Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase vacancies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garnet-structured ceramic electrolyte material, preparation method and application therefor

The invention relates to a garnet-structured ceramic electrolyte material, a preparation method and an application therefor. The chemical composition of the garnet-structured ceramic electrolyte material is (1-z) Li (7-2x+2y) La3Zr (2-x) WxO (12+y)+ zA, wherein x is more than 0 and less than or equal to 1.00; y is more than 0 and less than or equal to 2.00; z is more than or equal to 0 and less than or equal to 10 wt.%; and A is any one of Li2O, MgO, CaO, SrO, BaO, Y2O3, B2O3, SiO2, WO3, CuO or Al2O3. According to the cubic garnet-structured lanthanum zirconate lithium crystal doped with W element provided by the invention, by doping W ion (+6 valence), which is higher than zirconium ions Zr4+ in valence, in the lanthanum zirconate lithium crystal to replace part of zirconium ions Zr4+ in crystal lattices, the number of lithium ions Li+ in the crystal is reduced, the vacancy of the lithium ions Li+ is increased, and the formation of an migration channel for the lithium ions Li+ is facilitated, so that the garnet-structured ceramic electrolyte material is higher in volume phase ionic conductivity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

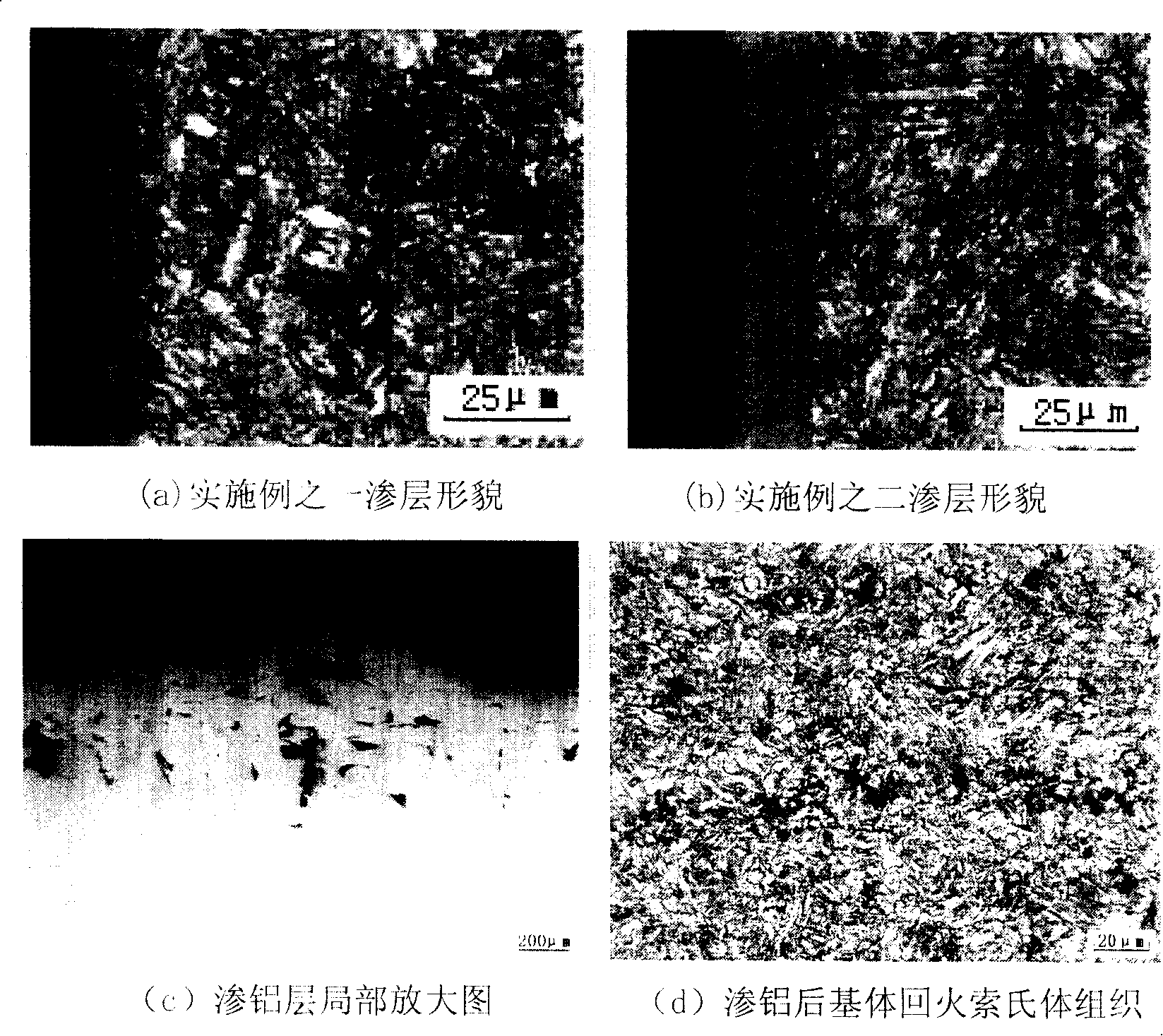

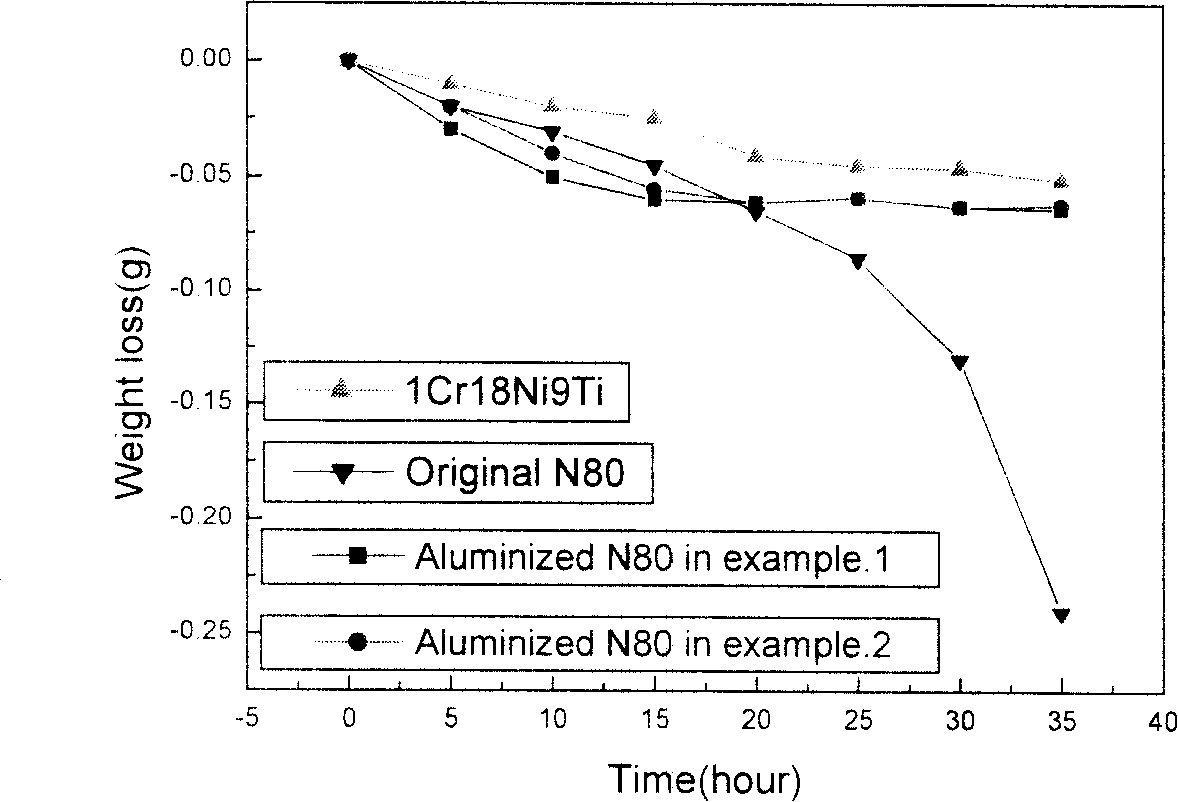

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

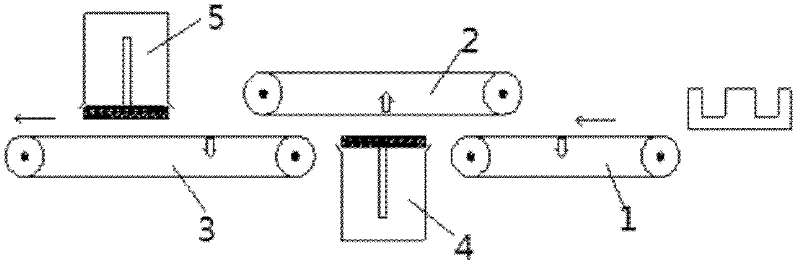

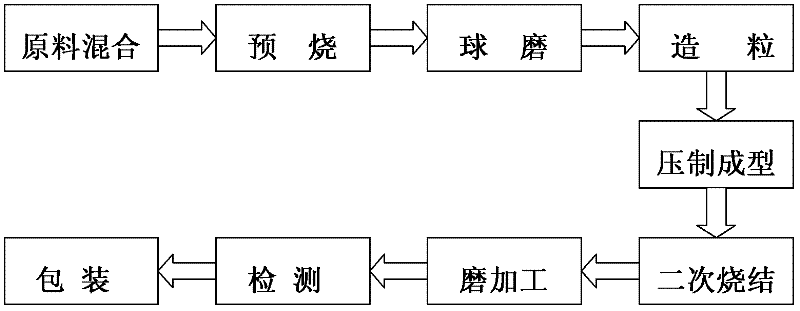

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

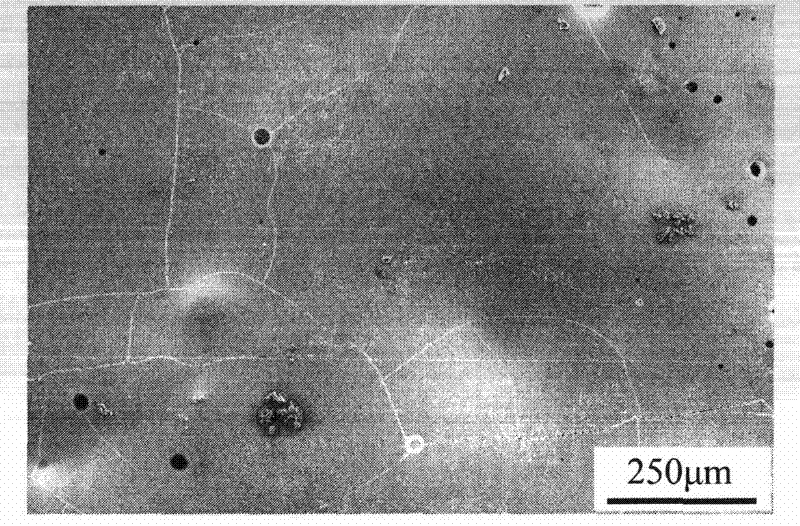

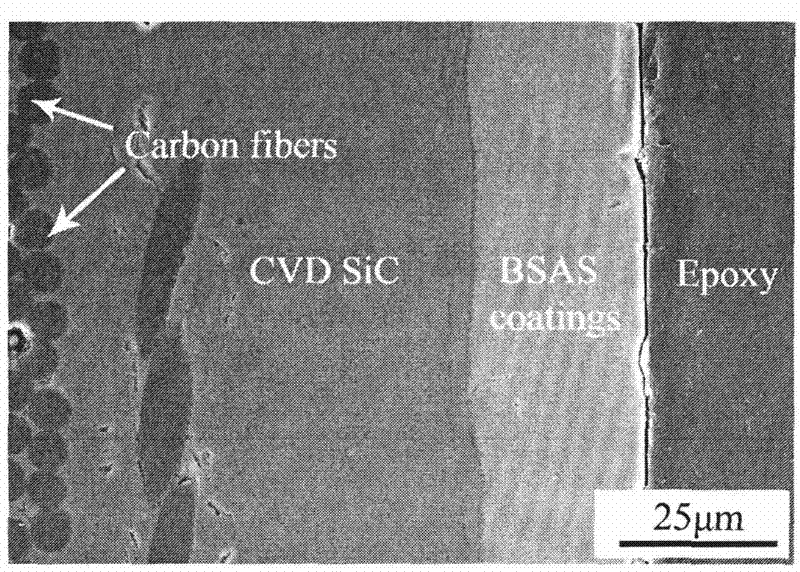

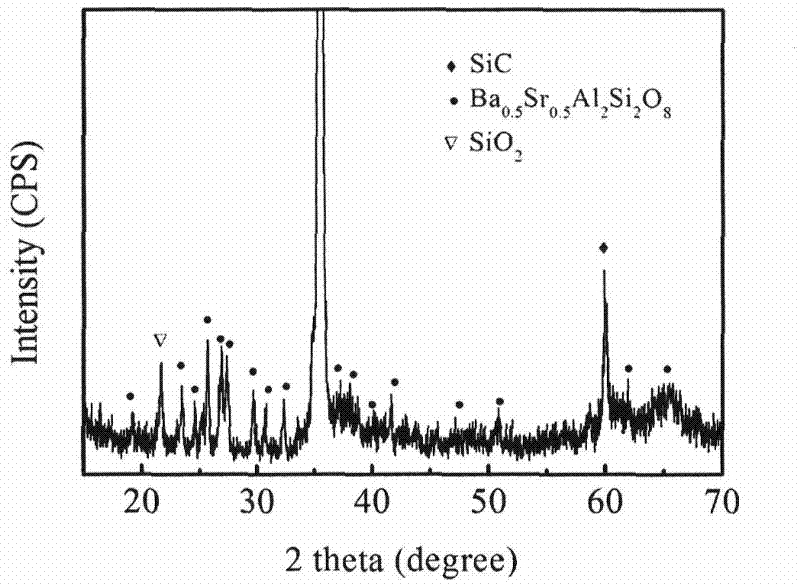

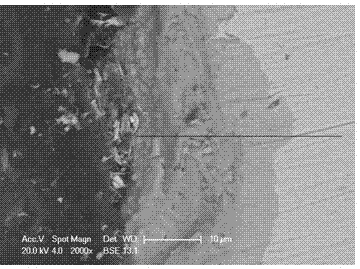

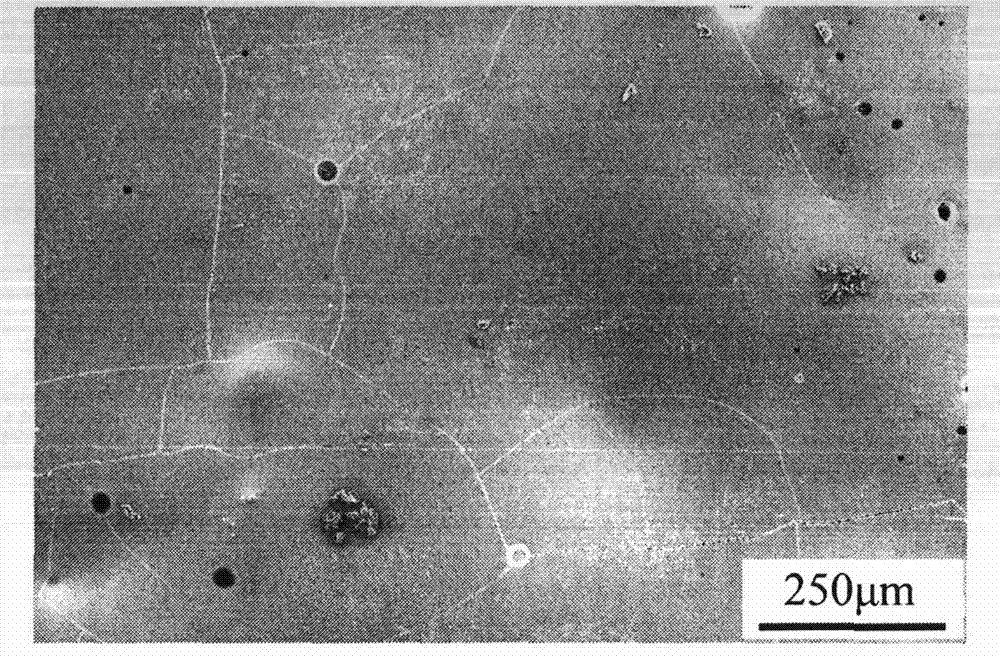

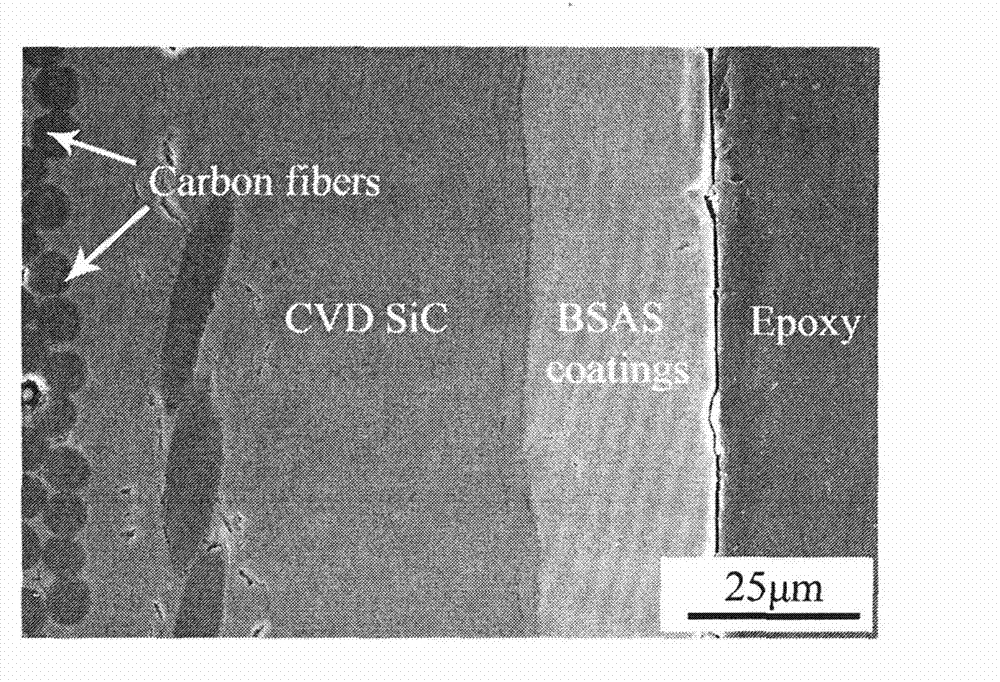

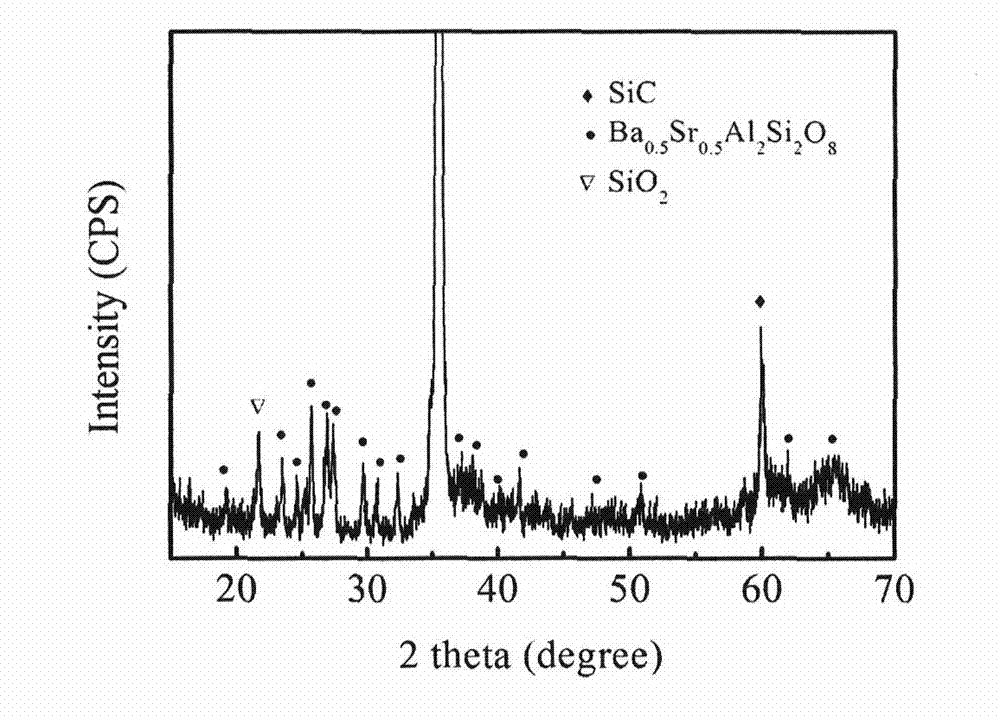

Method for preparing environment barrier coating at low temperature

InactiveCN102249735ADoes not affect environmental performanceIncrease vacanciesCarbon fibersFilling materials

