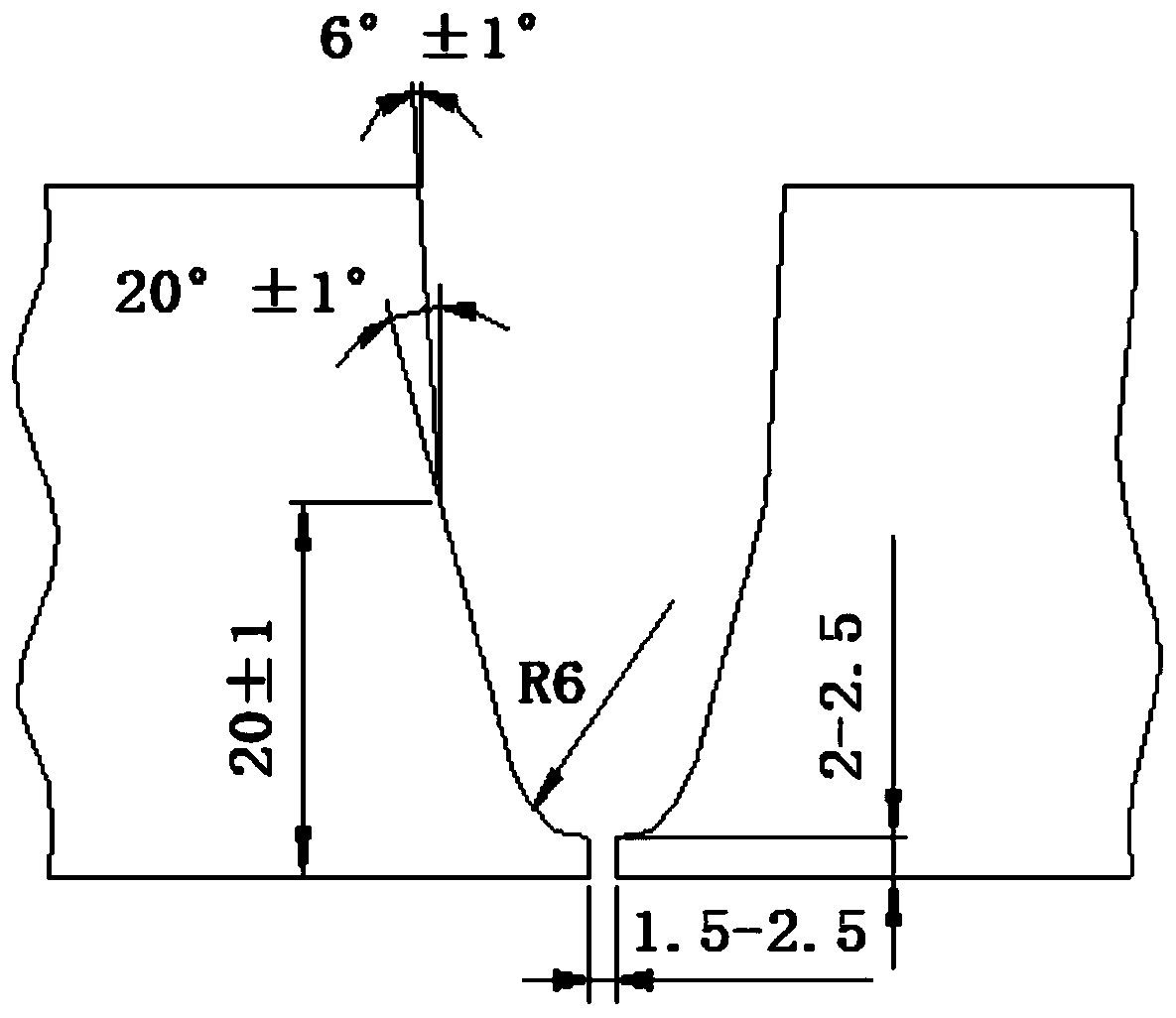

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that when preparing the groove in step 1, the groove is prepared according to the welding filling amount and side wall fusion, so as to facilitate observation of weld seam and defect grinding. The wall thickness of the pipe is ≤40mm, and the bevel angle on one side is between 10° and 20°; the wall thickness of the pipe is more than 40mm, and the bevel is prepared by changing the angle, and the bevel angle on one side before the angle change is between 10° and 20° After changing the angle, the single-side groove angle is between 5° and 8°.

[0037] Other steps are the same as in the first embodiment.

[0038] Clean the groove of the G115 large-diameter pipe and both sides of the inner and outer walls to remove water, oil and other dirt.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in the second step, electric heating or flame heating is used for preheating.

[0040] Other steps are the same as those in Embodiment 1 or 2.

[0041] Electric heating is preferred for preheating. If flame heating is used for preheating, the flame must not stay in the same position. At the same time, the flame combustion status should be controlled to prevent G115 from oxidation or carbonization. When electric heating or flame is used to preheat the outer wall, the welding seam is the center, and the heating width is not less than 75mm on both sides of the welding seam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com