A kind of preparation method of gas-permeable chlorine-analysis electrode

A chlorine evolution electrode, electrodeposition technology, applied in the direction of electrode, electrode shape/type, electrolysis components, etc., can solve the problems of high operating cost of sodium hypochlorite generator, poor conductivity of inert film, low electrode current efficiency, etc., to achieve good conductivity , The effect of improving adhesion and increasing the number of active points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of air gas analysis chlorine electrode, comprises the following steps:

[0029] 1) Substrate treatment: Porous titanium is used as the substrate, and the porous titanium is prepared by vacuum sintering method. The obtained porous titanium has a porosity of 30%-45%, a pore diameter of 5μm-20μm, and a thickness of 1mm. Vibrate in a NaOH solution with a concentration of 10% for 30 minutes to remove surface oil stains, and then use an oxalic acid solution with a concentration of 20% to perform surface pretreatment on the porous titanium to remove surface oxides to obtain a titanium matrix;

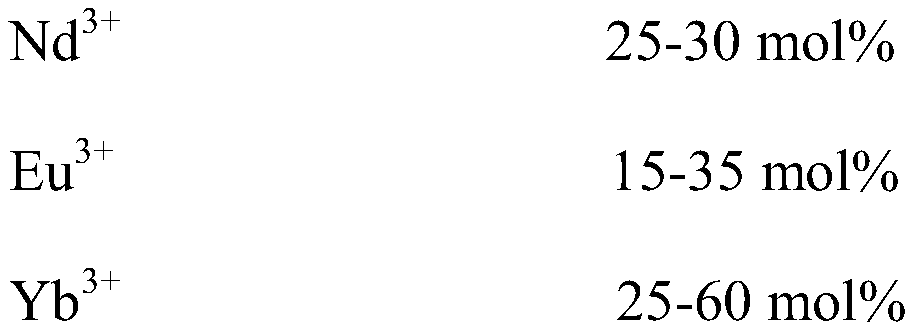

[0030] 2) Preparation of precursor deposition bath: add 80-150mL of absolute ethanol, 10-16mL of deionized water, and 10-20mL of precursor into the HCl solution, and then adjust the pH to 1-5 to obtain a precursor deposition bath;

[0031] 3) Preparation of deposition layer: add the precursor deposition bath obtained in step 2) to the electrolytic cell of th...

