Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about How to "Improve ball milling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing flake silver powder with low bulk density

The invention provides a method for preparing flake silver powder with low bulk density. The method comprises the following steps of reducing silver powder, i.e. adding pure water into a reaction container, and adding silver nitrate under a stirring condition to make the silver nitrate completely dissolved; adding a PH(Potential Of Hydrogen) value regulator, stirring, adding formaldehyde serving as a reducer to perform chemical reaction, washing the silver powder and drying; and ball-milling, i.e. weighing the silver powder, adding zirconia, filling in a ball-milling pot, adding a ball-milling solvent, a ball-milling aid and an emulsifier, ball-milling, sieving, washing by using a cleaning solvent, and drying to obtain the flake silver powder. The silver powder prepared in the reducing process by the method is not added with any dispersing agent, has low impurity content and high purity; and moreover, the technical process is simple, the ball-milling time is short, and the method is easily industrialized.

Owner:湘潭市泽宇新材料科技有限公司

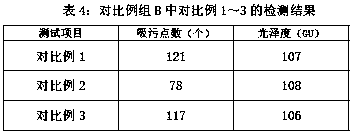

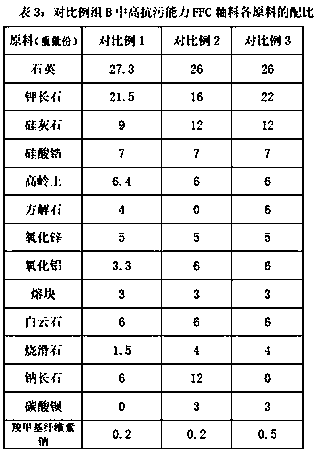

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

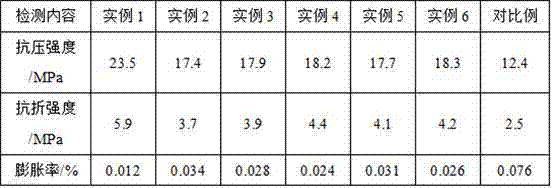

Method for preparing composite steel slag carbonized bricks

The invention discloses a method for preparing composite steel slag carbonized bricks, and belongs to the technical field of industrial waste slag utilization. According to the method, steel slags, kerosene and grinding aids are mixed, ball milled, ignited and cooled to obtain combustion slags; the combustion slags are then crushed and sieved to obtain pretreated steel slag powder; aggregates, thepretreated steel slag powder and hydrated lime are stirred and mixed with dispersion liquid to be poured into shape and placed at constant temperature and humidity to obtain unburned bricks; the unburned bricks are subjected to autoclave oxidation and fumigated with vinegar to obtain fumigated bricks; the fumigated bricks are then transferred to a carbonization box and subjected to carbonizationat constant temperature and humidity, and the composite steel slag carbonized bricks are obtained after discharge. The composite steel slag carbonized bricks prepared by adopting the method have excellent strength and stability.

Owner:CHANGZHOU OPTICAL MATERIAL

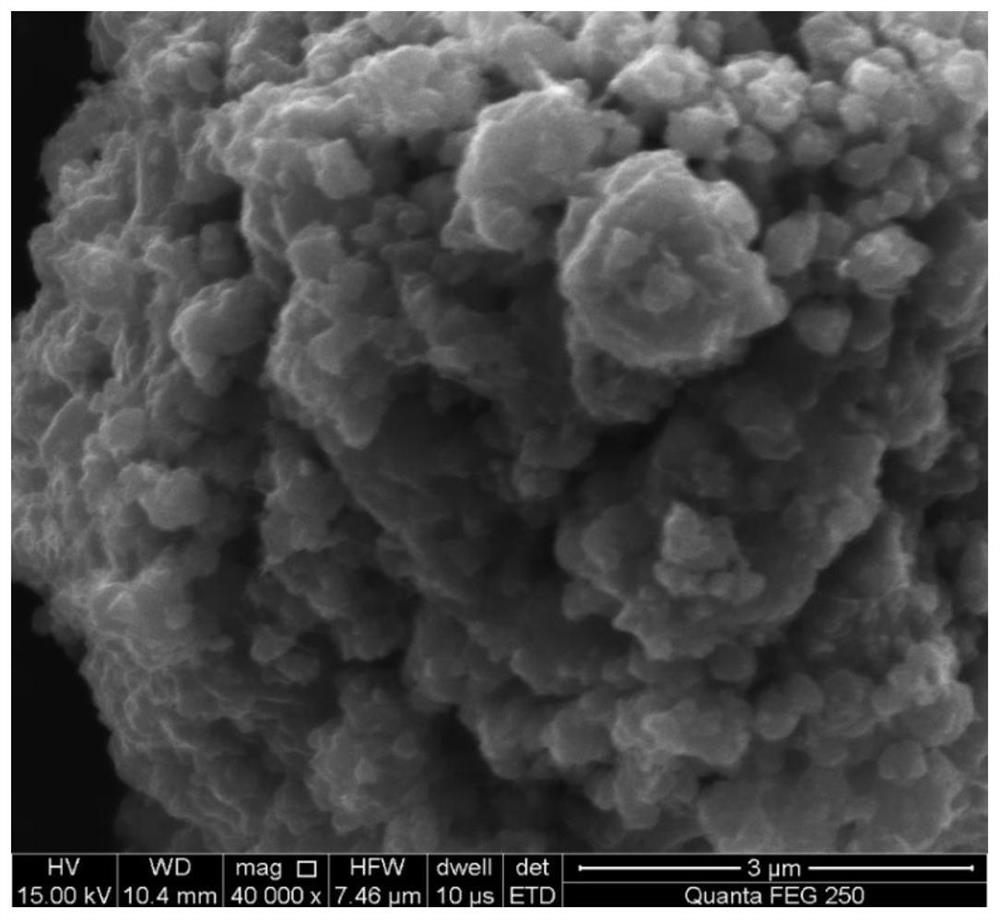

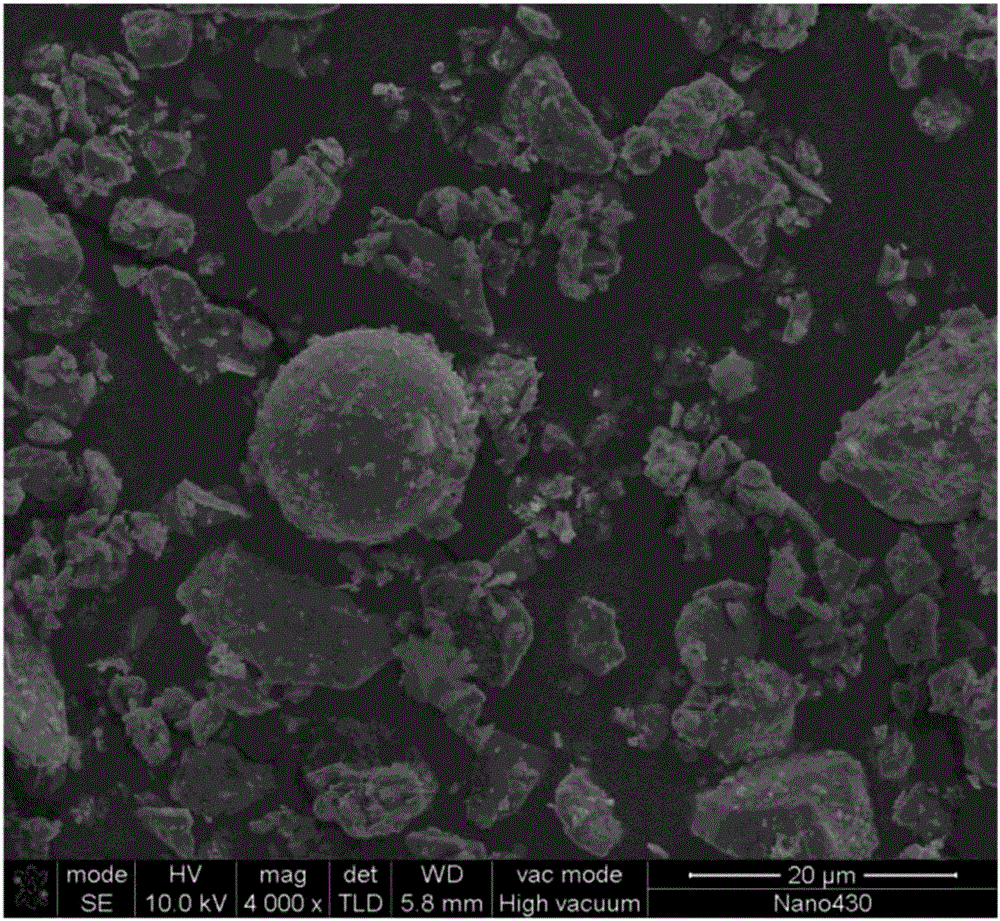

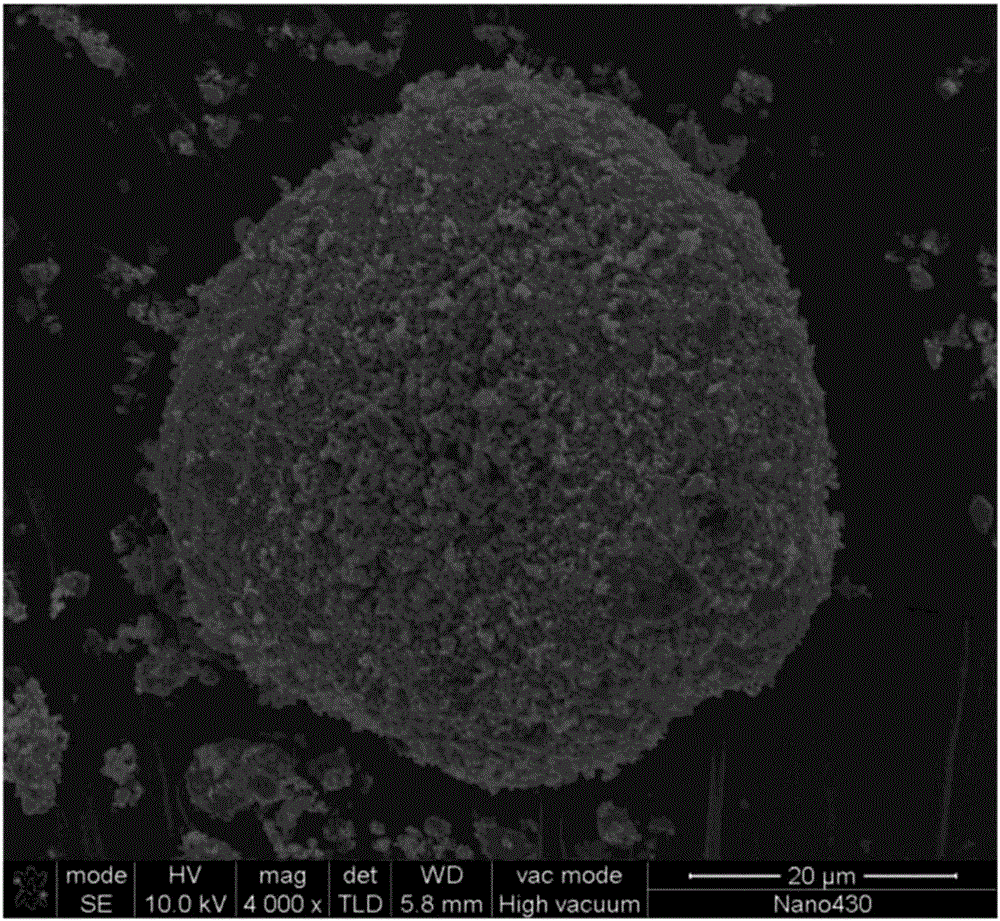

Nano ceramic metal composite powder for 3D printing and application

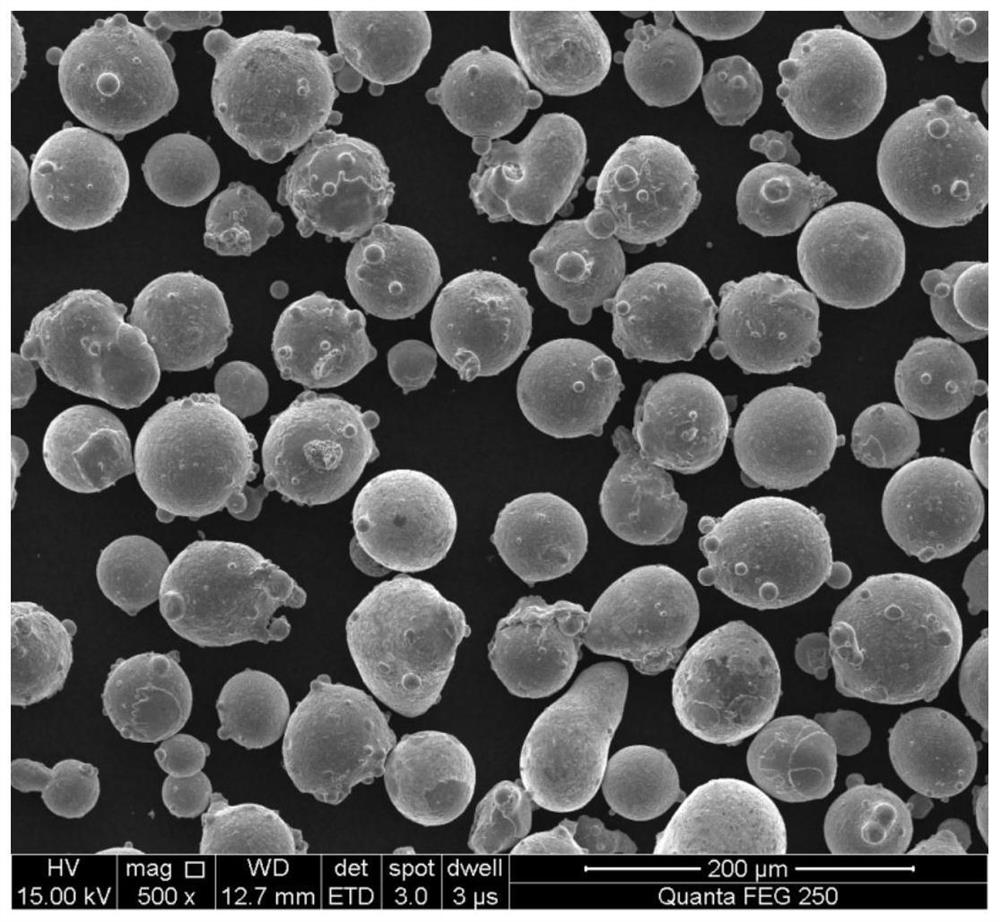

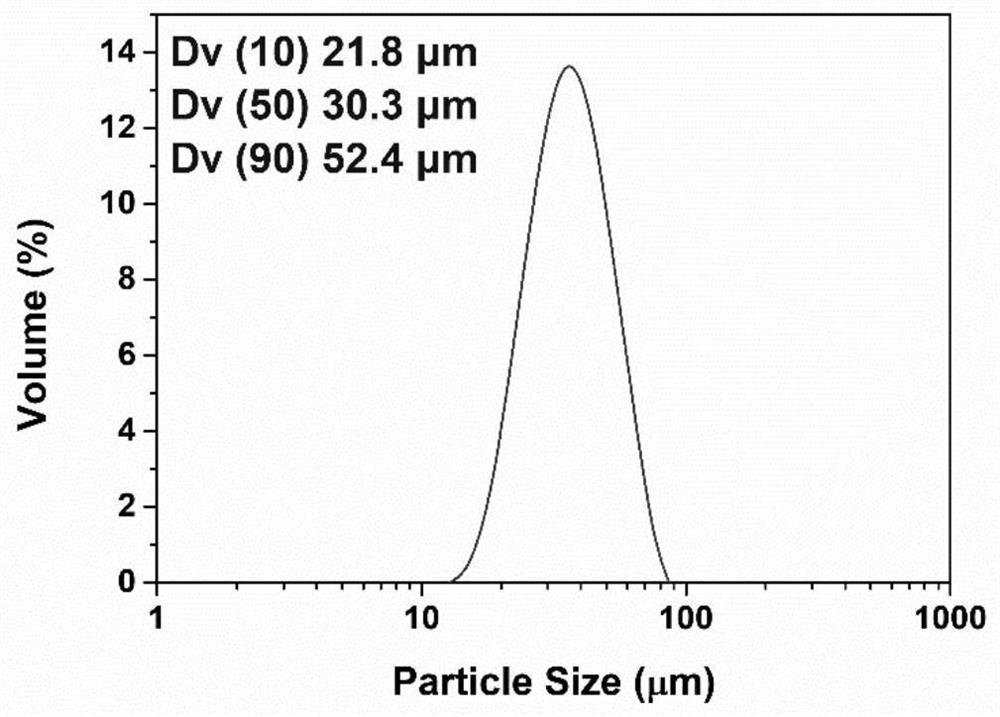

ActiveCN111940723AHigh sphericityGood liquidityAdditive manufacturing apparatusTransportation and packagingCeramic particleCeramic metal

The invention provides nano ceramic metal composite powder for 3D printing and application. A metal material is used as a matrix, and ceramic particles are used as a reinforcing phase. One or more ceramic particles of micron-sized TiC, TiB2, WC, SiC, CrC, Al2O3, Y2O3 and TiO2 are used as raw materials, the mass percent of the added ceramic particles is 0.5-10.0%, through a specific ball milling process, plasma spheroidization, airflow classification and screening, the metal composite powder with high sphericity, good fluidity, narrow particle size range and uniformly distributed nano-ceramicsis obtained, and the high requirement of a 3D printing technology for powder is met; and a nano-ceramic reinforced metal composite material is prepared through the 3D printing technology. According tothe prepared metal composite material, nano ceramic phases are uniformly distributed, and the metal composite material has excellent mechanical properties. Micron-sized ceramic particles are adopted,uniform dispersion is achieved through nanocrystallization, and the cost is low; and parts in any complex shape can be integrally formed and prepared, and the material utilization rate is increased.

