Preparation method of alumina porcelain ball for dry process ball mill

A technology of alumina and alumina powder, applied in the field of new materials, can solve the problems of not being suitable for large-scale production applications, increased production costs, performance deterioration, etc., and achieve the effects of high strength, low wear and few internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

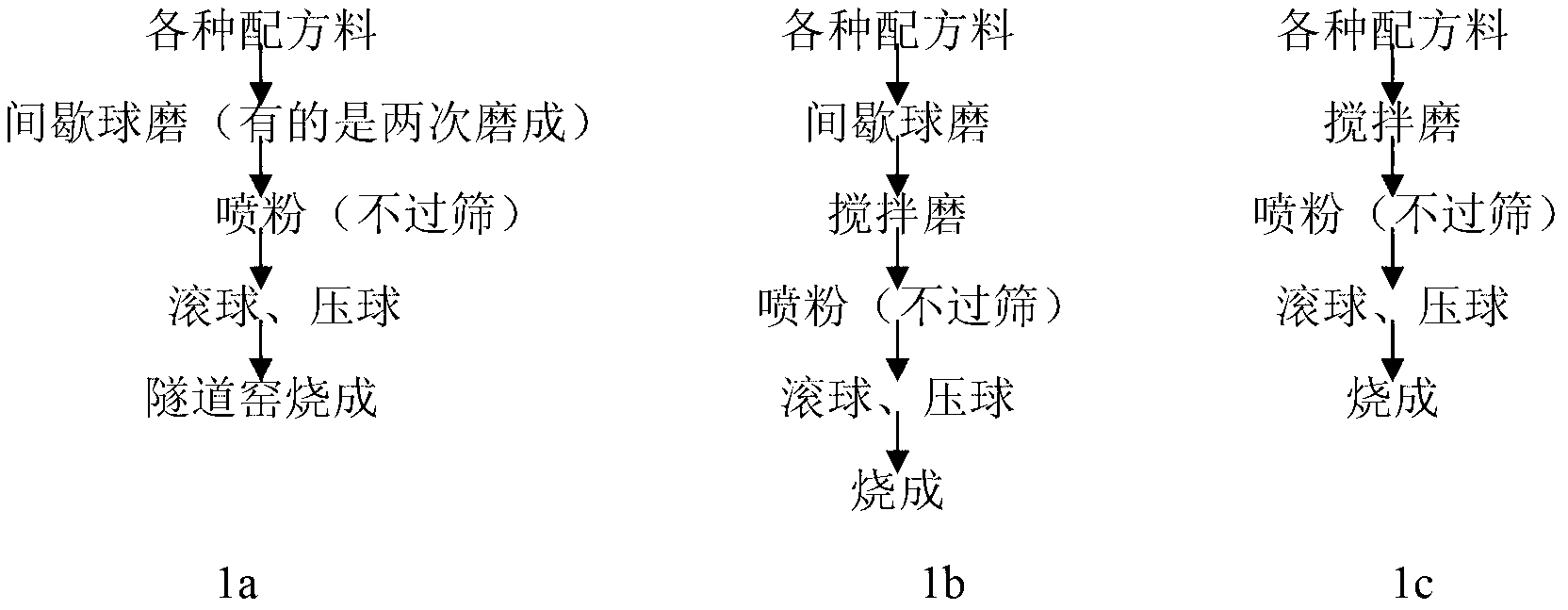

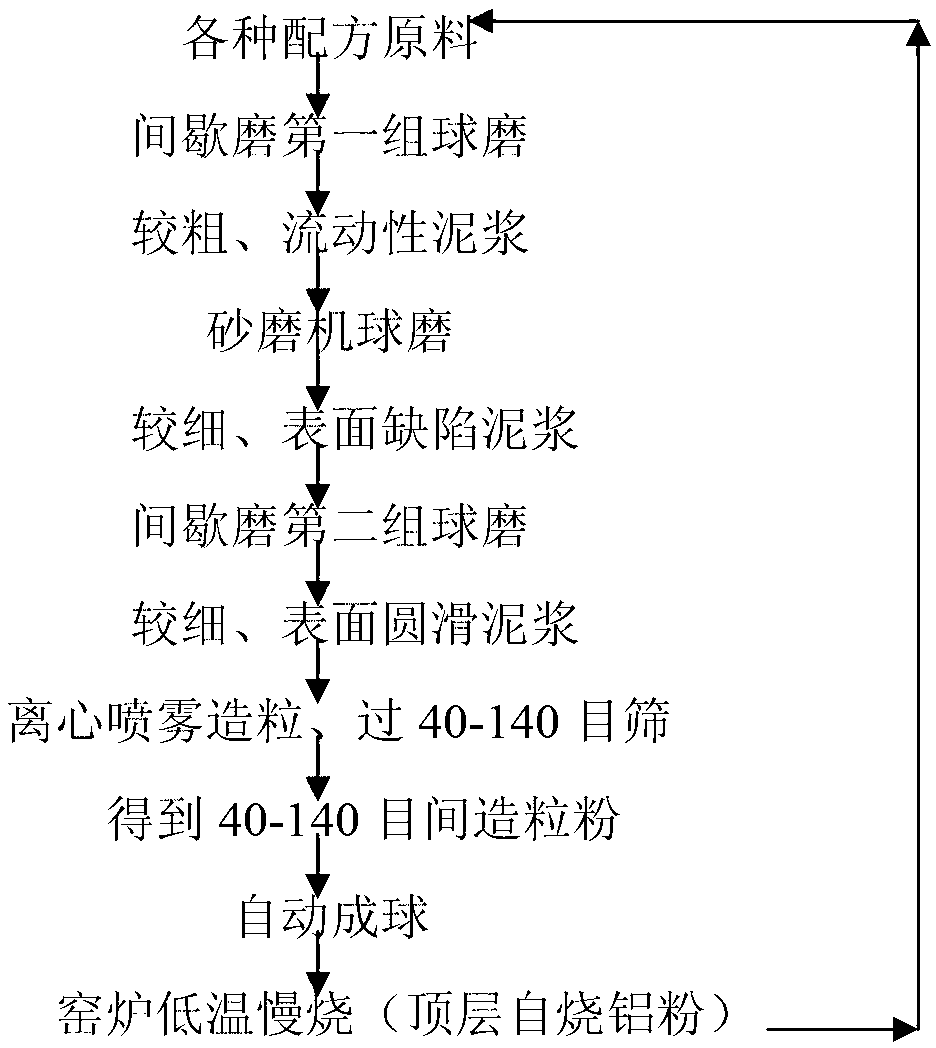

Method used

Image

Examples

Embodiment 1

[0040] (1) Raw materials and parts by weight

[0041] Main ingredients: 52 parts of self-fired alumina powder, 37 parts of commercially available alumina powder, 3 parts of kaolin, 3 parts of burnt gemstone clinker;

[0042] Composite sintering aids: 2 parts of diopside, 1.5 parts of talc, 1.5 parts of dolomite;

[0043] (2) Put self-fired alumina powder, commercially available alumina powder, kaolin, coke gemstone clinker and composite sintering aid into a batch ball mill for 15 hours. The fineness of the slurry is 10 μm, and the moisture content is controlled at 43%. Alumina balls are used as the grinding medium, according to the mass ratio: ball: water = 1:3:0.8, after passing through a 40-mesh sieve, the mud is pumped into the horizontal sand mill with a plunger pump for ball milling, and the spindle speed is 1200r / min , the slurry fineness is 2.5μm, the grinding medium is made of wear-resistant alumina micro-beads, according to the mass ratio slurry: ball = 1:4, pass thr...

Embodiment 2

[0049] (1) Raw materials and parts by weight

[0050] Main ingredients: 60 parts of self-fired alumina powder, 30 parts of commercially available alumina powder, 3 parts of kaolin, 3 parts of burnt gemstone clinker;

