Method for producing soft magnetic ferrite core

A technology of soft magnetic ferrite and magnetic core, which is applied to machine tools suitable for grinding the edge of workpieces, machine tools for surface polishing, grinding machines, etc. It can solve the problems of high sintering temperature, unfavorable energy saving and environmental protection, and large energy consumption. Achieve the effect of smooth surface, high magnetic permeability and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

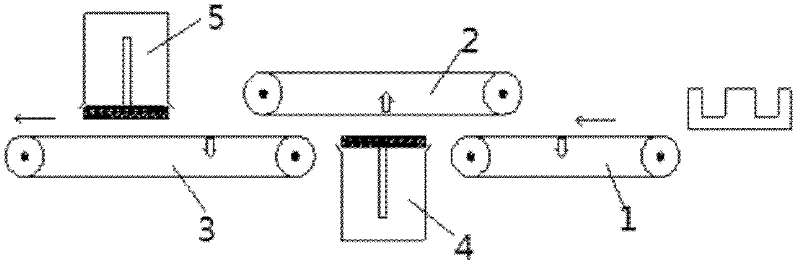

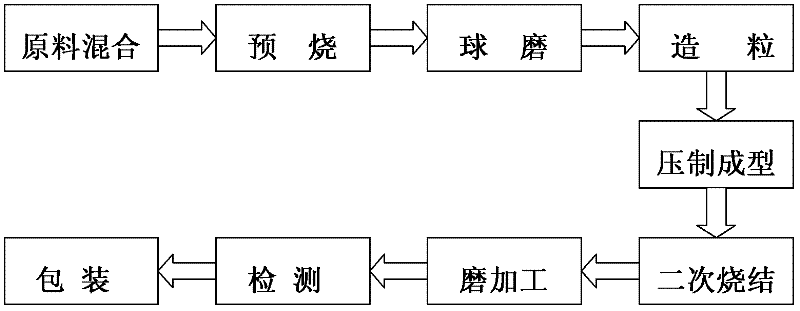

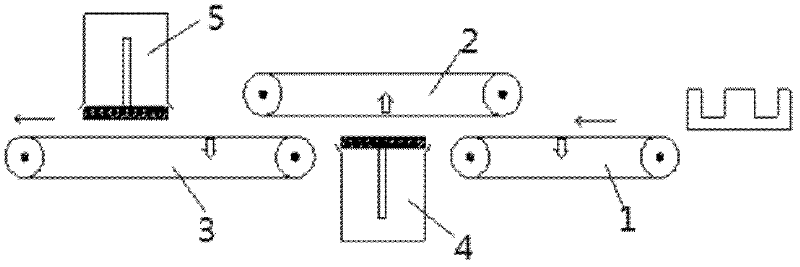

[0024] Referring to the accompanying drawings, the method for producing soft ferrite cores includes the following processes: raw material mixing, pre-calcination, ball milling, press molding, secondary sintering, grinding, testing, and the integrated magnetic suction is used in the grinding process The double-sided grinding machine, the integrated magnetic suction double-sided grinding machine, includes a conveying platform 1 and a conveying platform 3 3, and a grinding wheel 4 is fixedly installed between the conveying platform 1 and the conveying platform 3 3, and the described Conveying platform two 2 is installed on the top of emery wheel one 4, emery wheel two 5 is fixedly installed above described conveying platform three 3, described emery wheel one 4, two 5 are adjustable up and down; Described conveying platform one 1, two 2, The interior of the three 3 is installed with magnetic elements to make it have downward, upward and downward magnetic forces respectively.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com