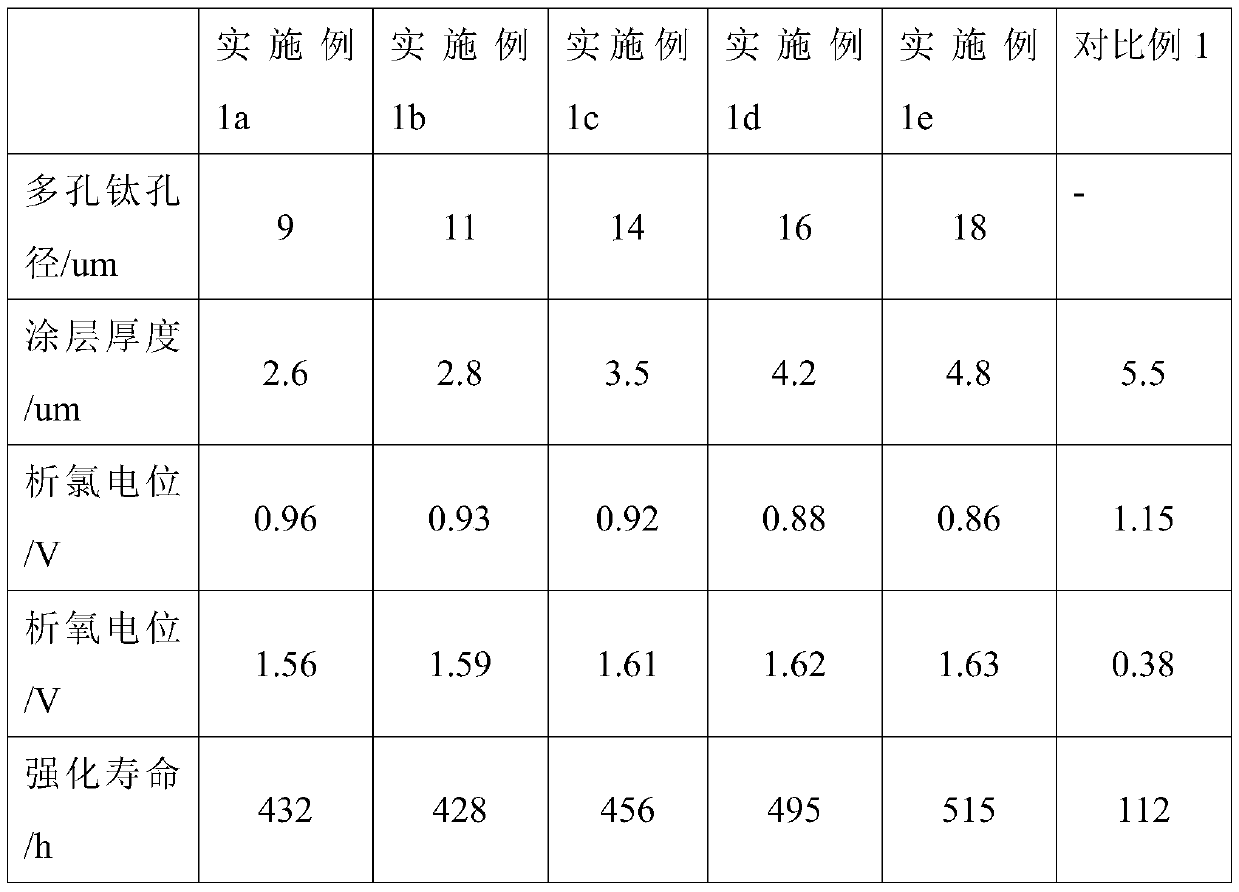

Embodiment 1a

[0046] A kind of preparation method of air gas analysis chlorine electrode, comprises the following steps:

[0047] 1) Substrate treatment: Porous titanium is used as the substrate, and the porous titanium is prepared by vacuum sintering method. The obtained porous titanium has a porosity of 35%, a pore diameter of 9 μm, and a thickness of 1 mm. The porous titanium is first placed in a concentration of 10%. Vibrated in NaOH solution for 30 minutes to remove surface oil, and then use 20% oxalic acid solution to pretreat the surface of porous titanium to remove surface oxides to obtain a titanium matrix;

[0048] 2) Precursor deposition bath preparation: Add 80-150mL of absolute ethanol, 10-16mL of deionized water, and 10-20mL of IrCo solution into the HCl solution, and then adjust the pH to 2 to obtain a precursor deposition bath;

[0049] 3) Preparation of deposition layer: add the precursor deposition bath obtained in step 2) to the electrolytic cell of the three-electrode sy...

Embodiment 1b

[0056] A kind of preparation method of air gas analysis chlorine electrode, comprises the following steps:

[0057] 1) Substrate treatment: Porous titanium is used as the substrate, and the porous titanium is prepared by vacuum sintering method. The obtained porous titanium has a porosity of 35%, a pore diameter of 11 μm, and a thickness of 1 mm. The porous titanium is first placed in a concentration of 10%. Vibrated in NaOH solution for 30 minutes to remove surface oil, and then use 20% oxalic acid solution to pretreat the surface of porous titanium to remove surface oxides to obtain a titanium matrix;

[0058] 2) Precursor deposition bath preparation: add 80-150mL of absolute ethanol, 10-16mL of deionized water, and 10-20mL of IrSn solution into the HCl solution, and then adjust the pH to 3 to obtain a precursor deposition bath;

[0059] 3) Preparation of deposition layer: add the precursor deposition bath obtained in step 2) to the electrolytic cell of the three-electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com