Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Quaternary alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quaternary Alloys Quaternary alloys can be created by using a compound semiconductor and a ternary alloy as base materials. The compound semiconductor in most cases will be available in the material database (defined as a 'semiconductor' type material). The AlxGayIn1-x-ySb quaternary alloy can be created by mixing AlSb, GaSb, and InSb.

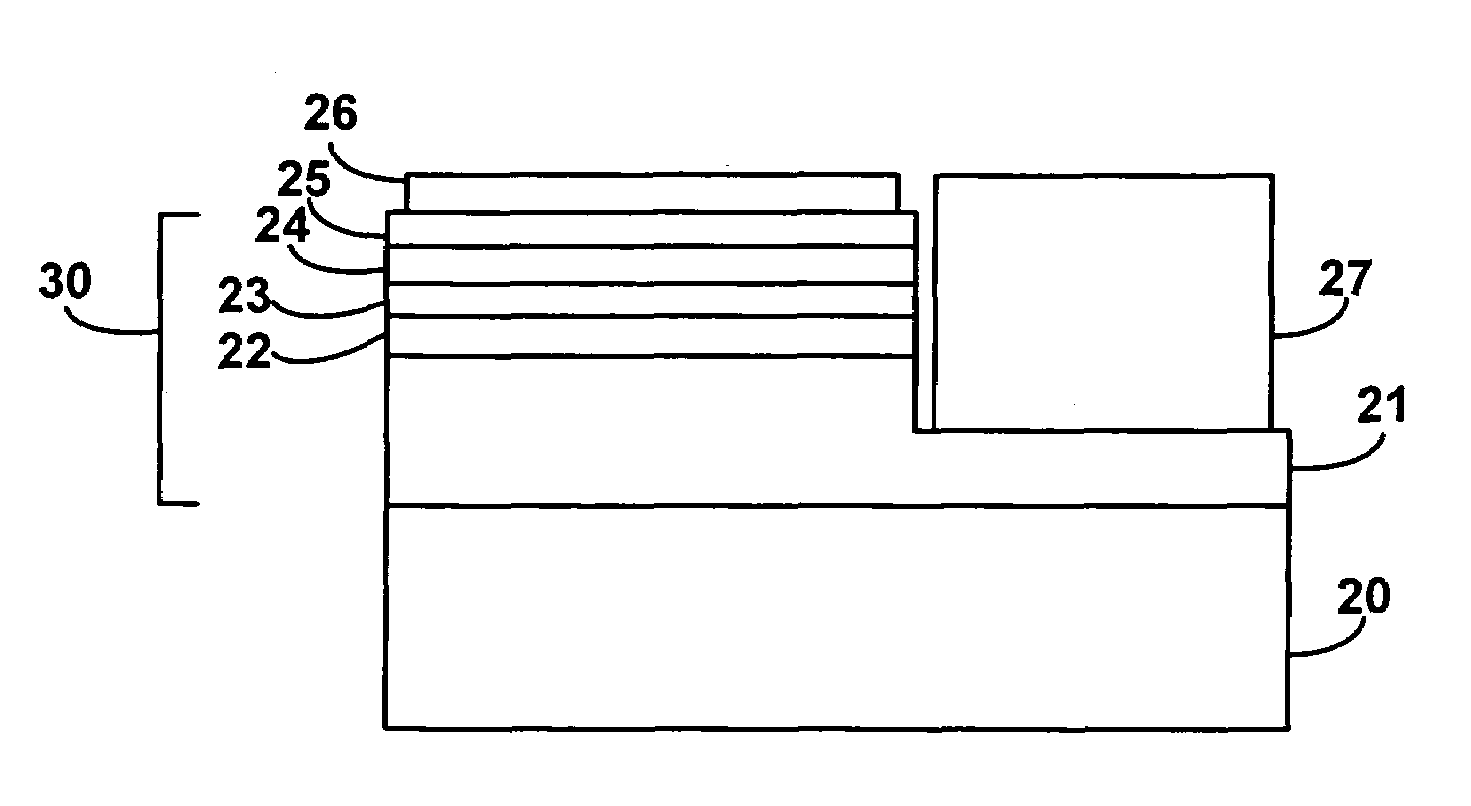

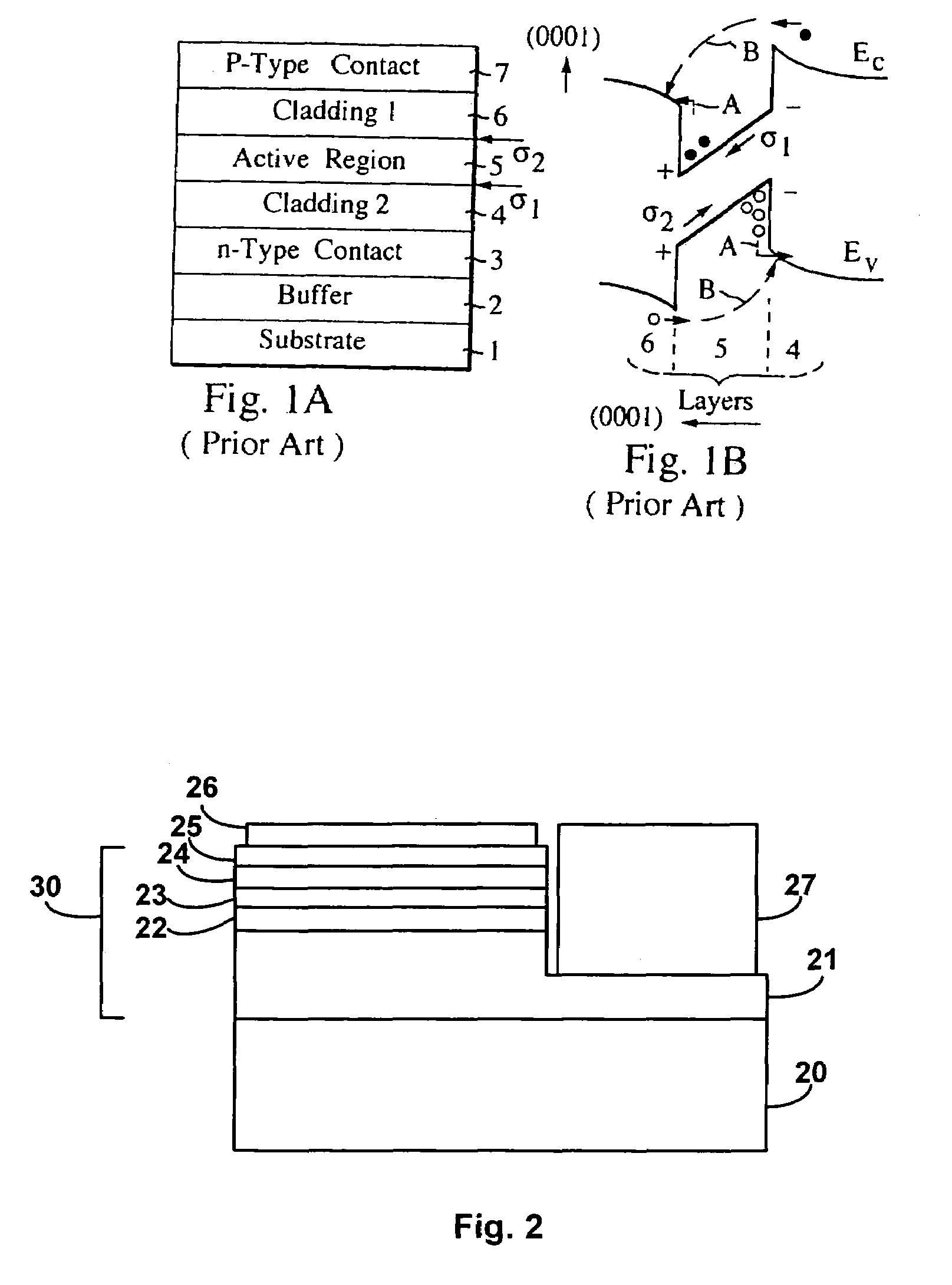

