QLED device and preparation method thereof

A device and thin film technology, applied in the field of QLED devices and their preparation, can solve the problems of short service life of QLED devices, and achieve the effects of increasing nickel vacancies, increasing hole extraction efficiency, conductivity, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present application also provides a preparation method of the above-mentioned QLED device preparation method, which includes the following steps:

[0038] S1. Coating the rubidium-doped nickel oxide precursor solution on the side of the anode away from the substrate, at 270-310°C, such as 270°C, 275°C, 280°C, 285°C, 290°C, 295°C, 300°C, 305°C or 310°C isothermal annealing for 15-25min to form a rubidium-doped nickel oxide film.

[0039] Wherein, the rubidium-doped nickel oxide precursor solution is prepared by the following method:

[0040] Dissolving rubidium acetate and nickel acetate tetrahydrate in an organic solvent and stirring at room temperature for 10-14 hours; wherein, the organic solvent includes ethylene glycol solution containing diethylamine. By annealing at 270-310° C. for 15-25 minutes, the organic solvent can be effectively removed and a rubidium-doped nickel oxide film can be formed. Wherein, the ratio of rubidium acetate and nickel acetate tetra...

Embodiment 1

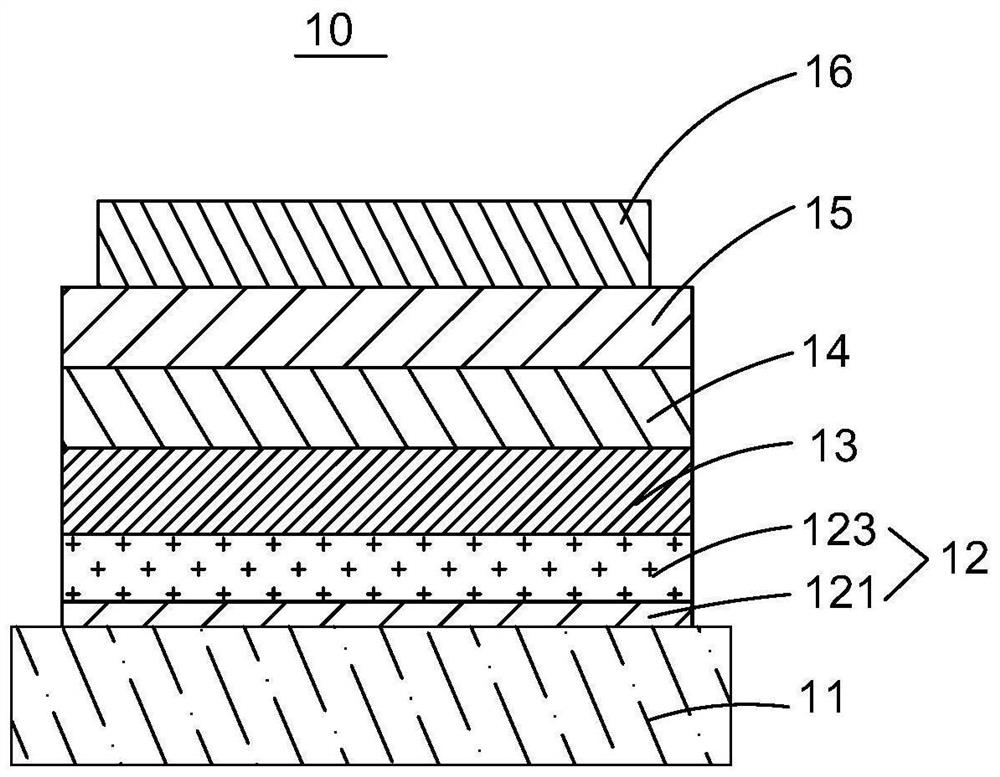

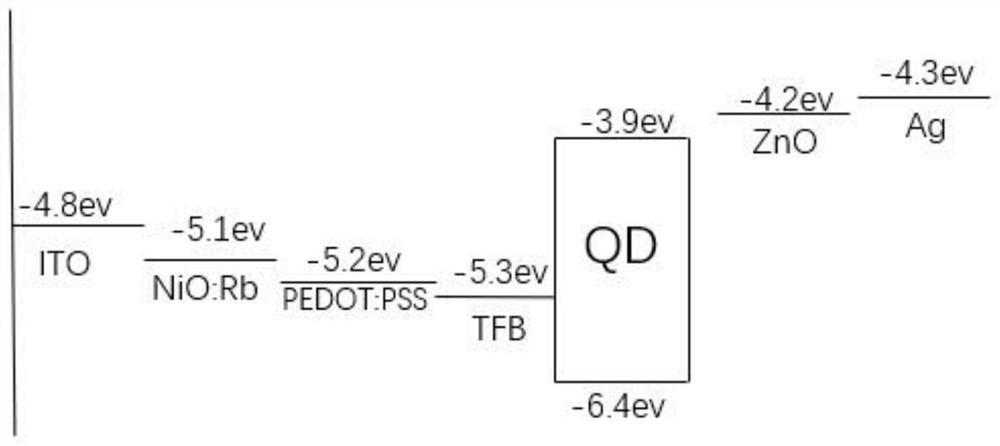

[0053] A kind of QLED device, its structure is as figure 1 As shown, it is prepared by the following preparation method:

[0054] Step S1: ultrasonically clean the ITO glass substrate in deionized water, acetone and isopropanol for 15 minutes, and then use a UV-ozone cleaner for 15 minutes;

[0055] Step S2: Dissolve 0.3g of nickel acetate tetrahydrate and 28mg of rubidium acetate in 10g of ethylene glycol solution containing 0.1g of diethylamine, and stir at room temperature to synthesize a Rb:NiO solution with an Rb doping amount of 10% mol.

[0056] On the ITO film on the ITO glass substrate, spin-coat NiO:Rb solution at 3000rpm for 40s, and anneal at 300°C for 20min to form a rubidium-doped nickel oxide film with a thickness of 30nm; then spin-coat PEDOT:PSS aqueous solution at 5000rpm for 40s , annealed at 150° C. for 15 minutes in air to form a PEDOT:PSS film with a thickness of 40 nm, and the rubidium-doped nickel oxide film and the PEDOT:PSS film together form a compo...

Embodiment 2

[0065] It differs from Example 1 only in step S2: dissolving nickel acetate tetrahydrate and rubidium acetate in a certain proportion in an ethylene glycol solution containing diethylamine, stirring overnight at room temperature, and preparing a synthetic Rb with a doping amount of 8% mol of Rb: NiO solution as a hole injection layer.

[0066] The final structure of the QLED device of Example 2 is: ITO / NiO:Rb(8%) / PEDOT:PSS / TFB / R-QD / ZnO / Ag device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com