The invention relates to a method for preparing environment barrier coating at a low temperature. In the method, organosilicon as a precursor is mixed with proper powder to form filling materials, and then a proper amount of a sintering additive is added to prepare slurry. Specifically, organosilicon is added with 40%-80% of environment barrier coating powder and 2%-10% of the sintering additive.After ball milling for material mixing, a green coating can be prepared. On the basis of different environment barrier coating powder, a compact coating can be obtained by sintering the powder at a low temperature ranging from 1200DEG C to 1350DEG C. The method of the invention prepares the coating at a temperature of 100-200DEG C lower than the regular slurry method, so that carbon fibers or silicon carbide fibers in matrix materials can be protected effectively. In addition, the adding of the sintering additive does not influence the high temperature environment performance of the coating prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

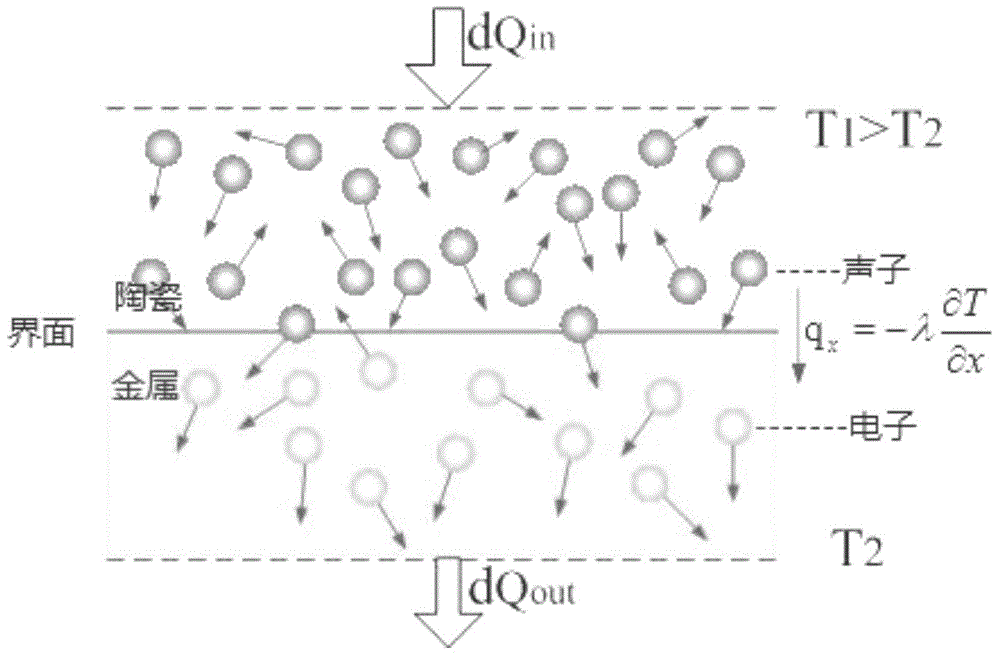

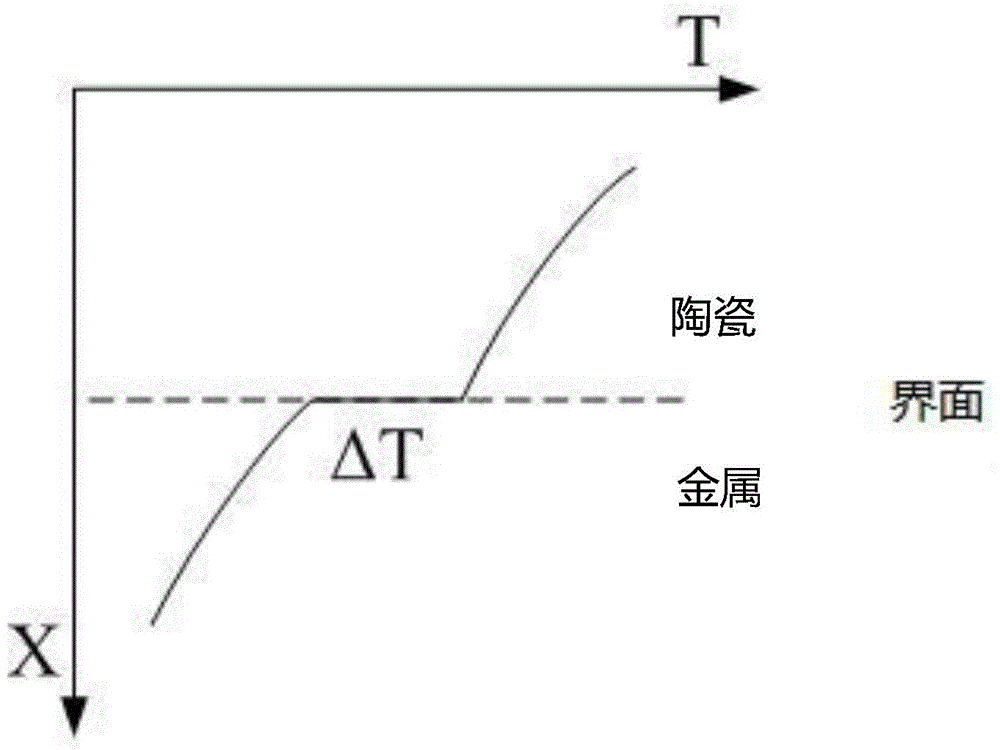

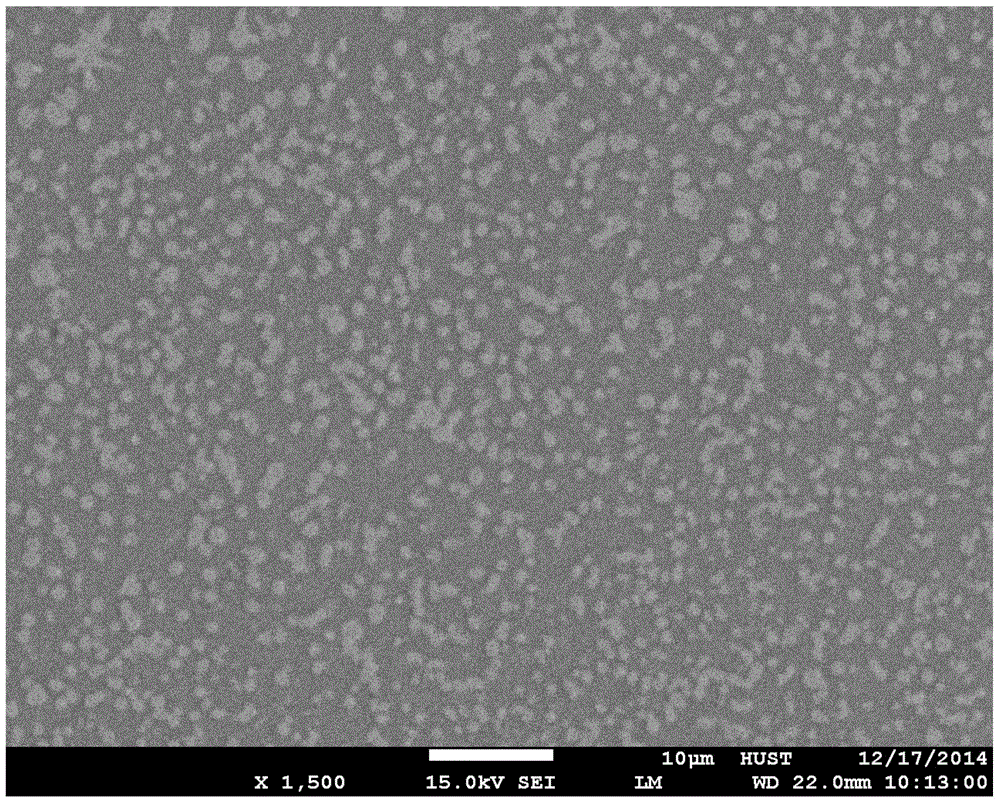

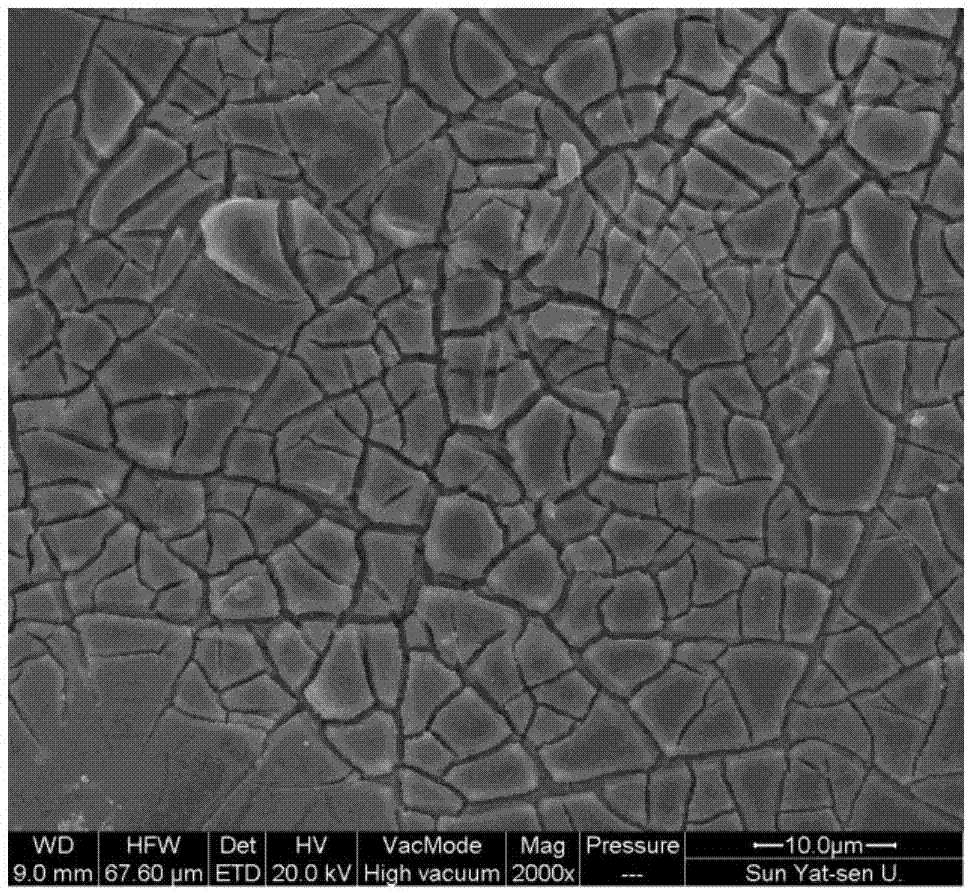

Method for preparing gradient thermal barrier coating

ActiveCN104630688AImprove wettabilityImprove bindingMolten spray coatingNanoparticleThermal insulation

The invention discloses a method for preparing a gradient thermal barrier coating and the method is used for preparing the gradient thermal barrier coating on the surface of a metal. 40-80mu m ceramic particles are bound on the surface of a metal substrate by virtue of a thermal spraying or laser cladding method to prepare the nano-ceramic particle-reinforced thermal barrier coating, wherein the nano-ceramic particles are uniformly dispersed and have a particle size of 100-500nm, the 40-80mu m ceramic particles are obtained by agglomerating initial nanoparticles and comprise Al2O3 particles, ZrO2 particles and rare earth zirconate particles and the component of the rare earth zirconate particles is A2Zr2O7, wherein A is one or more of Ln, La, Gd and Nd. The gradient thermal barrier coating prepared by the method is good in thermal-insulation effect and is firmly bound with the metal substrate and the problems that the existing gradient thermal barrier coating is difficult to be successfully applied and is easy to fall off to cause failure under thermal cycling conditions are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

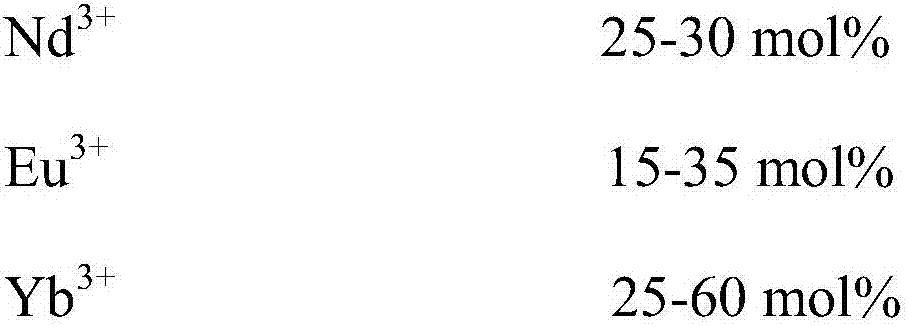

Preparation method of sodium chlorate generator electrode

ActiveCN107034483AChlorine evolution potential is lowHigh oxygen evolution potentialElectrodesSodium chlorateElectrolysis

The invention discloses a preparation method of a sodium chlorate generator electrode. The preparation method comprises the following steps of (1) matrix treatment, (2) preparation of inner-layer active coating liquid, (3) preparation of inner-layer metal oxide, (4) preparation of outer-layer active coating liquid, and (5) preparation of the electrode. According to the novel preparation method of the sodium hypochlorite generator electrode, the prepared electrode has the advantages of being low in chlorine evolution potential, high in oxygen evolution potential, energy-saving, environmentally friendly, long in service life and high in electrolytic efficiency.

