Preparation method of high-permeability ferrite magnetic material

A magnetic material and high magnetic permeability technology, applied in the direction of inductor/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of large eddy current loss and inconspicuous advantages, achieve low porosity and improve mobility , the effect of increasing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

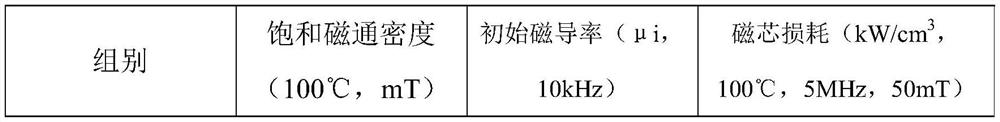

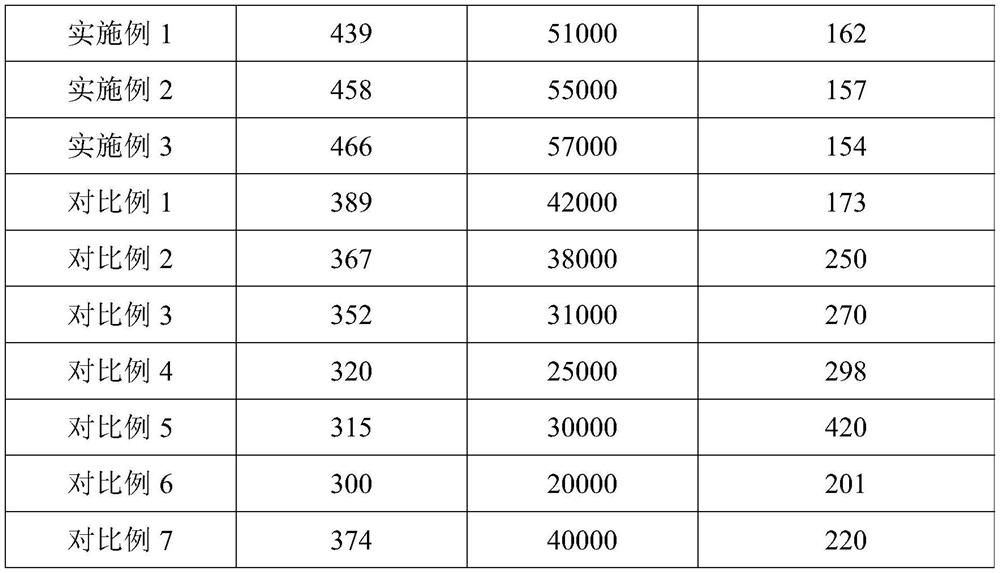

Embodiment 1

[0033] A preparation method of high magnetic permeability ferrite magnetic material, comprising the following specific steps:

[0034] S1. Raw material preparation: prepare each raw material composition according to mass percentage: Fe 2 o 3 53%, MnO 26%, ZnO 120%, polyimide resin powder 0.3%, MoO 3 0.6%, other dopants 0.1%; said other dopants are SO 3 , γ-Bi 2 o 3 Mixed powder with CaO, its mass ratio is 3:1:4;

[0035] S2. Pretreatment: Fe 2 o 3 , MnO, and ZnO are placed in a high-temperature electric furnace, and heat-treated in a nitrogen environment. The heat treatment method is to raise the temperature to 550°C at a rate of 4°C / min, keep it warm for 2 hours, and then naturally cool down to room temperature;

[0036] S3. Primary grinding: the pretreated Fe in S2 2 o 3 , MnO, and ZnO were mixed and added to the grinder, and then other dopants were added, and ground for 2 hours at a grinding speed of 500r / min to obtain a primary grinding product;

[0037]S4. Pri...

Embodiment 2

[0043] A preparation method of high magnetic permeability ferrite magnetic material, comprising the following specific steps:

[0044] S1. Raw material preparation: prepare each raw material composition according to mass percentage: Fe 2 o 3 54%, MnO 25%, ZnO 19%, polyimide resin powder 0.4%, MoO 3 0.4%, other dopants 0.2%; said other dopants are SO 3 , γ-Bi 2 o 3 The mixed powder with CaO, its mass ratio is 5:2:3;

[0045] S2. Pretreatment: Fe 2 o 3 , MnO, and ZnO are placed in a high-temperature electric furnace, and heat-treated in a nitrogen environment. The heat treatment method is to raise the temperature to 600°C at a rate of 5°C / min, keep it warm for 2 hours, and then naturally cool down to room temperature;

[0046] S3. Primary grinding: the pretreated Fe in S2 2 o 3 , MnO, and ZnO were mixed and added to the grinding machine, and then other dopants were added, and the grinding was performed for 3 hours at a grinding speed of 400r / min to obtain a grinding p...

Embodiment 3

[0053] A preparation method of high magnetic permeability ferrite magnetic material, comprising the following specific steps:

[0054] S1. Raw material preparation: prepare each raw material composition according to mass percentage: Fe 2 o 3 56%, MnO 24%, ZnO 19%, polyimide resin powder 0.5%, MoO 3 0.2%, other dopants 0.3%; said other dopants are SO 3 , γ-Bi 2 o 3 The mixed powder with CaO, its mass ratio is 9:3:4;

[0055] S2. Pretreatment: Fe 2 o 3 , MnO, and ZnO are placed in a high-temperature electric furnace, and heat-treated in a nitrogen environment. The heat treatment method is to raise the temperature to 650°C at a rate of 6°C / min, keep it warm for 1.5h, and then naturally cool down to room temperature;

[0056] S3. Primary grinding: the pretreated Fe in S2 2 o 3 , MnO, and ZnO were mixed and added to the grinder, and then other dopants were added, and ground for 4 hours at a grinding speed of 250r / min to obtain a primary grinding product;

[0057] S4. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com