Owner:CENT SOUTH UNIV

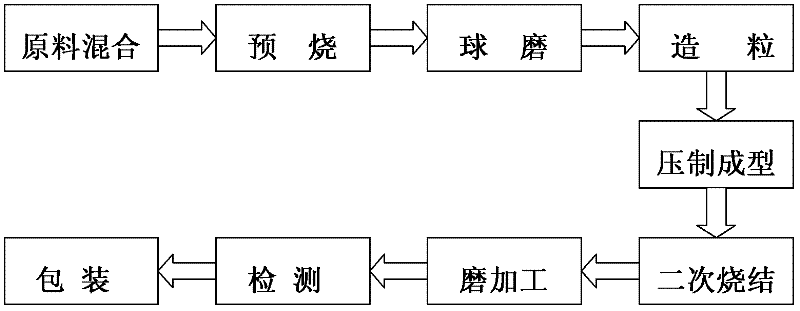

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

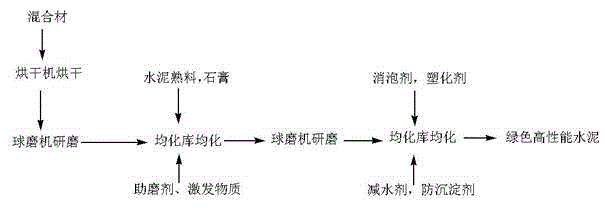

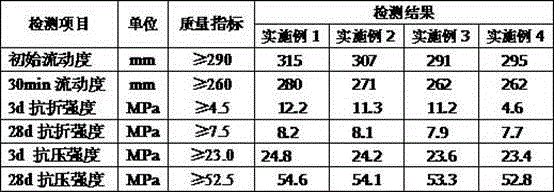

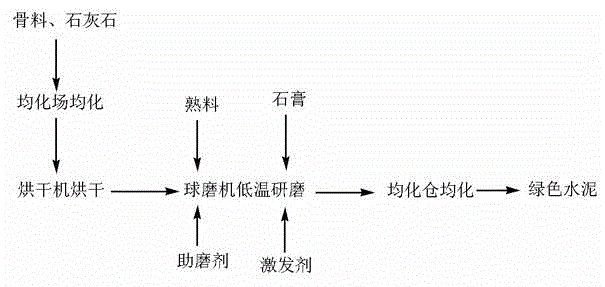

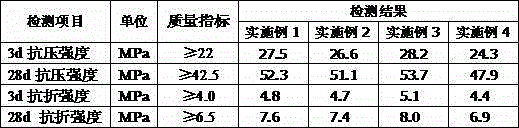

Environment-friendly high-performance cement and production method thereof

ActiveCN103601381AReduce crushing efficiencyImprove liquidityCement productionPlasticizerCement slurry

The invention provides environment-friendly high-performance cement which is characterized by consisting of the following raw materials in parts by weight: 50-60 parts of admixture, 32-40 parts of cement clinker, 6-8 parts of gypsum, 0.03-0.05 part of grinding aid, 3-5 parts of excitation substance, 0.05-0.1 part of antifoaming agent, 0.05-0.1 part of plasticizer, 0.03-0.05 part of anti-precipitating agent and 0.2-0.4 part of water reducing agent. In the environment-friendly high-performance cement provided by the invention, a large mixing amount of cement slurry can be realized by adopting a mechanical-chemical excitation production process, a great quantity of industrial waste residues can be consumed, the yield is increased, and the production cost is lowered; moreover, by adding a functional additive, the performance of the product is improved, and the needs of civil engineering are met.