Owner:AWS ENVIRONMENT TECH LTD

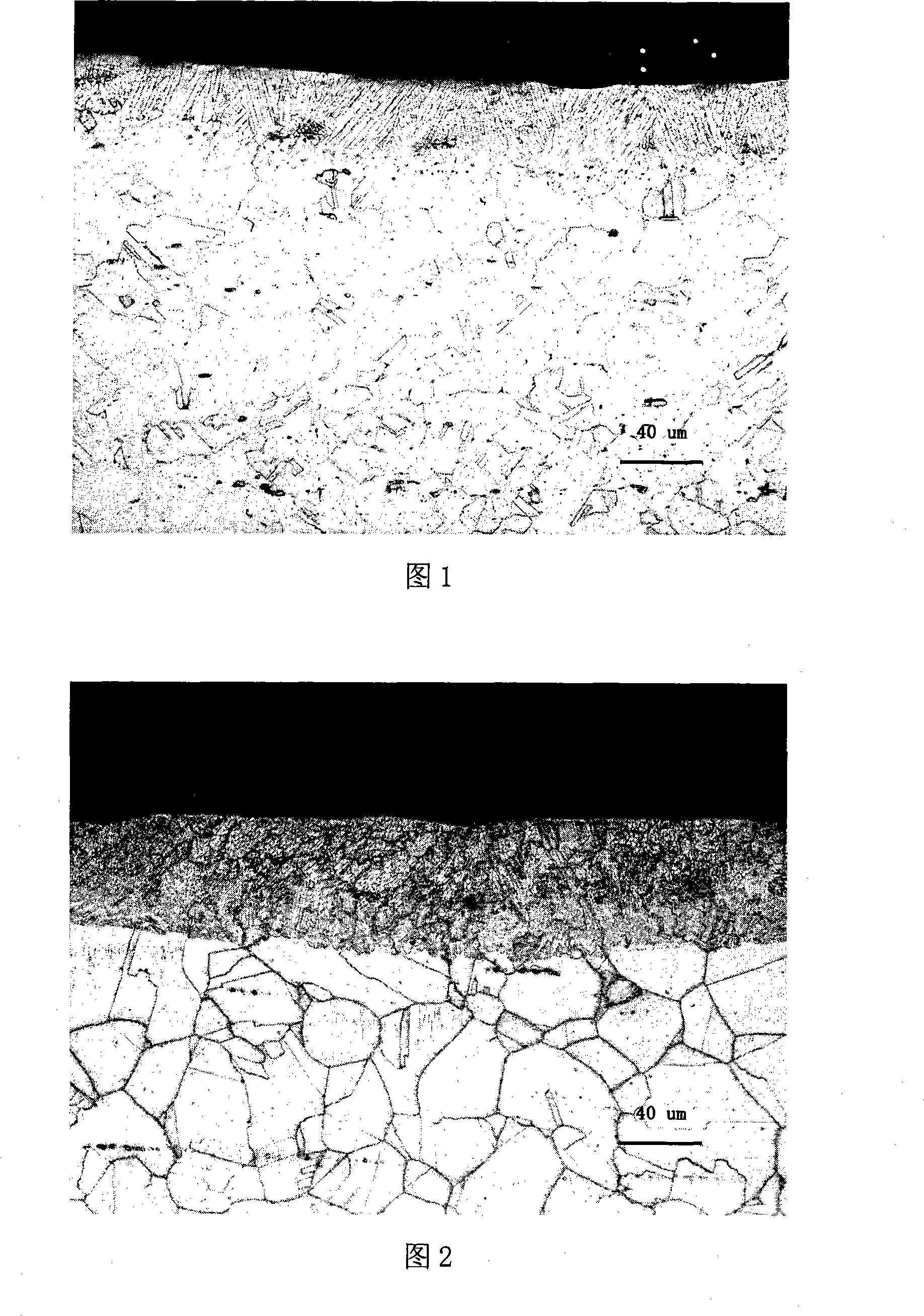

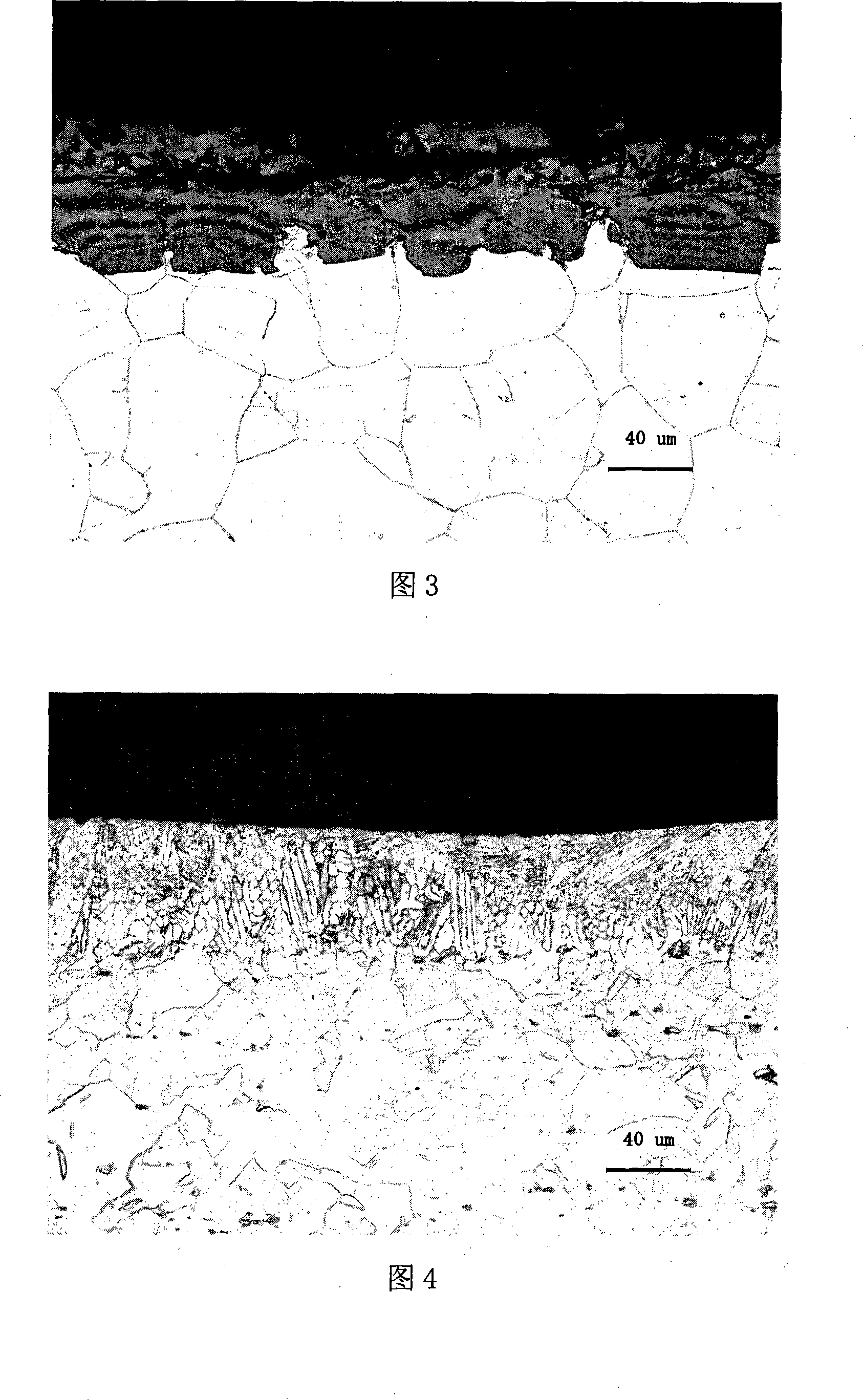

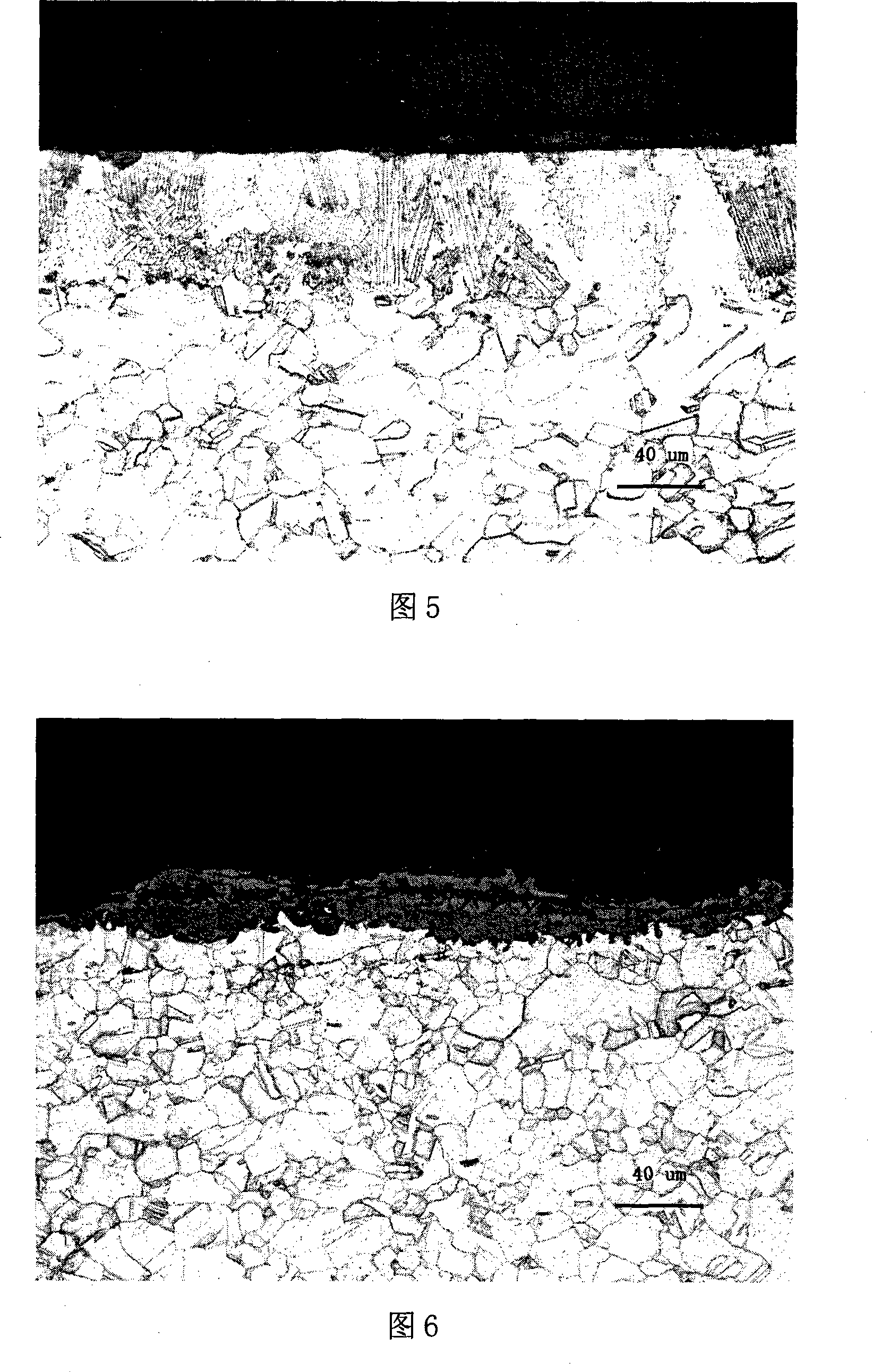

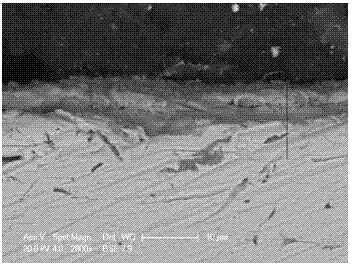

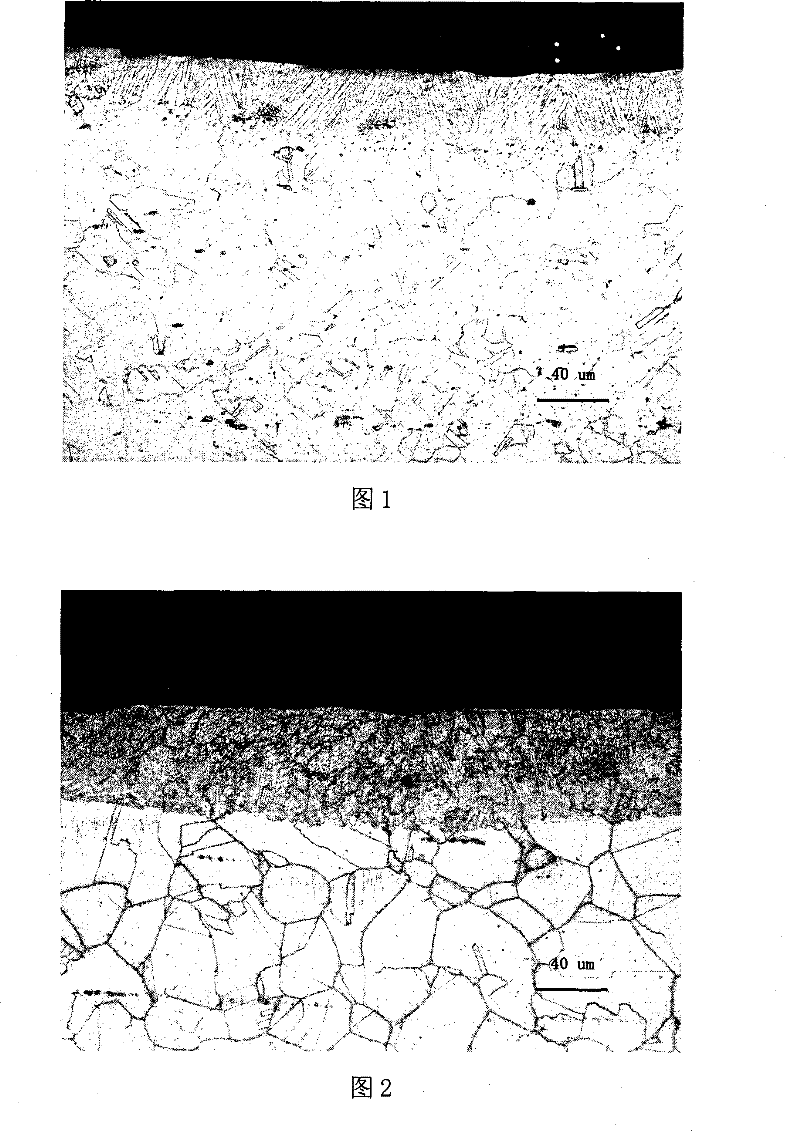

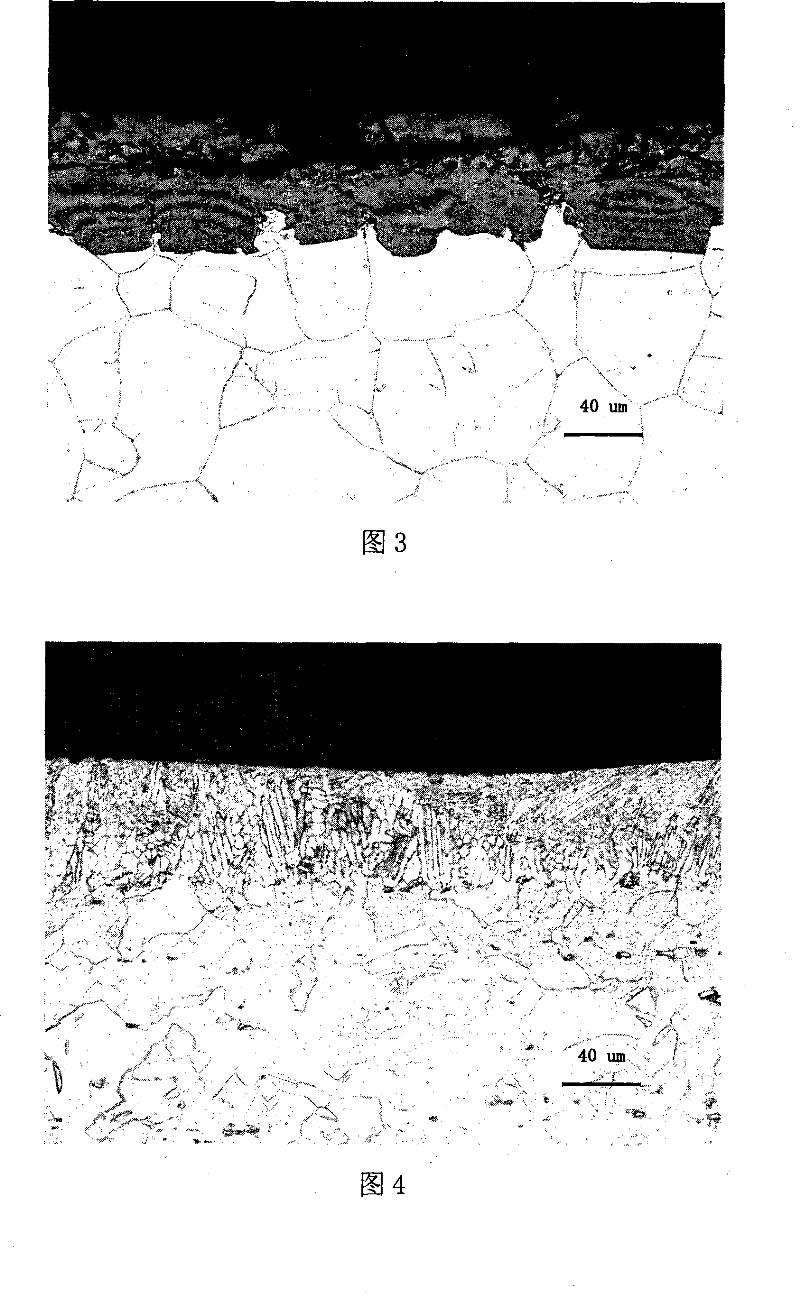

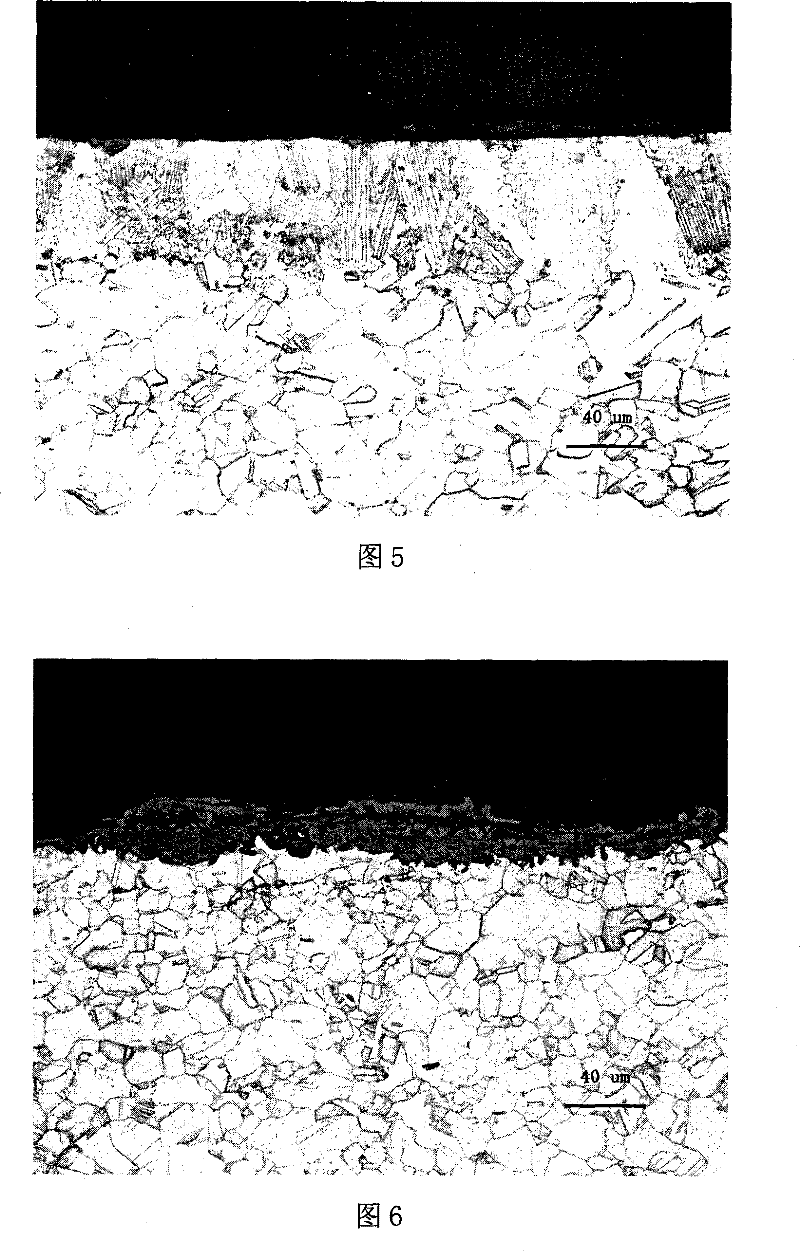

Method for improving resistant property of heat resistant steel for high-temperature water vapour oxidation

InactiveCN101225465AIncrease the dislocation densityIncrease vacanciesHeat treatment process controlLattice defectsHigh density

The invention relates to a method to improve the anti-oxidation performance of refractory steel in high temperature steam atmosphere, which is characterized in that: the surface of refractory steel waiting for treatment is conducted laser surface remelting treatment; the temperature of the surface of refractory steel rises quickly above the melting point and the refractory steel melts; then the refractory steel is freezed with the cooling rate of above 103 DEG C / s; the properties of quick heating and quick cooling of laser surface remelting is utilized to form the steel surface into a fine-grain region with the grain size smaller than 25 Mum; the lattice defects of high-density grain boundary, sub-boundary, twin boundary, dislocation and vacancy in the treatment layer are utilized to promote the diffusion of elements such as Cr and Si, thus improving the anti-oxidation performance in high temperature steam atmosphere.

Owner:XIAN THERMAL POWER RES INST CO LTD

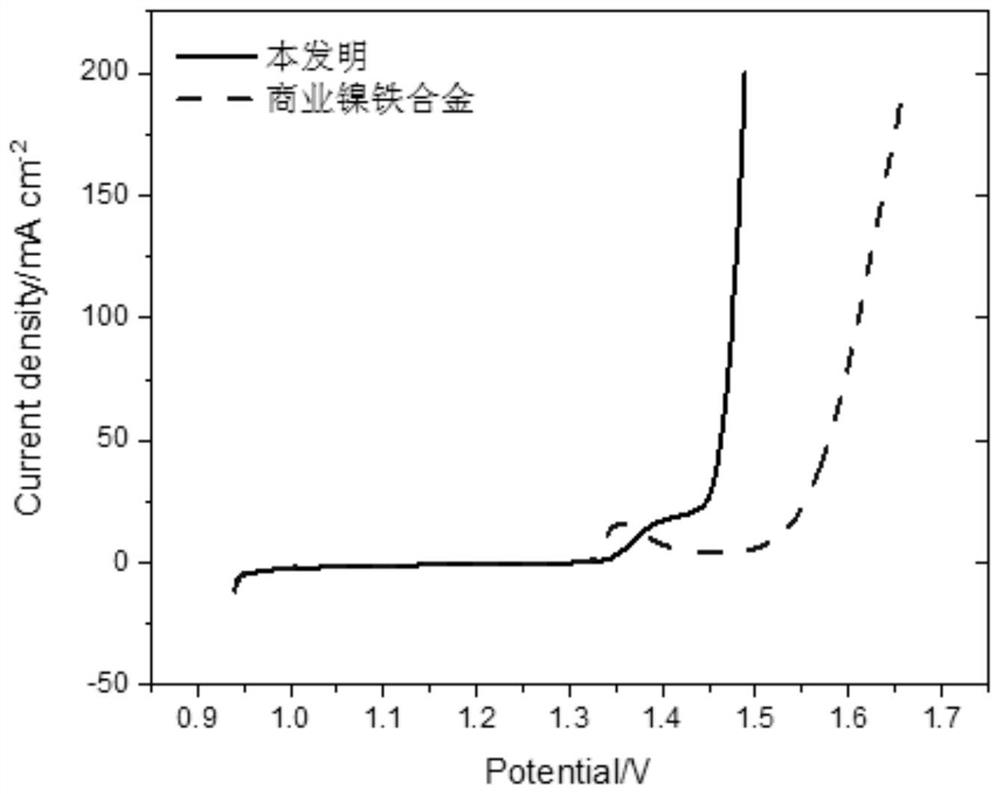

Preparation method of ferronickel catalyst for hydrogen production through water electrolysis

The invention discloses a preparation method of a ferronickel catalyst for hydrogen production by electrolysis of water, which comprises the following steps: (1) adding nickel sulfate hexahydrate and ferrous sulfate heptahydrate into water for dissolving to obtain a dissolved solution; (2) selecting sodium chloride, boric acid, sodium citrate, a benzenesulfinic acid agent, lauryl sodium sulfate and saccharin as regulator raw materials, sequentially adding the regulator raw materials into the dissolved solution, and uniformly mixing to obtain a dark green transparent mixed solution; (3) adjusting the pH value of the mixed solution to 3-3.5 to obtain an electroplating solution; (4) transferring the electroplating solution into an electroplating bath, and raising the temperature to 45-55 DEG C; and (5) selecting a nickel net as a carrier, using an electrochemical workstation, and carrying out electrodeposition by adopting a chronoamperometry to obtain the nickel-iron alloy catalyst. According to the invention, the electrodeposition conditions are controlled, and the composition and morphology structure of the plating layer are regulated and controlled by changing the composition of the plating solution, so that the electrocatalytic performance of the nickel-iron catalyst is accurately controlled, and the catalyst has good catalytic performance and stable performance.

