Battery positive electrode material ball milling device capable of screening materials

A battery positive electrode and screening device technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of inconvenient use, loss of positive electrode materials, low screening efficiency, etc., and achieve the effect of improving screening efficiency, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

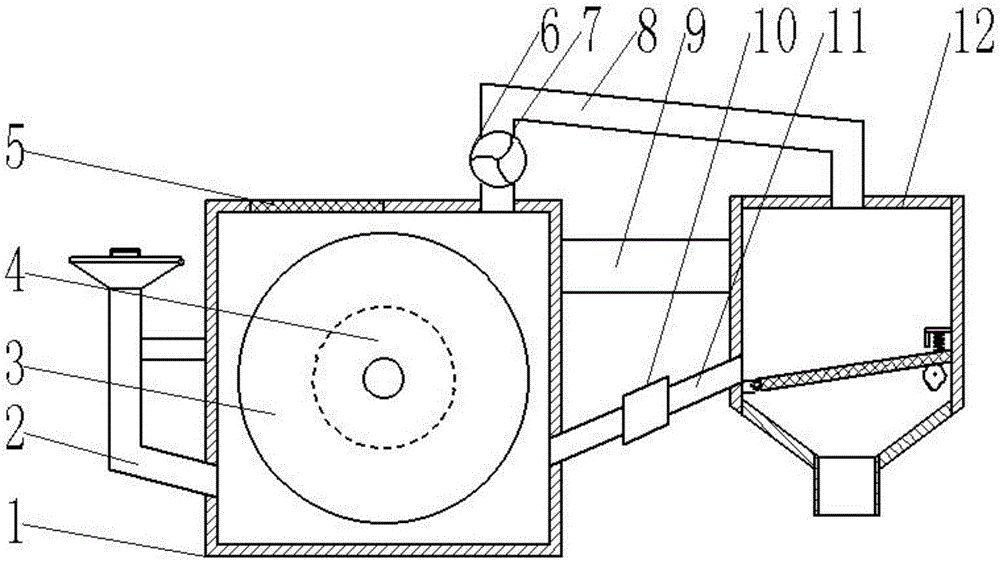

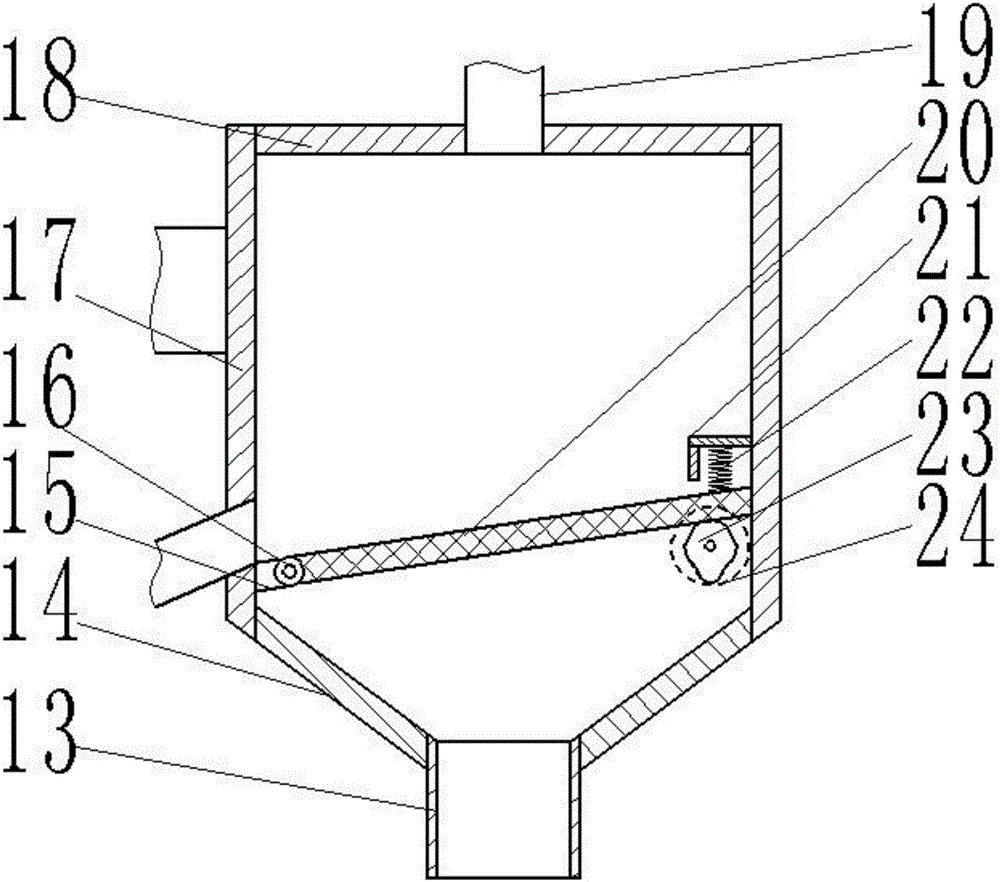

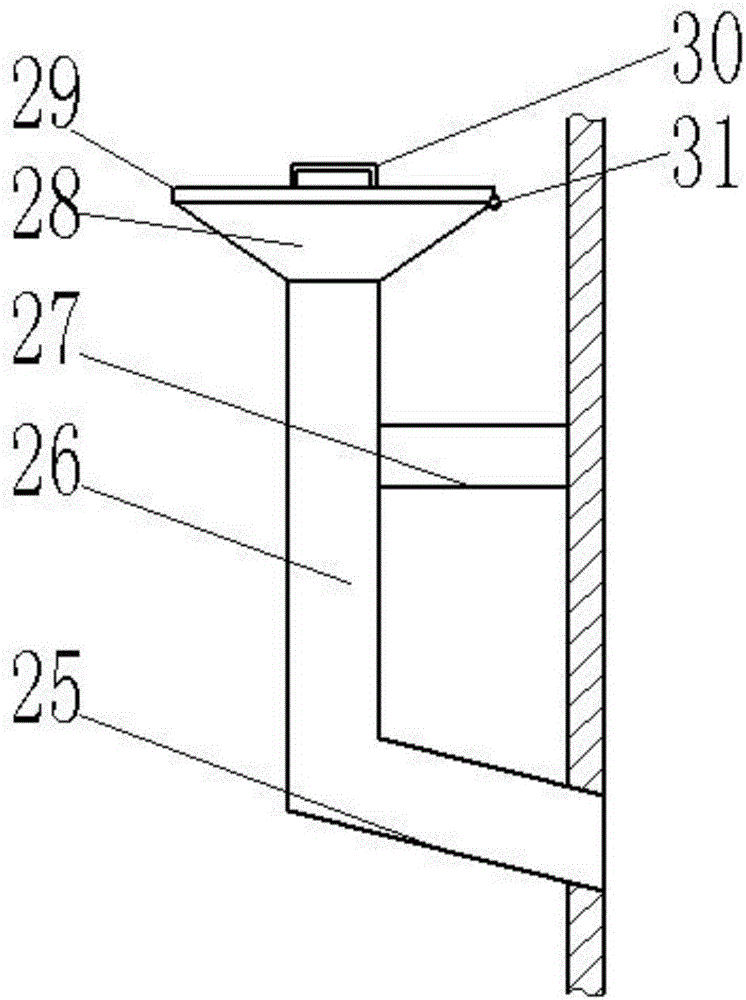

[0020] see Figure 1-4 , a ball milling device capable of sifting material for battery cathode materials, comprising a milling box 1, a driving device 4, a packing device 2 and a screening device 12; A screening device 12 is provided, a ball milling wheel 3 is arranged in the ball milling box 1, and the ball milling wheel 3 is installed on the driving device 4, an observation window 5 is provided on the upper part of the ball milling box 1, and a transmission port is provided on the ball milling box 1 on the right side of the observation window 5. Material pipe 7; the observation window 5 is made of glass material, which can observe the ball milling situation of the material in the ball mill box 1; the material delivery pipe 7 is provided with a material pump 6, and the top of the delivery pipe 7 is provided with an inclined pipe 8. The inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com