Owner:广西云燕特种水泥建材有限公司

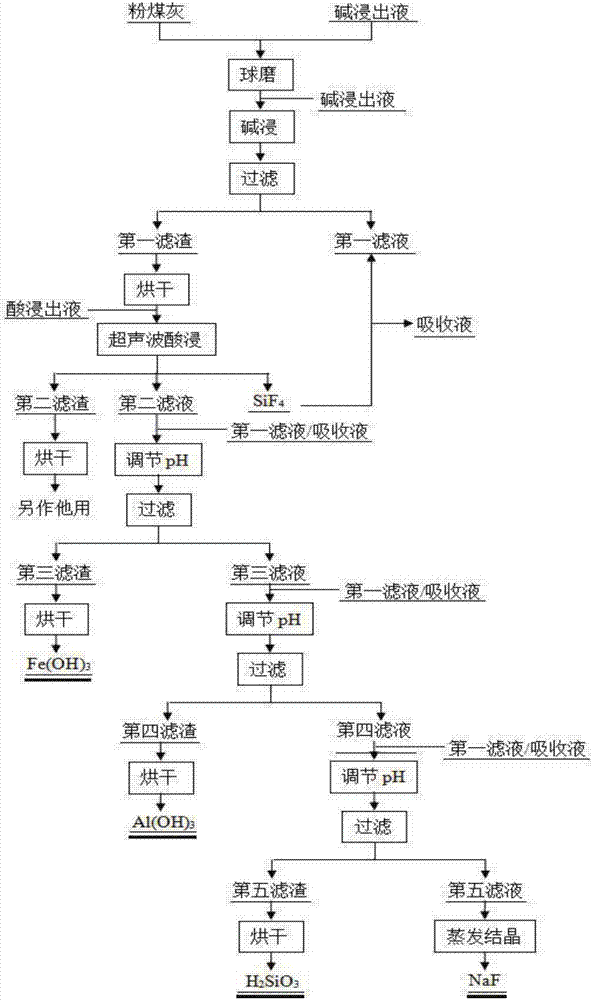

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

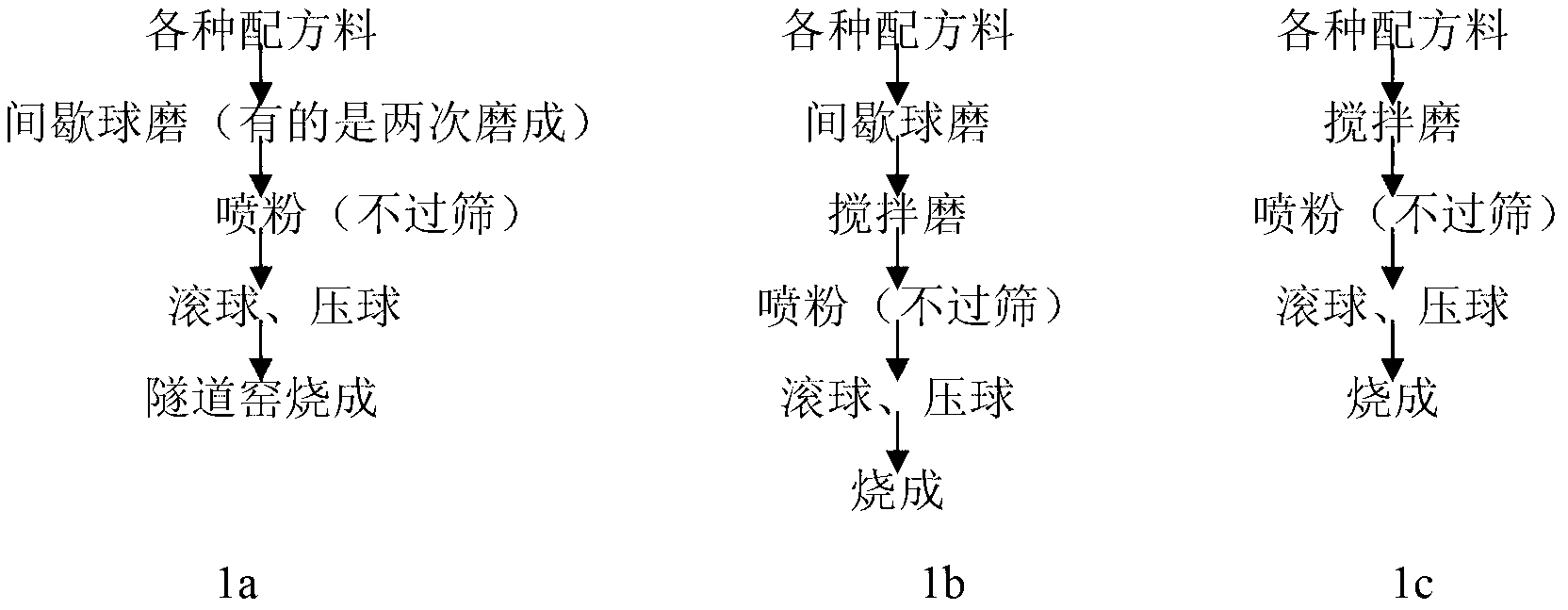

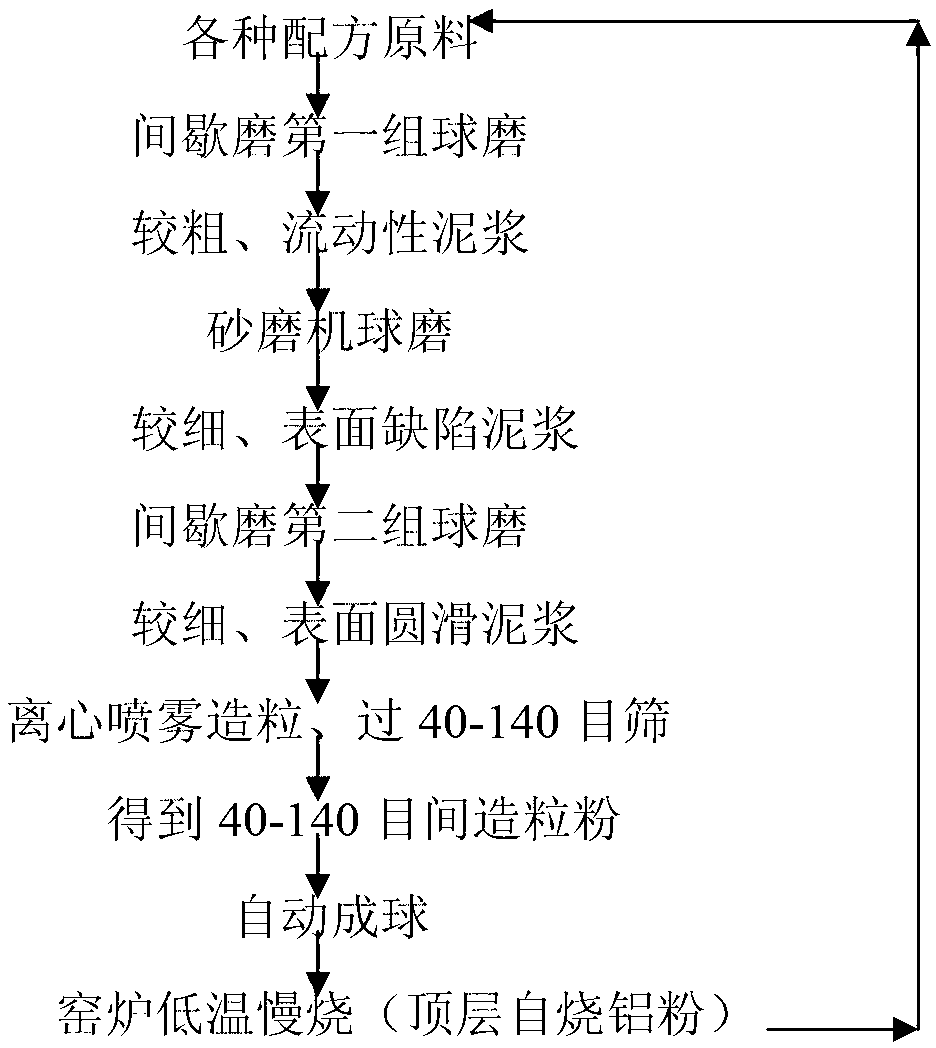

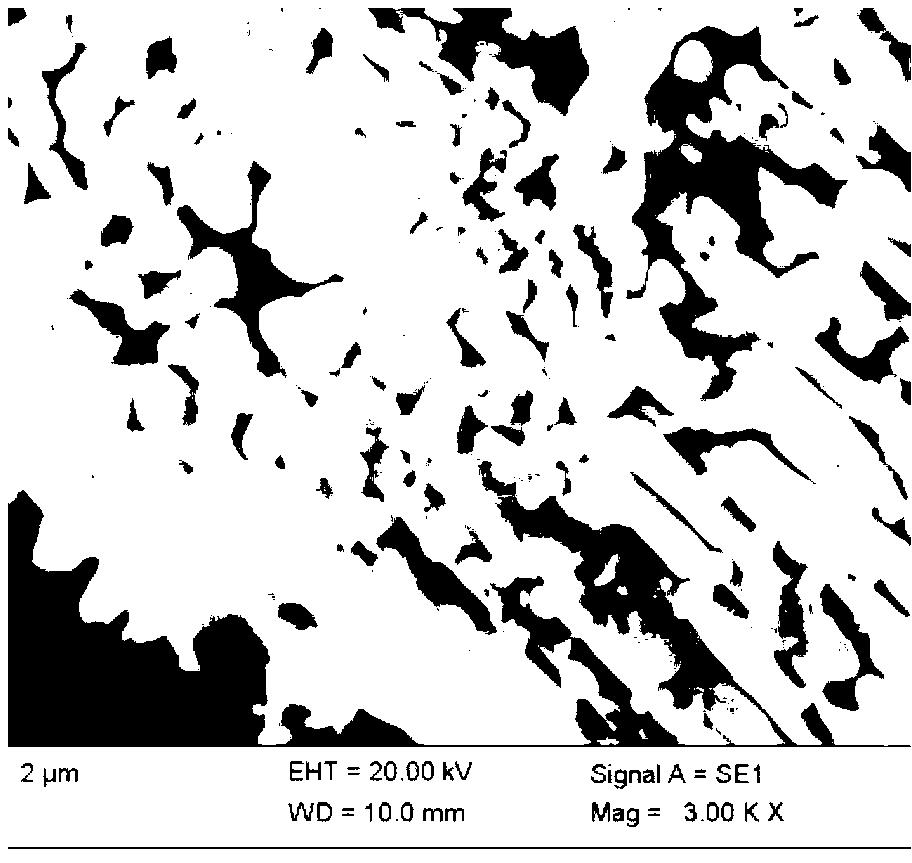

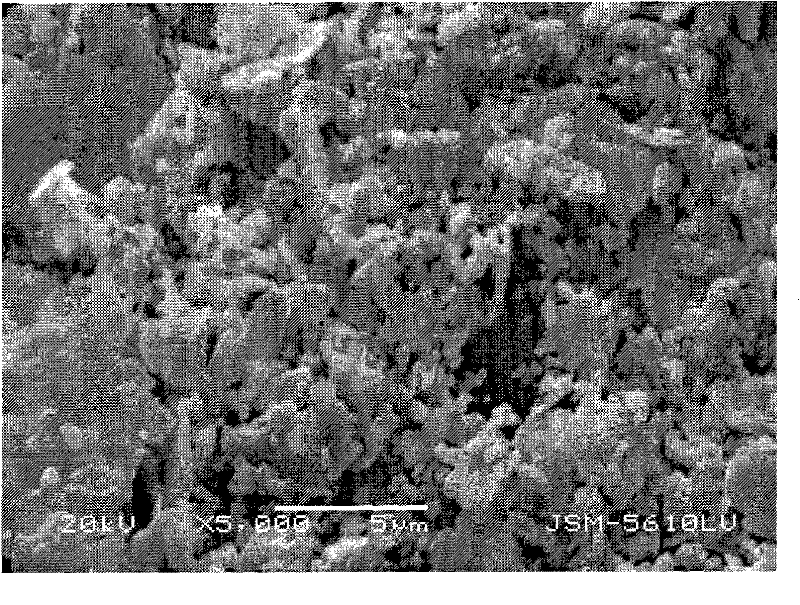

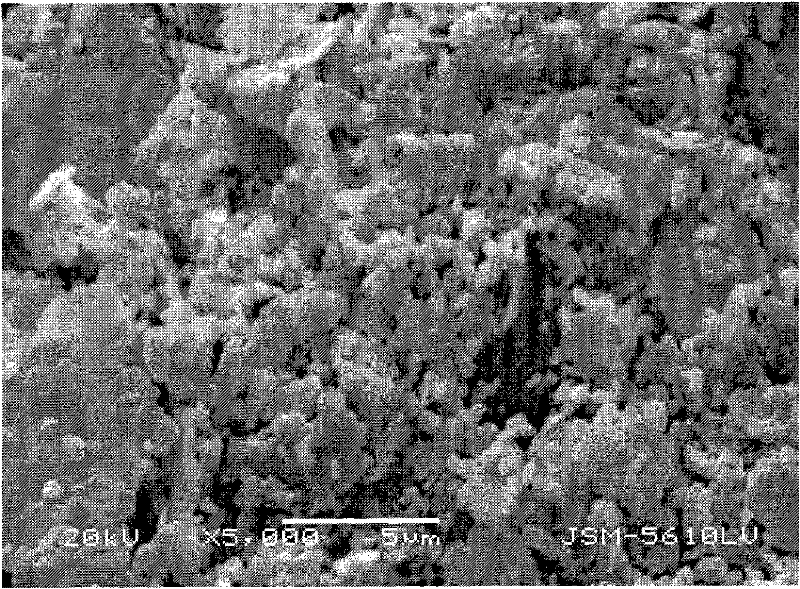

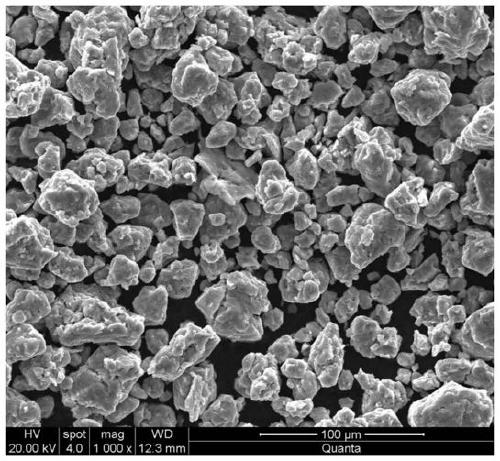

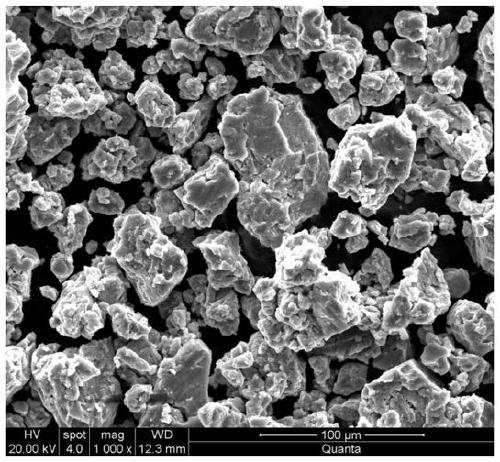

Preparation method of alumina porcelain ball for dry process ball mill

The invention discloses a preparation method of an alumina porcelain ball for a dry process ball mill. The method adopts self-baked alumina powder as main material; alumina powder bought from Shandong Aluminium Corporation is used as auxiliary material; flint clay clinker, kaolin and complex sintering assistant are added; and the end product can be obtained after triple special ball milling, spray pelletization ball formation, and low temperature slow baking. The self-baked alumina disclosed by the invention has a conversion rate of 98%; the D90 is smaller than 3 microns; uniform and unified alumina powder is obtained through adding complex mineralizer, and is a mixture of sheet structure and column structure; ball milling is made from self-baked alumina powder and alumina powder bought from the market according to a reasonable proportion; the purpose of increasing impact resistance is achieved without using expensive raw material; through triple special ball milling process, the purposes of adjusting alumina dry ball mill microstructure, optimizing property and lowering manufacture cost are achieved; and the alumina porcelain ball has the characteristics of low abrasion, high intensity, high density, fewer inner deficiencies, good impact resistance and the like, so that the comprehensive performance is excellent.

Owner:JINGANG NEW MATERIALS

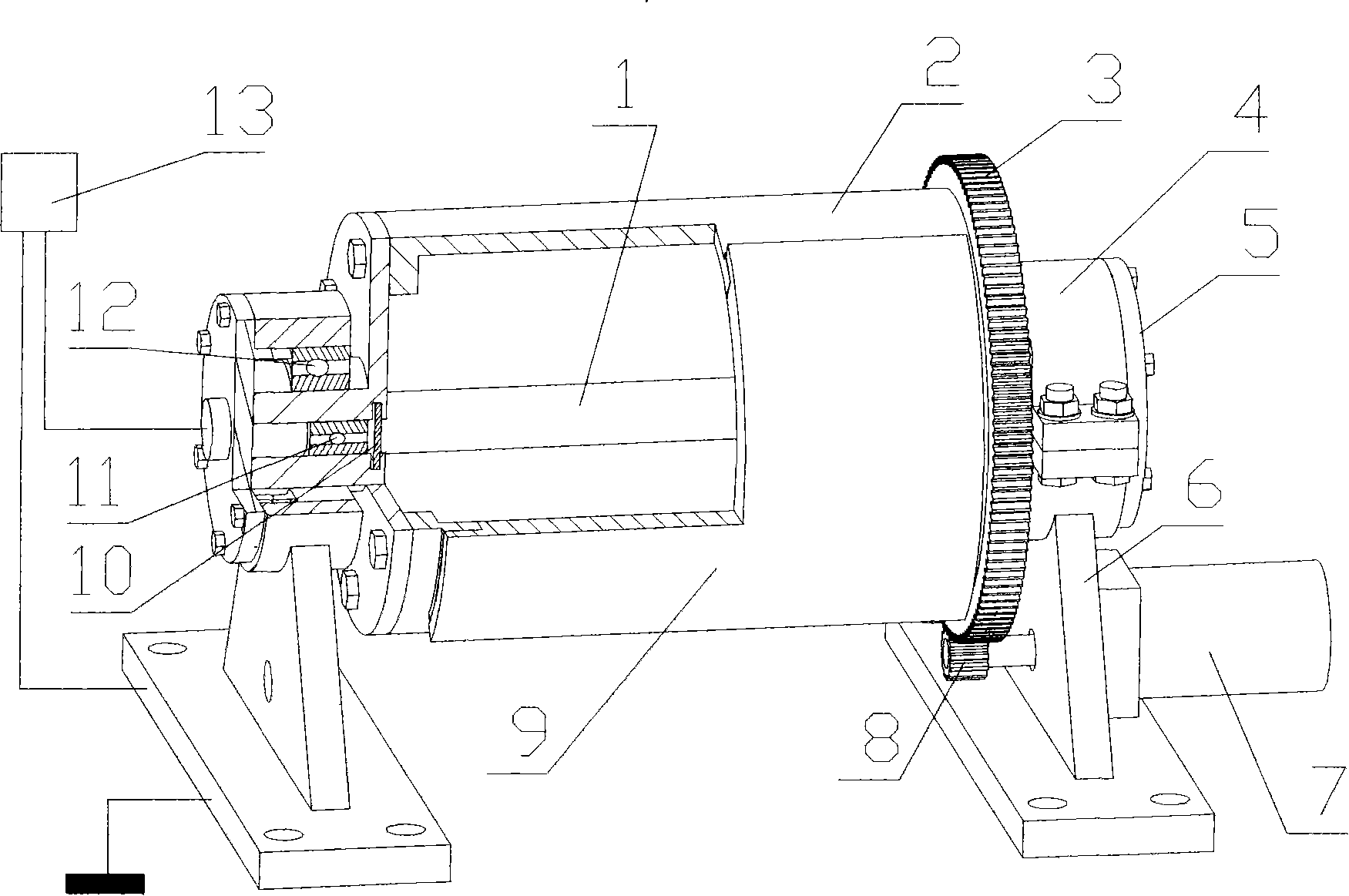

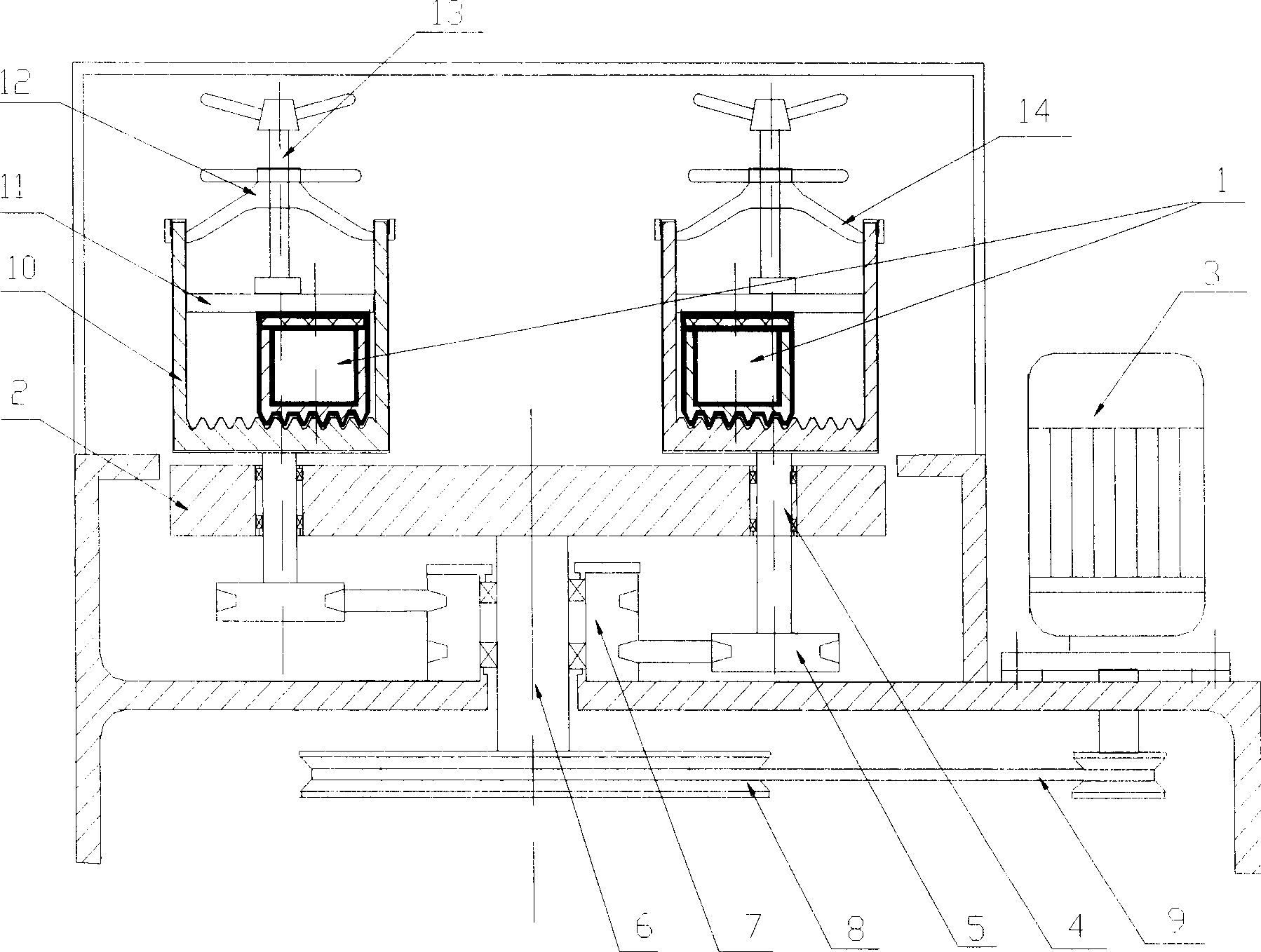

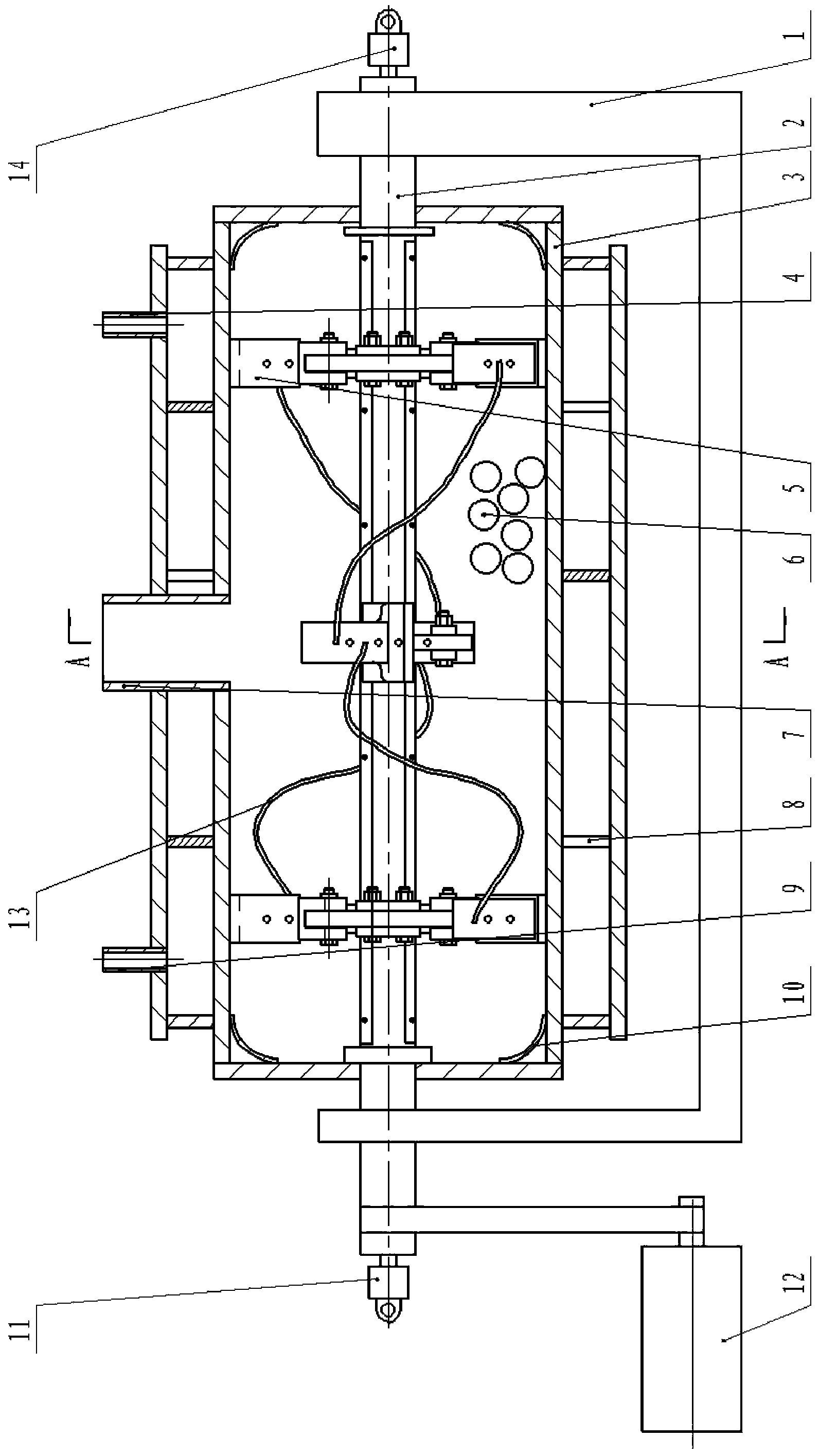

Plasma auxiliary high-energy roller ball mill device

ActiveCN101239334ASolve the difficult problem of mutual interferenceImplementation importGrain treatmentsHigh energyCoaxial line

The present invention provides a high-powered ball grinding technology, specifically a plasma assisting high powered roller ball grinder. The device is changed on the base of traditional roller ball grinder, specifically an electrode axis having a coaxial-line with the roller mounted and fixed by bearing base lid in the roller ball grinder. The aim of the introducing plasma to the roller ball grinder by the device is achieved, the ball grinding speed is accelerated, the diameter distribution is narrow, the grinding efficiency is effectively enhanced at the same time. The device overcomes the deficiency of high vibration and noise of plasma assisting high powered roller ball grinder. The device of the invention has a simple structure, reasonanle and easy to prepaation, the method is easy to achieve, and the device also effectively pushes the application and popularization of the plasma assisting high powered roller ball grinder in the large-scale production in batch of the micronano.