Owner:QINGDAO CHUANGQI XINNENG CATALYSIS TECH CO LTD

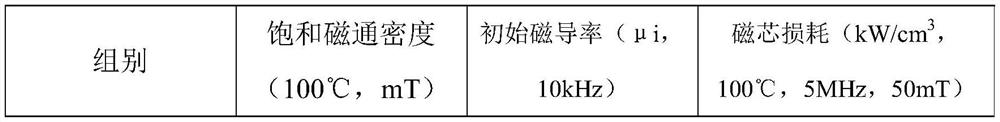

Surface nanocrystallization manufacture method for improving oxidation resistance performance of heat resistant steel

The invention provides a surface nanocrystallization manufacture method for improving the oxidation resistance performance of heat resistant steel. According to the surface nanocrystallization manufacture method, a spinning mechanical device is used for conducting circular rolling and grinding on the surface of a material, a rolling press head is made of hard alloy, grinding pressure is smaller than or equal to 20 MPa, effective grinding-rotating size ranges from 100 mm to fai 220 mm, the grinding time ranges from 30 minutes to 60 minutes, and the grinding-rotating speed is smaller than or equal to 65 rpm. The problem that by the adoption of an existing method, oxidation resistance performance is not ideal, a nanolayer easily drops from a base body, material oxidation is accelerated, environment is polluted and large-sized workpieces cannot be treated due to workpiece size influence is solved. The surface nanocrystallization manufacture method belongs to the field of performance improvement of the heat resistant steel.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

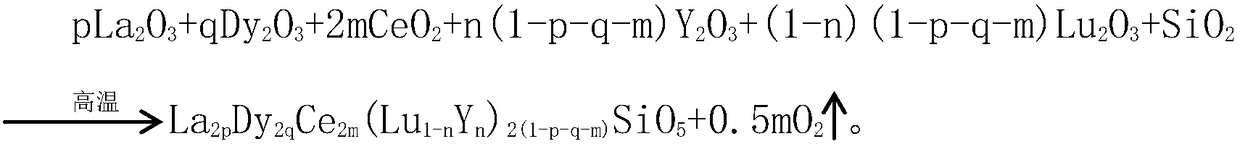

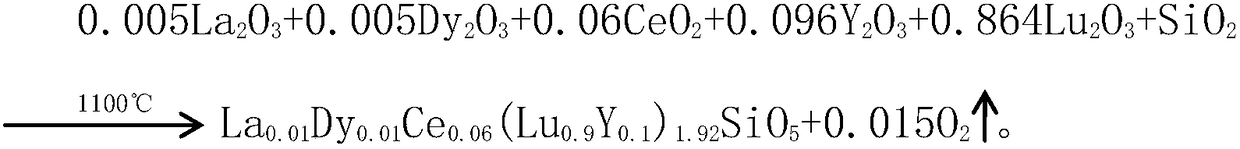

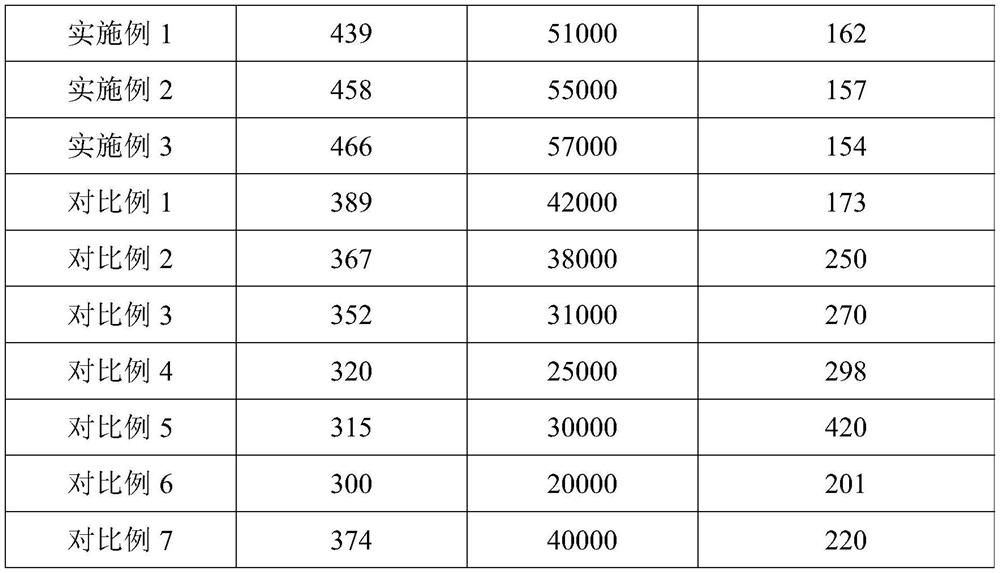

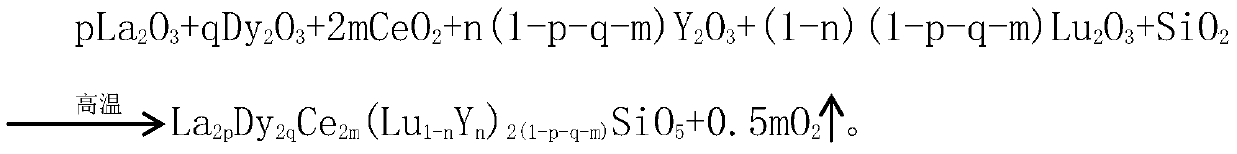

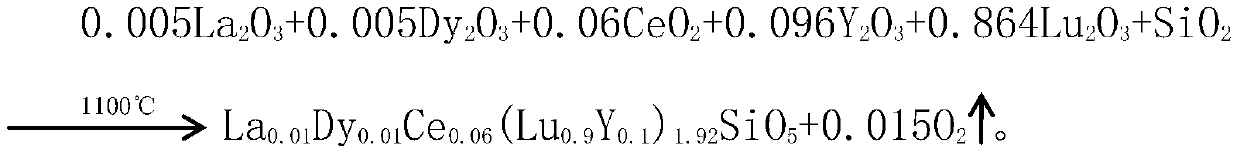

Lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and crystal growth method

ActiveCN108560053AIncrease vacanciesAvoid excessive oxidationPolycrystalline material growthFrom solid stateLutetiumCerium

The invention discloses a lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and a crystal growth method of the lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material. The chemical formula of the scintillating crystal is La2pDy2qCe2m(Lu(1-n)Yn)2(1-p-q-m)SiO5, wherein p is more than 0 and less than or equal to 0.02, q is more than 0 and less than or equal to 0.02, m is more than 0 and less than or equal to 0.03, n is more than or equal to 0.01 and less than or equal to 0.1, p, q and m meet the condition that pplus q plus m is more than 0 and less than or equal to 0.05; the growth method is as follows: S1: synthesizing a poly-crystal material block at the solid phase at the high temperature; S2: compressing and fusing the poly-crystal at the atmosphere of the protective gas; and S3: growing at equal diameter, and using a PID algorithm to automatically cool and anneal. The Dy and the La are doped in LYSO, the vacancy for growing the crystal is increased, the excessive oxidation of the crystal is avoided, the scintillating performance of the crystal is guaranteed, the luminescence spectrum of the crystal is expanded, and the case substitution rates of the ions Lu and Y are increased by means of cold isostaitc pressing, the automatic temperature-controlled growth is implemented through the PID algorithm, and the consistency of the crystals growing in batches is guaranteed.

Owner:安徽晶宸科技有限公司

Preparing method of air-permeable chlorine-evolution electrode

ActiveCN107419292AChlorine evolution potential is lowLow running costElectrode shape/formsSodium hypochloriteOperating cost

The invention discloses a preparing method for an air-permeable chlorine-evolution electrode. The preparing method comprises the following steps of (1) base body treatment, (2) precursor deposition bath preparing, (3) deposited layer preparing, (4) thin film middle layer preparing, (5) active solution preparing, and (6) sintering. The preparing method for the air-permeable chlorine-evolution electrode of a novel sodium hypochlorite generator is low in chlorine evolution potential, long in service life, high in electrolytic efficiency and low in operating cost.

Owner:AWS ENVIRONMENT TECH LTD

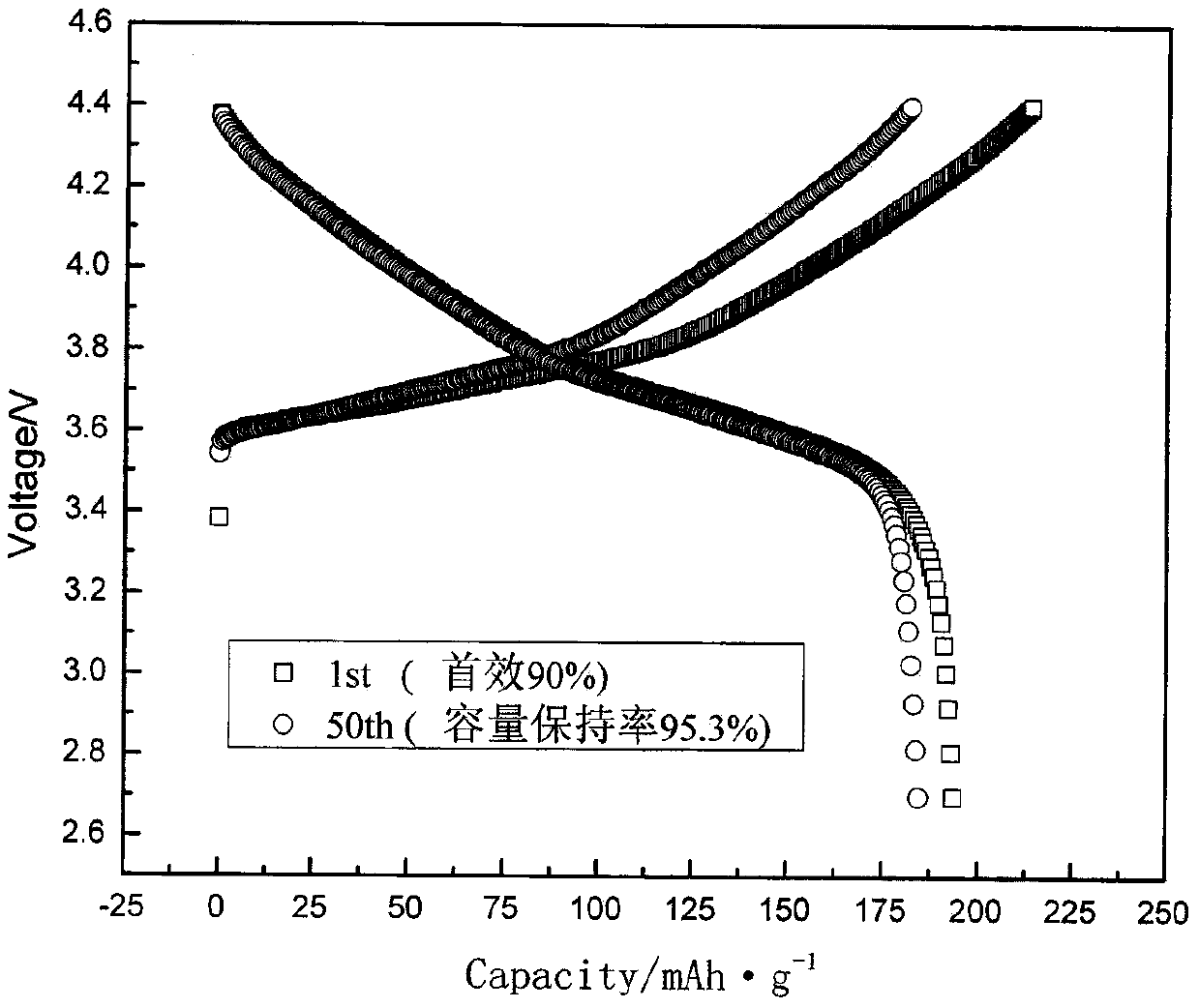

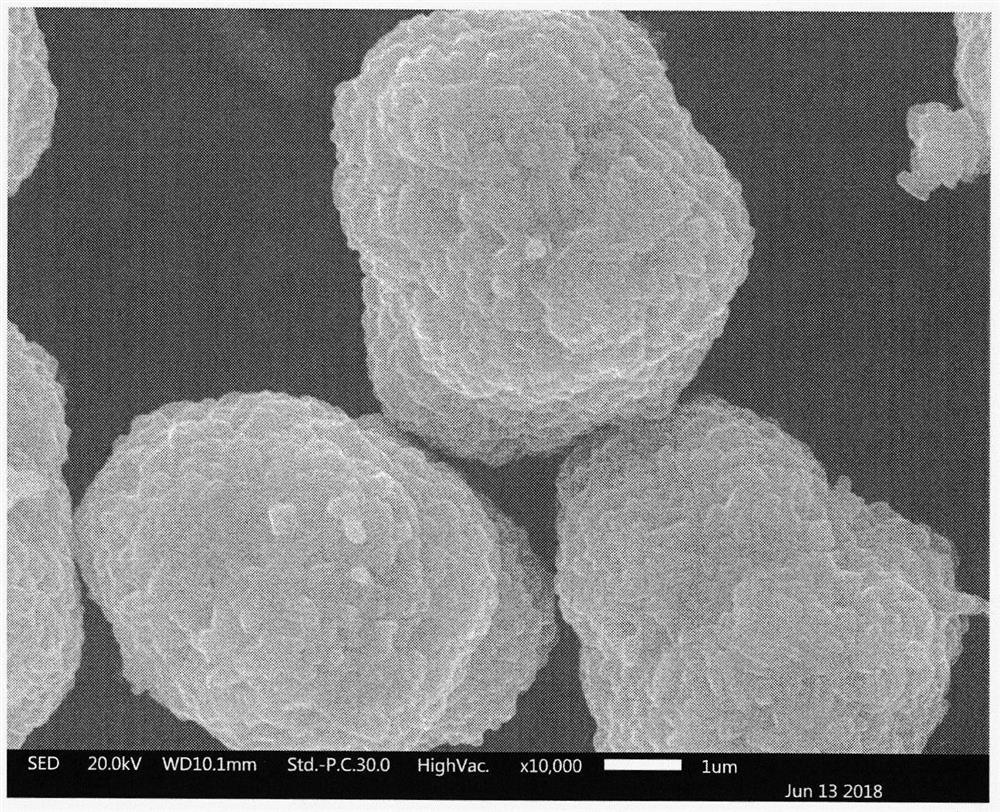

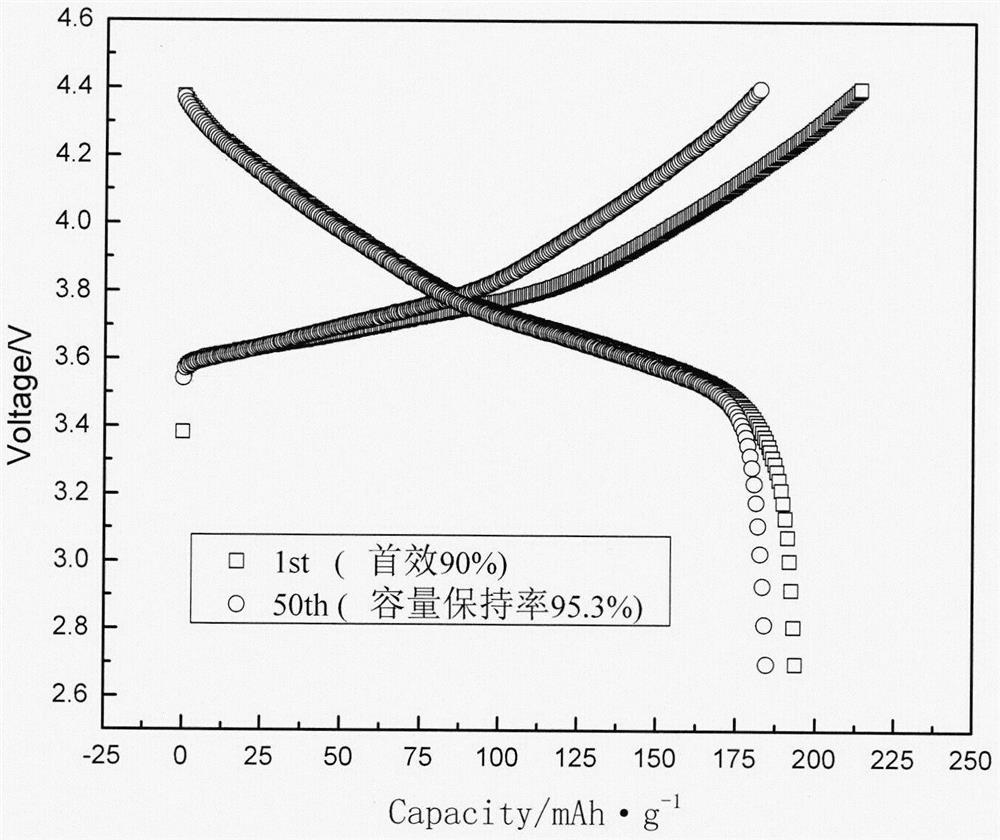

Preparation method of modified LiNi0.6Co0.2Mn0.2O2 ternary positive electrode material, and product and battery

ActiveCN109755524AFacilitated DiffusionImprove charge and discharge performanceCell electrodesSecondary cellsTungstate ionManganese

The invention discloses a preparation method of a modified LiNi0.6Co0.2Mn0.2O2 ternary positive electrode material, and a product and a battery. The preparation method of the ternary positive electrode material comprises the following steps of firstly introducing a magnesium element when preparing a nickel-cobalt-manganese hydroxide precursor, and then adopting an ammonium metatungstate water solution as a complexing agent at the later stage of co-precipitation reaction, wherein the ammonium metatungstate is hydrolyzed in water to show in the forms of ammonia ions and tungstate ions; the ammonia ions are used as the complexing agent to be used for compensating the co-precipitation reaction, and the tungstate ions are partially deposited on the surface of the nickel-cobalt-manganese hydroxide precursor formed in the precipitation reaction stage, so that the in-situ introduction of the tungsten element is realized; and then lithiation treatment is carried out so as to obtain the ternarypositive electrode powder containing the tungsten element on the surface. According to the method, by adding the magnesium element and the surface part in-situ doped tungsten element, the charge and discharge performance, the cycle performance and the like of the obtained modified ternary positive electrode powder are effectively improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Superconductor cold pressing connecting method

InactiveCN103920983AReduce decompositionIncrease vacanciesConductorsMetal working apparatusHigh temperature superconductingUltimate tensile strength

The invention discloses a superconductor cold pressing connecting method, relates to a superconductor connecting method, and belongs to the technical field of superconductor connecting. The superconductor cold pressing connecting method solves the problems that a high-temperature superconducting material obtained according to an existing welding method is low in strength and the superconducting performance is reduced. The superconductor cold pressing connecting method comprises the first step of rubbing down and polishing the end faces of two circular-bar-shaped superconductors, the second step of processing superconductor powder into a cake shape, and the third step of carrying out welding in an ice pressure welding mode. The superconductor cold pressing connecting method is used for connecting the superconductors.

