Rare earth modified Mo2FeB2 base metal ceramic and preparation method thereof

A technology for preparing rare earth elements and ceramics, which is applied in the field of rare earth element modified Mo2FeB2-based cermet and its preparation, can solve the problems of unfavorable application and promotion, increase the introduction of impurities, increase the cost, etc., so as to shorten the preparation period and improve the performance. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

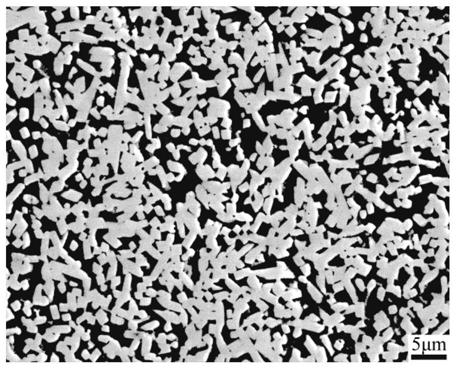

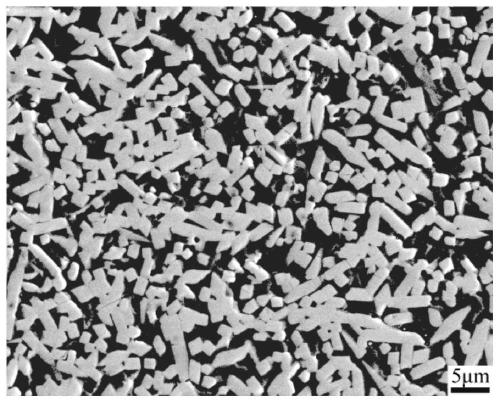

Image

Examples

preparation example Construction

[0031] A kind of rare earth element modified Mo of the present invention 2 FeB 2 The preparation method of the base cermet comprises the following steps:

[0032] S1, mixing

[0033] Select Mo, FeB, Fe and rare earth powder with a purity of not less than 99.0%, the rare earth powder is La or Y, and the percentage by weight is: Mo: 45.0-51.0%, FeB: 26.0-33.0%, Fe: 16.0-28.5%, Y: 0 to 1.0%, La: 0 to 1.0%. Configure the powder and mix the powder;

[0034] S2, ball mill

[0035] Put the mixed powder into a ball mill jar, add 40% to 160% of the mass percentage of absolute ethanol as a process control agent, the ball-to-material ratio is 1 to 11:1, vacuumize the ball mill jar and fill it with argon Air for wet grinding, the speed of the ball mill is 140-360r / min, and the milling time is 3-37 hours;

[0036] S3, drying

[0037] Pour the milled slurry into an eggplant-shaped bottle for drying. The drying temperature is 30-110°C, the rotation speed of the eggplant-shaped bottle ...

Embodiment 1

[0044] A method for preparing rare earth Y element-modified Mo2FeB2-based cermets, comprising steps of mixing materials, wet grinding, drying, molding, and vacuum sintering in sequence:

[0045] (1) Mixing step: select Mo, FeB, and Fe powders with a purity of not less than 99.0%, by weight percentage: Mo: 45.0%, FeB: 26.0%, Fe: 28.5%, without adding Y powder or La powder. Configure the powder and mix the powder;

[0046] (2) Ball milling step: Put the mixed powder into a ball mill jar, add 40% of the mass percentage of absolute ethanol as a process control agent, the ball-to-material ratio is 1:1, vacuumize the ball mill jar and fill it Argon gas is carried out wet milling, and ball mill rotating speed is 140r / min, and ball milling time is 3 hours;

[0047] (3) Drying step: Pour the ball-milled slurry into an eggplant-shaped bottle for drying, the drying temperature is 30°C, the rotation speed of the eggplant-shaped bottle is 45r / min, and the drying time is 1 hour, using a ro...

Embodiment 2

[0052] A kind of rare earth Y element modified Mo 2 FeB 2 The preparation method of the base cermet comprises the steps of mixing materials, wet grinding, drying, compression molding and vacuum sintering in sequence:

[0053] (1) Mixing step: select Mo, FeB, Fe powder and Y powder with a purity of not less than 99.0%, and the percentages by weight are: Mo: 46.0%, FeB: 27.0%, Fe: 26.3%, Y: 0.2%. Configure the powder and mix the powder;

[0054] (2) Ball milling step: put the mixed powder into a ball mill jar, add 70% by mass of absolute ethanol as a process control agent, the ball-to-material ratio is 3:1, vacuumize the ball mill jar and fill it Argon is used for wet milling, the speed of the ball mill is 200r / min, and the ball milling time is 11 hours;

[0055] (3) Drying step: Pour the ball-milled slurry into an eggplant-shaped bottle for drying, the drying temperature is 50°C, the rotation speed of the eggplant-shaped bottle is 75r / min, and the drying time is 2.0 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com