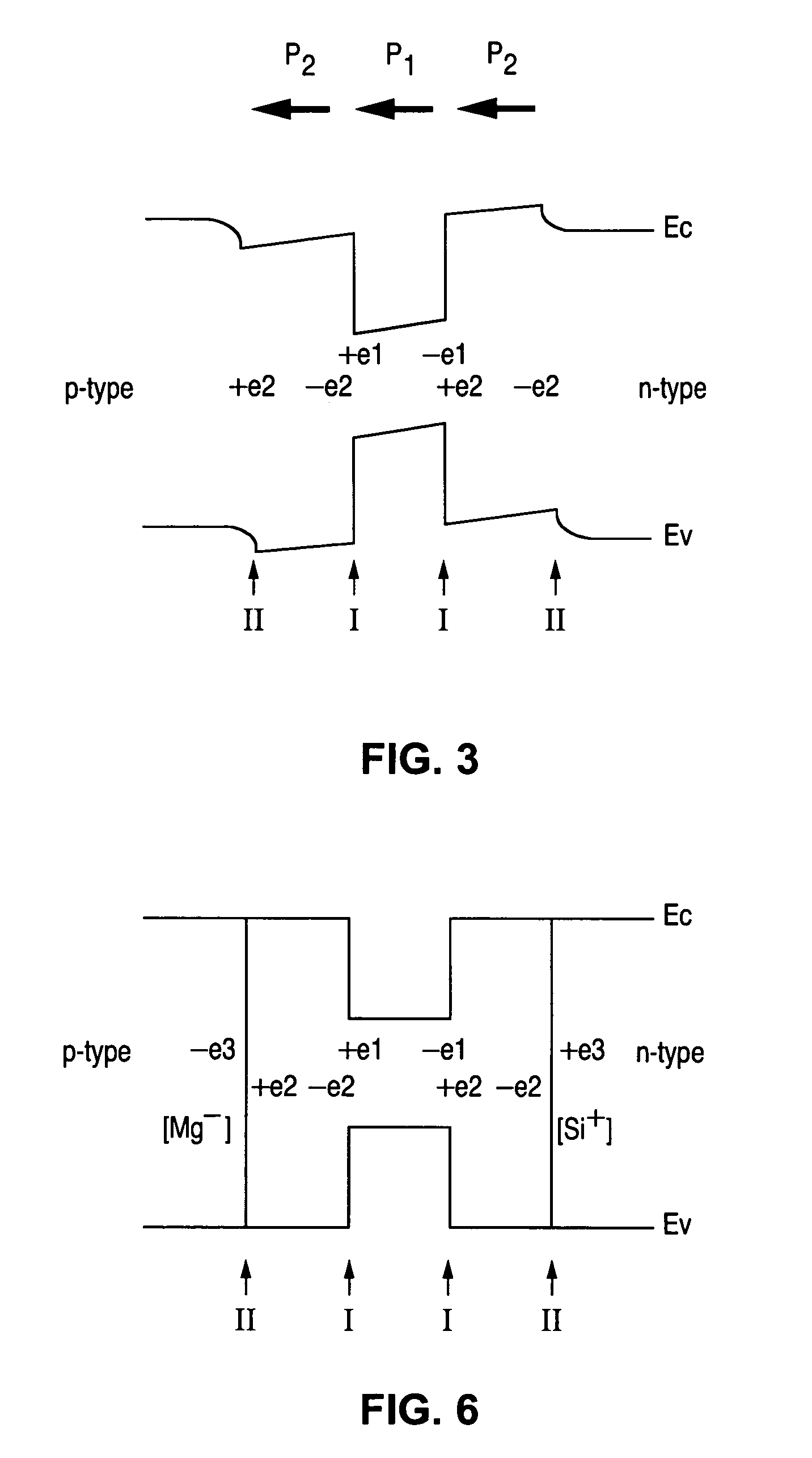

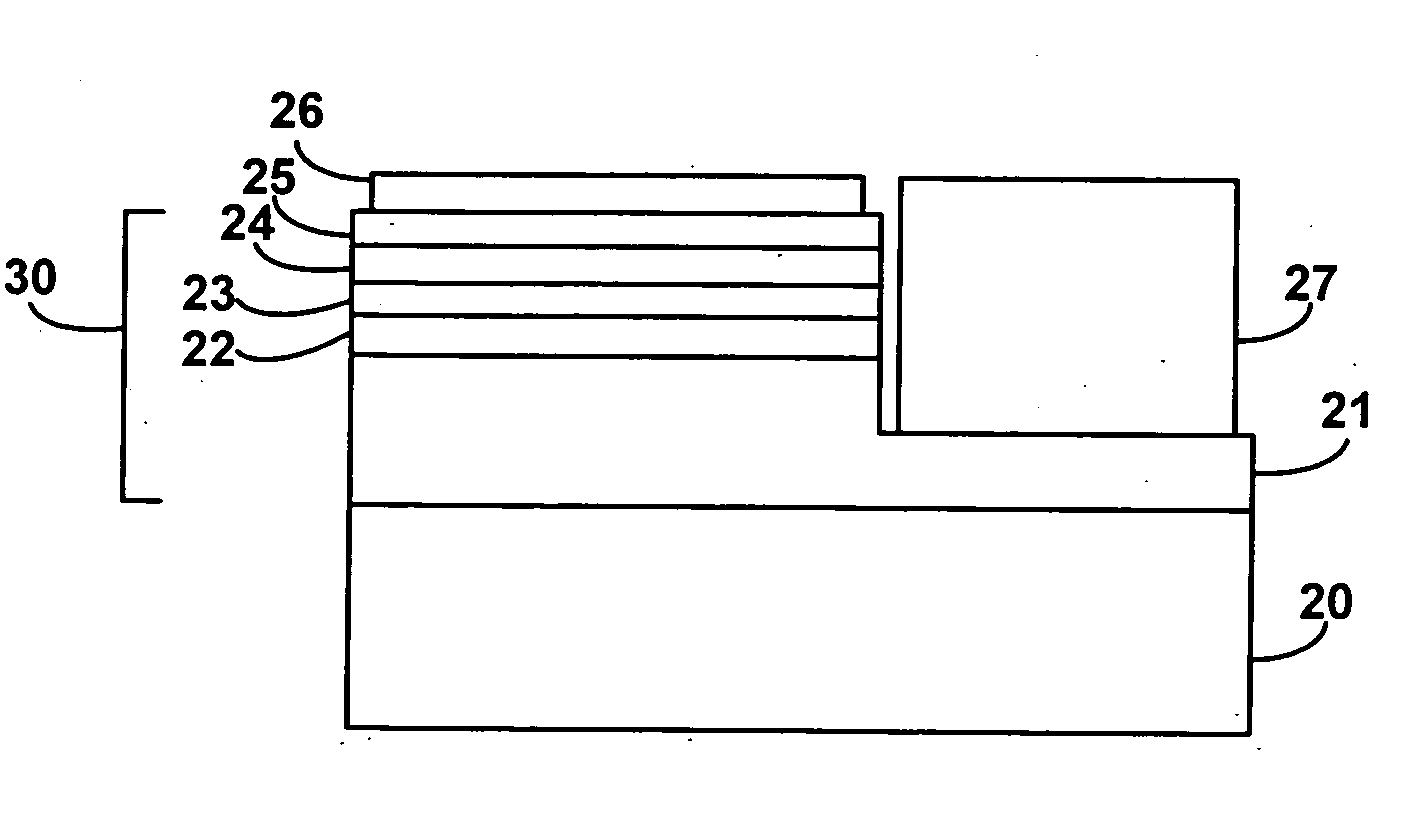

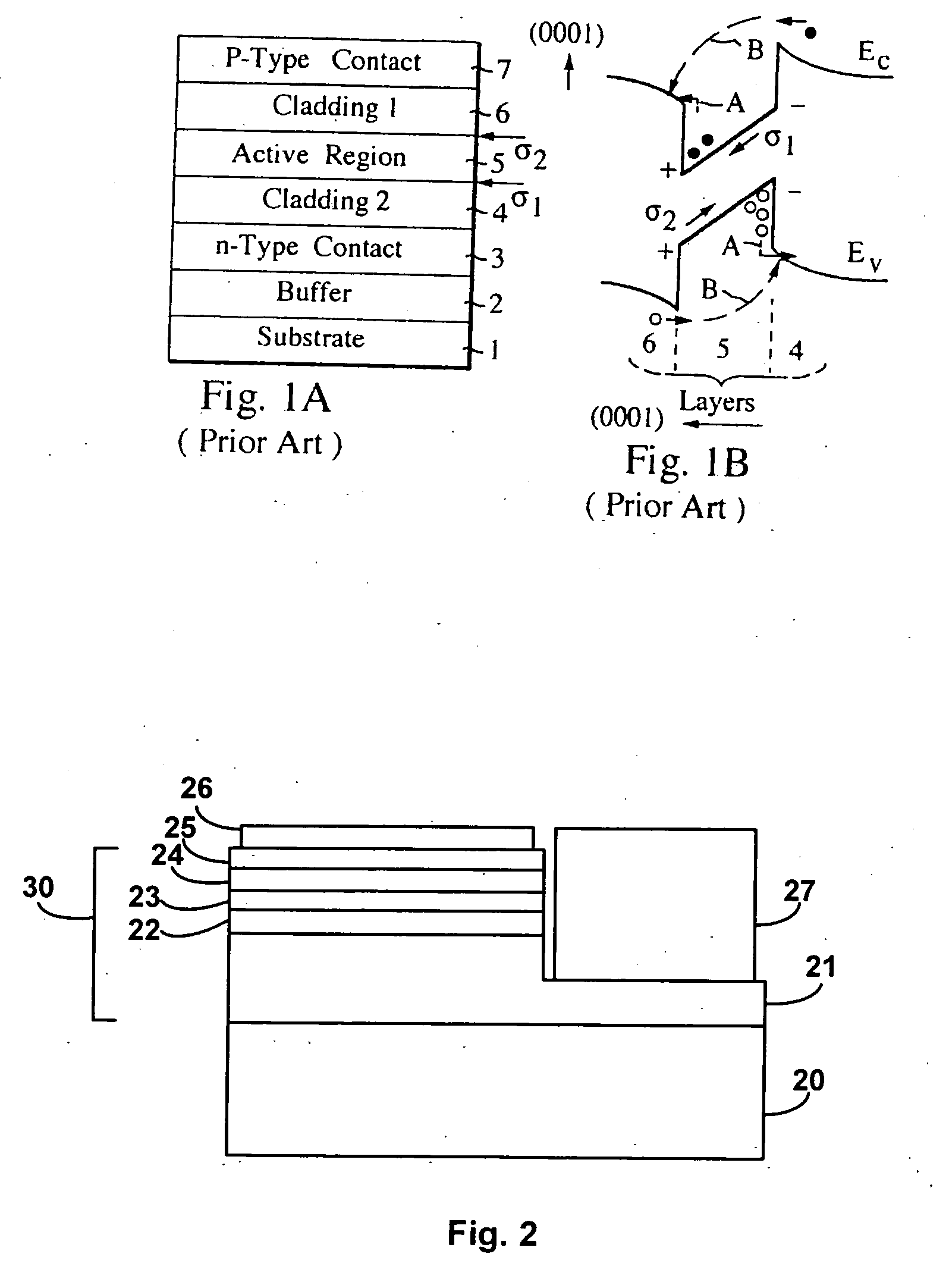

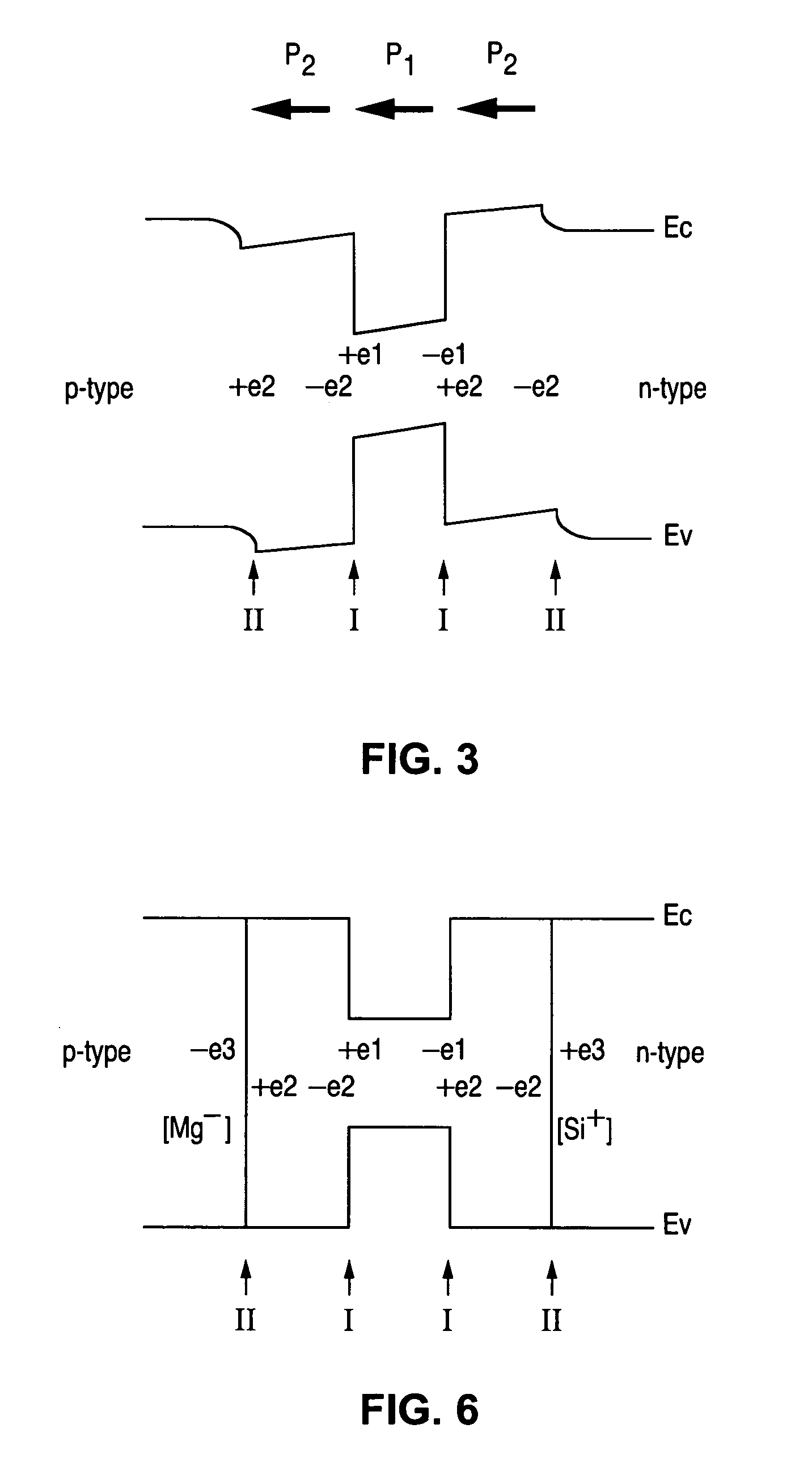

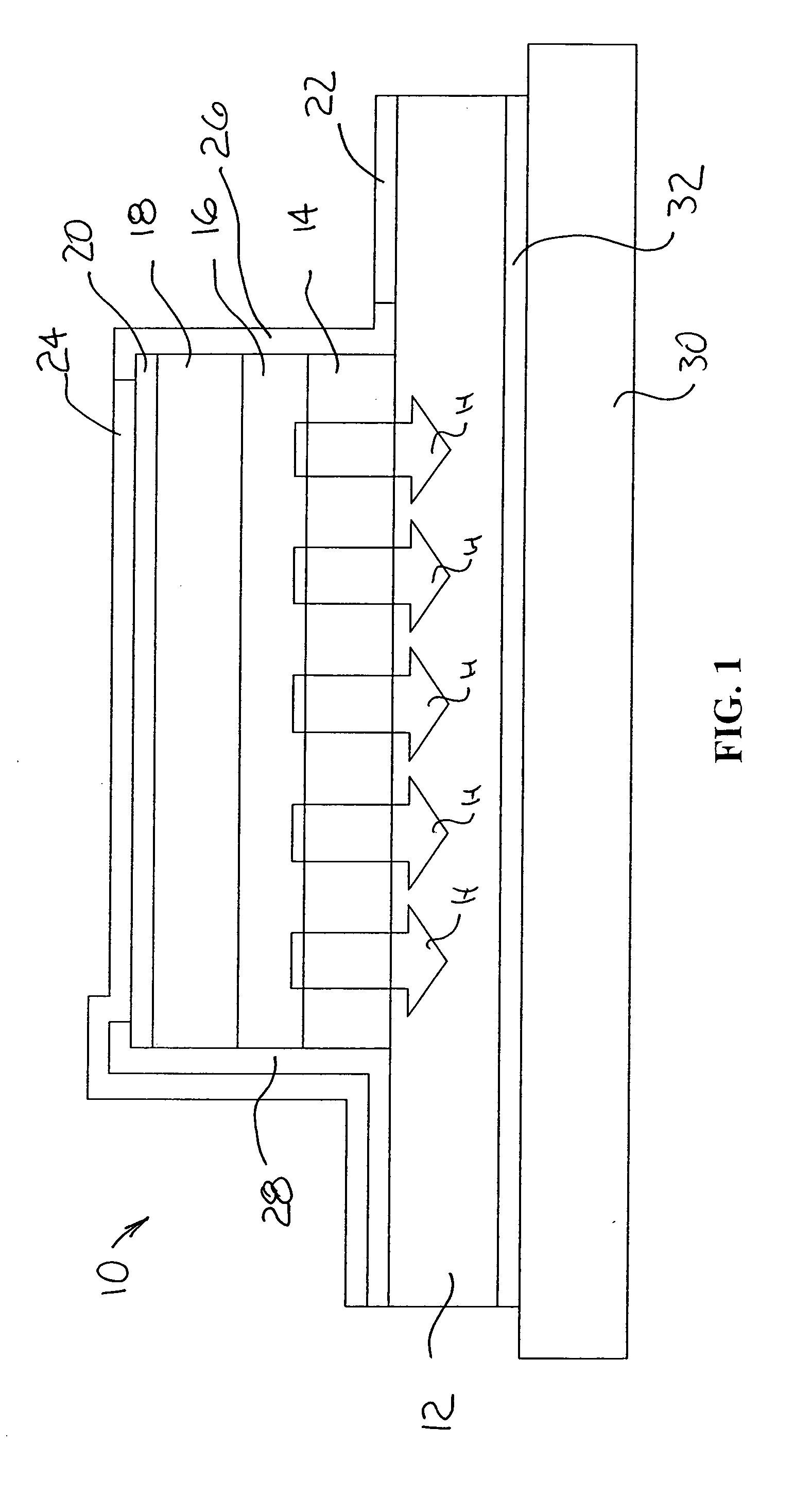

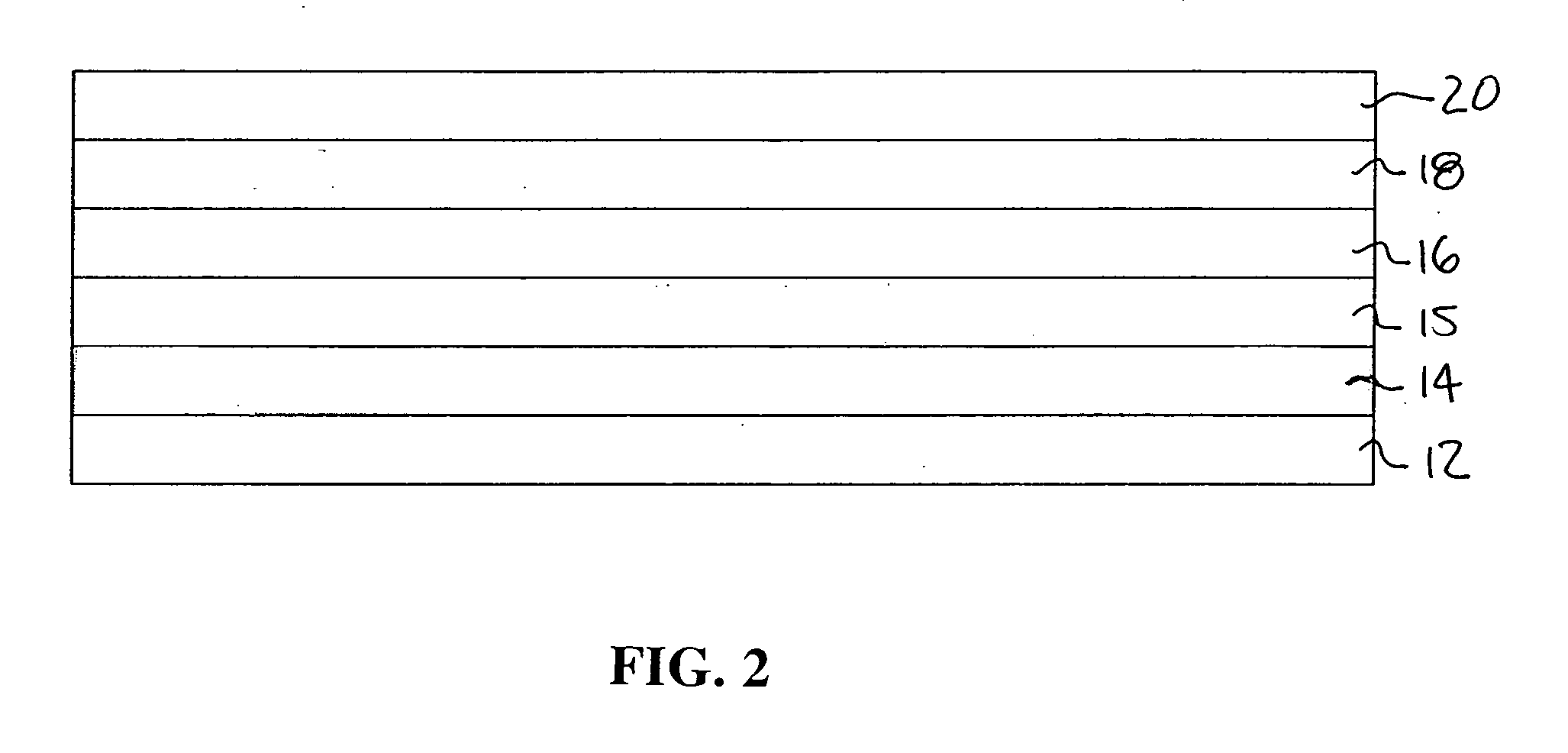

III-nitride light emitting device with reduced polarization fields

ActiveUS7115908B2Reduced polarization fieldAvoid the inefficiencies causedSolid-state devicesSemiconductor devicesIndiumNitrogen

A semiconductor light emitting device includes a light emitting layer sandwiched between two spacer layers. The difference between the net polarization in at least one of the spacer layers and the net polarization in the light emitting layer is less than in the device with conventional spacer layers, such as GaN spacer layers. The difference between the net polarization in at least one of the spacer layers and the net polarization in the light emitting layer is less than about 0.02 C / m2. In some embodiments, at least one of the spacer layers is a quaternary alloy of aluminum, indium, gallium, and nitrogen.

