Nano-magnesium-based composite hydrogen storage material and preparation method thereof

A hydrogen storage material and nano-magnesium technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as uneven material composition, achieve excellent performance, improve ball milling efficiency, and overcome the effect of sticking to the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 1kg of pure magnesium ingots (purity greater than 99%) and 0.15kg (15wt%) of misch metal into the magnesia crucible of the vacuum induction melting furnace, and evacuate to 2.0×10 -2 Pa below, and then filled with 0.04-0.06MPa pressure of high-purity argon (purity 99.999Vol.%). Adjust the power of the intermediate frequency induction coil to 8-10kW, heat the metal raw material, and after all the metal blocks are completely melted, continue to keep warm for 10-15 minutes to homogenize the alloy composition. After the smelting is completed, the alloy melt is poured into a circular ingot with a diameter of 30mm in a cast iron mold, and the magnesium-rare earth alloy ingot is obtained after cooling to room temperature. Cross 100 mesh standard sieves after the alloy ingot is mechanically pulverized, then get magnesium-rare earth alloy powder 5g, carbonyl nickel powder 0.25g (5wt%), graphite powder 0.15g (3wt%), organic liquid grinding aid tetrahydrofuran 5g (100wt%) ) p...

Embodiment 2

[0039] The other steps of the material preparation method in the present embodiment are the same as in Example 1, except that the ball milling time is 5 hours, the carbonyl nickel powder in the ball milling process is 0.5g (10wt%), and the graphite powder is 0.25g (5wt%) , the grinding aid is ethanol, and the grinding aid addition is 2.5g (50wt%).

[0040] No obvious wall sticking phenomenon was found in the material after ball milling, and the material recovery rate was about 94%. The hydrogen absorption kinetic curve of the composite material after five times of hydrogen absorption and desorption activation is shown in the attached Figure 6 shown. It can be seen that the saturated hydrogen absorption capacity of the material after 5 minutes at 300° C. is about 5.2 wt%, which is slightly lower than that of Example 1. The material also has good hydrogen absorption kinetics at 100°C, and the hydrogen absorption amount can reach more than 5wt% within 30 seconds.

Embodiment 3

[0042] The other steps of the material preparation method in this embodiment are the same as in Example 1, except that the amount of rare earth added in the alloy smelting process is 0.1kg (10wt%), and the quality of carbonyl nickel powder in the ball milling process is 0.15g (3wt%) , the graphite powder quality is 0.05g (1wt%), and the grinding aid is n-heptane.

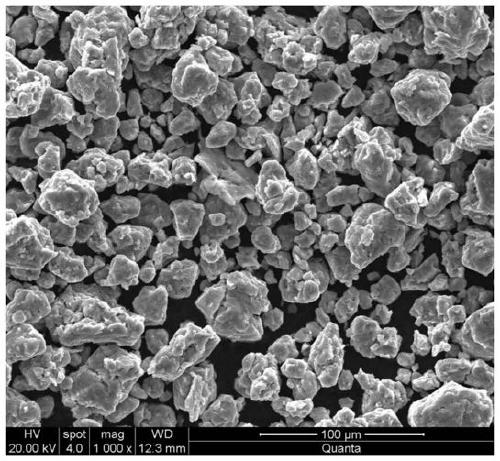

[0043] The material after ball milling has obvious wall sticking phenomenon, and the sample recovery rate is about 68%. The SEM microstructure of the composite material of this embodiment is as attached figure 2 As shown, the material is also made of fine particle clusters, and the large particle size is 10-70 microns. The hydrogen absorption kinetic curve of the material after five times of hydrogen absorption and desorption activation is shown in the attached Figure 7 shown. It can be seen that the saturated hydrogen absorption capacity of the material after 5 minutes at 300°C is about 6.3wt%, but the hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com