Owner:SOUTHWEAT UNIV OF SCI & TECH

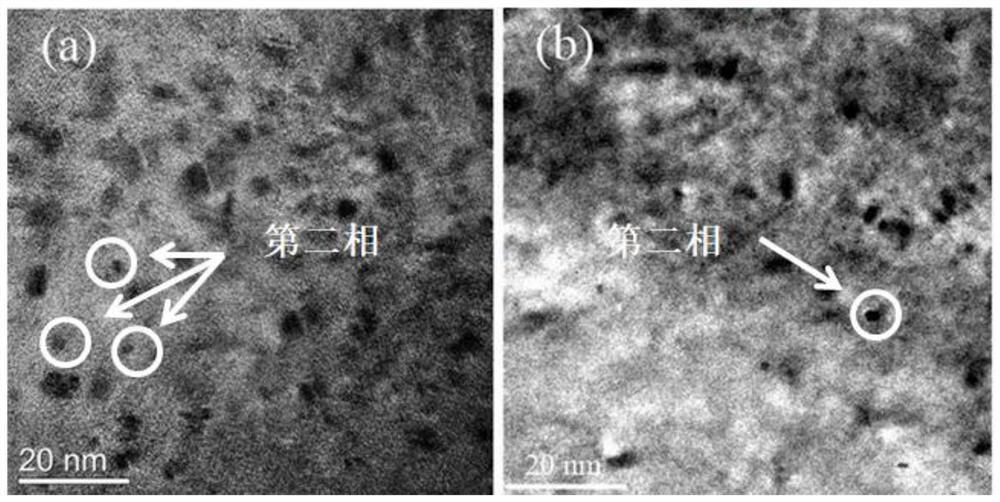

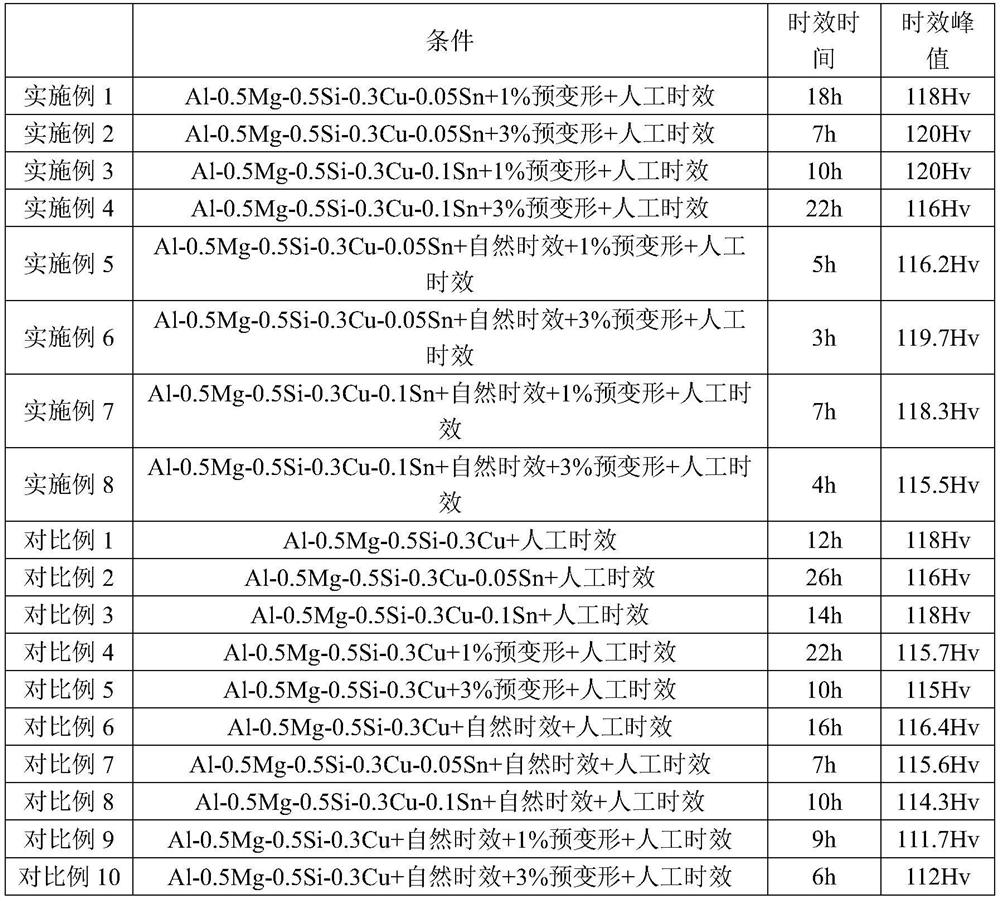

High-performance Al-Mg-Si-Cu-Sn aluminum alloy and preparation method thereof

ActiveCN114703407AImprove mechanical propertiesIncrease peak hardening timePre deformationNatural aging

The invention discloses a high-performance Al-Mg-Si-Cu-Sn aluminum alloy and a preparation method thereof, and the high-performance Al-Mg-Si-Cu-Sn aluminum alloy comprises the following alloy components in percentage by mass: 0.1 to 1.0 percent of Mg, 0.3 to 1.2 percent of Si, 0.1 to 0.6 percent of Cu, 0.01 to 0.2 percent of Sn, less than or equal to 0.02 percent of inevitable impurities and the balance of Al. According to the alloy component proportion, the preparation method of the Al-Mg-Si-Cu-Sn alloy comprises the steps of smelting, pouring, homogenizing, extruding or rolling, solid solution, pre-deformation (natural aging can be carried out before pre-deformation) and artificial aging treatment. By optimizing the alloy component design and the synergistic effect of related processes, the number of second phases of the alloy is increased, and the precipitation rate of the second phases can be remarkably increased. Compared with the prior art, the effects of synchronously improving the mechanical property of the aluminum alloy and shortening the peak hardening time are achieved.

Owner:JILIN UNIV

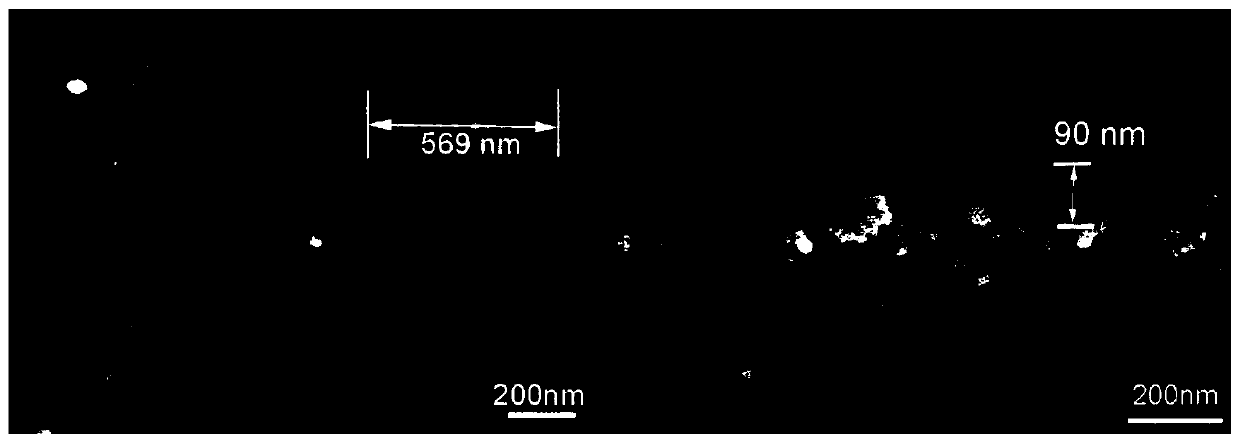

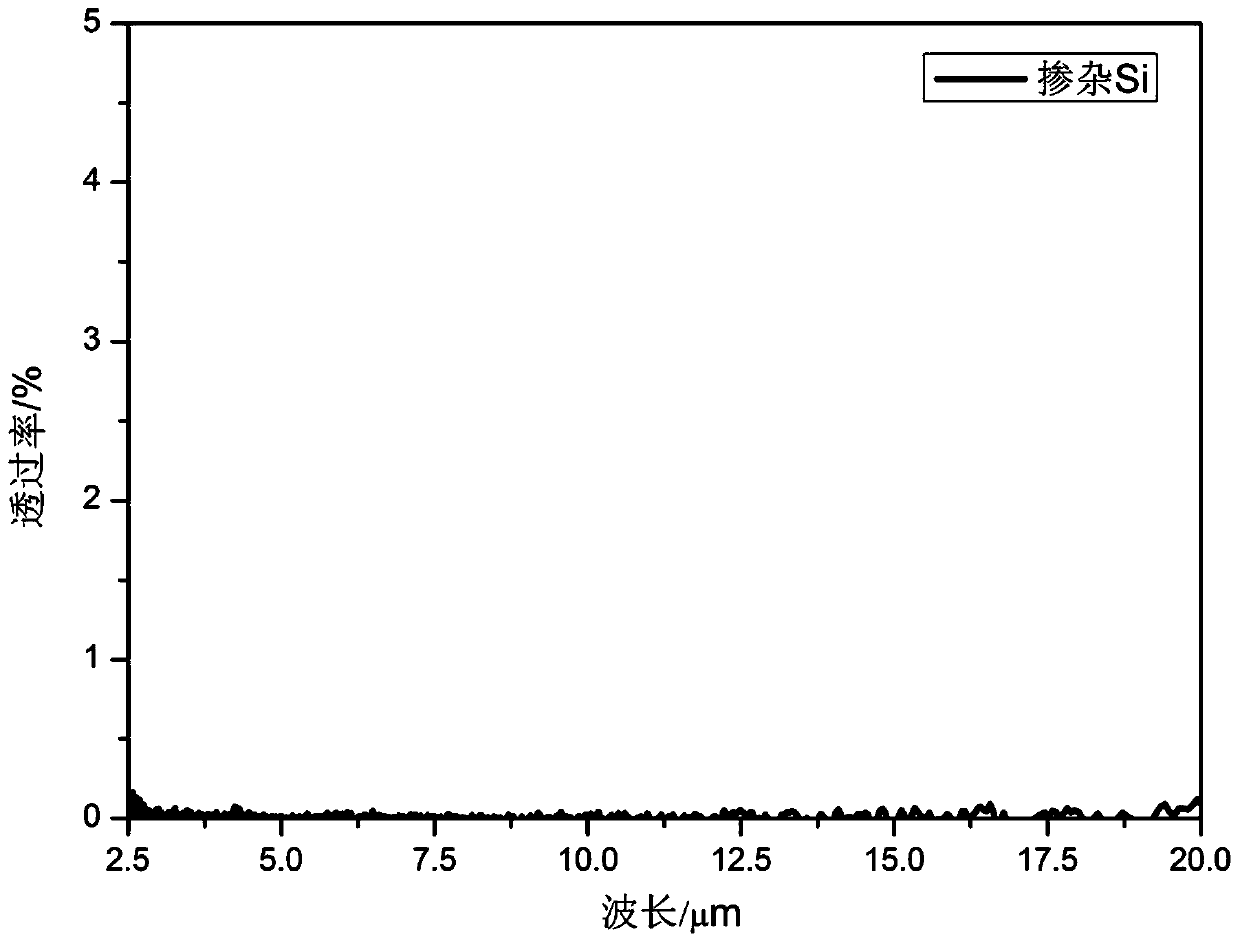

Infrared absorption doped silicon and preparation method thereof

ActiveCN109904068AImprove light absorption capacityRepair damageSemiconductor/solid-state device manufacturingSemiconductor devicesIon distributionTransmittance

The invention provides infrared absorption doped silicon and a preparation method thereof. The preparation method involved in the invention is characterized by including the following steps of: step 1, adopting a TRIM program to simulate the ion distribution of different types of ion-implanted silicon wafers, wherein the simulated ion species are selected from B+, P+, As+, Si+, or / and Ar+, He+, H+, Kr+, Xe+; during the simulation, the energy is set to 10-1000keV, and the simulation dose is 1014-1018ions / cm2; the target of simulation is that: after the silicon wafers are implanted, the ion distribution can enter the silicon body from the silicon surface, the depth distribution ranges from 2nm to 1000nm, and the transmittance of the silicon wafers after doping ions is 0; and step 2, performing ultrasonic cleaning on monocrystalline silicon wafers, and then drying with an air gun; step 3, performing ion implantation on the monocrystalline silicon wafers based on a simulation result; and step 4, performing thermal annealing to obtain the infrared absorption doped silicon.

Owner:WUHAN UNIV

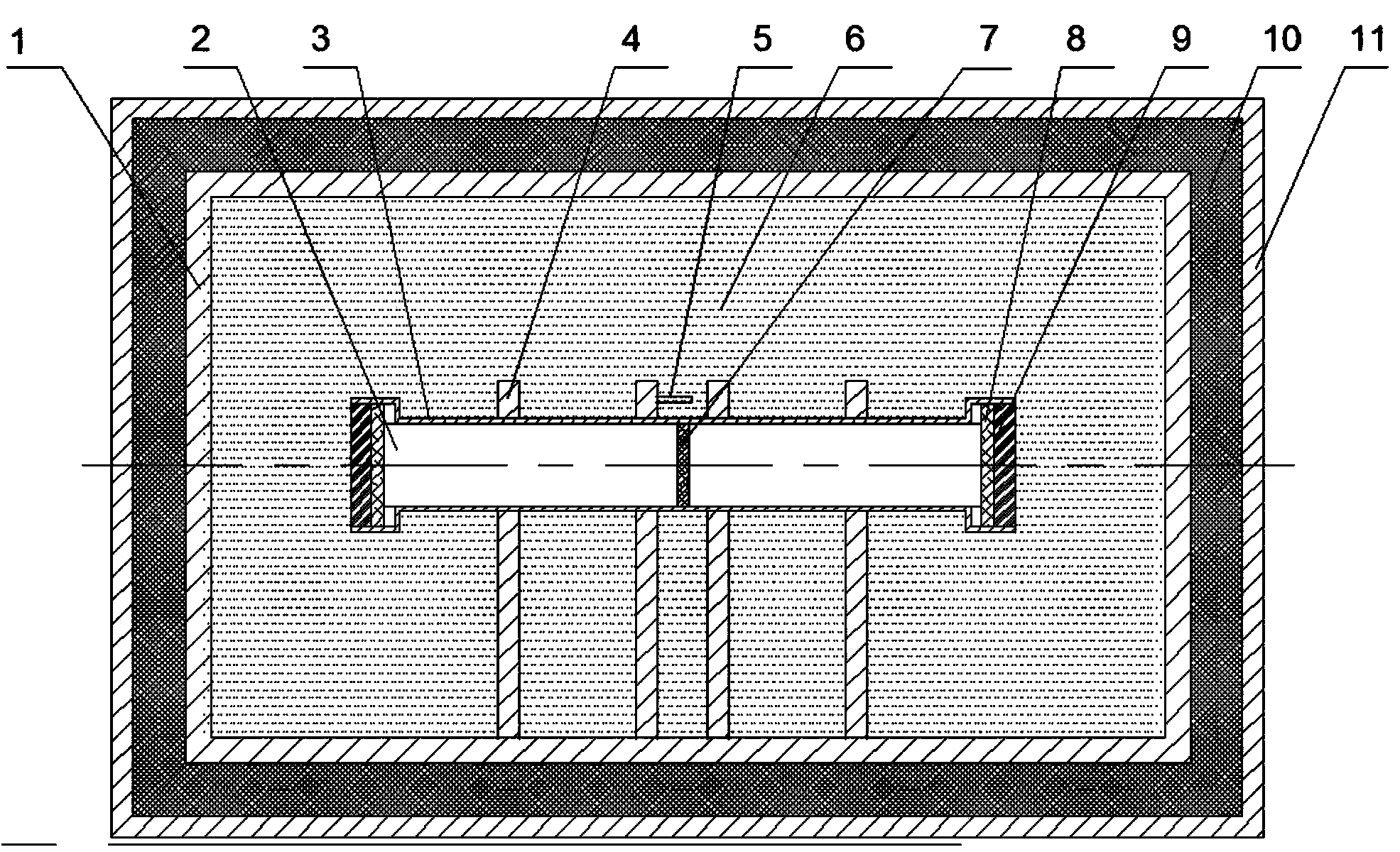

MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter and preparation method thereof

ActiveCN108439957AAvoid damageIncrease vacanciesSemi-permeable membranesMembrane filtersOxide ceramicSlurry

The invention discloses an MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter which can realize sintering at the low temperature and has excellent chemical stability and thermal shock resistance and a preparation method of the foam ceramic filter. The preparation method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and thebalance of magnesium oxide ceramic powder containing a nano titania sintering aid are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and uniform mixing, and ceramic slurry with the solid content of 60%-70% is prepared through vacuum exhausting; (2) a polyurethane foam plastic template is soaked in the ceramic slurry and is extruded by a roller press to remove redundant soaked hanging slurry, a biscuit is prepared, and the biscuit is heated to 80-120 DEG C and dried; (3) the dried biscuit is put in a sintering furnace, heated to 1,400-1,600 DEG C for high-temperature sintering and cooled to the room temperature with the furnace, and the magnesium oxide based foam ceramic filter is obtained.