Owner:LUMILEDS

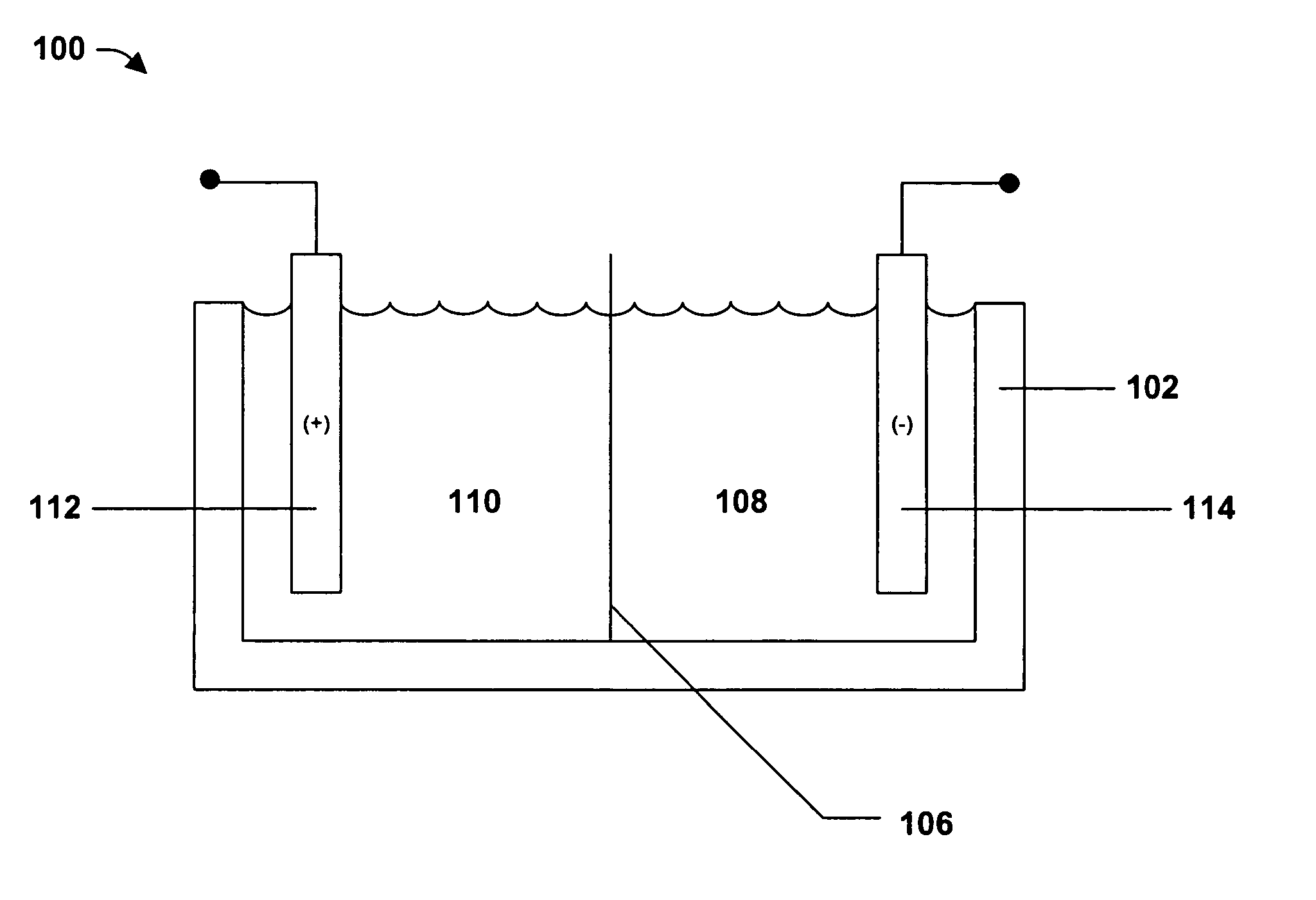

Electroplated quaternary alloys

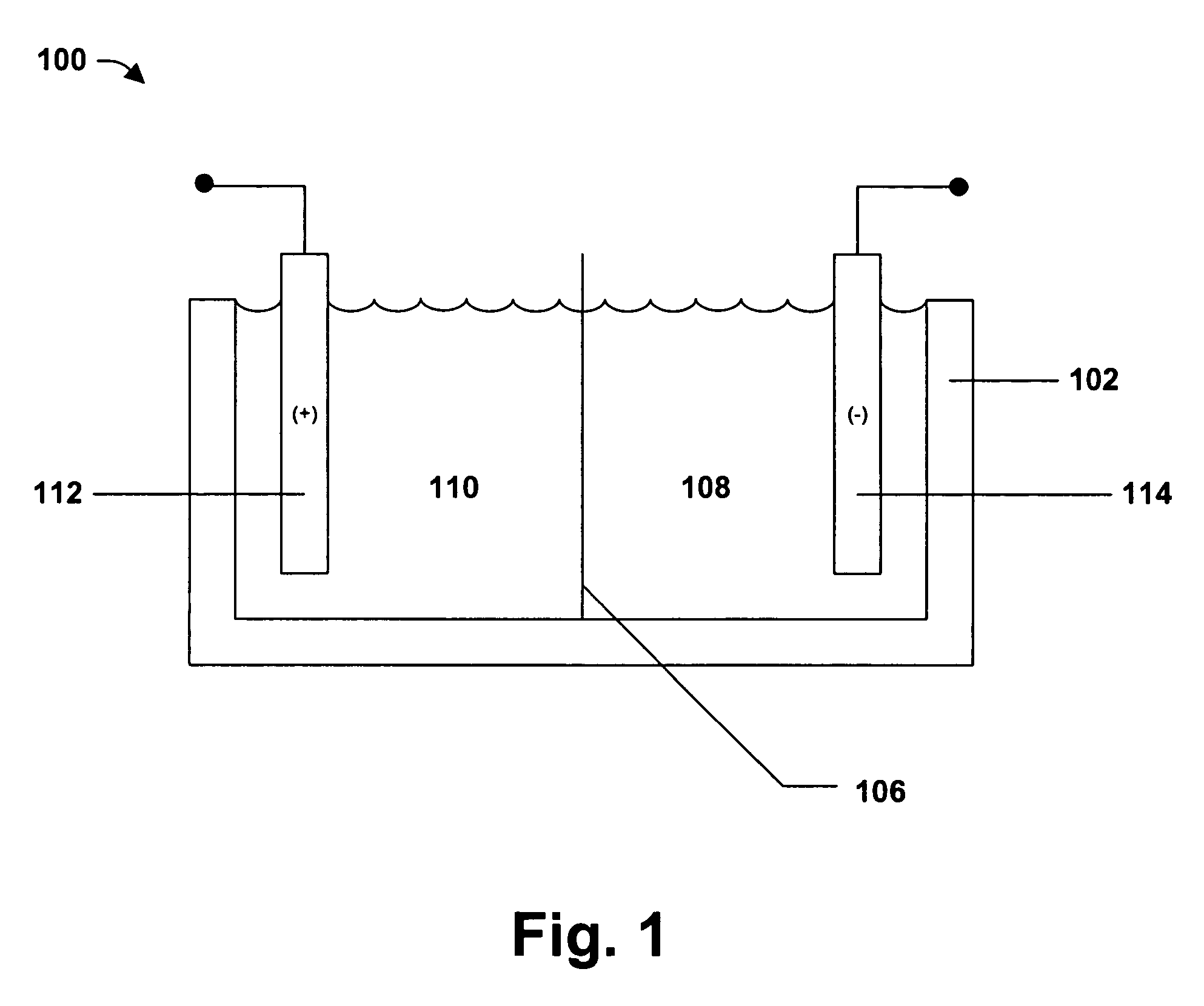

Disclosed are methods of electroplating a quaternary alloy containing nickel, cobalt, and at least two metal alloys involving providing an electroplating bath comprising ionic nickel, ionic cobalt, at least two ionic alloy metals, and at least one brightener; and applying a current to the electroplating bath whereby a quaternary alloy forms.

