High-performance Al-Mg-Si-Cu-Sn aluminum alloy and preparation method thereof

An al-mg-si-cu-sn, high-performance technology, applied in the field of high-performance Al-Mg-Si-Cu-Sn aluminum alloy and its preparation, can solve the problems of reducing the mechanical properties of the artificial age hardening rate alloy, Achieve the effects of increasing the response rate of artificial aging, increasing the precipitation rate, and increasing the density of vacancies and dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

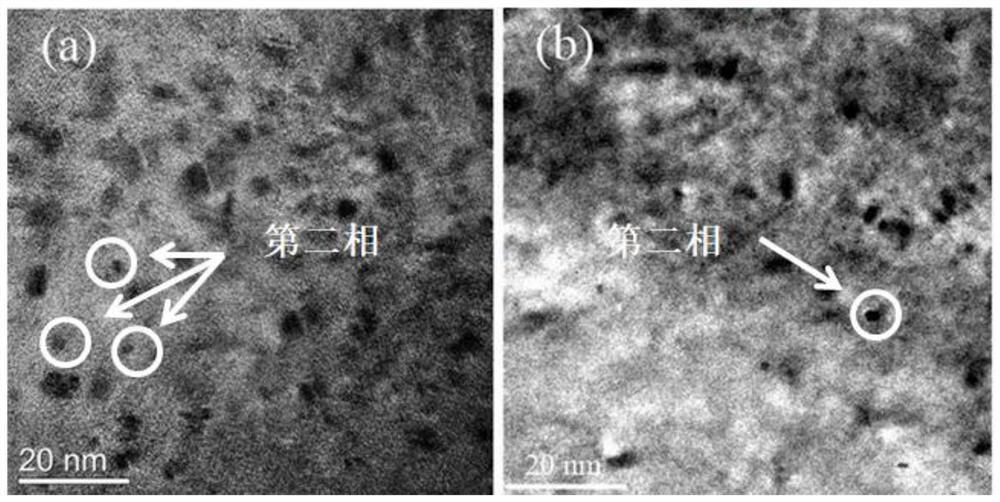

Image

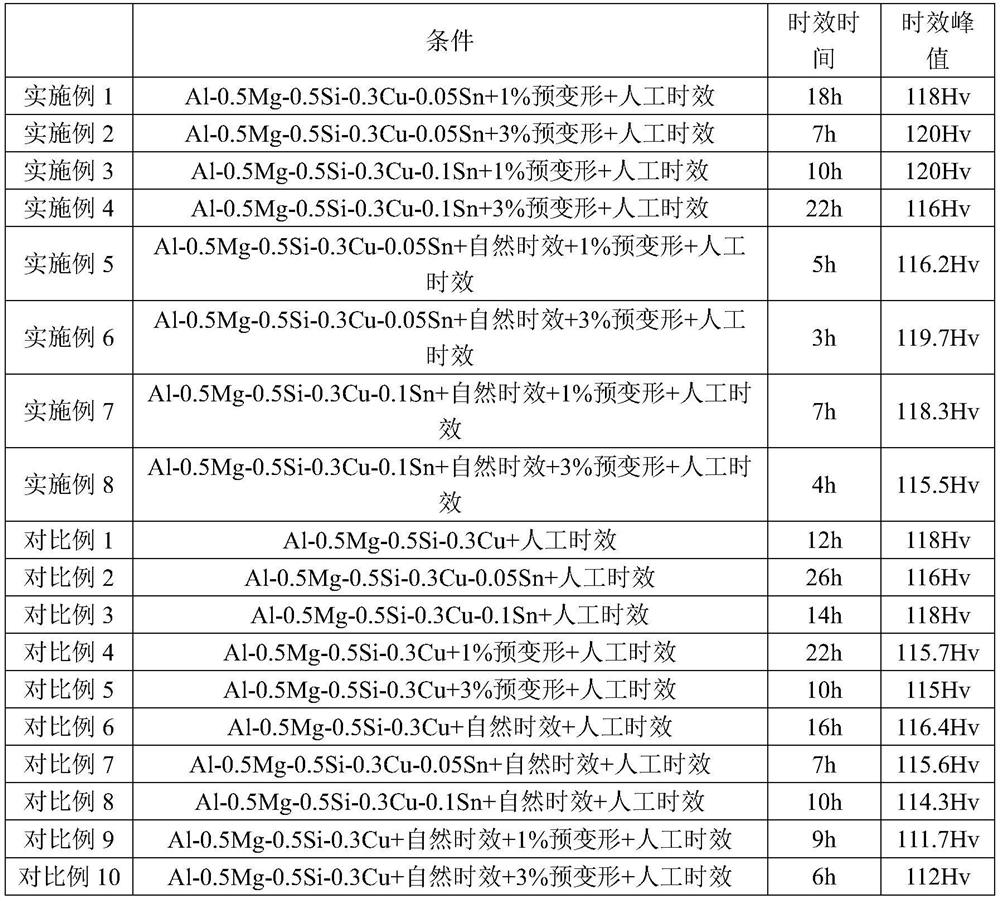

Examples

Embodiment 1

[0029] (1) An aluminum alloy of Al-0.5Mg-0.5Si-0.3Cu-0.05Sn, the alloy is composed of the following components according to the mass ratio: Mg: 0.5%, Si: 0.5%, Cu: 0.3%, Sn: 0.05 %, inevitable impurities≤0.02%, and the balance is Al. According to the above ratio of raw materials, pure aluminum, aluminum-silicon master alloy Al-20%Si, and aluminum-copper master alloy Al-50%Cu were preheated at 200°C, and then kept at 750°C for 1 h to obtain an alloy melt, which was then placed in sequence. Pure magnesium and pure tin were stirred and kept for 0.5h, then cooled to 720°C, added with grain refiner Al-5Ti-1B (0.2wt.%), and allowed to stand for 15min, then added to the iron mold at 200°C Casting in the middle to obtain aluminum alloy ingots;

[0030] (2) performing homogenization treatment on the alloy ingot obtained in step (1), quenching with water at 550° C. for 12 hours to obtain a homogenized ingot;

[0031] (3) Extrusion: the homogenized ingot obtained in step (2) is extrude...

Embodiment 2

