Brown fused alumina ball mill

A technology of ball mill and jade ball, which is applied in the direction of non-rotational vibration suppression, grain processing, etc., can solve the problems of long milling time, inconvenient movement, low efficiency, etc., and achieve the effect of enhanced wear intensity, convenient disassembly, installation and replacement, and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

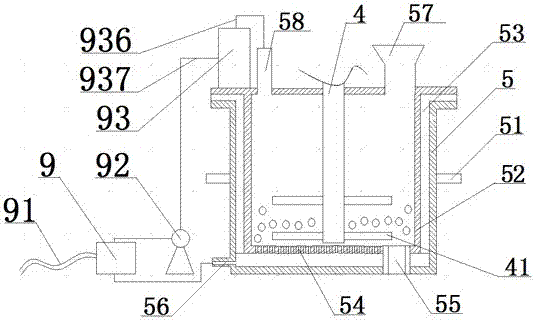

[0038] A brown corundum ball mill, the ball mill includes a mobile support device, a power assembly, a ball mill body and a water cleaning device;

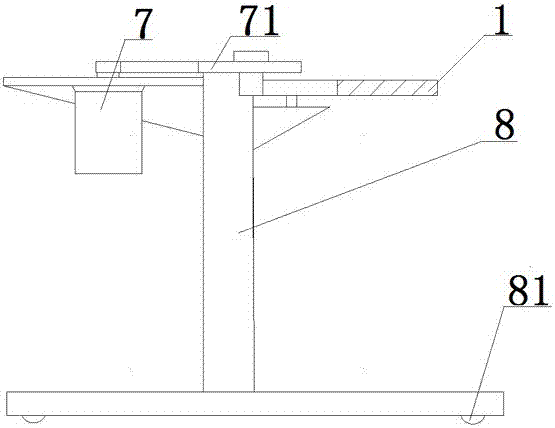

[0039] Such as figure 2 As shown, the mobile support device includes a mobile support base and a support 8, and the bottom of the mobile support base is provided with a roller 81, and the roller 81 is provided with a brake pad, and the parking requirement is realized when the ball mill moves to a certain position;

[0040] Support 8 is vertically fixed on the middle part of the mobile support base, a support platform is installed on the top of support 8, and the power assembly is placed on the support platform;

[0041] The power assembly includes a motor 7 and a transmission belt 71, one end of the transmission belt 71 is connected with the motor 7, and the other end is connected with the pulley 1;

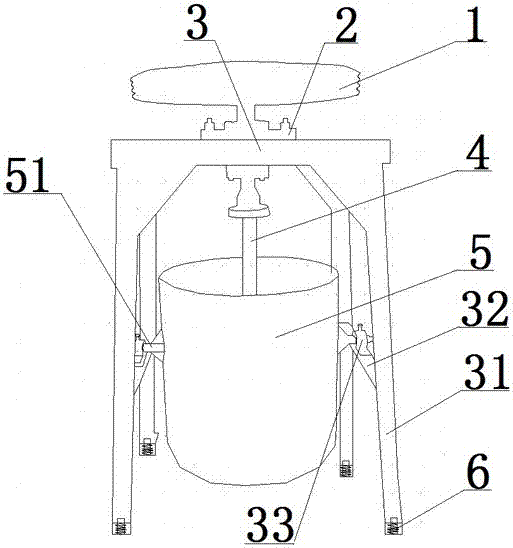

[0042] Such as figure 1 , image 3 As shown, the ball mill body includes a workbench 3, which is fixedly placed on the mobile s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com