Owner:TASKEM

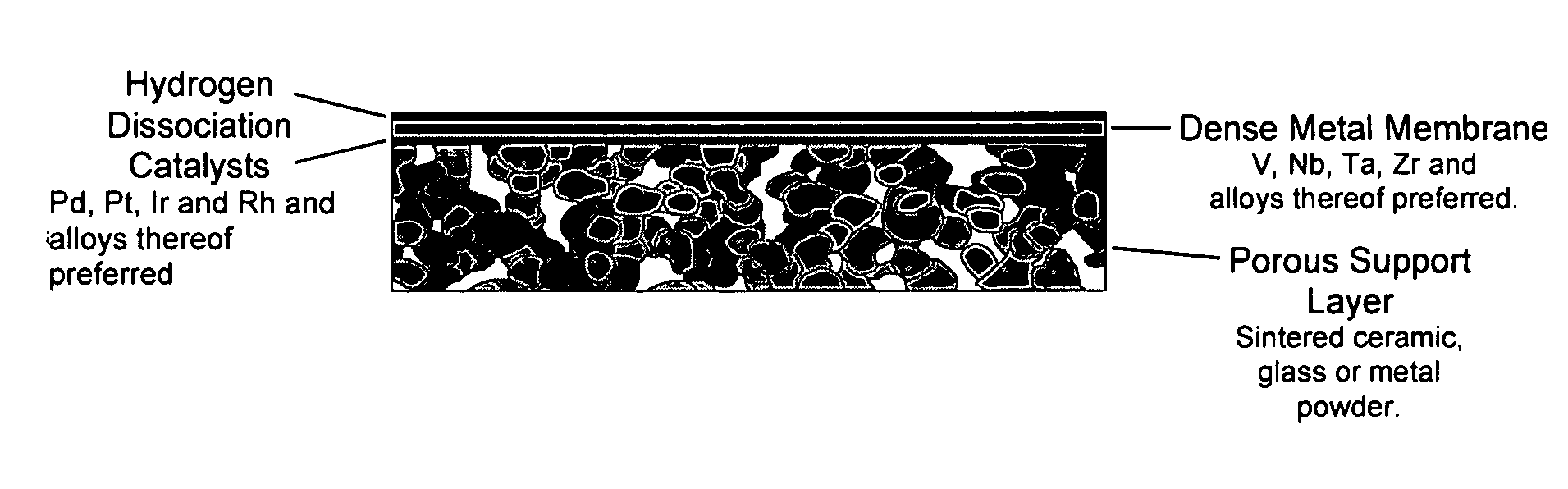

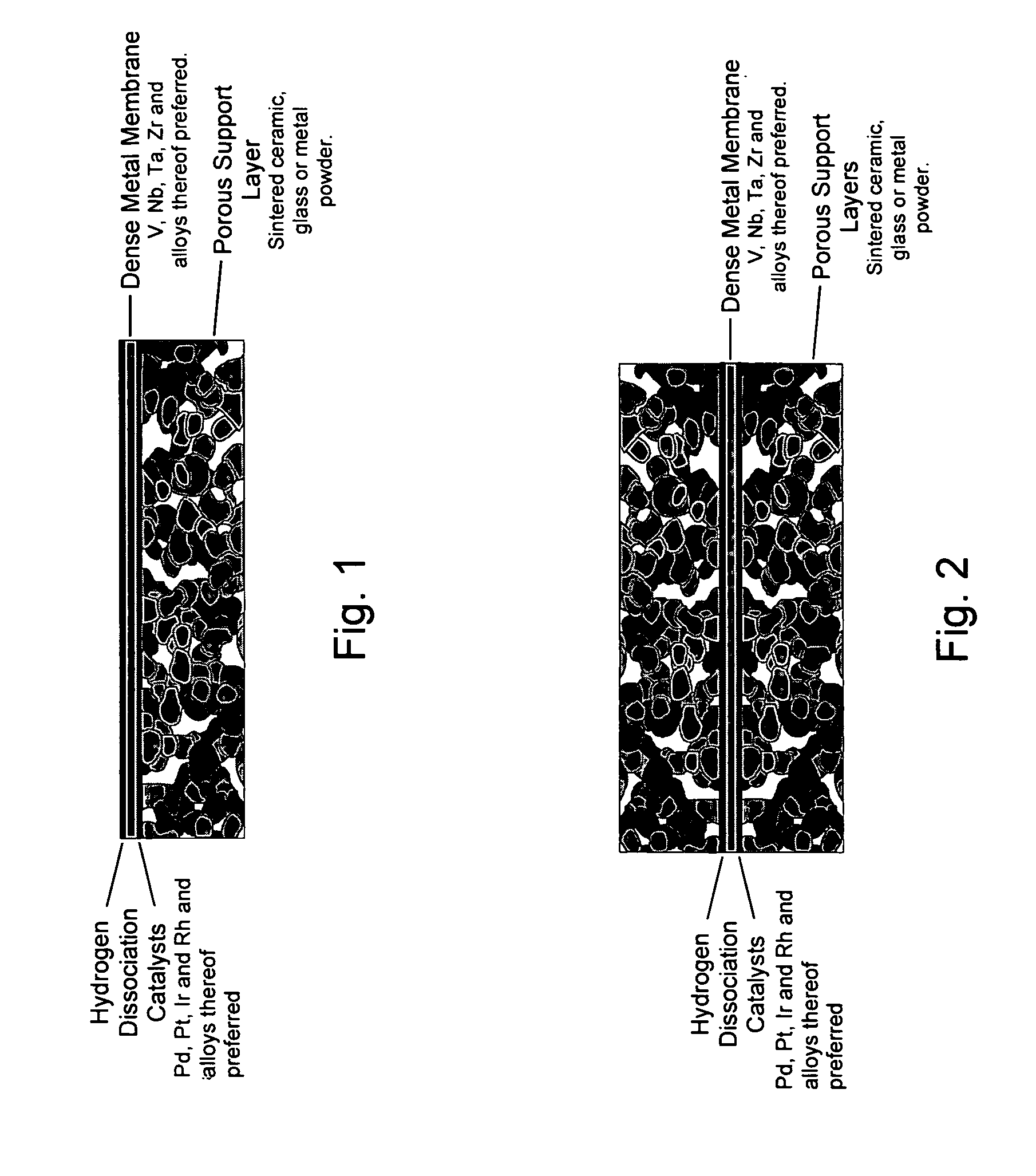

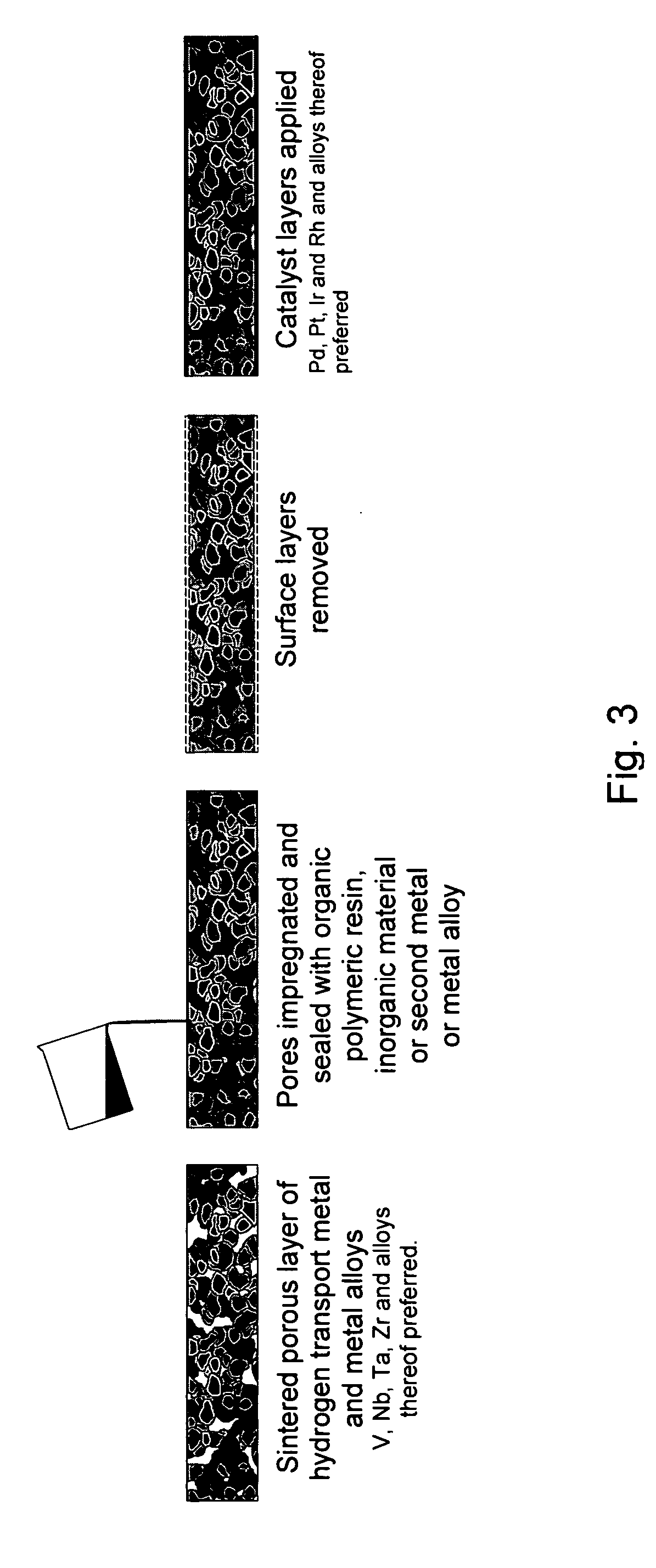

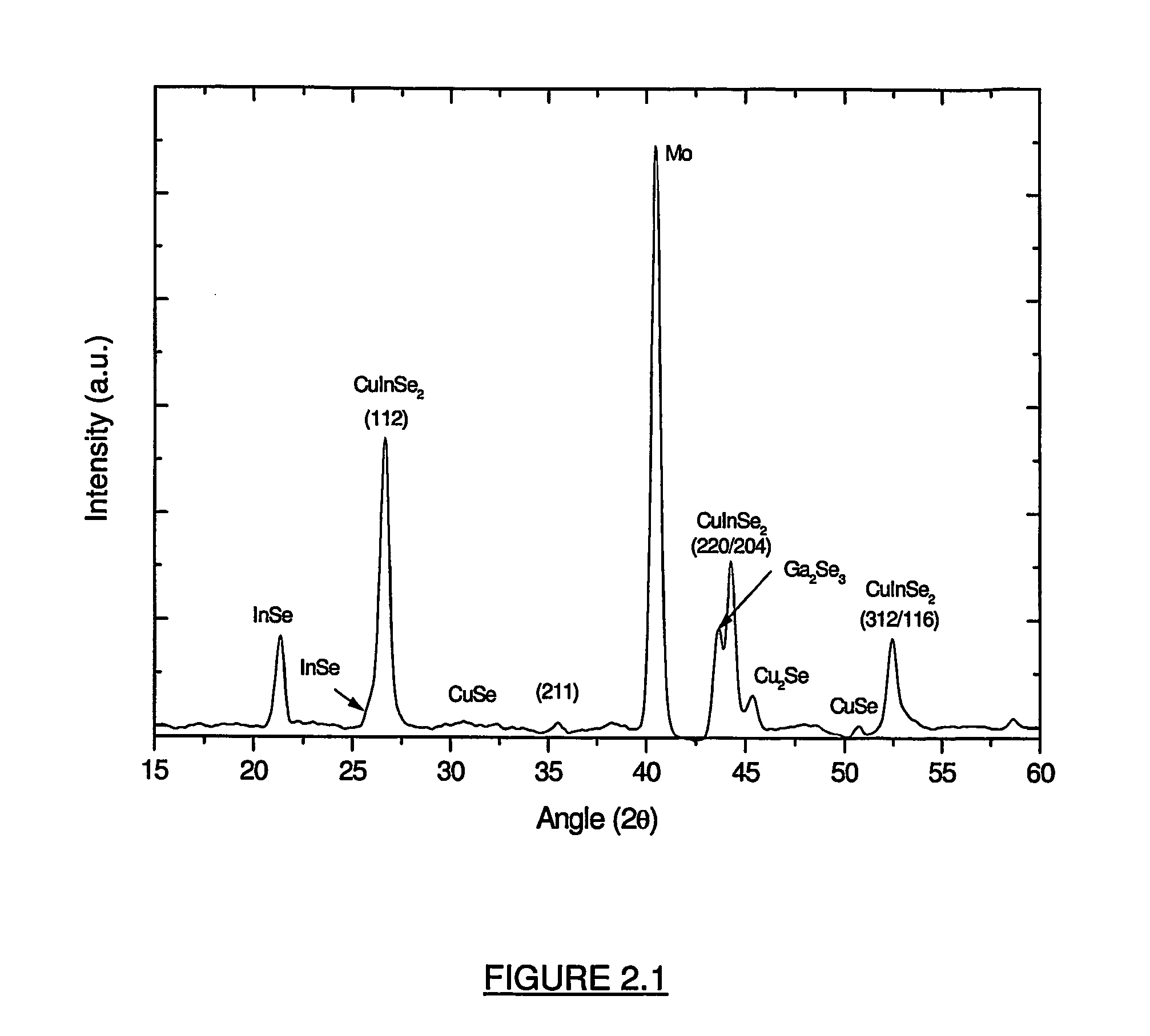

Hydrogen transport membranes

InactiveUS20050241477A1Thickness minimizationImprove permeabilitySemi-permeable membranesMembranesDifferential pressureMetal alloy

Composite hydrogen transport membranes used for extraction of hydrogen from gas mixtures are provided. Membranes are described comprising metals and metal alloys which exhibit high hydrogen permeability and which exhibit resistance to differential pressures across the membrane and wherein the metals and alloys are protected from embrittlement by hydrogen. Support materials of the membranes are selected in some cases to be lattice matched to the metals and alloys. In specific embodiments, membranes useful in the invention contain binary, ternary or quaternary alloys of vanadium which exhibit high hydrogen permeability and improved strength and / or longevity in application.

Owner:ELTRON RES

Car body aluminum alloy plate and manufacturing method thereof

InactiveCN103173661ALower yield strengthExcellent formabilityUltimate tensile strengthBake hardening

The invention provides a high-strength brake hardening car body aluminum alloy plate and a manufacturing method thereof, and belongs to the technical field of aluminum alloy. The aluminum alloy has the component characteristic that a Zn element is added on the basis of the conventional AL-Mg-Si-Cu quaternary alloy, so that the alloy has higher brake hardening performance; and interaction, strengthening-phase separation process and the like among solute elements are reasonably adjusted through reasonable pre-ageing process optimization control, and therefore, a novel car material Al-Mg-Si-Cu-Zn quinary aluminum alloy with excellent comprehensive performances is successfully developed. By adding the element Zn, the aluminum alloy material disclosed by the invention has the performance characteristic of being low in yield strength, good in plasticity and conductive to stamping and forming a car covering piece before baking finish; and after baking finish is finished, the yield strength is greatly improved, the tensile strength is high and the bake hardening performances are high.