Owner:FENGYANG L S NET FORMING CO LTD +2

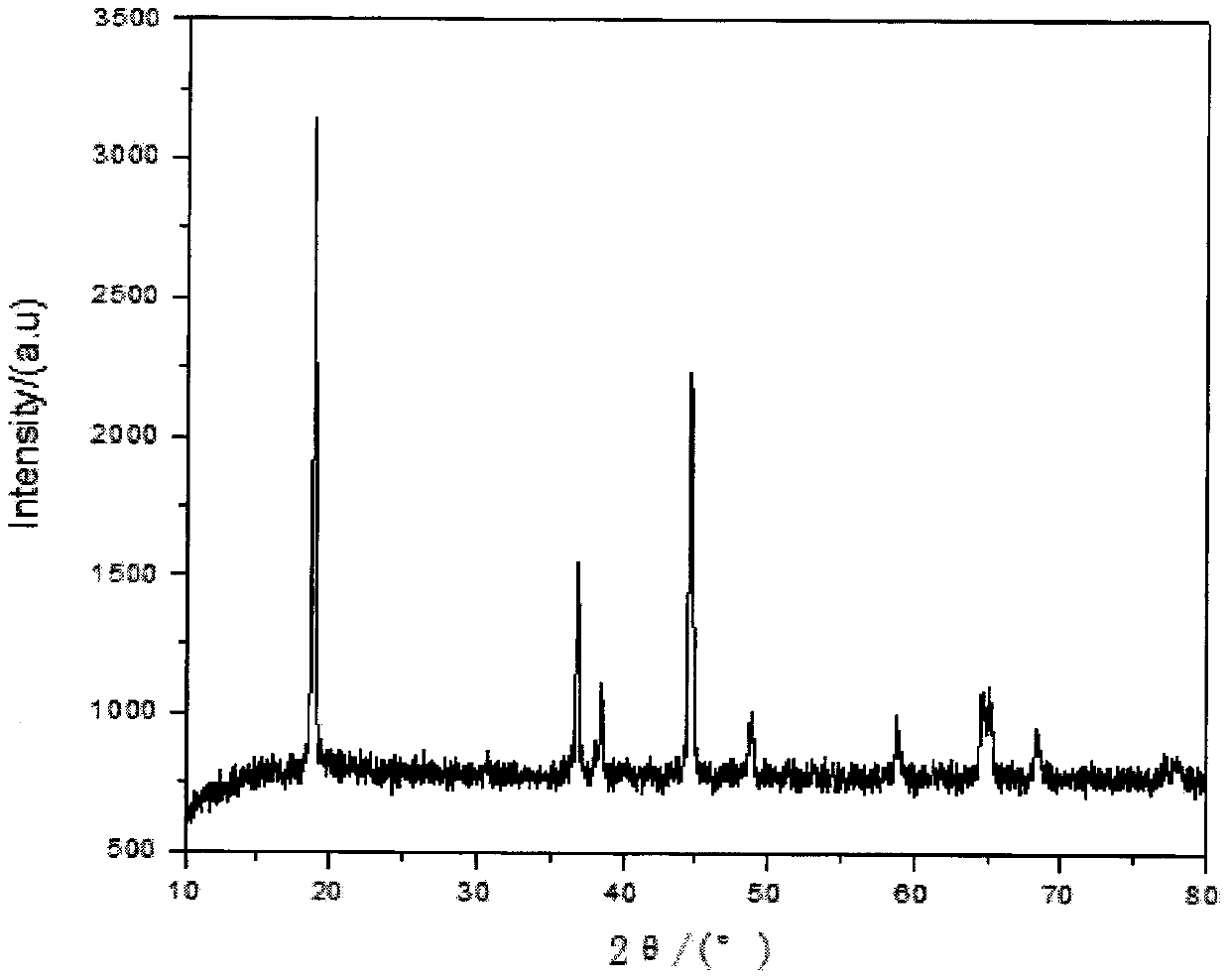

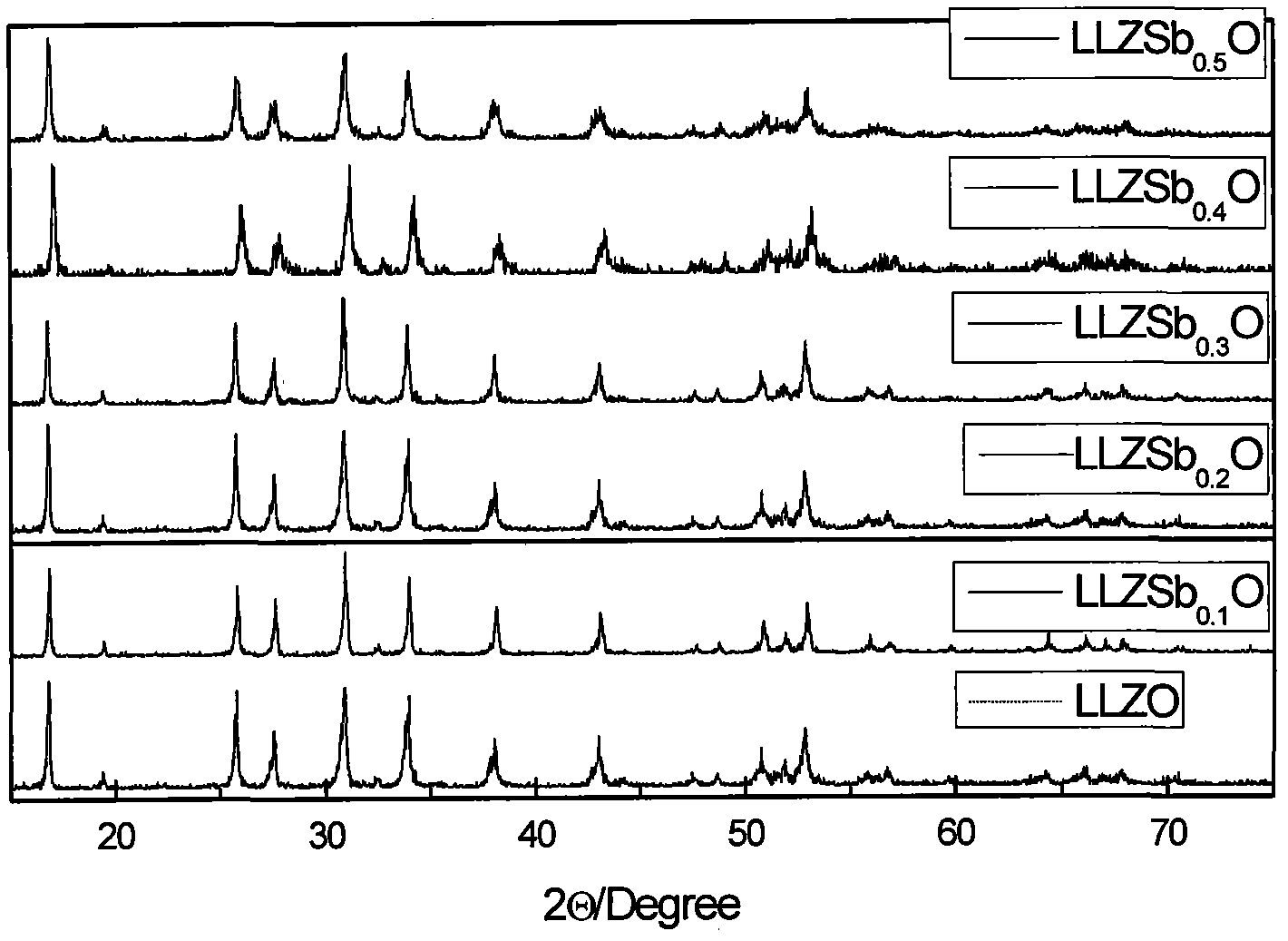

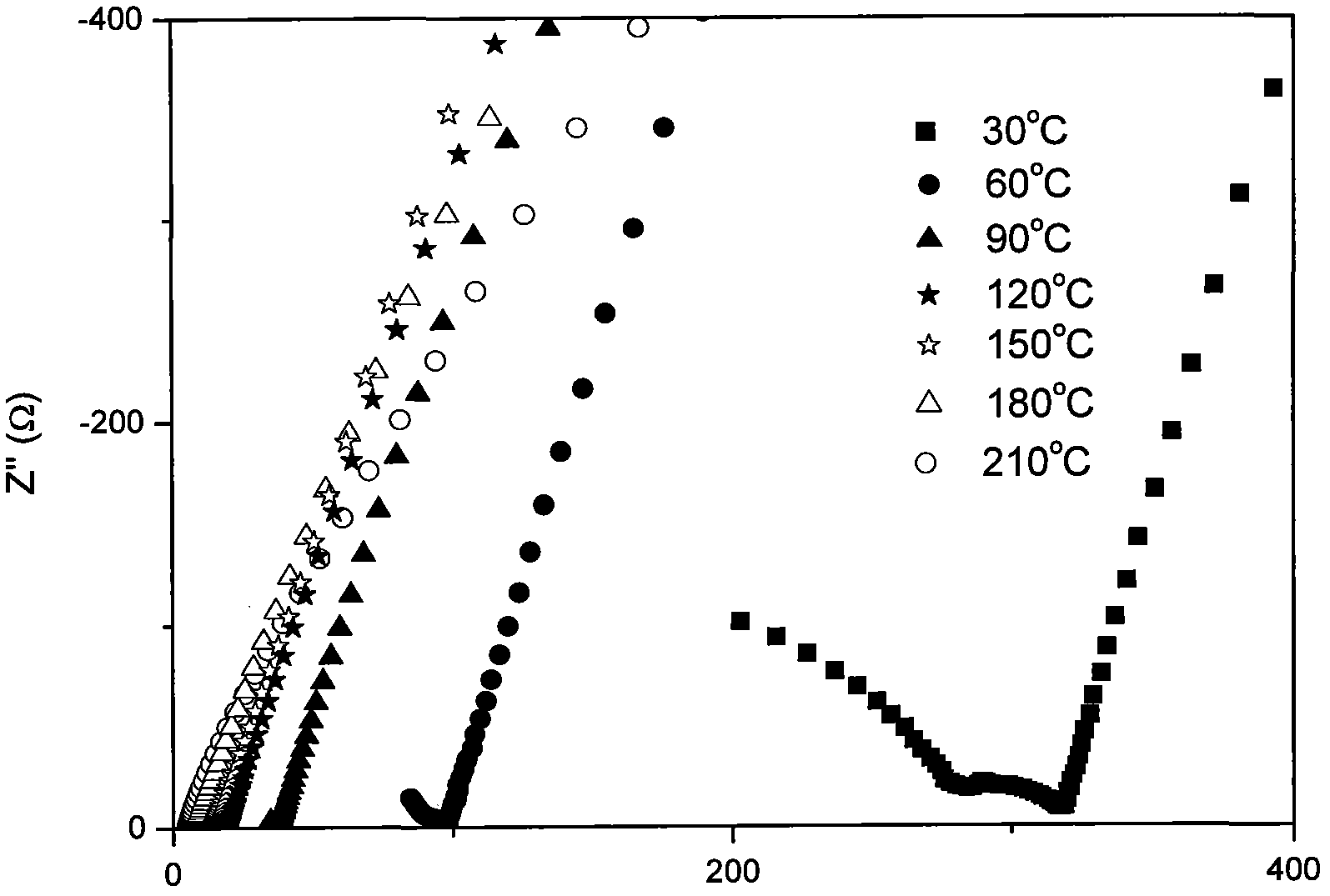

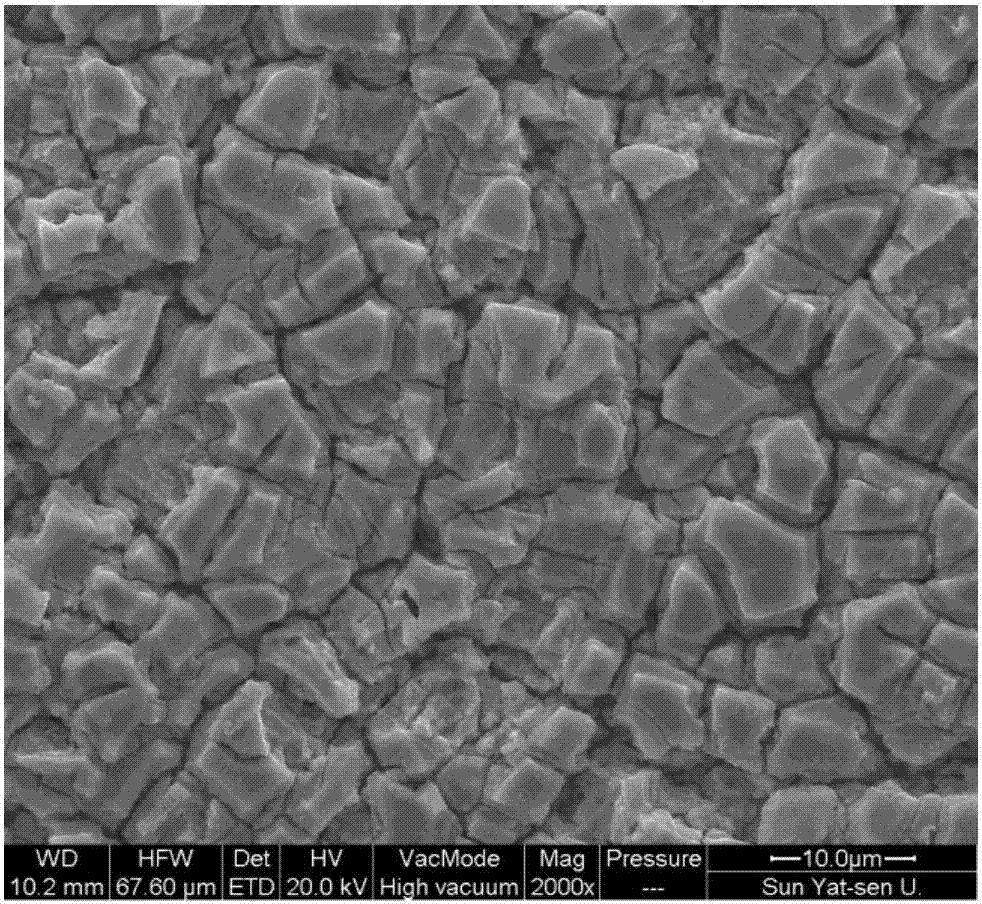

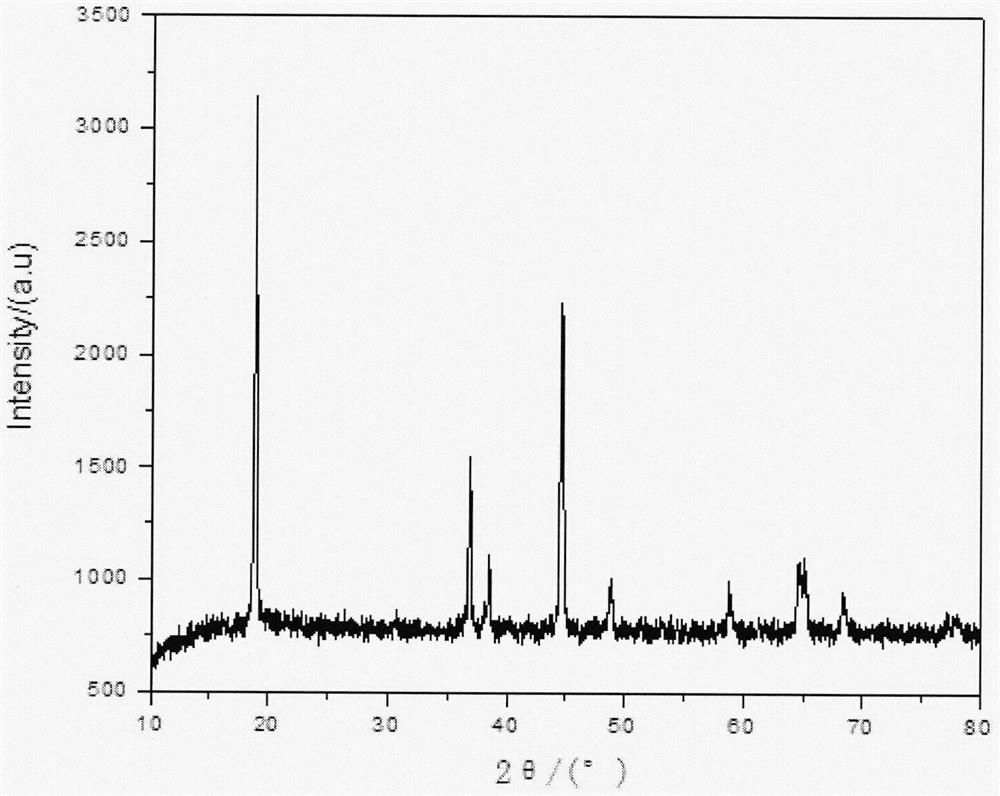

Stibonium-doped quasi garnet-structured lithium ion crystalline-state solid electrolyte material and synthesis method thereof

