Low-temperature welding technology of low alloy bridge steel

A technology for low-temperature welding and bridge steel, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as uncontrollable preheating temperature, coarse grains, uneven heating, etc., to avoid low-temperature brittle fracture and ensure Effective precipitation and avoiding cold cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] detailed description The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

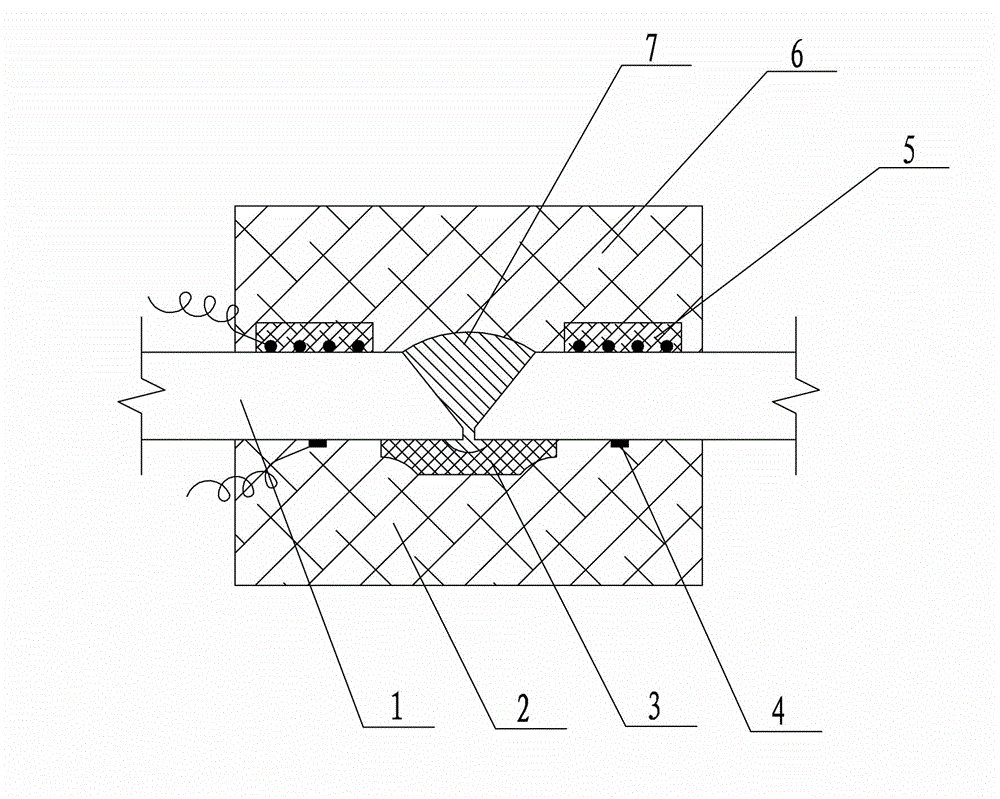

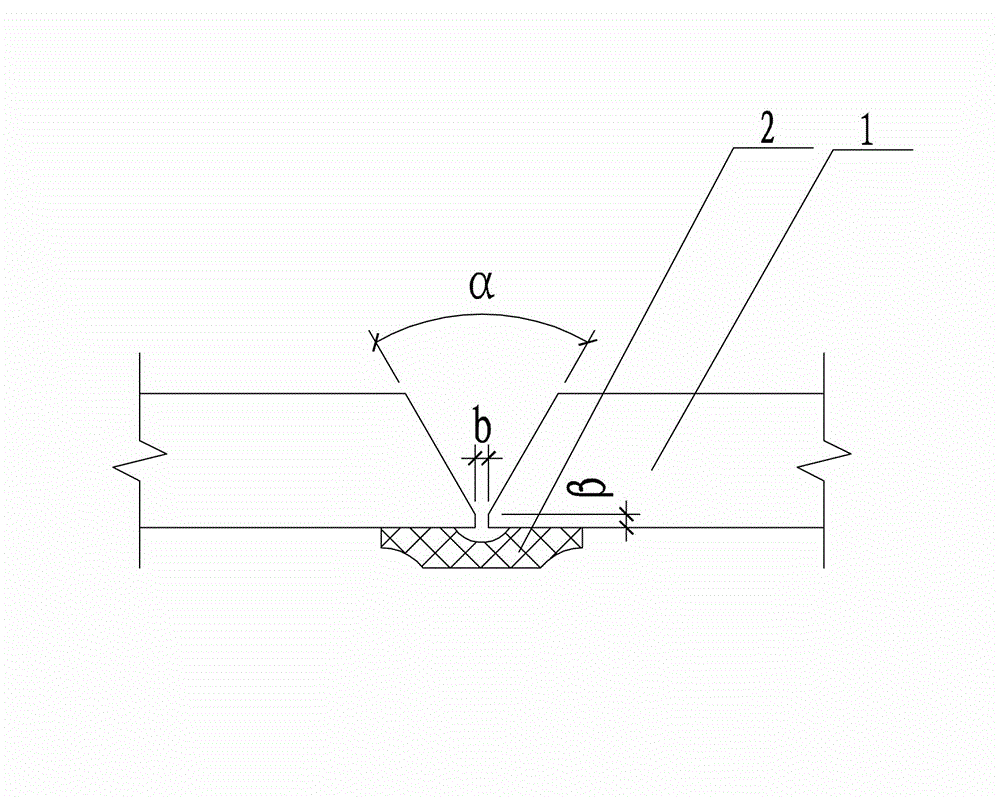

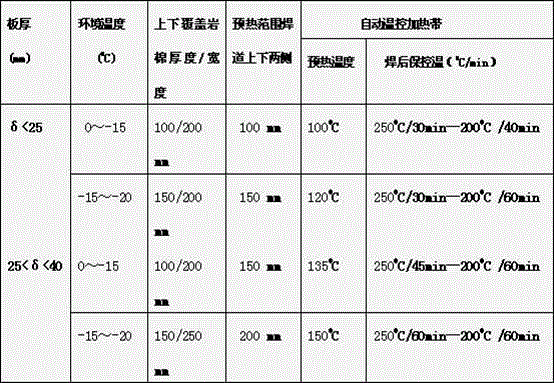

[0022] Such as figure 1 , figure 2 Shown, the low-temperature welding process of low-alloy bridge steel of the present invention comprises the processing of bead groove, pre-welding preheating and post-welding heat preservation, it is characterized in that concrete steps are as follows:

[0023] a) Make grooves on the two butt joint base metals 1 of low-alloy bridge steel respectively, and the groove angle α is 45 0 , the blunt edge clearance is 6mm,

[0024] The two grooves are butted to form a "Y" groove, where:

[0025] Groove angle α is 45 0 , the allowable deviation is -5 0 ~+10 0

[0026] The blunt edge gap b is 6mm, and the allowable deviation is -1.5~+6mm

[0027] The blunt edge height p is 2mm; the allowable deviation is ±1.5mm

[0028] b) Grind and derust the surface of the "Y" groove weld bead to clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com