Owner:UNIV OF SCI & TECH BEIJING +1

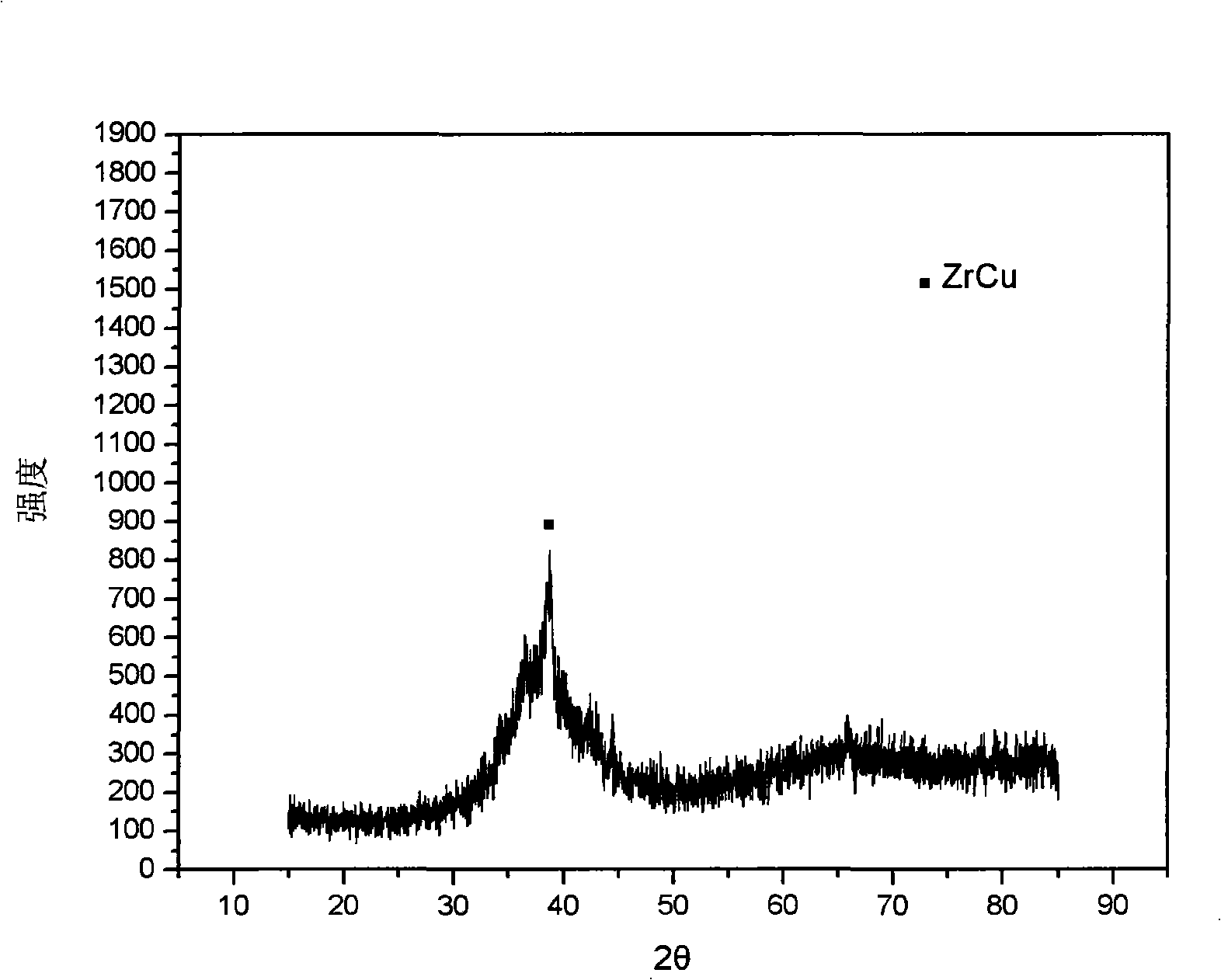

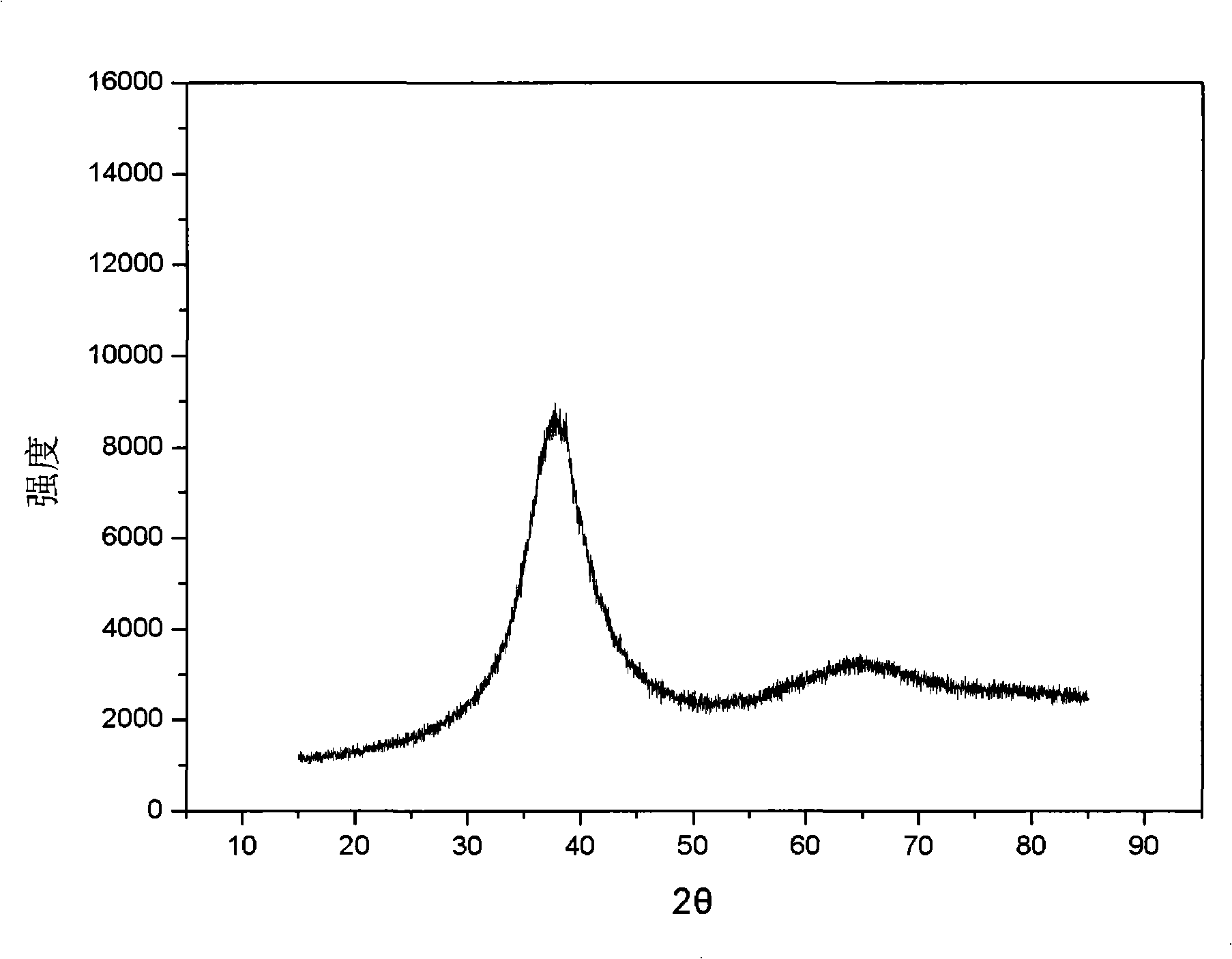

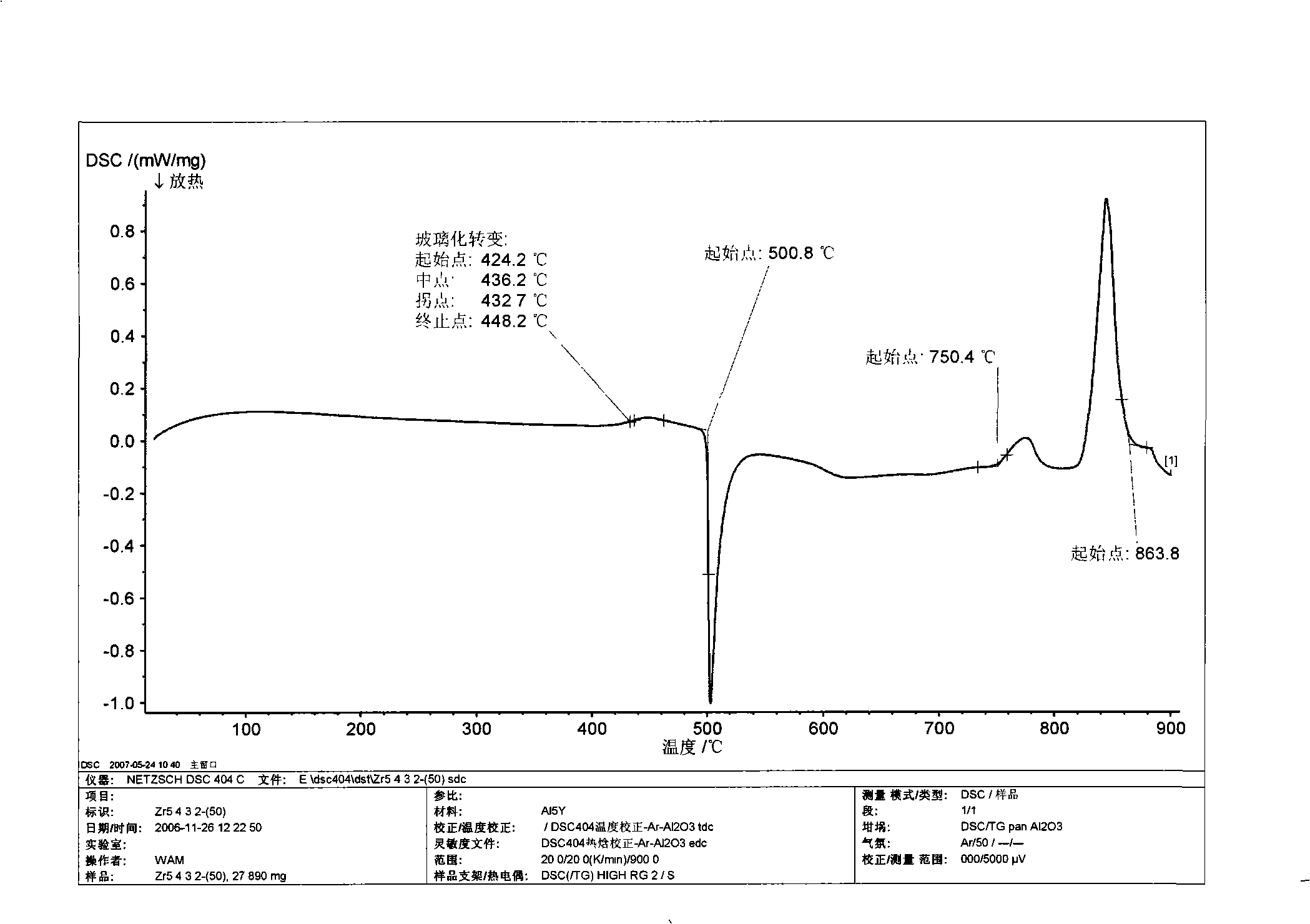

Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

The invention relates to a preparation technology of a block zirconium-base amorphous alloy, in particular to a Zr-Cu-Ni-Al-Ag alloy with higher glass-forming ability and a preparation method thereof, and the characteristic thermodynamics parameter and the mechanical property of the alloy are characterized and tested at the same time. The alloy system is the Zr-Cu-Ni-Al-Ag alloy, which has the component ranges (by atom percentage) that Zr is 41 to 63, Cu is 18 to 46, Al is 4 to 15, Ni is 1.5 to 12.5, and Ag is 1.5 to 26. Based on a Zr-Cu-Ni-Al quaternary alloy, the forming ability of the amorphous alloy is increased through inhibiting the precipitation of a crystalline state phase. The preparation technology adopts an electric arc melting method to prepare a master alloy ingot, then adopts a copper mold casting method to prepare amorphous alloy rods with different diameters, and the alloy in the system can easily prepare amorphous round bars, the diameter of which can reach 2cm. Due to stronger amorphous forming ability and good mechanical property, the alloy has good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

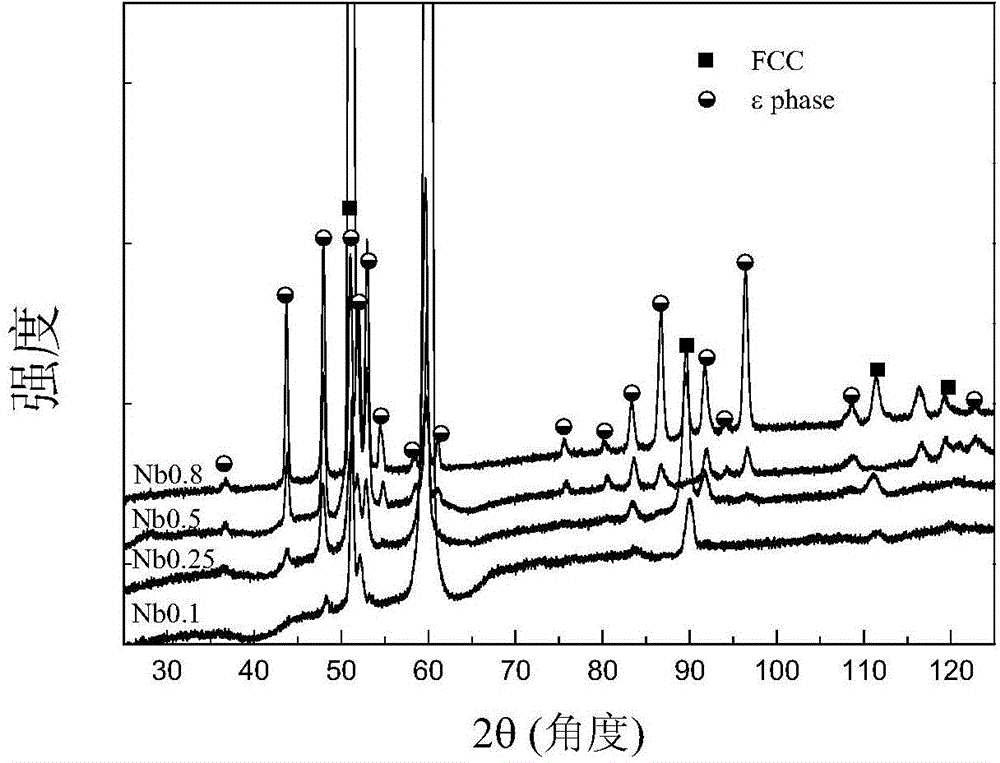

CrFeCoNiNbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

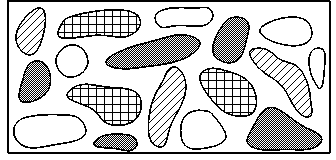

Zinc-containing multiphase liquid metal thermal interface material and preparation method thereof

The invention discloses a zinc-containing multiphase liquid metal thermal interface material and a preparation method thereof. The zinc-containing multiphase liquid metal thermal interface material comprises the following components: by weight, 30-40% of bismuth, 10-20% of tin, 10-20% of zinc, and the balance of indium. The multiphase structure liquid metal thermal interface material designed by the invention is a quaternary alloy, is completely in a solid structure at room temperature and rolling temperature, and in a liquid-solid state at working temperature. In the working status, the solid content is about 60%. The multiphase structure liquid metal thermal interface material can maintain the liquid-solid state in a large range of working temperature, can fully inhibit the heated melting fluidity of a low melting point alloy foil, and can eliminate the liquid droplet leak problem. In addition, the thermal interface material thickness remains in the vicinity of 0.04mm, and the liquid phase surface tension can be further used to achieve the anti leakage effect..

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

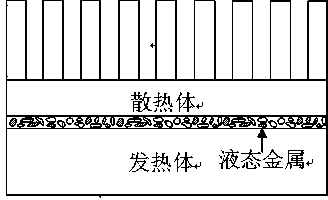

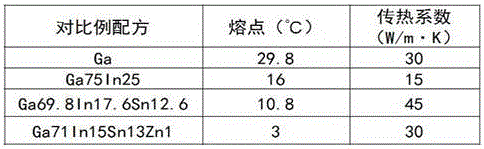

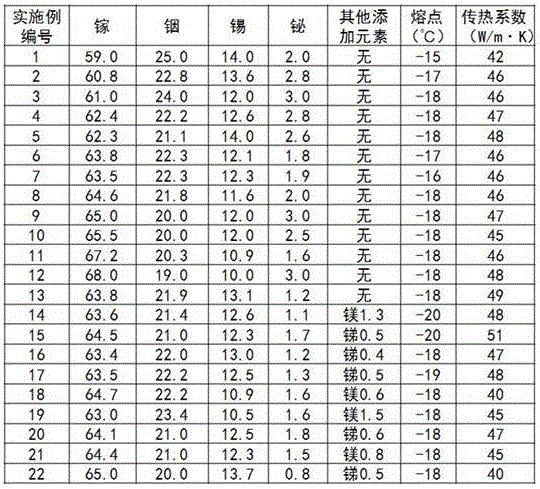

Novel liquid metal, and preparation method and application thereof

The invention discloses a novel liquid metal which is composed of the following components in percentage by mass: 59-68% of gallium, 19-25% of indium, 10-14% of tin and 0.5-3% of bismuth quaternary alloy. The novel liquid metal can also comprise 0.4-1.5 wt% of magnesium, niobium or antimony. By improving the composition of the gallium-base liquid metal, the invention provides a low-melting-point novel liquid metal. The liquid metal has the advantages of fewer alloy components and stable microstructure, effectively avoids the aberration probability in the microstructure, and can be used as a high-efficiency heat dissipation material in heat dissipation products.

