Preparation method of sodium chlorate generator electrode

A generator and sodium chlorate technology, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that are difficult to meet industrial applications, poor conductivity of inert films, and reduced electrode current efficiency, so as to improve oxygen evolution potential and service life , low chlorine analysis potential and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

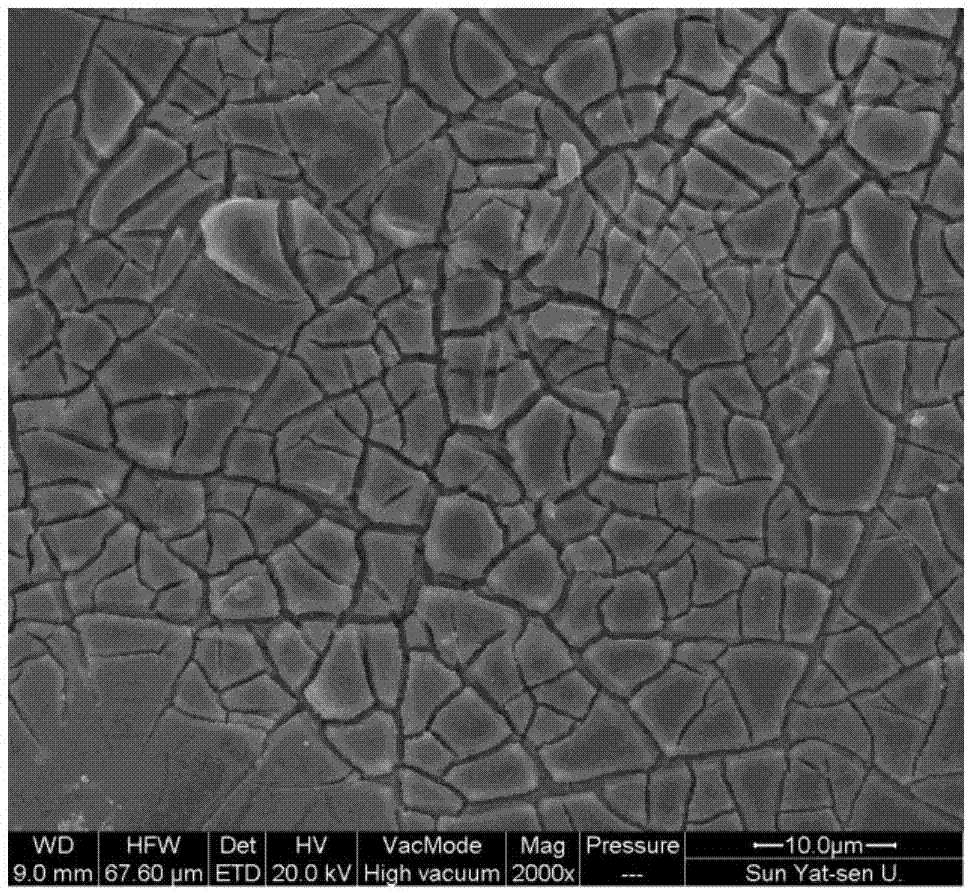

[0033] A kind of preparation method of sodium chlorate generator electrode, comprises the following steps:

[0034] 1) Use a titanium plate with a titanium content of 99.9% and a thickness of 1mm as the substrate. After the titanium plate is sandblasted and polished to remove the oxide layer, it is placed in a NaOH solution with a concentration of 10% and shaken for 30 minutes, and then the oxalic acid solution with a concentration of 20% is used. Etch the titanium plate for 2 hours, wash it and place it in an ethanol solution for use;