Owner:SOUTH CHINA UNIV OF TECH

Environment-friendly cement and production method thereof

ActiveCN103601382AReduce crushing efficiencyImprove liquidityCement productionMethods of productionToxic industrial waste

The invention discloses environment-friendly cement. The raw materials include various industrial waste residues, limestone, cement clinker, gypsum, a grinding aid and an excitation substance. The environment-friendly cement is characterized in that the weight parts of the raw materials are as follows: 50-60 parts of admixture, 32-40 parts of cement clinker, 4-8 parts of gypsum, 0.03-0.05 part of grinding aid and 3-5 parts of excitation substance. Since the production process of the environment-friendly cement adopts a low-temperature mechanical-chemical co-excitation technology, the mixing amount of the admixture is large, multiple industrial waste residues can be used as raw materials, the raw materials are widely available, the cost is low, a great quantity of industrial waste residues can be consumed, the waste is turned into wealth, and the performance of the obtained product is remarkably improved from the quality index.

Owner:广西云燕特种水泥建材有限公司

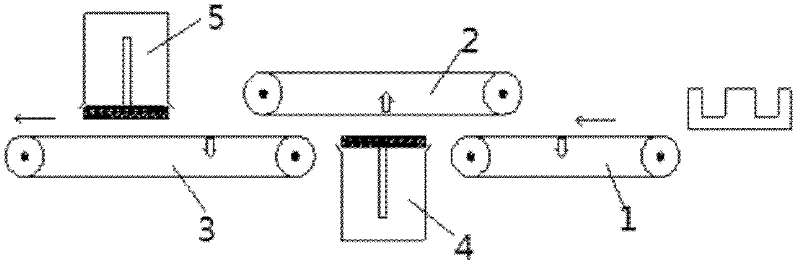

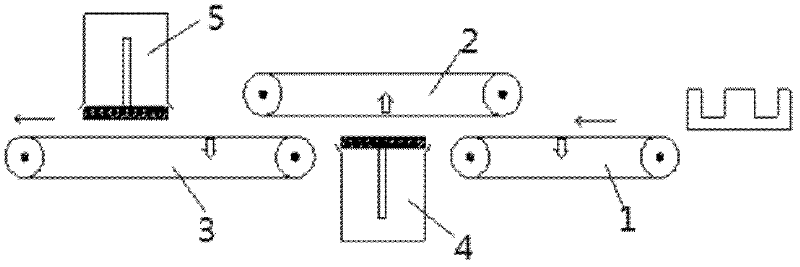

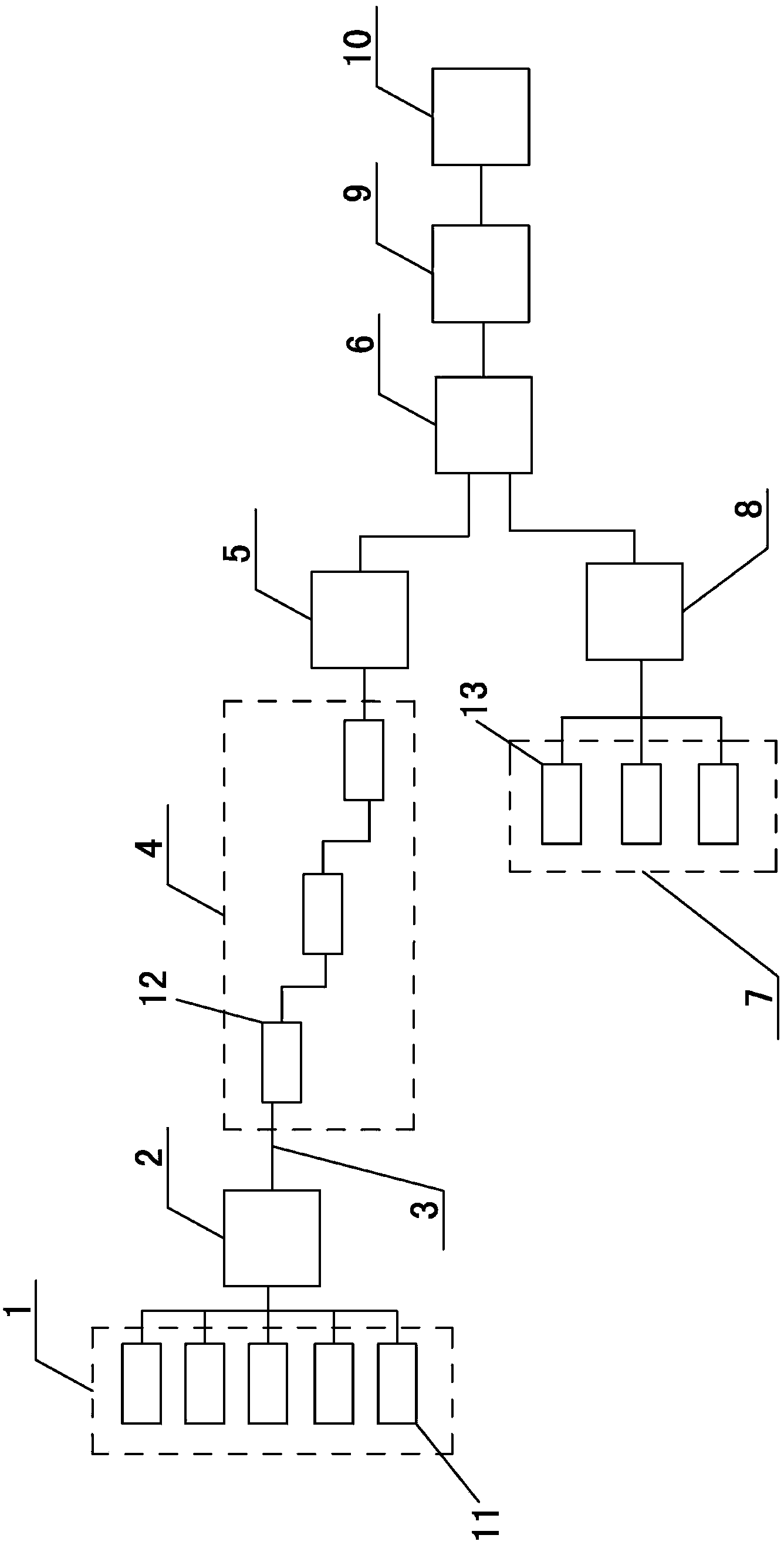

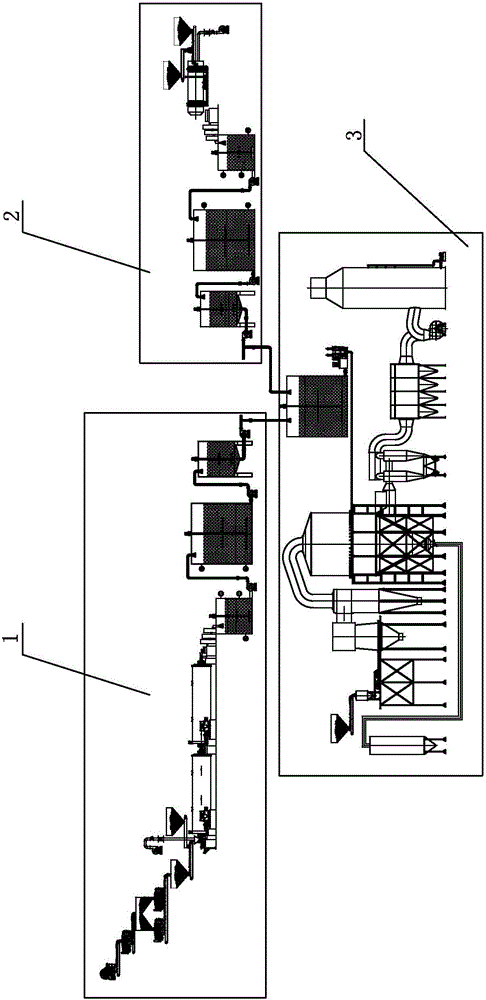

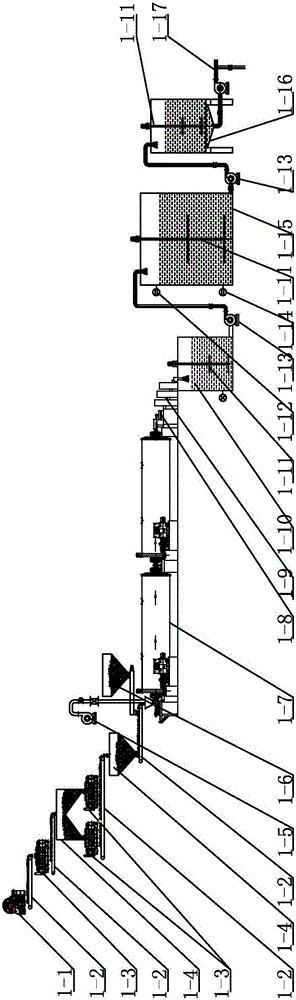

Standardized continuous treatment method of ceramic raw material and production line thereof

ActiveCN103664195AReduce manufacturing costImprove ball milling efficiencyProduction lineIron removal

The invention relates to a standardized continuous treatment method of a ceramic raw material and a production line thereof, wherein the production line comprises a sandstone feeding unit, vertical mill rough machining equipment, a continuous bowl mill unit, pulpifying equipment, an iron removing pool, a bowl mill and a spray drying tower. The sandstone is conveyed to the vertical mill rough machining equipment by the sandstone feeding unit according to a ratio requirement, and is continuously and steppedly ball-milled after the sandstone is coarsely broken below 1mm of fineness, and the slurry below 0.1mm of granularity after ball milling is conveyed to the iron removing slurry pool to remove iron and whiten; and various raw ore mud, after conveyed to the pulpifying equipment by the sandstone feeding unit according to a ratio requirement to remove the sand and impurities in the raw ore mud, and pretreated sandstone slurry are stirred in a big slurry pool, and finally the mixed slurry is conveyed to the bowl mill, and is spray-dried by the spray drying tower until the mixed slurry is ball-milled to 0.05mm. The invention provides the standardized continuous treatment method of the ceramic raw material with advantages of high ball milling efficiency, low energy consumption, stable powder component, high whiteness and low cost, and the production line thereof.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

Silicon oxide compound silver powder and preparation method thereof as well as conductive silver paste

InactiveCN102237151AImprove distributionReduce contentNon-conductive material with dispersed conductive materialMetal/alloy conductorsSilver pasteSilicon oxide

The invention provides silicon oxide compound silver powder comprising silicon oxide and silver particles at the mass ratio of (1.8-3):100, wherein silicon oxide is covered on the surfaces of the silver particles, the average particle diameter of silicon oxide is 40-200nm, and the average particle diameter of the silver particles is 1.3-4.0mu m. The invention also provides a preparation method for the silicon oxide compound silver powder and conductive silver paste containing the silicon oxide compound silver powder. The silicon oxide compound silver powder provided by the invention has the characteristic that silicon oxide is covered on the surfaces of the silver particles, so that the silver powder has better dispersing property; and the conductive silver paste containing the silicon oxide compound silver powder has better electrical conductivity.

Owner:深圳市新合富力科技有限公司

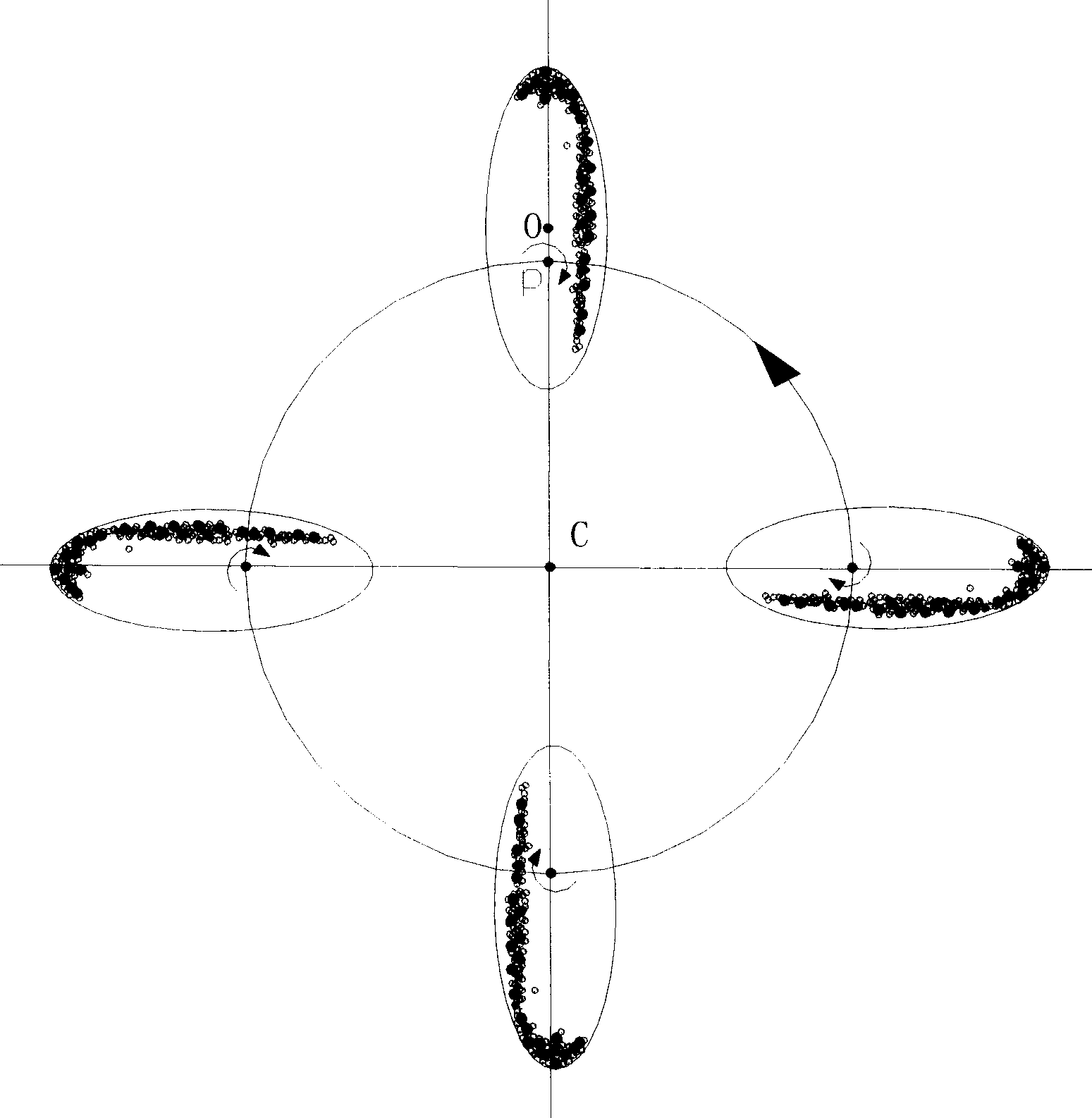

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

Modified alkali lignin ceramic grind-aid dispersing agent and preparation method thereof

ActiveCN102321224ARaw materials are readily available and renewableSimple ingredientsTransportation and packagingMixingSolubilitySulfonate

The invention discloses a modified alkali lignin ceramic grind-aid dispersing agent and a preparation method thereof. The preparation method comprises the following steps of: firstly heating an alkali lignin alkaline solution to 75-85 DEG C and adding sulfonating agents; regulating a system PH (Potential of Hydrogen) value to 3-4 by using dilute sulfuric acid, and adding carboxyl-containing materials dropwise; and then regulating the system PH value to 11-12 by using sodium hydroxide; adding initiating agents, sodium hypophosphite and sodium allyl sulfonate to perform a reaction for 1-5 hours at a temperature of 80-90 DEG C; and obtaining the modified alkali lignin ceramic grind-aid dispersing agent after the reaction is completed. A formulation comprises the following reaction materials in parts by weight: 100 parts of alkali lignin, 15-25 parts of sulfonating agent, 10-20 parts of carboxyl-containing material, 2-5 parts of initiating agent, 5-10 parts of sodium hypophosphite, and 5-10 parts of sodium allyl sulfonate. The molecules of the ceramic grind-aid dispersing agent have sulfonic groups, carboxyl and phosphonic acid groups and good water solubility so that a raw-material ball-grinding efficiency can be greatly increased; a raw-material ball-grinding time is shortened; a liquidity and stability of ceramic slurry are improved; and an obvious reinforcing effect on an embryonic plant is realized.

