Internal water-cooling ball mill, and ball mill method

A ball mill and water internal cooling technology, applied in grain processing and other directions, can solve the problems of wide range of slurry particle size distribution, poor cooling effect, long ball milling time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

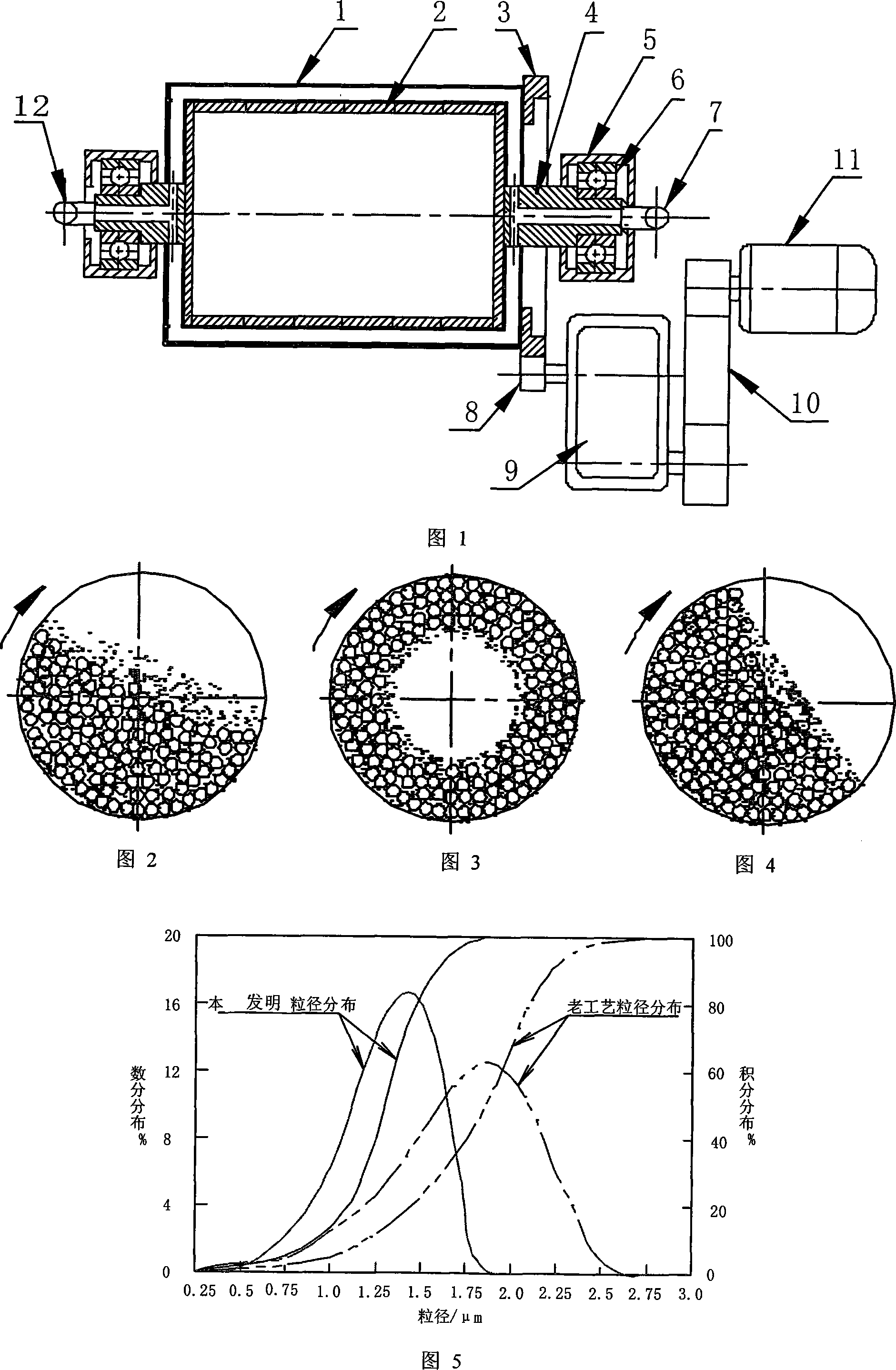

[0026] As shown in Figure 1, the cylinder 1 is supported by the main shaft 4, the bearing 6 and the bearing seat 5 to form a rotating body. The torque output by the motor 11 is transmitted to the reducer 9 through the transmission belt 10, and the output shaft of the reducer 9 is installed with The small gear 8 transmits the power to the big gear 3, and the big gear 3 is connected with the cylinder 1 to drive the cylinder 1 to rotate; the cylinder 1 has a lining 2, and the outside is a shell, and there is a hollow interlayer between the two layers, and the main shaft has a hollow The axial connecting pipe of the connecting pipe communicates with the hollow interlayer. The water inlet pipe 12 is connected with the connecting pipe of the main shaft on one side, and the water outlet pipe 7 is connected with the connecting pipe of the main shaft on the other side. The connection between the main shaft 4 and the shell is closed.

[0027] When the ball mill is running, the material...

Embodiment 2

[0031] The ratio of material, steel ball and water is material: steel ball: water=1:8:1.3. The ball mill is equipped with chromium alloy steel balls with a hardness of HRC62-65. At the same time, water is also added to the materials in the cylinder, and they are mixed and milled together. The constant C is 38, so the speed n of the ball mill is 38 1 / 2 / D rev / min to rotate. A ball mill with an inner diameter of 5 m is used, and the rotation speed is 1.233 rpm at this time. And the state of the steel balls in the ball mill at this time is shown in Figure 4.

[0032] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com