[0051] Composite sintering aids: 2 parts of diopside, 1.5 parts of talc, 1.5 parts of dolomite;

[0052] (2) Put self-fired alumina powder, commercially available alumina powder, kaolin, coke gemstone clinker and composite sintering aid into a batch ball mill for 15 hours. The slurry fineness is 9 μm, and the water content is controlled at 43%. Alumina ball stone is used as the grinding medium, according to the mass ratio: ball: water = 1: 2.8: 0.8, after passing through a 40-mesh sieve, the mud is pumped into the horizontal sand mill with a plunger pump for ball milling, and the spindle speed is 1250r / min, the slurry fineness is 2.3μm, the grinding medium is made of wear-resistant alumina micro-beads, according to the mass ratio slurry: ball = 1:4, pass throug...

Embodiment 3

[0058] (1) Raw materials and parts by weight

[0059] Main ingredients: 54 parts of self-fired alumina powder, 34 parts of alumina powder, 4 parts of kaolin, 2 parts of burnt gemstone;

[0060] Composite sintering aid: 3 parts of diopside, 2 parts of talc, 1 part of dolomite;

[0061] (2) Put self-fired alumina powder, commercially available alumina powder, kaolin, coke gemstones and composite sintering aids into a batch-type ball mill for ball milling for 15 hours. The fineness of the slurry is 8 μm, and the moisture is controlled at 43%. The ball stone is used as the grinding medium, according to the mass ratio: ball: water = 1:2.5:0.8, after passing through a 40-mesh sieve, the mud is pumped into the horizontal sand mill with a plunger pump for ball milling, and the spindle speed is 1230r / min. The fineness of the material is 2.3μm, and the grinding medium is made of wear-resistant alumina microbeads. According to the mass ratio of slurry: ball = 1:4, it passes through a 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com