Owner:SOUTH CHINA UNIV OF TECH

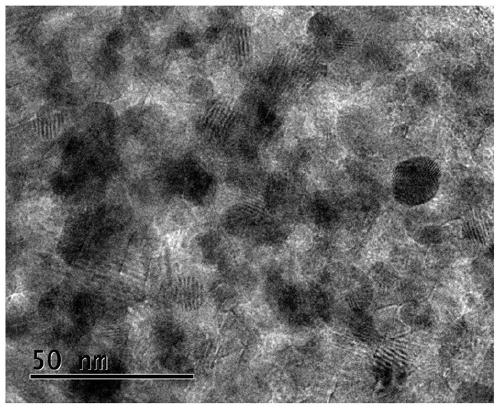

Nano-magnesium-based composite hydrogen storage material and preparation method thereof

ActiveCN109972010AEnhanced reversible hydrogen storage propertiesHigh recovery rateCell electrodesRare-earth elementIngot

The invention relates to a nano-magnesium-based composite hydrogen storage material and a preparation method thereof. The material comprises a main component of magnesium, and simultaneously comprisesa plurality of catalysts of mixed rare earth, carbonyl nickel powder and graphite so as to improve the low-temperature hydrogen absorption performance of the material. The material has a nanocrystalstructure, the grain size is 20-50 nanometer, and the material has excellent low-temperature hydrogen absorption dynamics performance. The preparation method comprises the following steps of firstly,carrying out vacuum smelting on pure magnesium and a certain amount of mixed rare earth by adopting a vacuum induction melting method to prepare a brittle magnesium-rare earth alloy ingot with magnesium doped with rare earth elements in situ; and then mixing the obtained alloy with carbonyl nickel powder, graphite powder and inert organic grinding aid, and further preparing a high-capacity magnesium-based composite hydrogen storage material through a mechanical ball milling method. The preparation method of the material overcomes a wall sticking phenomenon in a mechanical ball milling processof the magnesium-based hydrogen storage alloy, so that the material recovery rate is improved, and the high-capacity magnesium-based composite hydrogen storage material with excellent low-temperaturehydrogen absorption performance is obtained.

Owner:HEBEI UNIV OF TECH

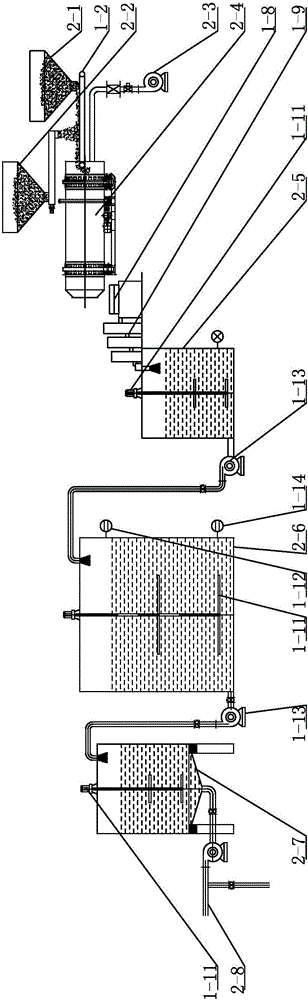

Ceramic raw material independent-grinding centralized preparation technique and device

ActiveCN105773834AReduce energy consumptionAvoid energy consumptionClay processing apparatusGrain treatmentsEconomic benefitsSlurry

The invention relates to a ceramic raw material independent-grinding centralized preparation technique and device and belongs to the technical field of ceramic raw material preparation. The ceramic raw material independent-grinding centralized preparation technique comprises the steps that firstly, various single kind of raw materials are crushed independently through a crusher; secondly, the crushed single kind of raw materials are conveyed to a ball mill for continuous ball milling; thirdly, the raw materials subjected to ball milling and mud are conveyed into a slurry mixing and storing tank according to a formula to be evenly mixed; and finally, evenly-mixed finished slurry is conveyed to a drying tower to be dried. The ceramic raw material independent-grinding centralized preparation device comprises a hard material treatment device, a mud treatment device and a slurry drying device. By the adoption of the technique and device, the existing disorder situation of raw materials for processing ceramic can be avoided, and the technique and device have remarkable economic benefits.

Owner:广东鼎汇能科技股份有限公司

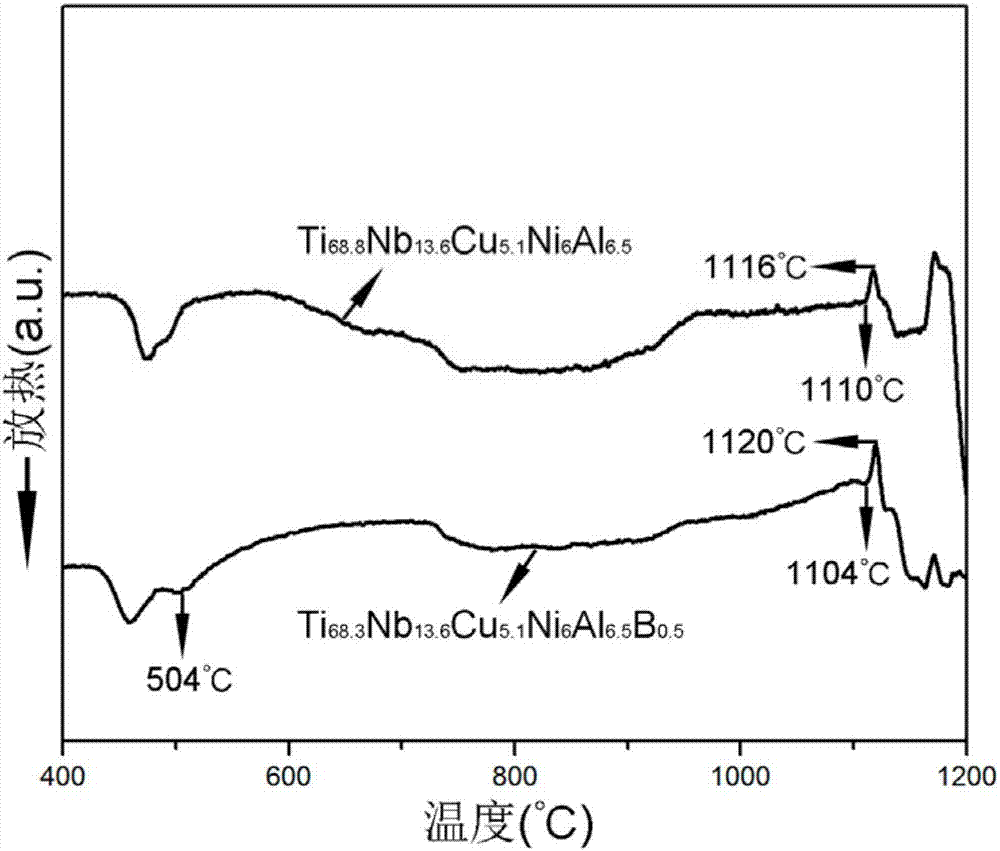

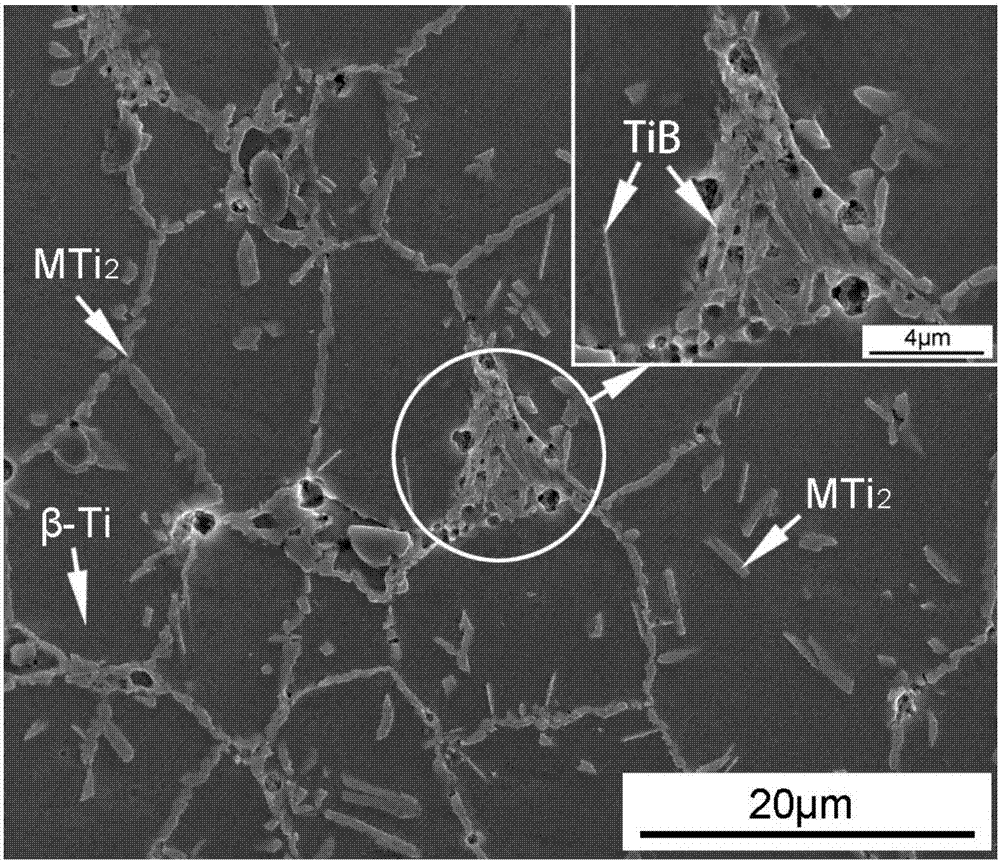

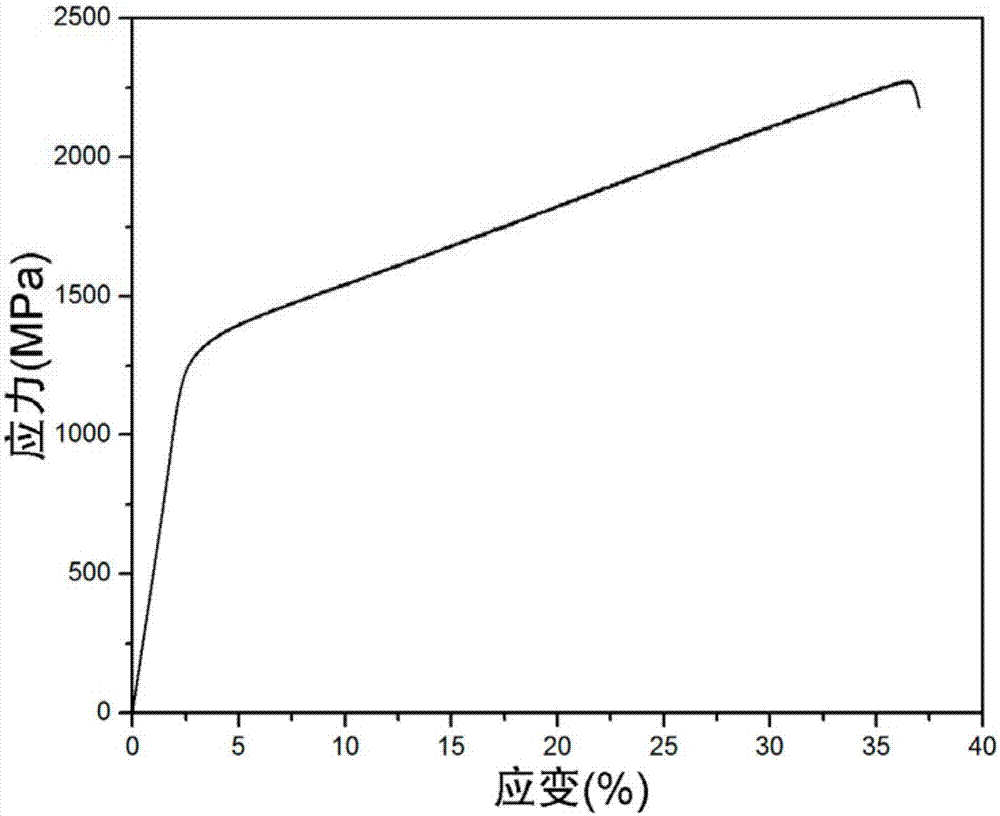

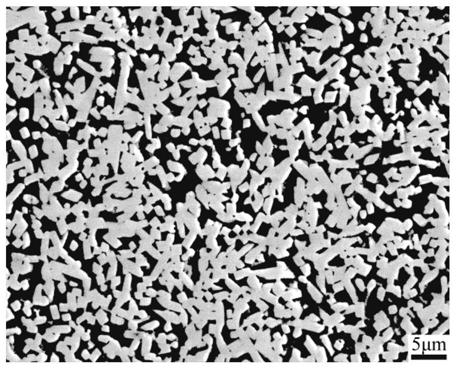

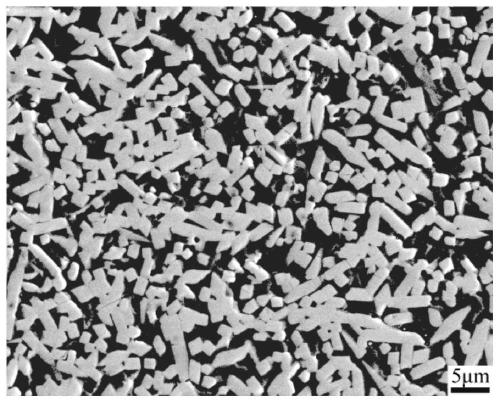

Double-scale structure titanium alloy based on in-situ whisker strengthening and toughening, preparation and application

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Multifunctional ceramic composite additive

The invention discloses a multifunctional ceramic composite additive, which is prepared by mixing layered crystalline sodium disilicate, modified 4A zeolite, sodium metasilicate, sodiumtripolyphosphate, sodium hexametaphosphate, polycarboxylate, sodium lignin sulfonate and sodium humate, has various functions of assisted grinding, slushing, plastifying and the like, and is suitable for preparation of ceramic mud added in various forming methods. The additive can lower the moisture content of the mud to 28-32%, improves the ball milling efficiency to a large extend, shortens the ball milling time by 20-30%, reduces the power consumption for raw material grinding by more than 40%, obviously enhances batch plasticity, increases the dried green strength of the product by 10-15%, and has the obvious functions of increasing production, saving energy and reducing consumption.