Owner:深圳市煦阳新材料技术有限公司

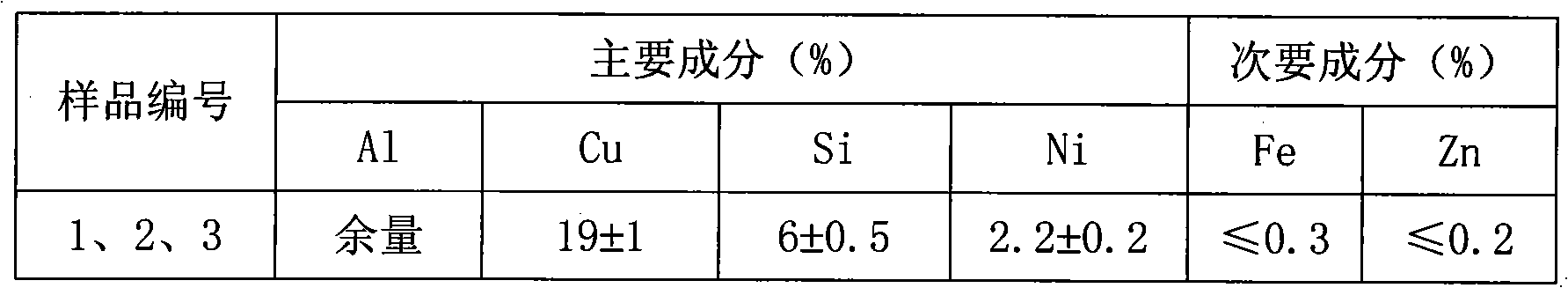

Al-Si-Cu-Ni alloy state foil-shaped brazing material and preparation method thereof

InactiveCN101811237AExtend usabilityExpand the scope of useWelding/cutting media/materialsSoldering mediaIntermediate frequencyIngot

The invention relates to a preparation method of an Al-Si-Cu-Ni alloy state foil-shaped brazing material, which comprises the following steps of: (1) confirming the components of brazing material alloy raw material: weighing a quaternary alloy component comprising about 18-20 percent of Cu, about 5.5-6.5 percent of Si, 2.0-2.4 percent of nickel and the balance of aluminum as a basic component of a low-temperature aluminum brazing material; (2) preparing intermediate alloy, wherein the intermediate alloy needing casting comprises the intermediate alloy of Al-Cu50 and Al-Si30, and the nonvaccum intermediate frequency furnace smelting is adopted in preparation; (3) smelting and casting a brazing material alloy plate; casting an alloy ingot by adopting a nonvaccum intermediate frequency inducing furnace; (4) heating to 400 DEG C in an annealing furnace and preserving the temperature for more than 12 hours to remove cast ingot segregation and tiny defects; (5) hot rolling and coldly rolling for molding. The prepared brazing material has a melting point of 518-538 DEG C, a width larger than 100 mm and a thickness 0.07-0.15 mm.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST +1

III-nitride light emitting device with reduced polarization fields

ActiveUS20050169333A1Reduced polarization fieldAvoid the inefficiencies causedLaser detailsSolid-state devicesIndiumNitrogen

A semiconductor light emitting device includes a light emitting layer sandwiched between two spacer layers. The difference between the net polarization in at least one of the spacer layers and the net polarization in the light emitting layer is less than in the device with conventional spacer layers, such as GaN spacer layers. The difference between the net polarization in at least one of the spacer layers and the net polarization in the light emitting layer is less than about 0.02 C / m2. In some embodiments, at least one of the spacer layers is a quaternary alloy of aluminum, indium, gallium, and nitrogen.

Owner:LUMILEDS

Electroplating technology for bearing quaternary alloy

The invention relates to a technology for electroplating quaternary alloy at the inner surface of a bearing, comprising the steps of ultrasonic oil removal, chemical oil removal, electrochemical oil removal, electrolysis pickling, pickling, electronickelling of grid, recovery, electroplating of Pb-Sn-Cu alloy, electroplating of indium layer; washing with hot water, drying, heat diffusion treatment, etc., the bearing quaternary alloy formed by four metallic chemical elements including lead, tin, copper and indium has firm bonding with substrate, good fatigue strength, carrying capacity and abrasive resistance, long service life, strong corrosive resistance and surface performance and high added value, and is widely used as a surface treatment technology for the bearing on aircraft engine, high-performance car, ship and heavy-duty vehicle engine.

Owner:四川双飞虹精密部件有限公司

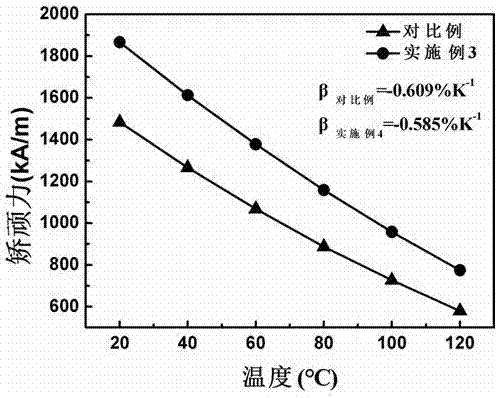

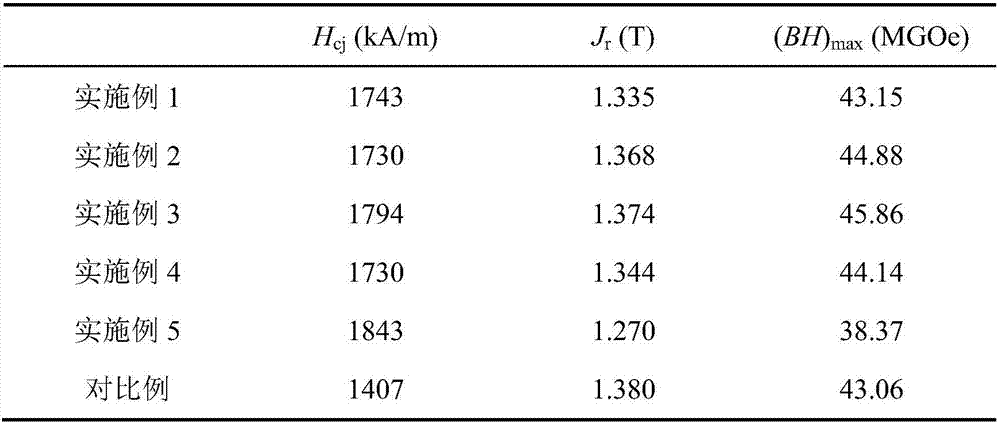

Crystal boundary diffusion method for improving coercive force and thermal stability of neodymium-iron-boron magnet

InactiveCN107093516ADiffusion rate is fastInhibit growthInductances/transformers/magnets manufactureRare earthHeat treated

The invention discloses a crystal boundary diffusion method for improving the coercive force and the thermal stability of a neodymium-iron-boron magnet, and belongs to the field of rare earth permanent magnet materials. According to the method, a quaternary alloy Dy-Ni-Al-Cu with a low melting point is used as a diffusion source and melted and prepared into a rapid-hardening strip, after coarse breaking, the strip casting is laid around the neodymium-iron-boron magnet, and by the adoption of a heat treatment method, the rapid-hardening strip diffuses and enters the magnet along the crystal boundary. After the processing, the coercive force of the magnet is significantly improved, and the magnetic energy product is improved to a certain extent; meanwhile, since the temperature of the diffusion treatment is low, energy consumption can be reduced, the cost can be lowered, and Nd2Fe14B crystal grains can be prevented from growing up; compared with a coating and magnetron sputtering method, the crystal boundary diffusion method omits a powder preparing and coating process in a coating technology and a thin film preparing process in a magnetron sputtering technology. After the technology processing of the crystal boundary diffusion method, the neodymium-iron-boron magnet with the high coercive force and the high thermal stability is finally obtained.