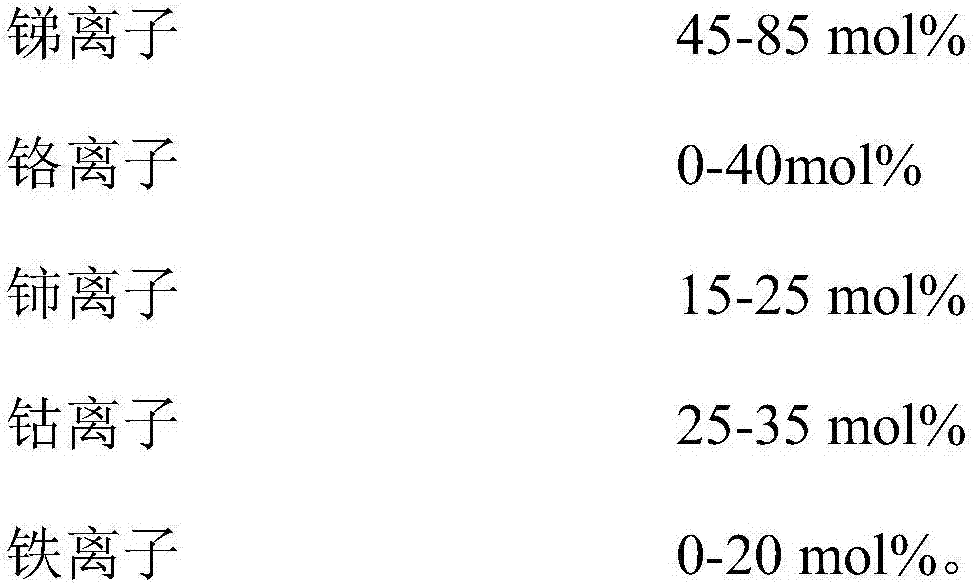

[0035]2) Preparation of inner layer active coating solution: use a mixed solution of n-butanol and isopropanol as solvent, the volume ratio of n-butanol and isopropanol is 2:1, use ruthenium trichloride, chloroiridic acid, titanic acid Tetrabutyl ester and oxygen evolution inhibitor are used as solute, and concentrated hydrochloric acid is used as a stabilizer to form an inner layer active coating solution; the metal ion concentration in the i...

Embodiment 1a

[0056] A kind of preparation method of sodium chlorate generator electrode, comprises the following steps:

[0057] 1) Use a titanium plate with a titanium content of 99.9% and a thickness of 1 mm as the substrate. After the titanium plate is sandblasted and polished to remove the oxide layer, it is placed in a NaOH solution with a concentration of 10% and shaken for 30 minutes, and then the oxalic acid solution with a concentration of 20% is used. Etch the titanium plate for 2 hours, wash it and place it in an ethanol solution for use;

[0058] 2) Preparation of inner layer active coating solution: use a mixed solution of n-butanol and isopropanol as solvent, the volume ratio of n-butanol and isopropanol is 2:1, use ruthenium trichloride, chloroiridic acid, titanic acid Tetrabutyl ester and oxygen evolution inhibitor are used as solute, and concentrated hydrochloric acid is used as a stabilizer to configure an inner layer active coating solution; the metal ion concentration i...

Embodiment 1b

[0066] A kind of preparation method of sodium chlorate generator electrode, comprises the following steps:

[0067] 1) Use a titanium plate with a titanium content of 99.9% and a thickness of 1 mm as the substrate. After the titanium plate is sandblasted and polished to remove the oxide layer, it is placed in a NaOH solution with a concentration of 10% and shaken for 30 minutes, and then the oxalic acid solution with a concentration of 20% is used. Etch the titanium plate for 2 hours, wash it and place it in an ethanol solution for use;

[0068] 2) Preparation of inner layer active coating solution: use a mixed solution of n-butanol and isopropanol as solvent, the volume ratio of n-butanol and isopropanol is 2:1, use ruthenium trichloride, chloroiridic acid, titanic acid Tetrabutyl ester and oxygen evolution inhibitor are used as solute, and concentrated hydrochloric acid is used as a stabilizer to form an inner layer active coating solution; in the inner layer active coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com