Method for preparing environment barrier coating at low temperature

An environmental barrier coating and low-temperature technology, which is applied in the field of low-temperature preparation of environmental barrier coatings, can solve problems such as damage, and achieve the effects of easy diffusion, good performance, and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Add 40wt% BSAS powder to the polysiloxane precursor, and then mix 5wt% boric acid as a sintering aid. Ball mill for 30 minutes using a vibrating ball mill.

[0030] 2. Brush the mixed slurry onto the surface of the C / SiC sample and cure at 120°C for 10 minutes.

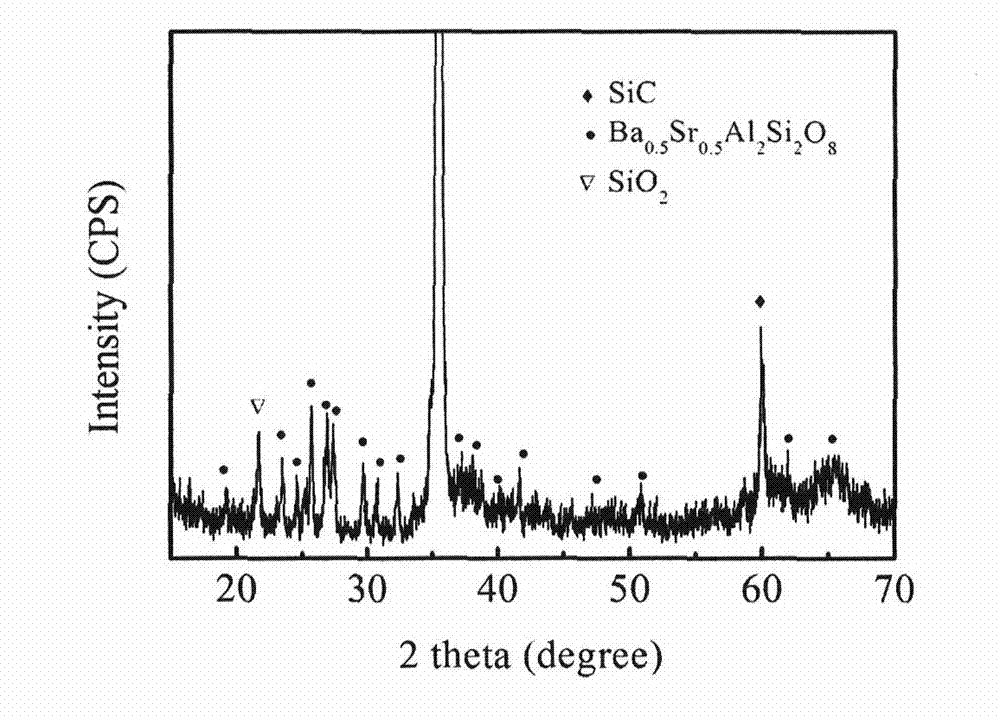

[0031] 3. Pass argon as a protective gas in a vacuum tube furnace, and heat-treat at 1200°C for 2 hours. A dense BSAS coating can be obtained.