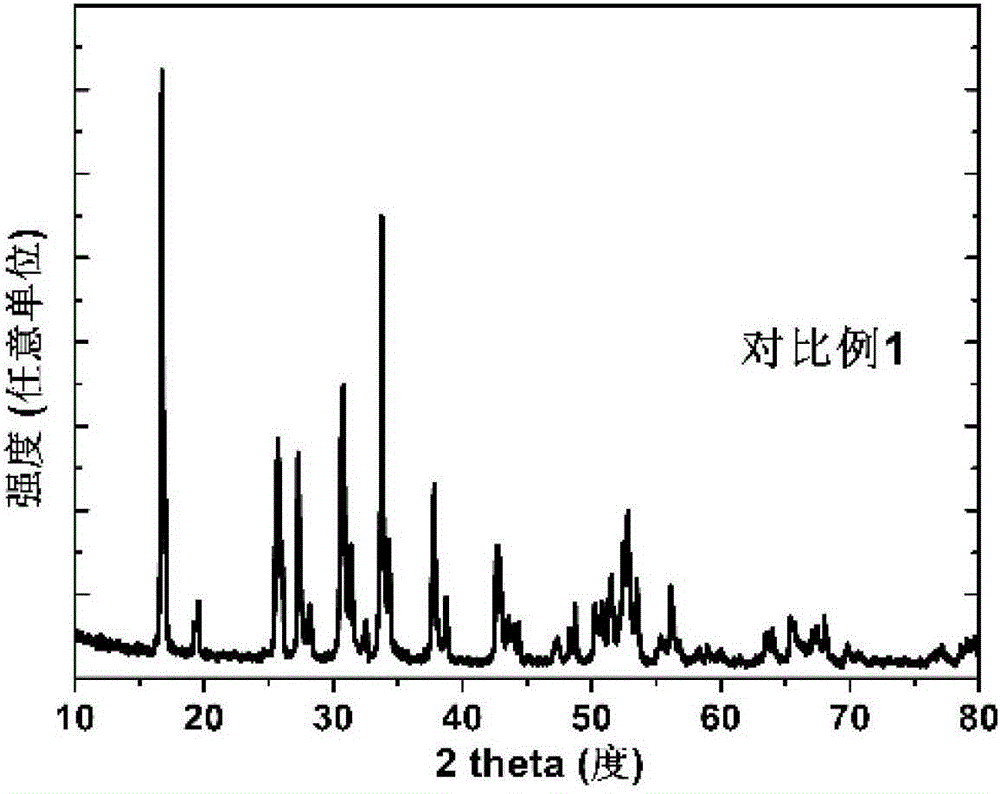

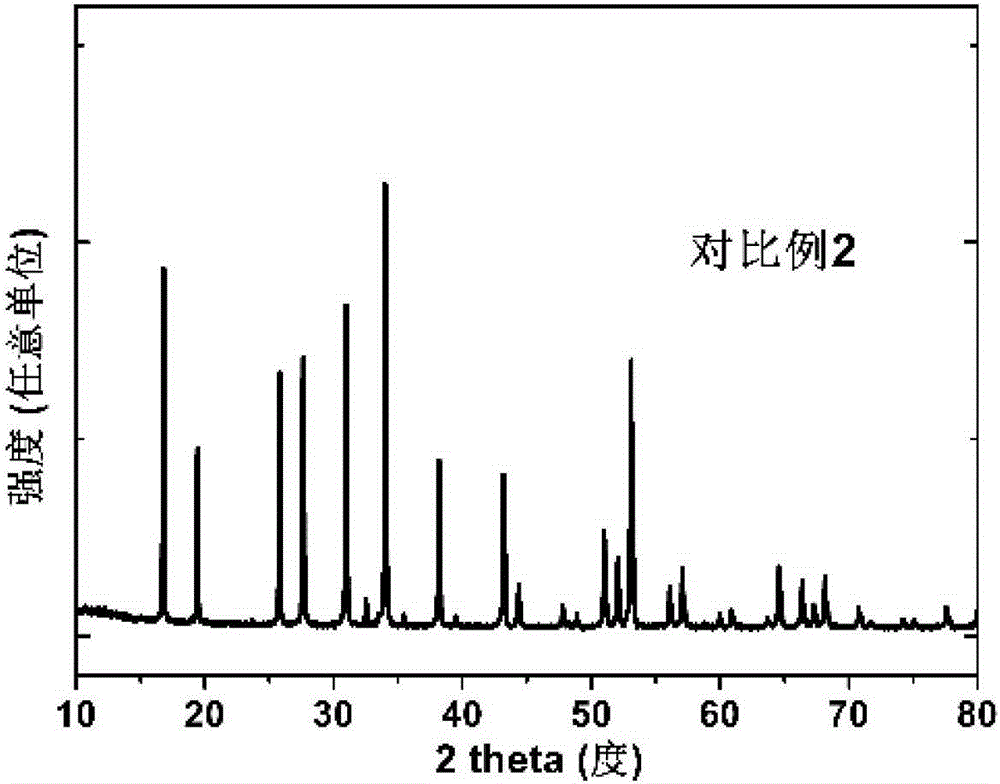

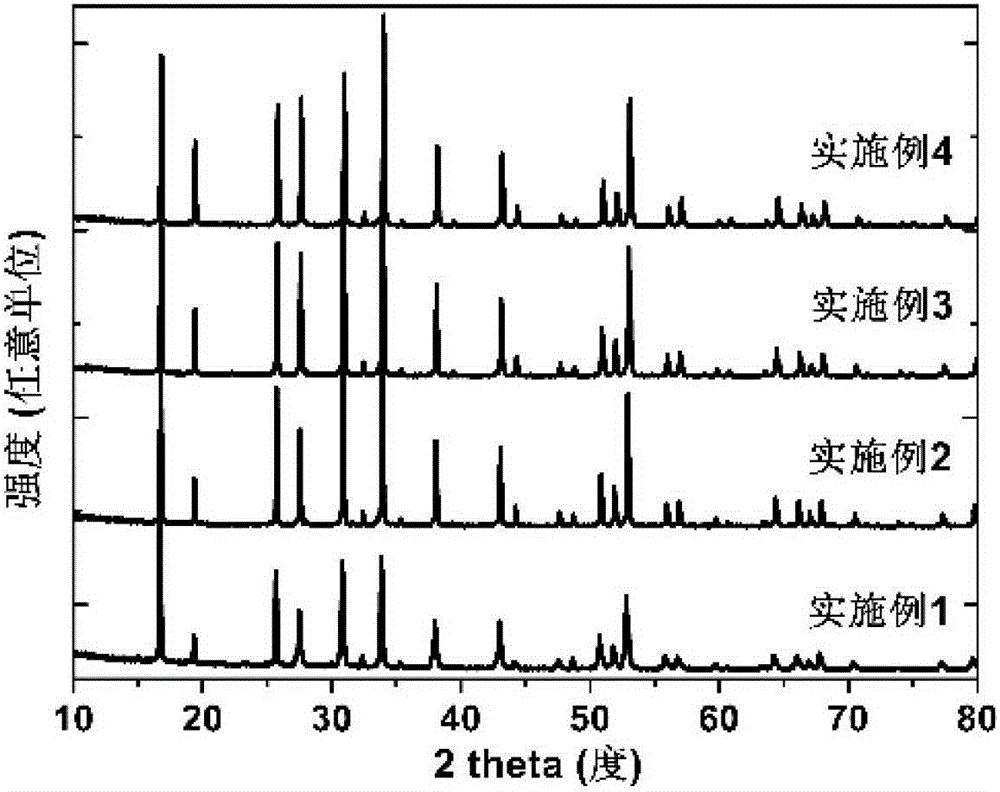

The invention provides a novel quasi garnet-structured lithium ion conductor (Li7-xLa3Zr2-xSbxO12, wherein x is more than 0 and less than or equal to 0.5) crystalline-state ceramic solid electrolyte material and a synthesis method thereof, and belongs to the field of lithium ion batteries. A novel quasi garnet-structured lithium ion conductor is synthesized by conventional solid-phase reaction. X-ray diffraction (XRD) diffraction peaks of Sb-doped samples show that the Sb-doped samples all have crystalline -state cubic phase quasi garnet-structures in the Sb doped range. The maximum lithium ion conductivity can reach 3.42*10<-4>S / cm at room temperature (30 DEG C). The sample is synthesized by the conventional solid phase method, a preparation process is simple, and sintering time is short. Zr is partially replaced by high-valence Sb, so the lithium ion vacancy is increased, the ionic conductivity is improved obviously, and antimonous oxide is low in price compared with zirconia, so manufacturing cost is reduced. Therefore, the synthesized compact ceramic solid electrolyte material can be probably applied to a lithium ion battery.

Owner:INNER MONGOLIA UNIV OF TECH

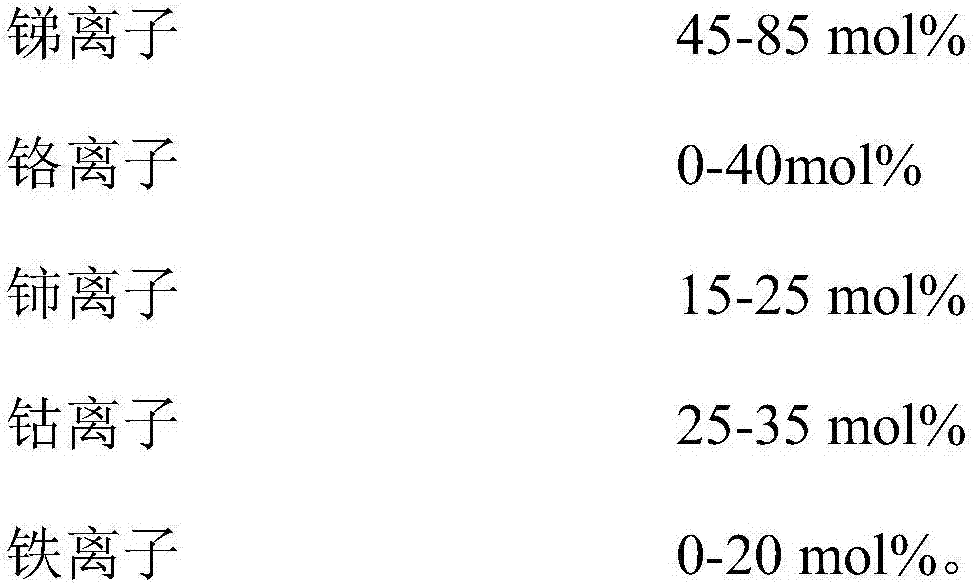

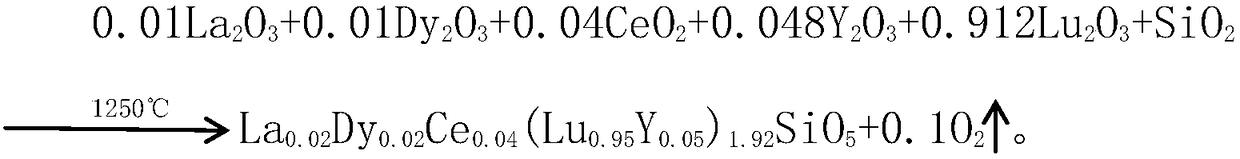

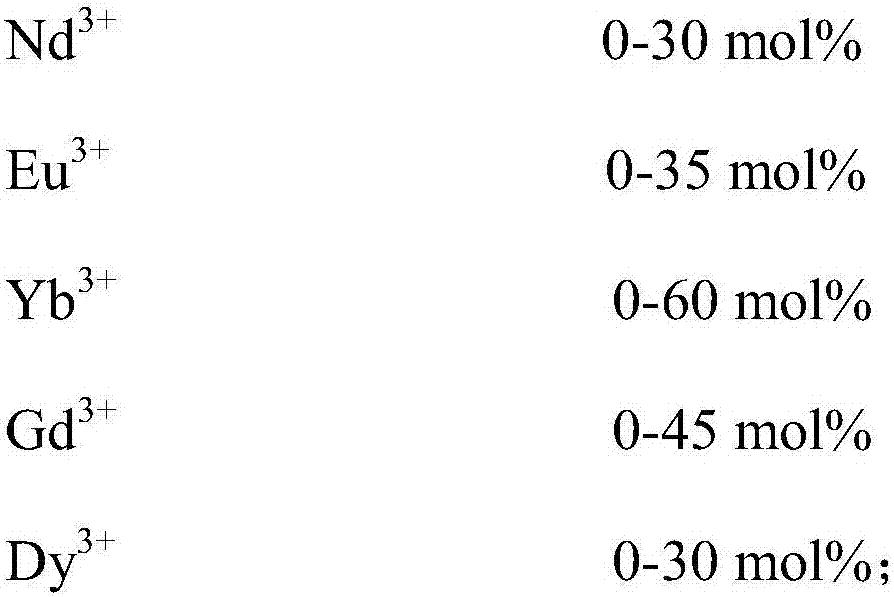

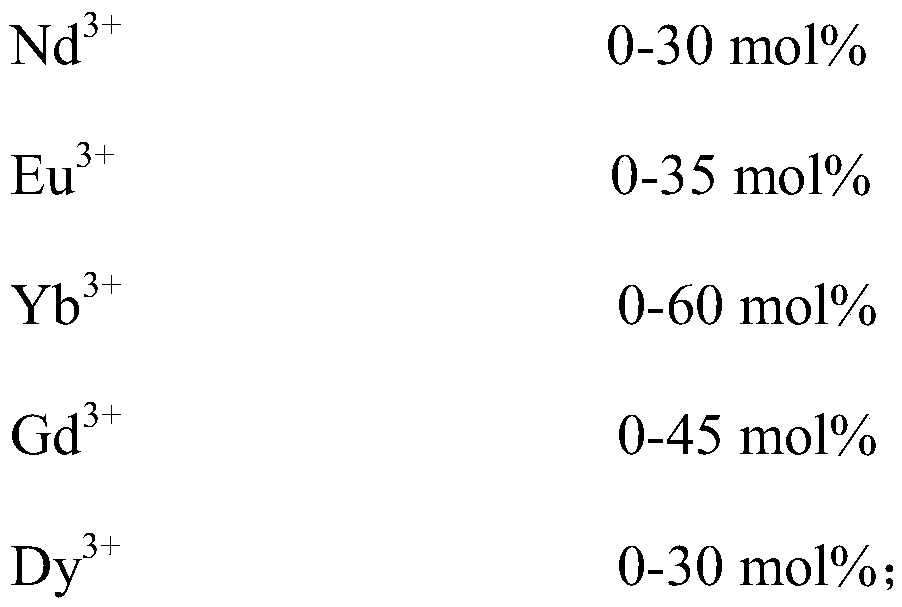

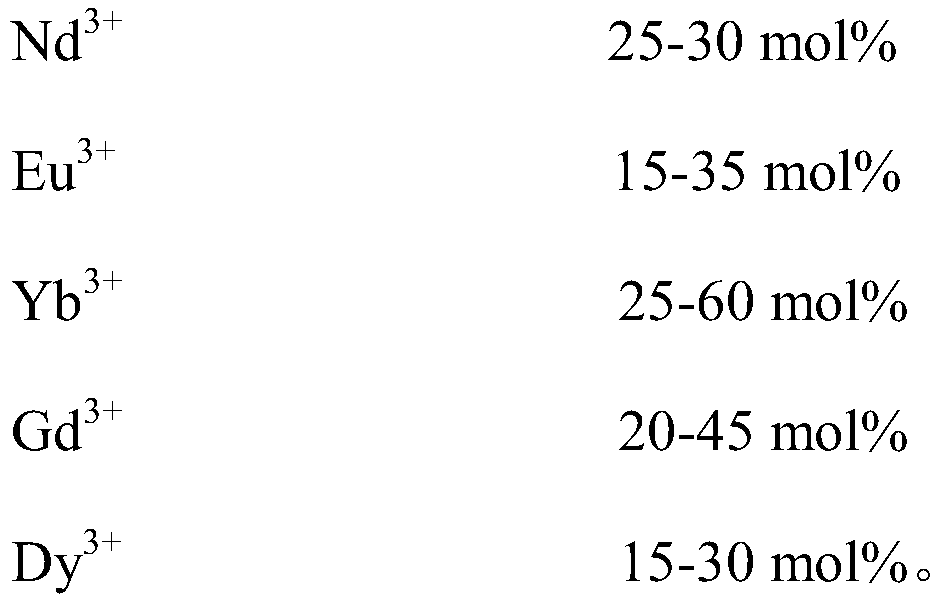

Chlorine evolution accelerator and preparation method thereof

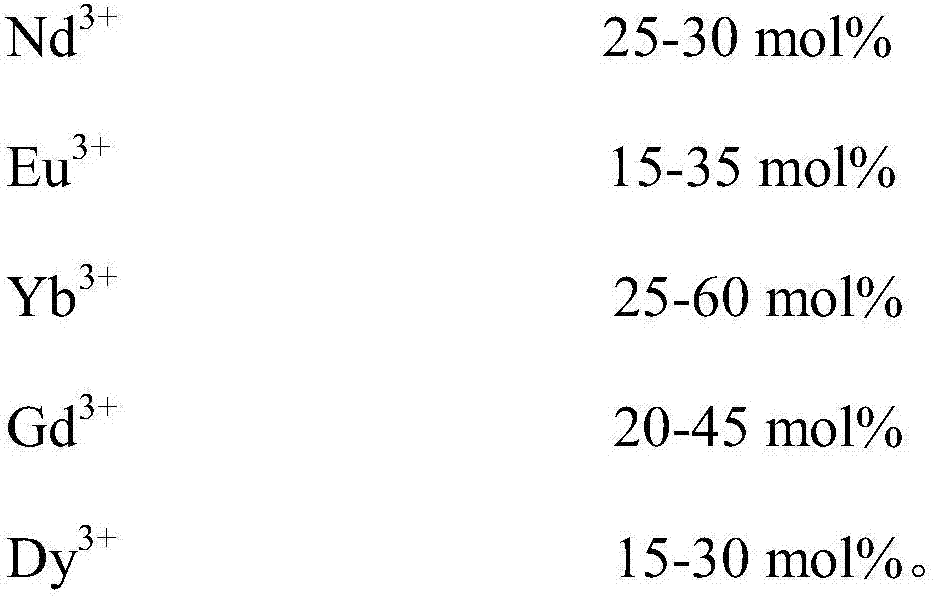

ActiveCN107029754APromote chlorine analysis reactionImprove Chlorine Analysis EfficiencyPhysical/chemical process catalystsElectrodesSodium hypochloriteDysprosium

The invention discloses a chlorine evolution accelerator and a preparation method thereof. The chlorine evolution accelerator is prepared from three or more of a neodymium compound, a europium compound, an ytterbium compound, a gadolinium compound and a dysprosium compound. The chlorine evolution accelerator is added to an electrode of a sodium hypochlorite generator so that the electrode of the sodium hypochlorite generator is high in chlorine evolution speed, high in electrolysis efficiency and low in operation cost. The invention aims at providing the preparation method of the chlorine evolution accelerator, the reparation method is simple in process, easy to operate, and conductive to large-scale and industrialized production.