[0034] (1) An aluminum alloy of Al-0.5Mg-0.5Si-0.3Cu-0.05Sn, the alloy is composed of the following components according to the mass ratio: Mg: 0.5%, Si: 0.5%, Cu: 0.3%, Sn: 0.05 %, inevitable impurities≤0.02%, and the balance is Al. According to the above ratio of raw materials, pure aluminum, aluminum-silicon master alloy Al-20%Si, and aluminum-copper master alloy Al-50%Cu were preheated at 200°C, and then kept at 750°C for 1 h to obtain an alloy melt, which was then placed in sequence. Pure magnesium and pure tin were stirred and kept for 0.5h, then cooled to 720°C, added with grain refiner Al-5Ti-1B (0.2wt.%), and allowed to stand for 15min, then added to the iron mold at 200°C Casting in the middle to obtain aluminum alloy ingots;

[0035] (2) performing homogenization treatment on the alloy ingot obtained in step (1), quenching with water at 550° C. for 12 hours to obtain a homogenized ingot;

[0036](3) Extrusion: the homogenized ingot obtained in step (2) is extruded...

Embodiment 3

[0039] (1) An aluminum alloy of Al-0.5Mg-0.5Si-0.3Cu-0.1Sn, the alloy is composed of the following components according to the mass ratio: Mg: 0.5%, Si: 0.5%, Cu: 0.3%, Sn: 0.1 %, inevitable impurities≤0.02%, and the balance is Al. According to the above ratio of raw materials, pure aluminum, aluminum-silicon master alloy Al-20%Si, and aluminum-copper master alloy Al-50%Cu were preheated at 200°C, and then kept at 750°C for 1 h to obtain an alloy melt, which was then placed in sequence. Pure magnesium and pure tin were stirred and kept for 0.5h, then cooled to 720°C, added with grain refiner Al-5Ti-1B (0.2wt.%), and allowed to stand for 15min, then added to the iron mold at 200°C Casting in the middle to obtain aluminum alloy ingots;

[0040] (2) performing homogenization treatment on the alloy ingot obtained in step (1), quenching with water at 550° C. for 12 hours to obtain a homogenized ingot;

[0041] (3) Extrusion: the homogenized ingot obtained in step (2) is extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com