Owner:HUNAN HANLIN NEW MATERIALS

Nanometer composite structure feed and preparing method thereof

ActiveCN105970140AQuality improvementImprove composite effectMolten spray coatingComposite effectHigh energy

The invention discloses nanometer composite structure feed. The nanometer composite structure feed is prepared through the reaction of TiB2 and NiCrCoAlY via a high energy ball milling method. The mass ratio of the TiB2 to the NiCrCoAlY is 1:1.2-2. A preparing method comprises the following steps that firstly, TiB2 powder and NiCrCoAlY powder are premixed, and mixed powder is obtained; secondly, the mixed powder is subjected to wet milling, and composite powder A is obtained; thirdly, the composite powder A is dried, and dried composite powder A is obtained; fourthly, the dried composite powder A is subjected to dry grinding, and dried composite powder B is obtained; and fifthly, the dried composite powder B is filtered, and the nanometer composite structure feed is obtained. The prepared nanometer NiCrCoAlY-TiB2 composite structure feed is good in composite effect, excellent in mobility and capable of being directly used for high velocity oxygen fuel (HVOF) coating. The preparing method is simple and easy to operate and friendly to the environment. The various properties of the prepared NiCrCoAlY-TiB2 composite structure feed are excellent.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

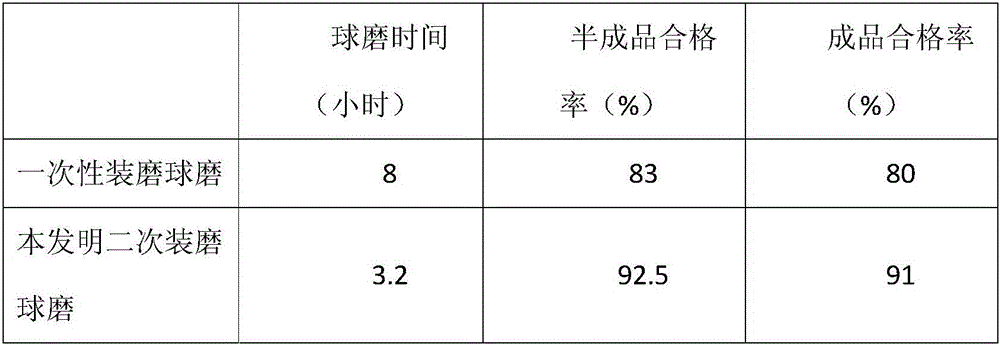

Sanitary ceramic slip ball-milling process

The invention discloses a sanitary ceramic slip ball-milling process. The sanitary ceramic slip ball-milling process comprises the steps that raw materials including, by weight, 900-1350 parts of a hard material, 600-950 parts of a soft material, 540-860 parts of water, 25-45 parts of water glass and 3-12 parts of sodium carbonate are weighed, and the materials are divided into primary entry milling materials and secondary entry milling materials, wherein 900-1350 parts of the hard material, 360-600 parts of the water, 150-300 parts of clay, 15-30 parts of the water glass and 3-12 parts of the sodium carbonate compose the primary entry milling materials, and the remaining parts, other than the primary entry milling materials, in the weighed raw materials compose the secondary entry milling materials; ball milling of the first time is conducted, wherein ball-milling elements and the primary entry milling materials are put into a ball mill, and ball milling is conducted for 6-9 hours, so that primary slip is obtained; and ball milling of the second time is conducted, wherein one third of the primary slip and the secondary entry milling materials are subjected to ball milling together for 30-50 minutes, so that secondary slip is obtained. By means of the process, energy consumption can be remarkably lowered, production efficiency can be improved, and the qualification rate of finished products can be increased.

Owner:福建科福材料有限公司

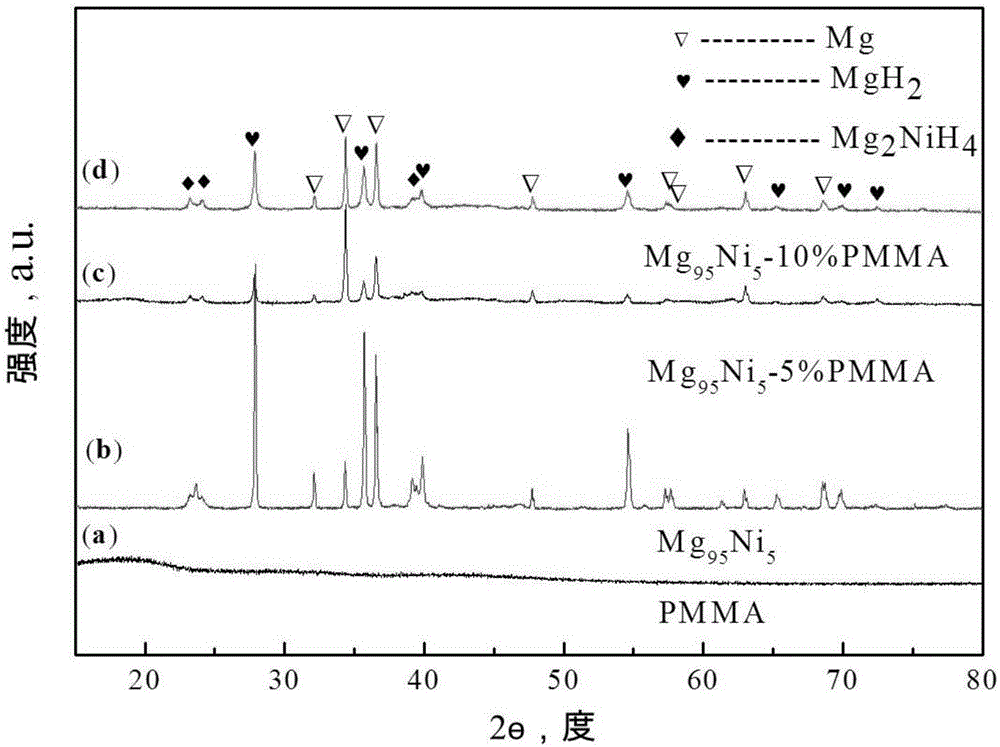

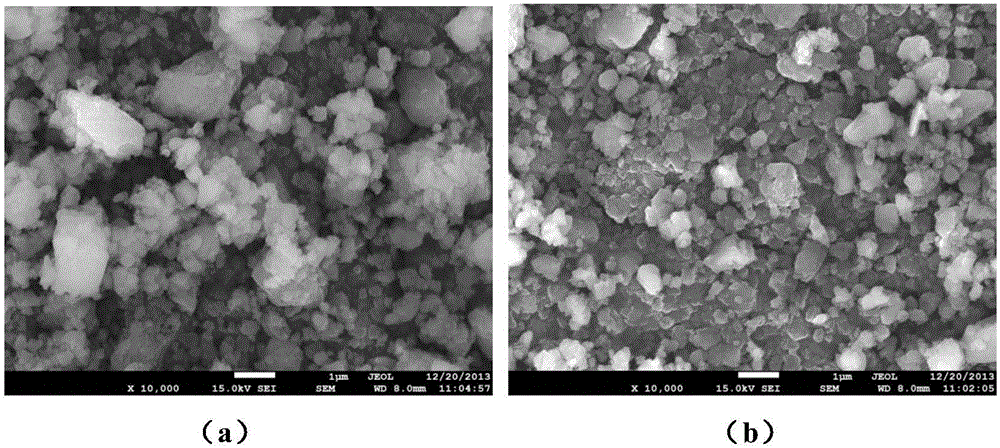

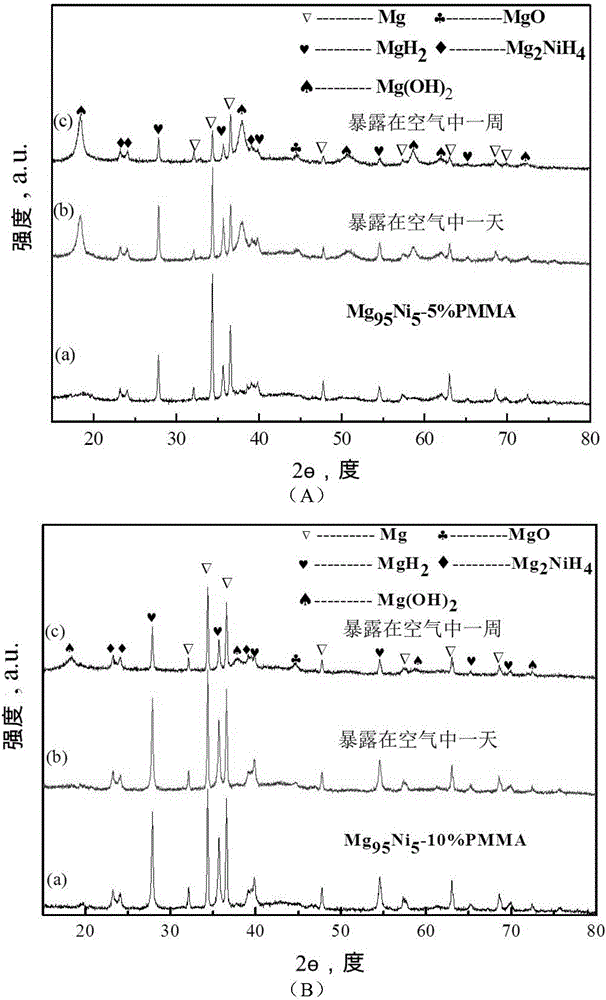

Polymer wrapped nano magnesium based hydrogen storage material and preparation method thereof

ActiveCN106566965AAnti-oxidation and chalking resistanceExcellent hydrogen absorption and desorption performance at low temperatureTransportation and packagingMetal-working apparatusMaterials preparationPolymer science

The invention relates to a polymer wrapped nano magnesium based hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage material preparation. The hydrogen storage material is prepared from the following components in percentage by weight: 80 to 98% of magnesium-nickel alloy, and 2 to 20% of polymer. Magnesium powder and nickel powder are taken as the raw materials and then are mixed and preprocessed; the mixture is hydrogenated, burned, and synthesized, and finally the product and polymers are fiercely and mechanically ball-milled to prepare the hydrogen storage material. The hydrogen storage material has excellent low temperature hydrogen absorption / desorption dynamics performances: at a temperature of 473K, the hydrogen absorption amount can reach 3.73 wt.% with 60 minutes; the hydrogen desorption amount can reach 1.02 wt.% within 120 minutes; at a temperature of 523 K, the hydrogen absorption amount is as high as 4.04 wt.% within 60 minutes, and the hydrogen desorption amount can reach 2.18 wt.% within 120 minutes. The hydrogen storage material can be used to store / transport hydrogen and prepare hydrogen fuel battery.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

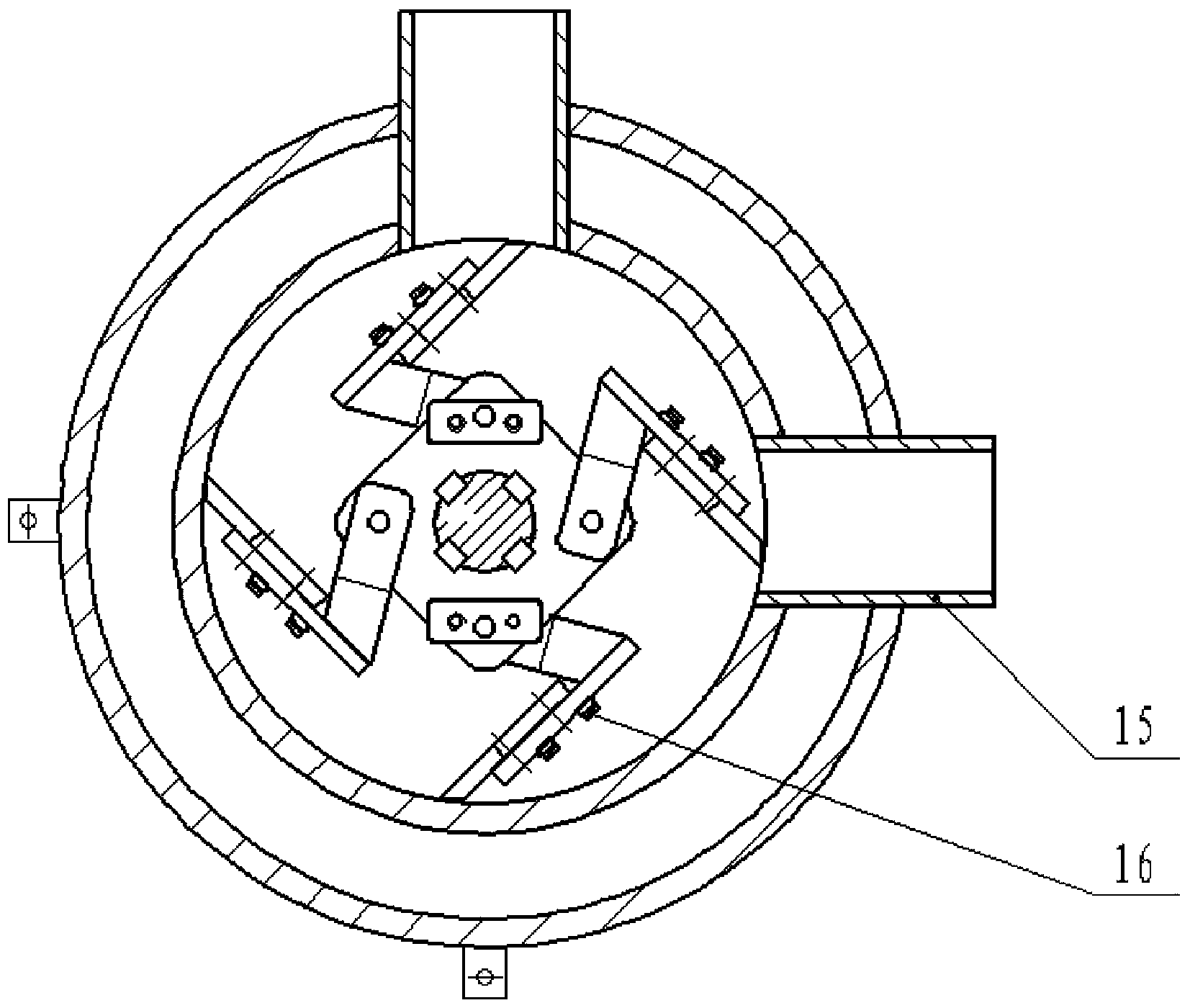

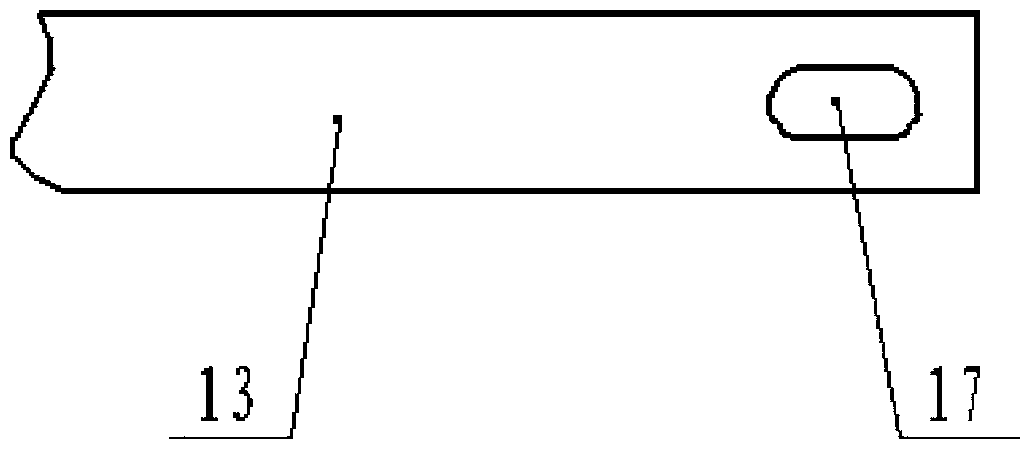

Horizontal type stirring ball-milling reactor for intensifying bentonite modification

The invention discloses a horizontal type stirring ball-milling reactor for intensifying bentonite modification, and provides a ball mill which is uniform in material blending, has no stirring dead angle and controllable ball-milling temperature, can add materials at any time, and is high in ball-milling efficiency and used for intensifying bentonite modification. According to the invention, the main body structurally comprises a bracket, a stirring shaft mounted on the bracket, a stirring device mounted on the stirring shaft and composed of plough disc stirring blades and S-shaped stirring blades, and a ball-milling cylinder; the S-shaped stirring blades are mounted on the adjacent two groups of plough disc stirring blades; the stirring shaft is connected with a motor through a belt; the ball-milling cylinder comprises two layers of an outer cylinder and an inner cylinder; a cooling liquid flow leading channel is formed between the outer cylinder and the inner cylinder; the outer cylinder is provided with a coolant inlet pipe, a feed opening, a discharge opening and a coolant return pipe; the coolant inlet pipe and the coolant return pipe are respectively connected with a coolant inlet pipeline and a coolant return pipeline of a cooling system; milling balls are arranged in the ball-milling cylinder. The reactor can be used for polysaccharide superpolymer modification.