Owner:AWS ENVIRONMENT TECH LTD

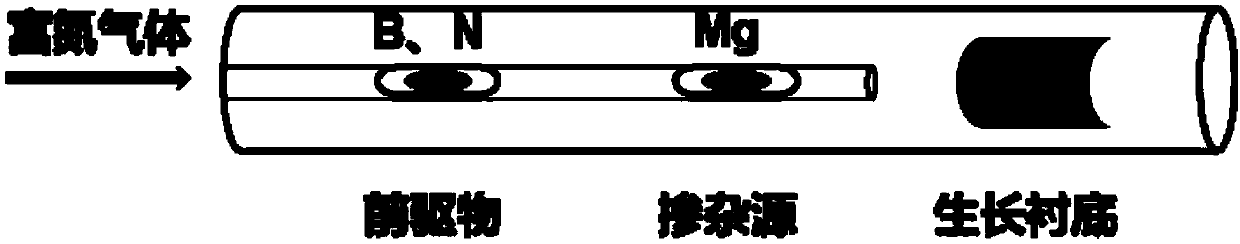

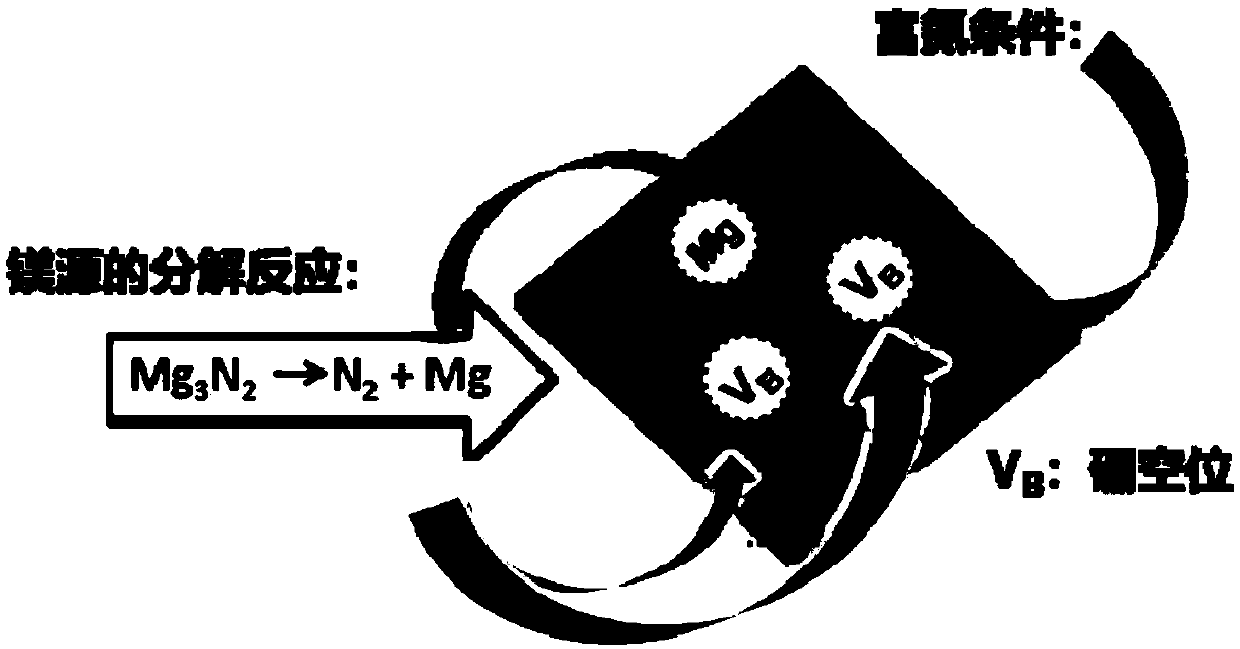

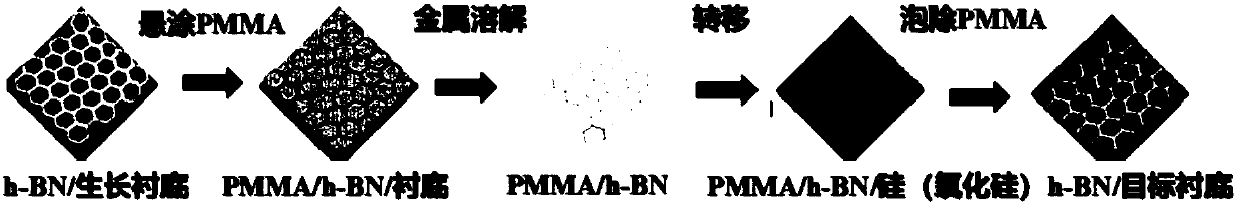

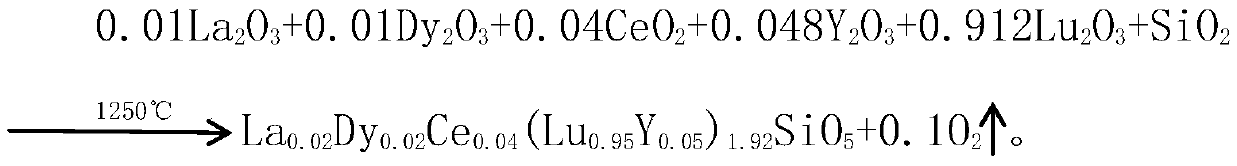

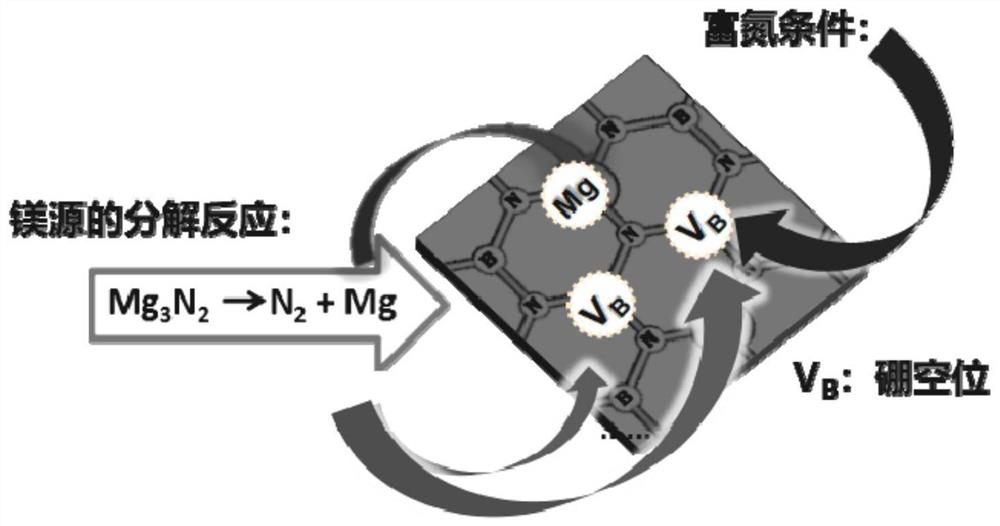

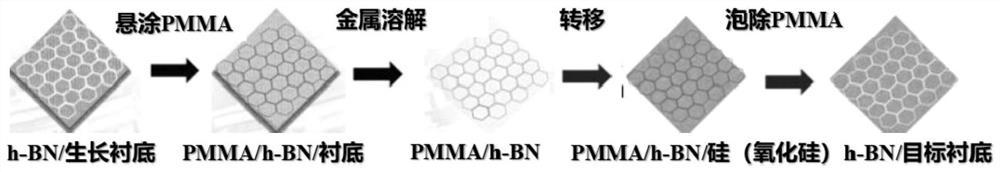

Method for reinforcing boron nitride film p-type conductive doping in nitrogen-enriched atmosphere

ActiveCN109518278AIncrease vacanciesEnhanced displacement dopingPolycrystalline material growthDiffusion/dopingHexagonal boron nitrideNitrogen

The invention discloses a method for reinforcing boron nitride film p-type conductive doping in a nitrogen-enriched atmosphere. The method comprises the following steps: firstly, promoting the acceptor level of B vacancy in a hexagonal boron nitride crystal at the nitrogen-enriched atmosphere; then sequentially performing through displacement doping of Mg in hexagonal boron nitride crystal lattices to reinforce the p-type conductive performance of a hexagonal boron nitride film.

Owner:XIAMEN UNIV

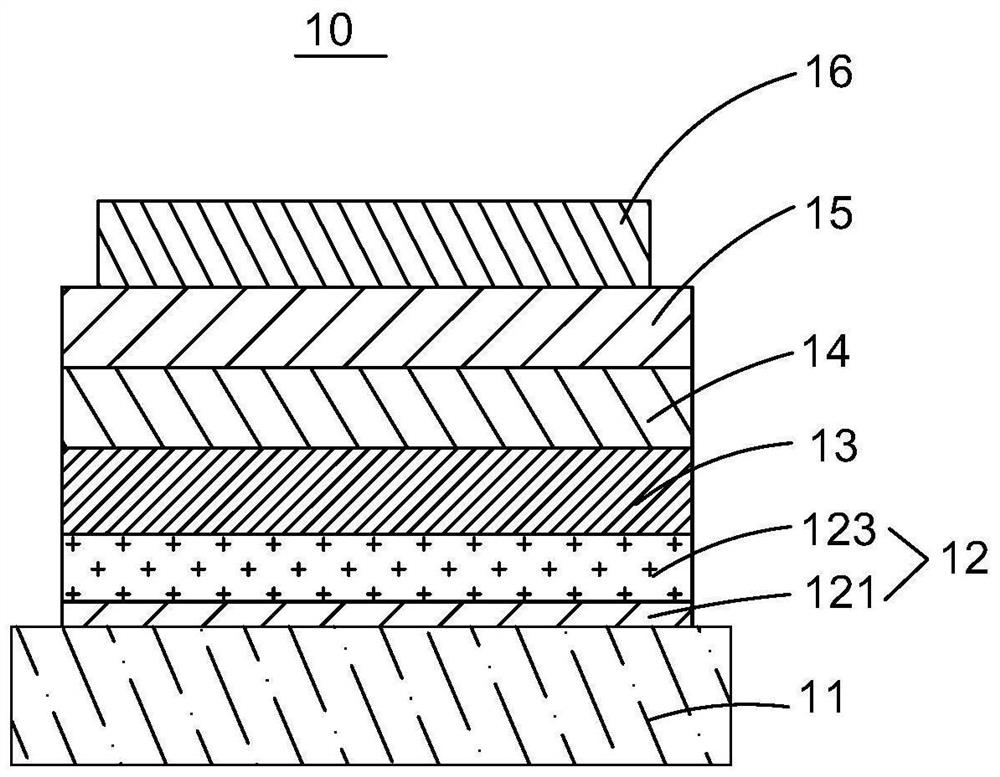

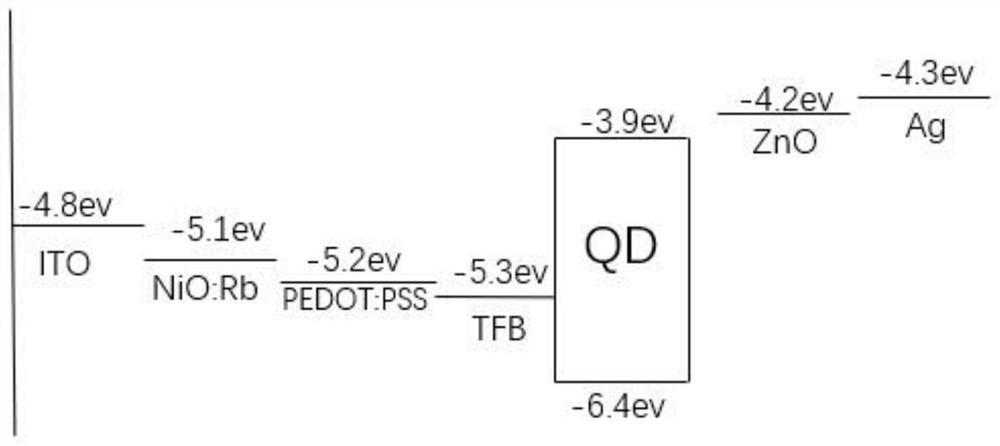

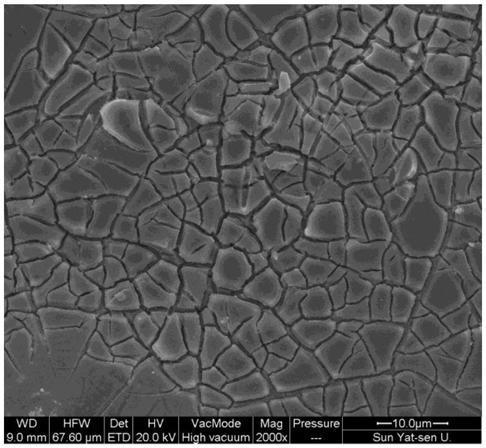

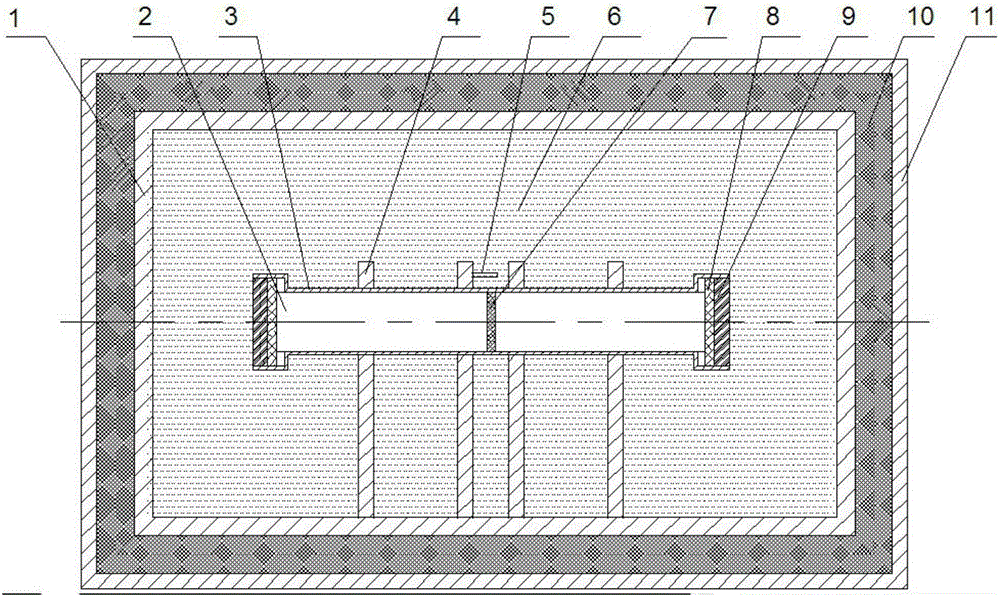

QLED device and preparation method thereof

PendingCN113851593ARaise the ratioIncrease vacanciesSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeHole injection layer

The invention discloses a QLED device and a preparation method thereof, and belongs to the field of QLED devices. The QLED device comprises a substrate, an anode and a composite hole injection layer which are sequentially stacked, wherein the composite hole injection layer comprises a rubidium-doped nickel oxide thin film and a PEDOT:PSS thin film which are alternately stacked, the composite hole injection layer is provided with a first surface connected with the anode and a second surface far away from the anode, the layer where the first surface is located is the rubidium-doped nickel oxide thin film, and the layer where the second surface is located is the PEDOT:PSS thin film. By the adoption of the composite hole injection layer, PEDOT:PSS can be prevented from corroding the anode, the stability of interface contact between the composite hole injection layer and the ITO glass substrate is kept, the energy level of the composite hole injection layer and the energy level of the quantum dot light-emitting layer are more adaptive, the hole extraction and injection efficiency can be improved, and therefore carriers are balanced, the performance of a device is improved, and the service life of the QLED device is finally prolonged.

Owner:合肥福纳科技有限公司

A kind of preparation method of sodium hypochlorite generator electrode

ActiveCN107034483BChlorine evolution potential is lowHigh oxygen evolution potentialElectrodesSodium chlorateElectrolysis

The invention discloses a preparation method of a sodium chlorate generator electrode. The preparation method comprises the following steps of (1) matrix treatment, (2) preparation of inner-layer active coating liquid, (3) preparation of inner-layer metal oxide, (4) preparation of outer-layer active coating liquid, and (5) preparation of the electrode. According to the novel preparation method of the sodium hypochlorite generator electrode, the prepared electrode has the advantages of being low in chlorine evolution potential, high in oxygen evolution potential, energy-saving, environmentally friendly, long in service life and high in electrolytic efficiency.

Owner:AWS ENVIRONMENT TECH LTD

A kind of superconductor cold-compression joining method

InactiveCN103920983BReduce decompositionIncrease vacanciesConductorsMetal working apparatusHigh-temperature superconductivityUltimate tensile strength

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing environment barrier coating at low temperature

InactiveCN102249735BDoes not affect environmental performanceIncrease vacanciesCarbon fibersFilling materials

The invention relates to a method for preparing environment barrier coating at a low temperature. In the method, organosilicon as a precursor is mixed with proper powder to form filling materials, and then a proper amount of a sintering additive is added to prepare slurry. Specifically, organosilicon is added with 40%-80% of environment barrier coating powder and 2%-10% of the sintering additive.After ball milling for material mixing, a green coating can be prepared. On the basis of different environment barrier coating powder, a compact coating can be obtained by sintering the powder at a low temperature ranging from 1200DEG C to 1350DEG C. The method of the invention prepares the coating at a temperature of 100-200DEG C lower than the regular slurry method, so that carbon fibers or silicon carbide fibers in matrix materials can be protected effectively. In addition, the adding of the sintering additive does not influence the high temperature environment performance of the coating prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of chlorine analysis accelerator and preparation method thereof

ActiveCN107029754BPromote chlorine analysis reactionLow running costPhysical/chemical process catalystsElectrodesElectrolysisDysprosium

The invention discloses a chlorine evolution accelerator and a preparation method thereof. The chlorine evolution accelerator is prepared from three or more of a neodymium compound, a europium compound, an ytterbium compound, a gadolinium compound and a dysprosium compound. The chlorine evolution accelerator is added to an electrode of a sodium hypochlorite generator so that the electrode of the sodium hypochlorite generator is high in chlorine evolution speed, high in electrolysis efficiency and low in operation cost. The invention aims at providing the preparation method of the chlorine evolution accelerator, the reparation method is simple in process, easy to operate, and conductive to large-scale and industrialized production.

Owner:AWS ENVIRONMENT TECH LTD

A method for improving the high temperature water vapor oxidation resistance of heat-resistant steel

InactiveCN101225465BIncrease the dislocation densityIncrease vacanciesHeat treatment process controlLattice defectsWater vapor

A method for improving the high-temperature water vapor oxidation resistance of heat-resistant steel. The surface of the heat-resistant steel to be treated is subjected to laser surface remelting treatment, so that the surface layer of the heat-resistant steel is heated to above the melting point at a rate of 103°C / s and melted, and then Solidify at a cooling rate above 103°C / s, and use the characteristics of rapid heating and rapid cooling of laser surface remelting to form a microcrystalline region with a grain size of less than 25 μm on the surface of the steel, through the high-density grain boundaries and subgrains of the treated layer Lattice defects such as grain boundaries, twin boundaries, dislocations, and vacancies promote the diffusion of elements such as Cr and Si to improve the resistance to high temperature water vapor oxidation.

Owner:XIAN THERMAL POWER RES INST CO LTD

Preparation method of high-permeability ferrite magnetic material

ActiveCN114031387AImprove permeabilityEasy to moveInorganic material magnetismInductances/transformers/magnets manufactureElectrical resistance and conductanceFerrite (magnet)

The invention belongs to the technical field of ferrite magnetic materials, and particularly relates to a preparation method of a high-permeability ferrite magnetic material, the preparation method comprises the following steps: preparing materials, pretreating, grinding for the first time, sintering for the first time, grinding for the second time, sintering for the second time, granulating, forming, sintering for the third time, and annealing to obtain the ferrite magnetic material. According to the preparation method, redundant impurities are removed through heat treatment of the raw materials, the magnetic conductivity is improved, and then auxiliary materials capable of improving the magnetic conductivity are doped to further improve the magnetic conductivity; by doping a small amount of high-resistance resin and combining multiple times of grinding and sintering, the obtained ferrite magnetic material has the characteristics of high magnetic conductivity and low loss.

Owner:江西伟普科技有限公司

A kind of lanthanum, dysprosium, cerium co-doped yttrium lutetium silicate scintillation material and its crystal growth method

ActiveCN108560053BIncrease vacanciesAvoid excessive oxidationPolycrystalline material growthFrom solid stateLutetiumSilicic acid

The invention discloses a lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and a crystal growth method of the lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material. The chemical formula of the scintillating crystal is La2pDy2qCe2m(Lu(1-n)Yn)2(1-p-q-m)SiO5, wherein p is more than 0 and less than or equal to 0.02, q is more than 0 and less than or equal to 0.02, m is more than 0 and less than or equal to 0.03, n is more than or equal to 0.01 and less than or equal to 0.1, p, q and m meet the condition that pplus q plus m is more than 0 and less than or equal to 0.05; the growth method is as follows: S1: synthesizing a poly-crystal material block at the solid phase at the high temperature; S2: compressing and fusing the poly-crystal at the atmosphere of the protective gas; and S3: growing at equal diameter, and using a PID algorithm to automatically cool and anneal. The Dy and the La are doped in LYSO, the vacancy for growing the crystal is increased, the excessive oxidation of the crystal is avoided, the scintillating performance of the crystal is guaranteed, the luminescence spectrum of the crystal is expanded, and the case substitution rates of the ions Lu and Y are increased by means of cold isostaitc pressing, the automatic temperature-controlled growth is implemented through the PID algorithm, and the consistency of the crystals growing in batches is guaranteed.

Owner:安徽晶宸科技有限公司

A method for enhancing the p-type conductive doping of boron nitride thin film in a nitrogen-rich atmosphere

ActiveCN109518278BEnhanced p-type conductanceIncrease hole concentrationPolycrystalline material growthDiffusion/dopingAcceptorMetallurgy

The invention discloses a method for reinforcing boron nitride film p-type conductive doping in a nitrogen-enriched atmosphere. The method comprises the following steps: firstly, promoting the acceptor level of B vacancy in a hexagonal boron nitride crystal at the nitrogen-enriched atmosphere; then sequentially performing through displacement doping of Mg in hexagonal boron nitride crystal lattices to reinforce the p-type conductive performance of a hexagonal boron nitride film.

Owner:XIAMEN UNIV

Modified lini 0.6 co 0.2 mn 0.2 o 2 Preparation method and product of ternary cathode material and battery

ActiveCN109755524BFacilitated DiffusionImprove charge and discharge performanceCell electrodesSecondary cellsTungstate ionElectrical battery

The invention discloses a modified LiNi 0.6 co 0.2 mn 0.2 o 2 A preparation method and product of a ternary cathode material and a battery. The preparation method of the ternary positive electrode material includes: first introducing magnesium element when preparing the precursor of nickel cobalt manganese hydroxide, and then using ammonium metatungstate aqueous solution as complexing agent in the later stage of co-precipitation reaction, using ammonium metatungstate in the After hydrolysis in water, ammonia ions and tungstate ions appear, and ammonia ions are used as complexing agents to compensate for the co-precipitation reaction, while tungstate ions are partially deposited on the surface of the nickel-cobalt-manganese hydroxide precursor formed in the precipitation reaction stage, The in-situ introduction of tungsten element is realized, followed by lithiation treatment to obtain ternary cathode powder with tungsten element on the surface. In the present invention, by adding magnesium element and in-situ doping tungsten element on the surface, the charging and discharging performance, cycle performance and the like of the obtained modified ternary positive electrode powder are effectively improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com