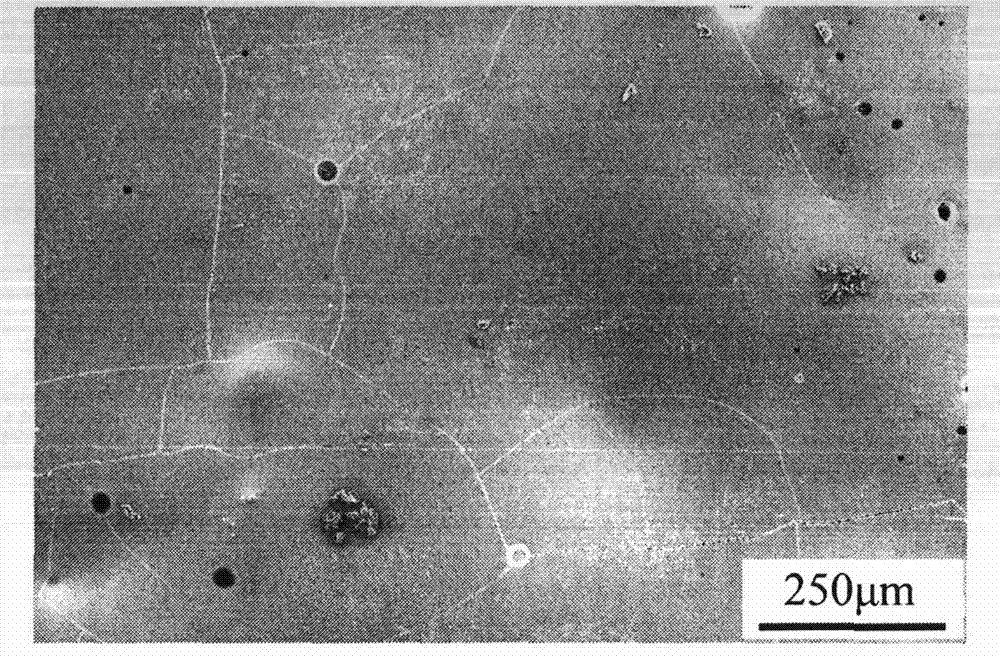

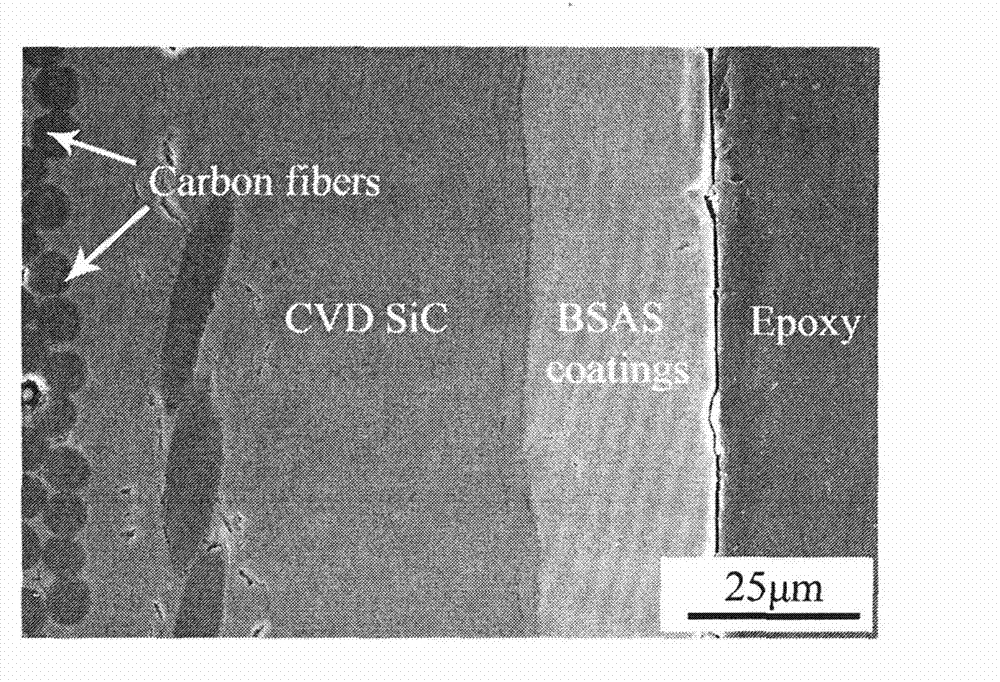

[0032] 4. The performance assessment of the coating is carried out in the water-oxygen corrosion device. The conditions of the whole water-oxygen corrosion experiment are as follows: the temperature in the furnace is 1250 ° C, the atmosphere is 50% H 2 O-50%O 2 , the gas flow rate is 8.5×10 -4 m / s (the flow rate is an estimated value at room temperature), the pressure is 1 atm, and the entire water-oxygen corrosion time is 200 hours. From the cross-section of the sample after water and oxygen corrosion, it can be seen that the coated sample, the C fibers in th...

Embodiment 2

[0035] Example 2: Mixing Sc with polyazide silane as a precursor 2 Si 2 o 7 Powder preparation slurry, using Li 2 CO 3 Preparation of Sc at 1250°C as a sintering aid 2 Si 2 o 7 Environmental barrier coatings.

[0036]1. Add 70wt% Sc 2 Si 2 o 7 The powder was added to the precursor of polyazide silane, and then mixed with 5wt% Li 2 CO 3 As a sintering aid, add an appropriate amount of alcohol to reduce the viscosity of the slurry. Ball mill for 30 minutes using a vibrating ball mill.

[0037] 2. Brush the mixed slurry onto the surface of the C / SiC sample, and cure it at 120°C for 8 hours.

[0038] 3. Pass argon as a protective gas in a vacuum tube furnace, and heat-treat at 1250°C for 2 hours. can get dense Sc 2 Si 2 o 7 coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com