A kind of chlorine analysis accelerator and preparation method thereof

An accelerator and chlorine evolution technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis components, etc., can solve the problems of complex operation, high operating cost, secondary pollution, etc. Chlorine evolution efficiency and effect of increasing chlorine evolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

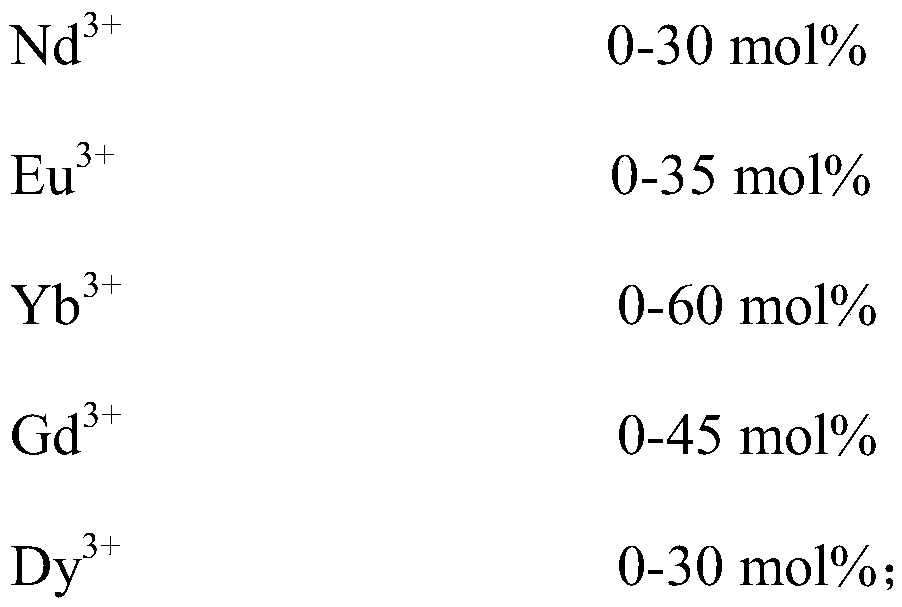

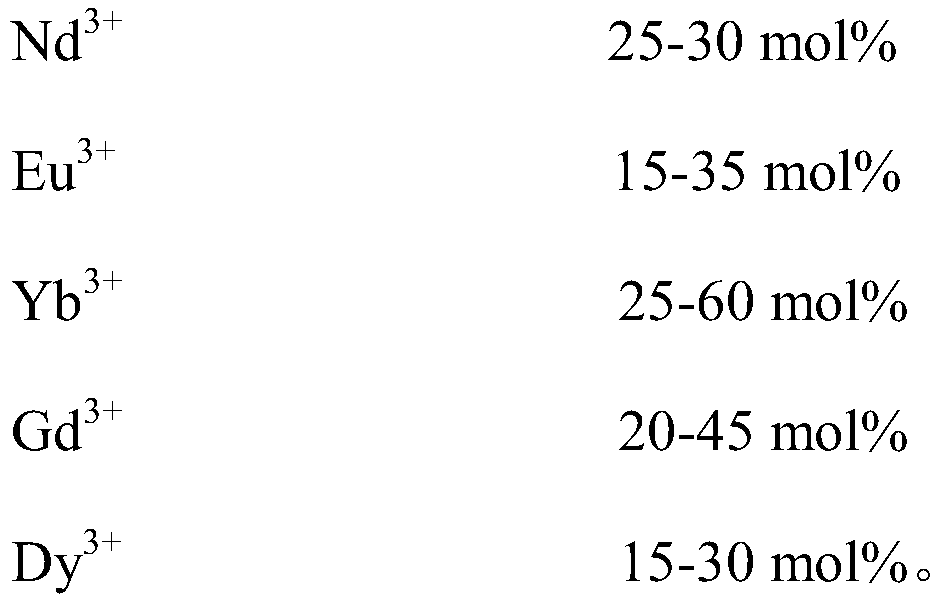

[0051] In embodiment 1-5, the molar percentage composition of each component ion and ion is shown in the table below:

[0052] Table 1 embodiment 1-5 component and proportioning ratio

[0053] Nd 3+

Eu 3+

Yb 3+

Gd 3+

Dy 3+

Example 1 25mol% 15mol% 60mol% - - Example 2 - - 40mol% 40mol% 20mol% Example 3 - 25mol% - 45mol% 30mol% Example 4 30mol% 30mol% - 20mol% 20mol% Example 5 25mol% 35mol% 25mol% - 15mol%

[0054] - Indicates that it does not contain this component

[0055] Wherein, the neodymium ion of embodiment 1 comes from neodymium chloride, neodymium nitrate, europium ion comes from europium chloride, europium nitrate, ytterbium ion comes from ytterbium sulfate, ytterbium carbonate; The ytterbium ion of embodiment 2 comes from ytterbium nitrate, gadolinium ion comes from chloride Gadolinium, gadolinium nitrate, gadolinium sulfate, and dysprosium ion are from dys...

experiment example

[0058] The chlorine analysis accelerators of Examples 1-5 were introduced into the electrodes of the sodium hypochlorite generator, and the chlorine analysis reaction and the chlorine analysis efficiency of the sodium hypochlorite generator electrodes were tested.

[0059] The experimental steps are as follows:

[0060] (1) Use a titanium plate with a titanium content of 99.9% and a thickness of 1 mm as the substrate. After the titanium plate is sandblasted and polished to remove the oxide layer, it is placed in a NaOH solution with a concentration of 10% and shaken for 30 minutes, and then the oxalic acid with a concentration of 20% The solution etches the titanium plate for 2 hours, and after cleaning, place it in an ethanol solution for use;

[0061](2) Preparation of active coating liquid: use n-butanol: isopropanol = 2:1 mixed solution as solvent, ruthenium trichloride, chloroiridic acid, tetrabutyl titanate, chlorine evolution accelerator as solute, and Concentrated hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com