Owner:中国科技开发院广西分院 +2

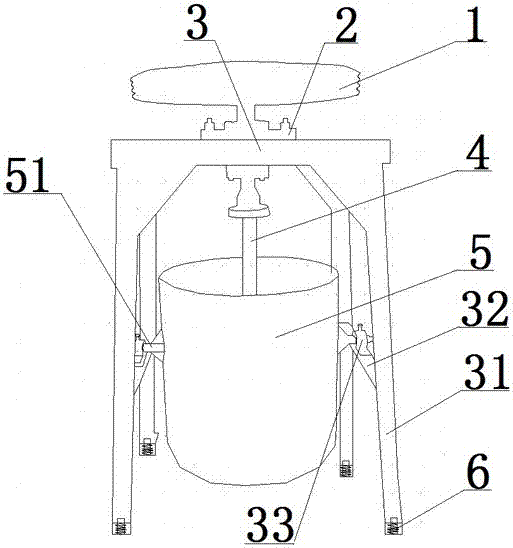

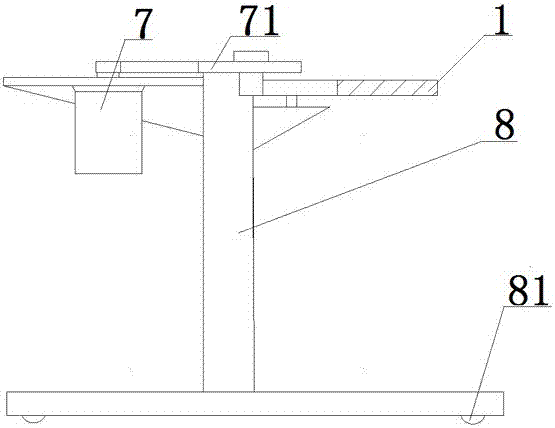

Brown fused alumina ball mill

InactiveCN106984399ASmooth releaseRelease stabilityNon-rotating vibration suppressionGrain treatmentsEngineeringBall mill

The invention relates to the technical field of ore crushing equipment, in particular to a brown fused alumina ball mill. The brown fused alumina ball mill synthesizes the ball milling characters of a dry ball mill and a wet ball mill and integrates the functions of efficient ball milling, thorough cleaning and free movement, and the technical problems that an existing ball mill is long in ball milling time, not high in efficiency and inconvenient to move can be solved.

Owner:禹州市银星专用磨料有限公司

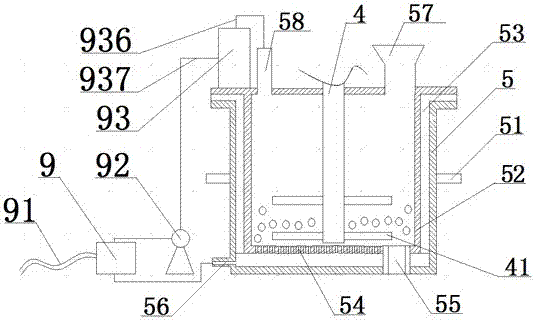

Foamed ceramic composite plate based on shale and copper tailings as main materials and production method of foamed ceramic composite plate

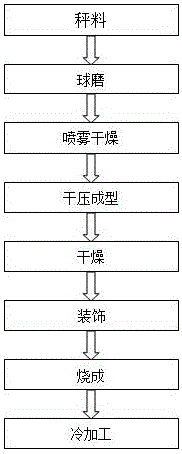

InactiveCN106699109AFine foamGood priceCeramic materials productionCeramicwareCeramic compositeThermal insulation

The invention discloses a foamed ceramic composite plate based on shale and copper tailings as main materials and a production method of the foamed ceramic composite plate. The foamed ceramic composite plate comprises a foamed ceramic material, a toughened ceramic material and a decorative glaze material, and the materials are used for producing and molding the composite plate according to the steps of material weighing, ball milling, spray drying, dry-pressing molding, drying, decoration, firing and cold processing; the foamed ceramic composite plate disclosed by the invention is produced by adopting process methods including secondary distributing one-step molding, a composite decorating process, naked foaming firing without a liner plate, and crusting foaming; the product has a low coefficient of thermal conduction, a low volume density, a low rate of water absorption, a high strength, a high hardness and a high-fidelity stone decoration effect; and as a key material of a foamed ceramic composite plate external wall thermal insulation system, the foamed ceramic composite plate disclosed by the invention, together with adhesive mortar, anchoring parts and joint sealing materials, forms an external wall thermal insulation system, so as to meet requirements for integrated thermal insulation and decoration in various environments.

Owner:安徽省隆达建材科技有限公司

Wet detoxification method for chromium slag and chromium-containing pollutants

ActiveCN103934256AShorten the timeImprove ball milling efficiencySolid waste disposalSulfate radicalsChromium(III) hydroxide

The invention relates to a wet detoxification method for chromium slag and chromium-containing pollutants. The wet detoxification method comprises the following steps: screening and crushing the chromium slag and the chromium-containing pollutants, performing wet milling on the chromium slag and the chromium-containing pollutants in a ball mill, adding a filtrate containing sulfate ions, leaching out acid-soluble calcium chromate in chromium slag slurry, adding the chromium slag slurry and a first reducing agent sequentially into a reaction tank, stirring and mixing the chromium slag slurry with the first reducing agent to perform reduction reaction, reducing the acid-soluble calcium chromate in chromium slag slurry to trivalent chromium, adding concentrated sulfuric acid and to stirring and mixing for regulating, adjusting pH value of the chromium slag slurry to be 7+ / -0.5, then adding a second reducing agent into the reaction tank and stirring and mixing for reducing, stirring the reduced slag slurry to cure the reduced slag slurry, and converting hexavalent chromium in the chromium slag slurry to chromic hydroxide sediment; and separating solid and liquid of the cured chromium slag slurry. The wet detoxification method has the characteristics of low cost, no waste liquid, no slag returning phenomenon, good detoxification effect and capability of being applicable to the large-scale industrial production.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

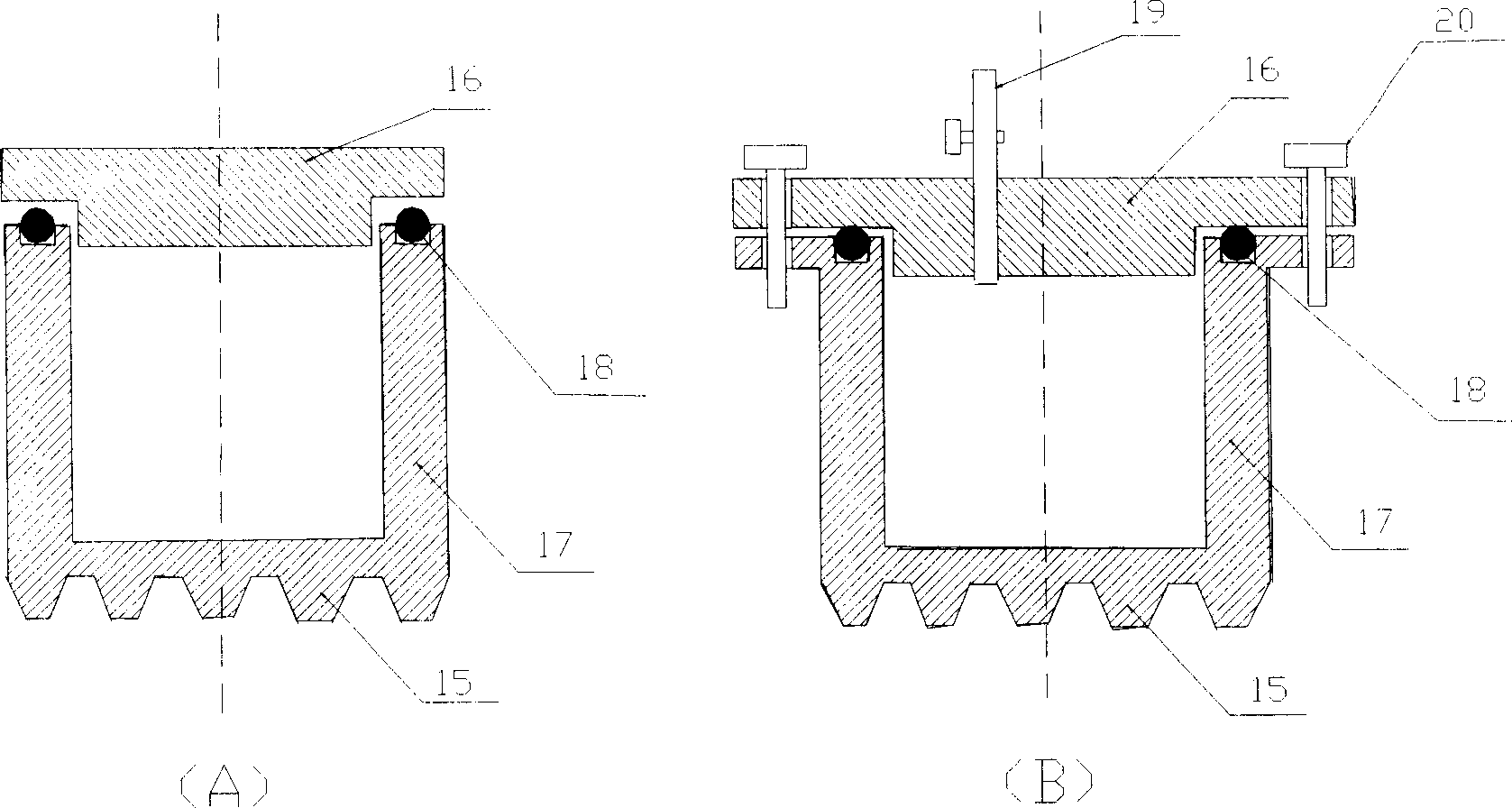

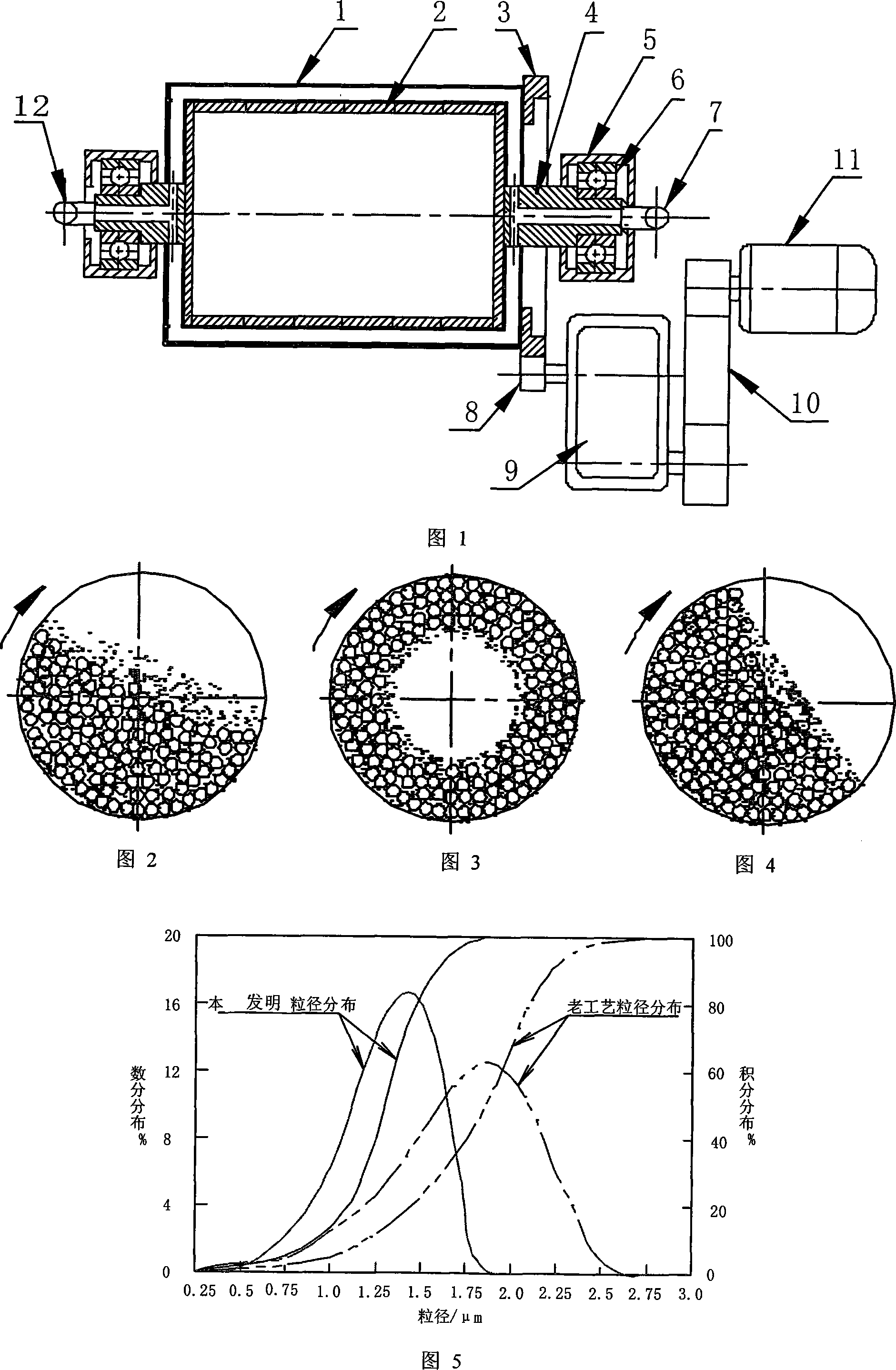

Internal water-cooling ball mill, and ball mill method

ActiveCN101091934AReduce noise pollutionSolve the shortcomings of heavy pollution and loud noiseGrain treatmentsReduction driveWater flow

The invention relates to a ball grinding method which is used in the ferrite magnetic material profession, particularly relates to water inside cold ball mill and its ball grinding method. The invention aims at the questions which has bad cooling performance, the long ball grinding time, the wide ground paste grain-size distribution scope and so on, provides a water inside cold ball mill which has a reasonable structure, the good cooling performance, the short ball grinding time, reasonable ground paste grain-size distribution scope and its ball grinding method. The primary coverage of the invention is: water inside cold ball mill, which is composed of the tube body, the main axle of company connecting sleeve body, the electric motor, the link electric motor and reduction gear of main axle, bearing seat of supports main axle, the tube body structure is the double-deck, there is a hollow interlayer between two layers, the main axle has the mid heaven axial connecting pipe; the cooling water flows from an center bore of end main axle, flows out through the tube body band from center bore of another end main axle, the tube body rotates by the speed n.

Owner:东阳富仕特磁业有限公司

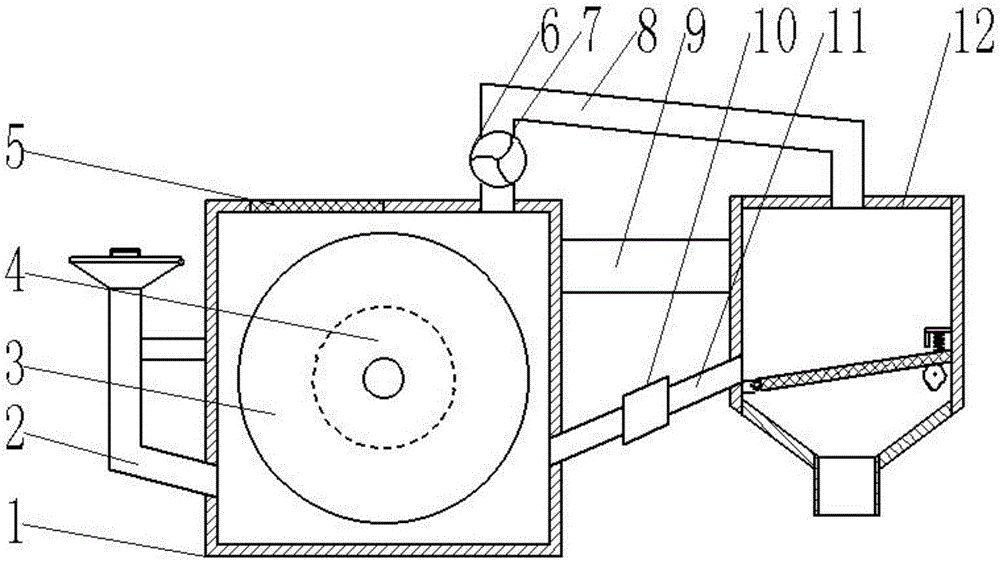

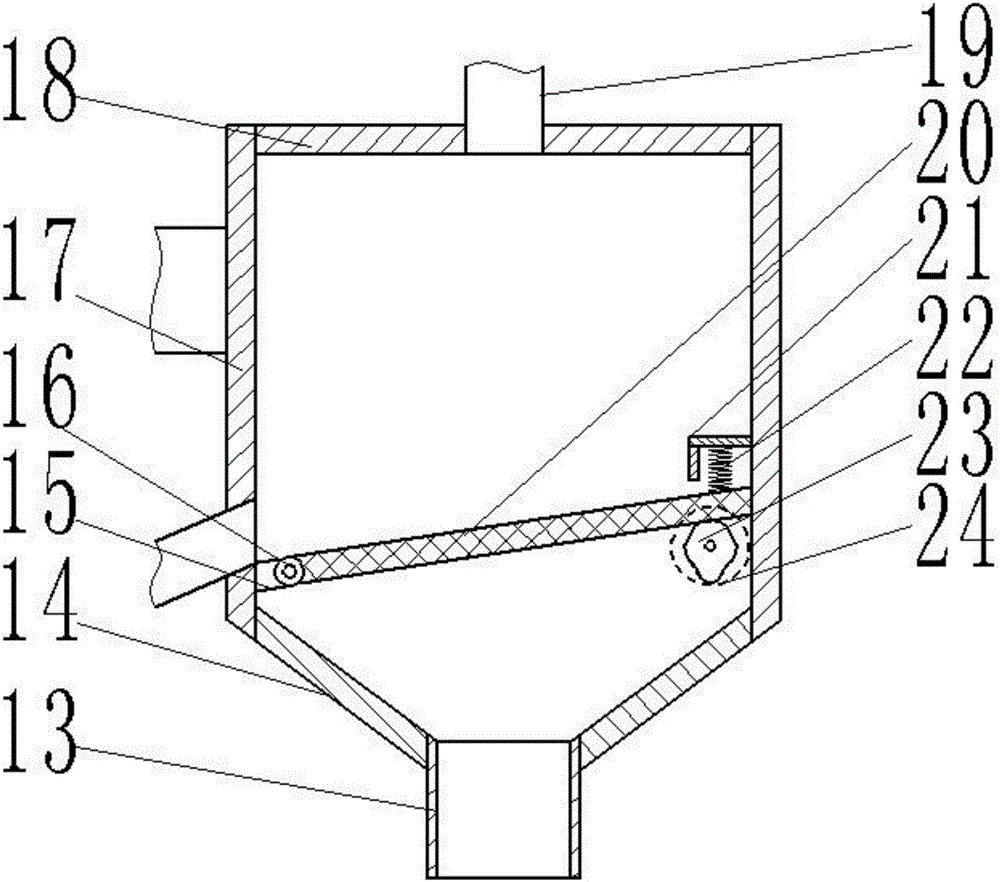

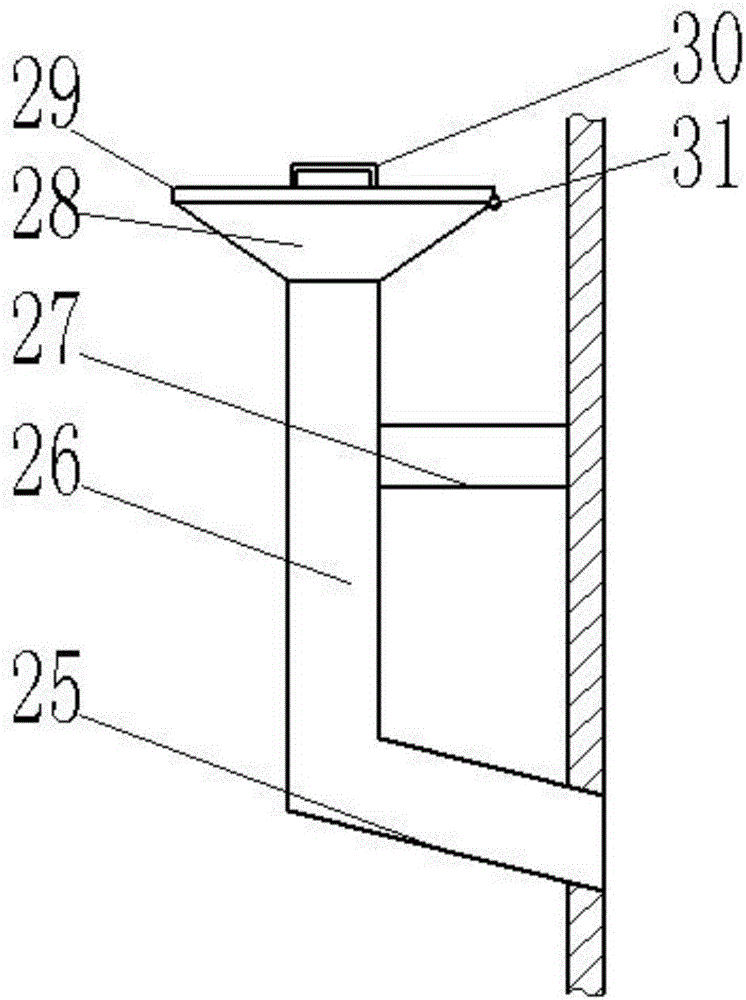

Battery positive electrode material ball milling device capable of screening materials

The invention provides a battery positive electrode material ball milling device capable of screening materials. The device comprises a ball milling box, a driving device, a filling device and a screening device; the filling device is arranged on the left portion of the ball milling box, a ball milling wheel is arranged in the ball milling box and installed on the driving device, and an observation window is arranged on the upper portion of the ball milling box; the driving device is composed of a driving motor, a support, a support plate, a coupler, a transmission, a rotation shaft and a bearing; the filling device is composed of a leakage pipe, a filling pipe, a connecting rod, a filling bin, a top cover, a handle and a second hinge; the screening device is composed of a discharging pipe, a discharging hopper, a support rod, a first hinge, a screening box, a top plate, a feeding pipe, a filter screen, a protective cover, a spring, a cam and a screening motor. According to the battery positive electrode material ball milling device capable of screening the materials, the materials which are not fully ball-milled can be screened out and then discharged into the ball milling box through the screening pipe to continue to be ball-milled, and therefore the ball milling efficiency is improved; the filter screen can vertically wobble, and therefore the screening efficiency can be improved.

Owner:江苏华清能源科技有限公司

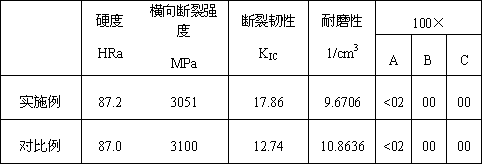

Hard alloy with iron-nickel as binder metal and preparation method thereof

The invention relates to hard alloy with iron-nickel as binder metal and a preparation method thereof. The binder metal powder is iron-nickel alloy powder; the iron-nickel alloy powder is spherical; the grain size is smaller than or equal to 4 microns; the iron-nickel alloy powder is prepared from 50-80% of iron element and 20-50% of nickel element; the alloy powder phase is composed of austenite and martensite; and the hard alloy comprises the following components in percentage by weight: 80-97% of WC powder, and 3-20% of Fe-Ni alloy powder. The preparation method comprises the steps of firstly, wetly grinding and mixing the WC powder and Fe-Ni alloy powder in a solvent in preparation, and then drying, molding and sintering. The hard alloy employing the iron-nickel alloy as the binder metal has better strength / toughness ratio, can be widely applied to the fields such as engineering geology and mining, compared with the traditional tungsten carbide-cobalt hard alloy; not only can application of strategic resource cobalt be reduced, but also the service life of a hard alloy tool can be prolonged.

Owner:SHAREATE TOOLS

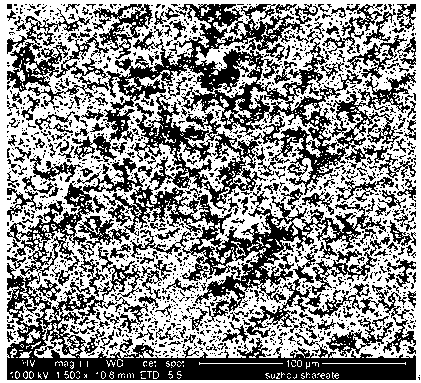

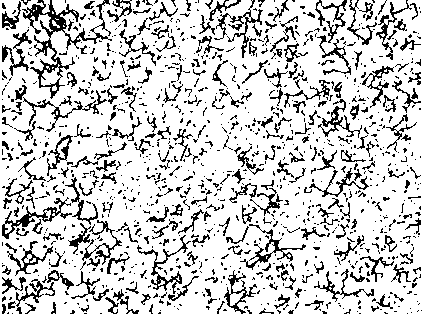

Rare earth modified Mo2FeB2 base metal ceramic and preparation method thereof

The invention discloses rare earth modified Mo2FeB2 base metal ceramic and a preparation method thereof. Mo with the purity being not less than 99.0%, FeB with the purity being not less than 99.0%, Fewith the purity being not less than 99.0% and rare earth powder are mixed, absolute ethyl alcohol is added for ball-milling, then ball-milled pulp is dried and sieved, then compression moulding forming is conducted, vacuum liquid-phase sintering and furnace cooling are conducted, and thus the rare earth modified Mo2FeB2 base metal ceramic with the hardness being 87.7-89.1 HRA is obtained. The rare earth modified Mo2FeB2 base metal ceramic is simple in component and does not contain other chemical elements, the production cost and the possibility of introducing impurities are reduced, the technology is simple, and the cost is low; and by adding rare earth, a crystal boundary is purified, the grain size of a hard phase is refined, and the prepared Mo2FeB2 base metal ceramic can be used forworking conditions of abrasion, corrosion, and interaction of abrasion and corrosion.

Owner:XI AN JIAOTONG UNIV

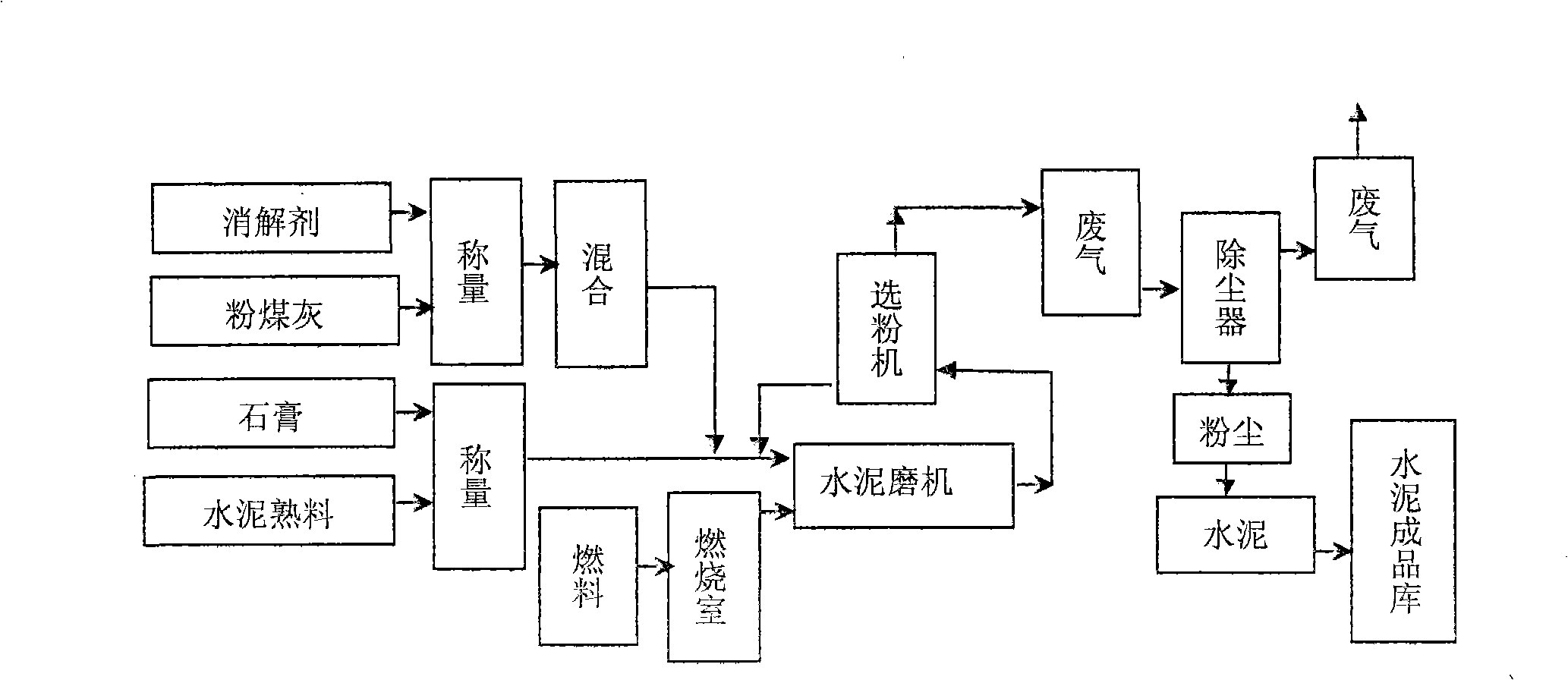

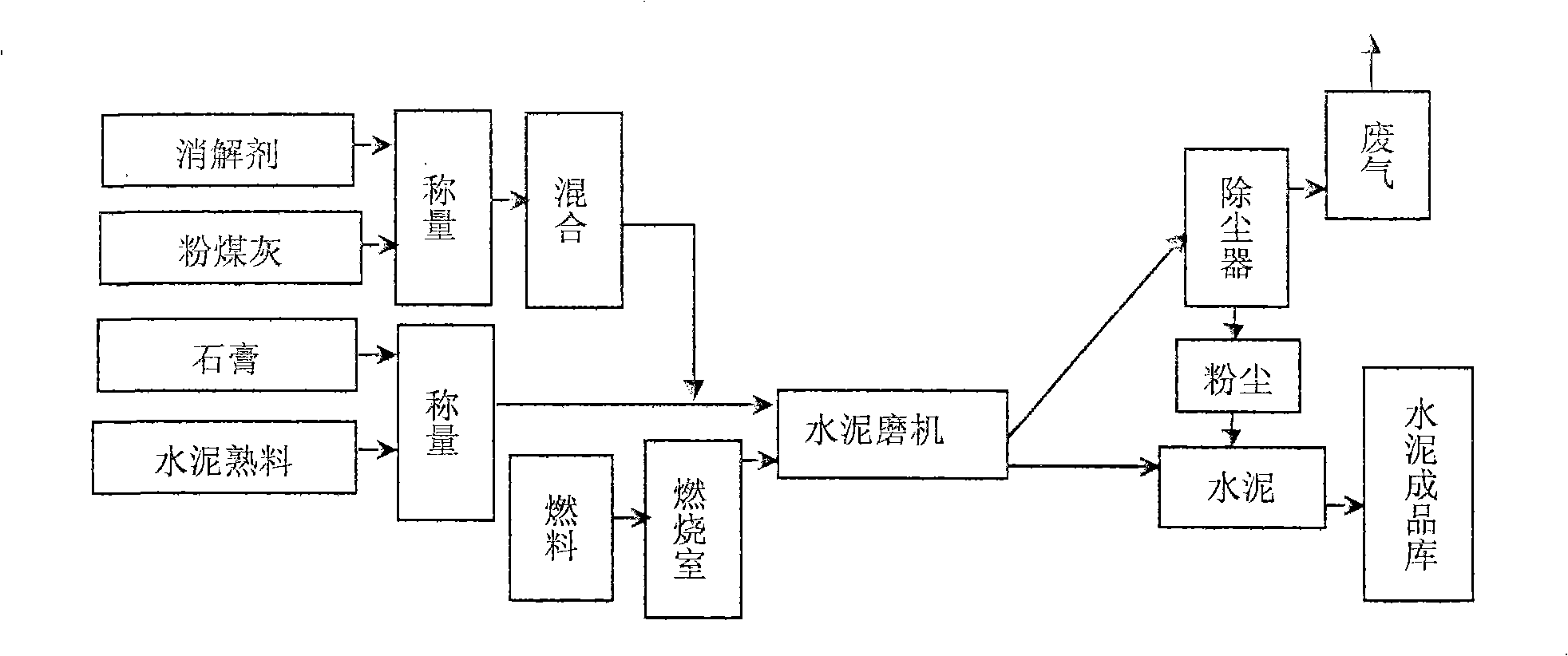

Method for preparing high-calcium fly-ash cement with high-calcium fly-ash

The invention discloses a process for preparing high calcium fly ash cement by high calcium fly ashes. A combustion chamber is arranged at the head part of the existing ball mill for pre-mixing measured high calcium fly ashes and a digesting agent and then feeding measured cement clinker, gypsum, blast furnace slag, etc. into a ball mill for ball grinding; and the material temperature in the mill is rising under the mechanical action of the mill, additionally, the grinding head combustion chamber provides heat, so the water in the digestion solution is evaporated and the digestion solution and free calcium oxide in the high calcium fly ashes have the mechanical and chemical action, the free calcium oxide digestion is realized during the cement grinding process, and finally the high calcium fly ash cement is prepared. The process is simple and needs not to add the special high calcium ash treating process before producing the cement, the free calcium oxide digestion effect is obvious, the mixing amount of the high calcium ashes in the cement can be greatly increased and the cement manufacturing cost is reduced. The process overcomes the defect that the humidity-control and digestion of fly ash free calcium oxide need two to seven days, and can implement the continuous production, and the ball-milling efficiency of the cement mill is improved by over 10 percent in the meantime.

Owner:榆林恒源利尔新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com