Owner:SOUTH CHINA UNIV OF TECH

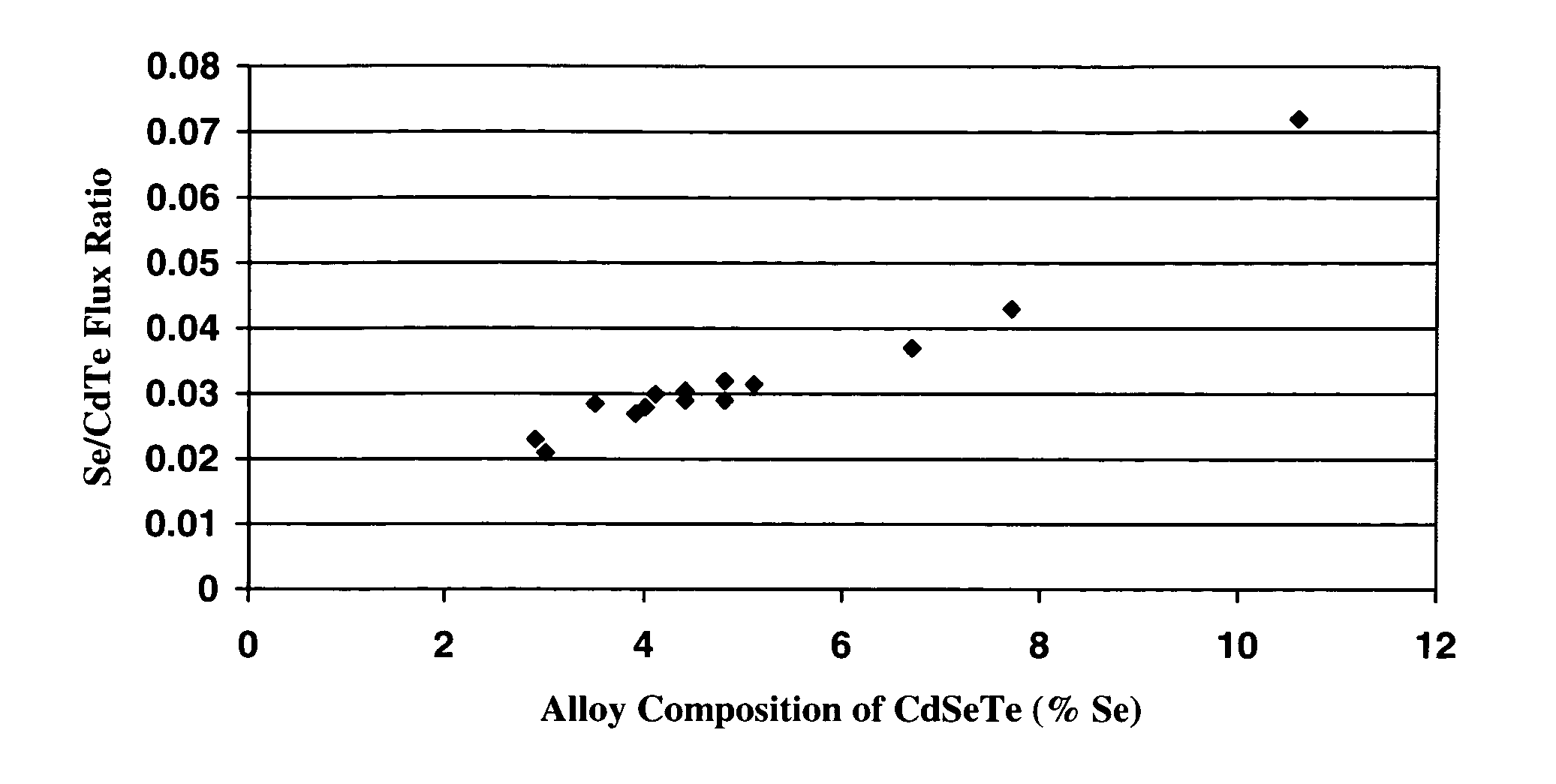

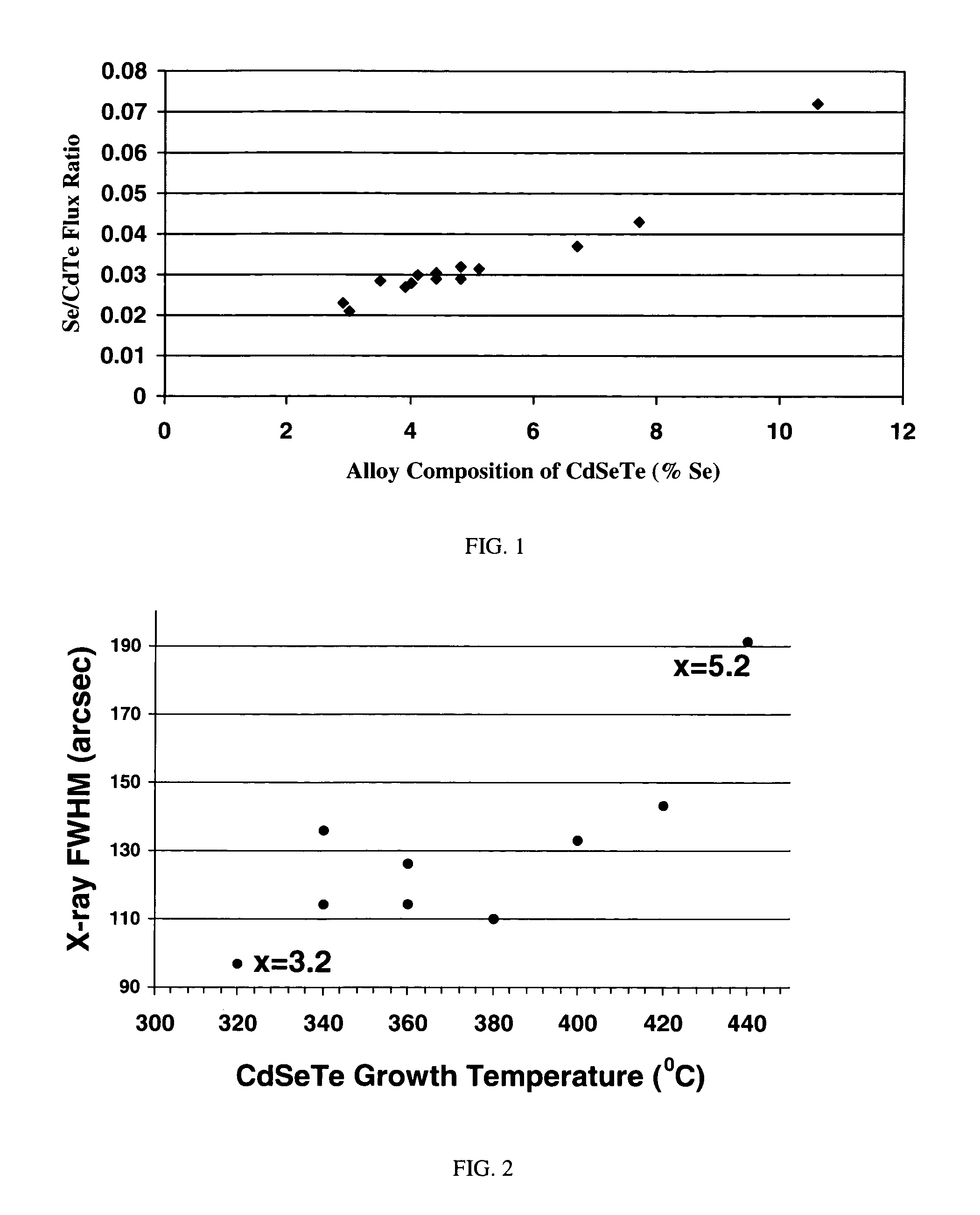

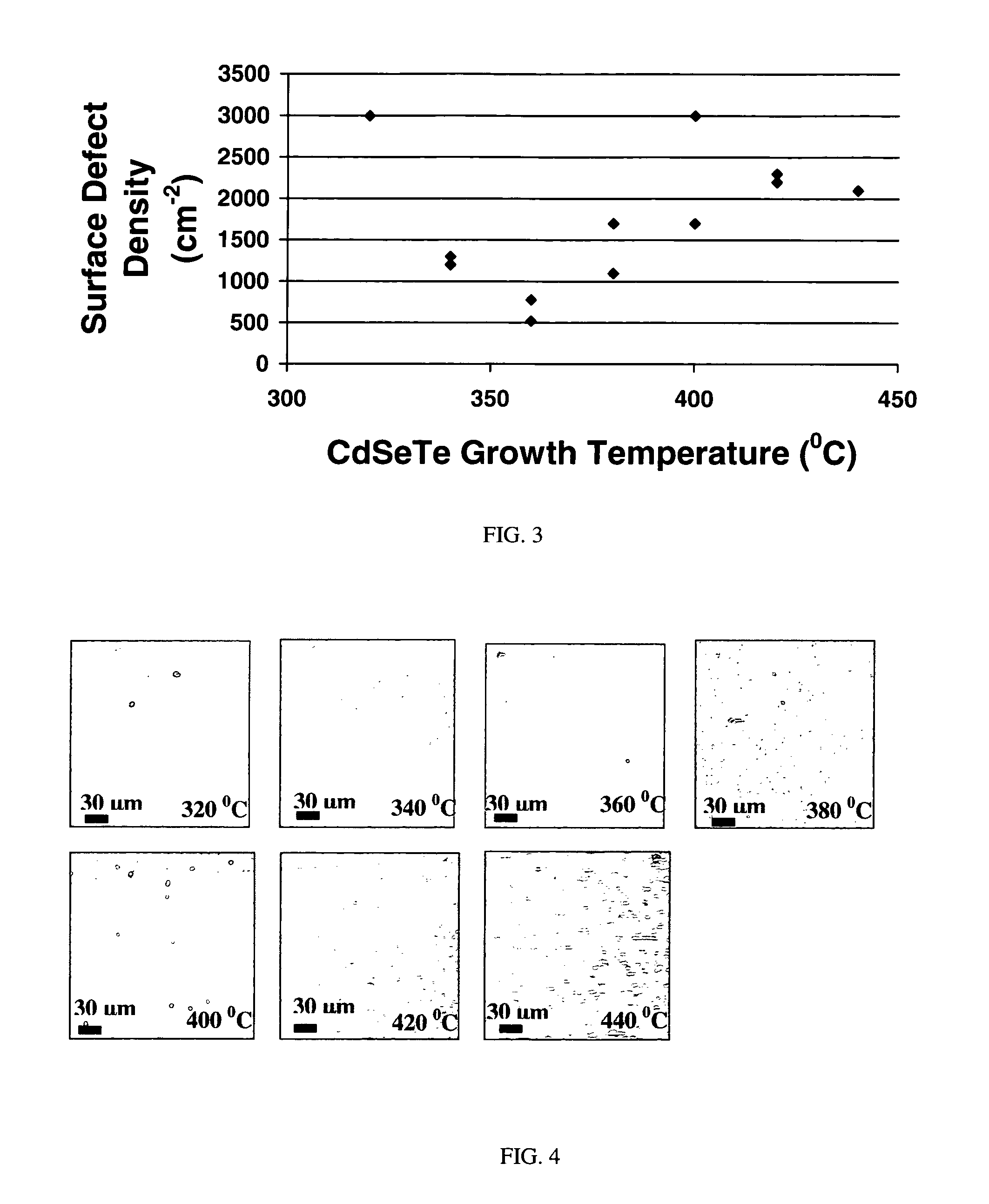

Molecular beam epitaxy growth of ternary and quaternary metal chalcogenide films

InactiveUS7518207B1Improve surface morphologyReduce surface defect densitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationRocking curveSulfur

The ternary alloy CdSexTe1-x(2 1 1) and the quaternary alloy Cd1-zZnzSexTe1-x have been grown on Si(2 1 1) substrates using molecular beam epitaxy (MBE). The growth of CdSeTe is facilitated using a compound CdTe effusion source and a Se effusion source while the growth of CdZnSeTe is facilitated using a compound CdTe effusion source, a compound ZnTe effusion source, and an elemental Se source. The alloy compositions (x) and (z) of CdSexTe1-x ternary compound and Cd1-zZnzSexTe1-x are controlled through the Se / CdTe and ZnTe / CdTe flux ratios. The rate of Se incorporation is higher than the rate of Te incorporation as growth temperature increases. As-grown CdSeTe with 4% Se and CdZnSeTe with 4% Zn+Se, which is substantially lattice matched to long-wavelength infrared HgCdTe materials, exhibits excellent surface morphology, low surface defect density (less than 500 cm2), and a narrow X-ray rocking curve (a full-width at half maximum of 103 arcsec).

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

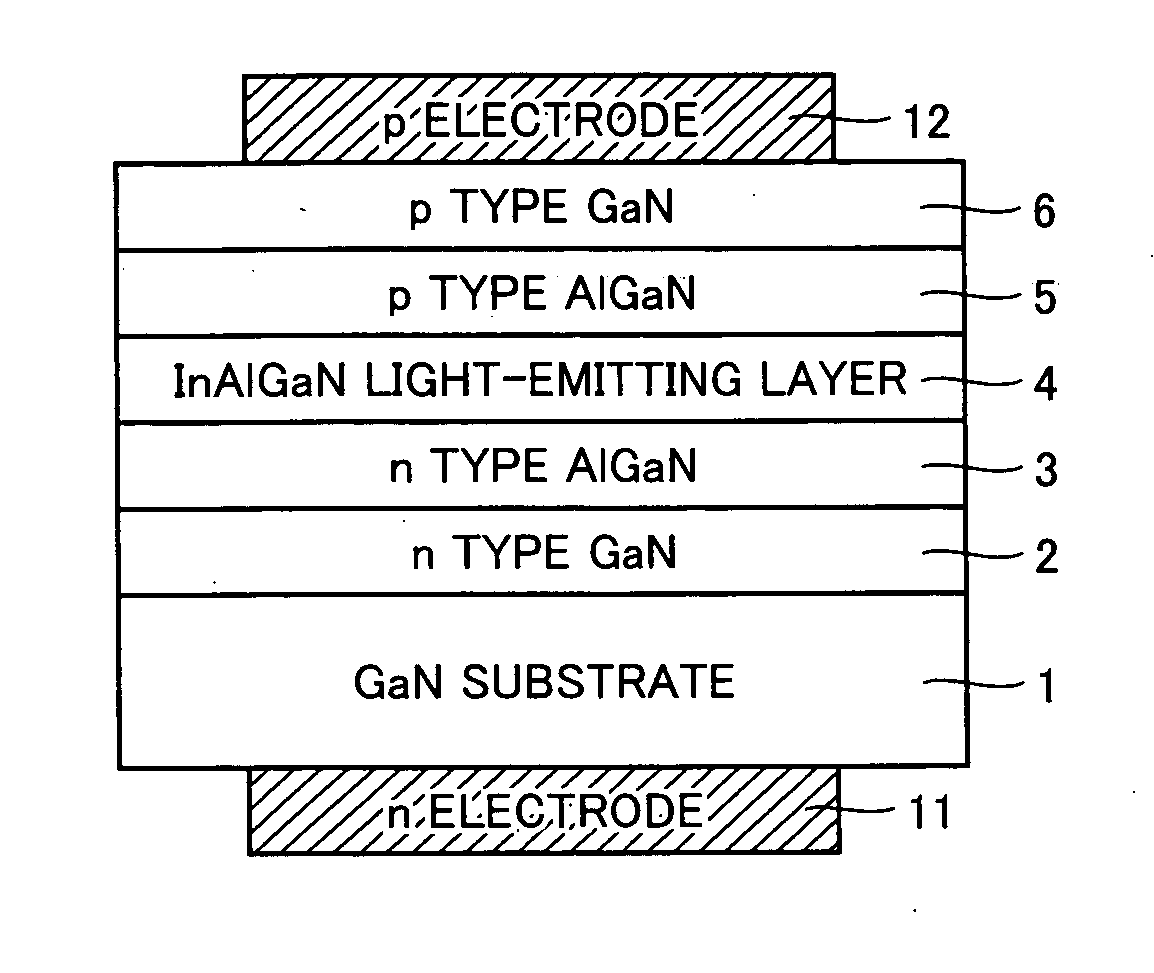

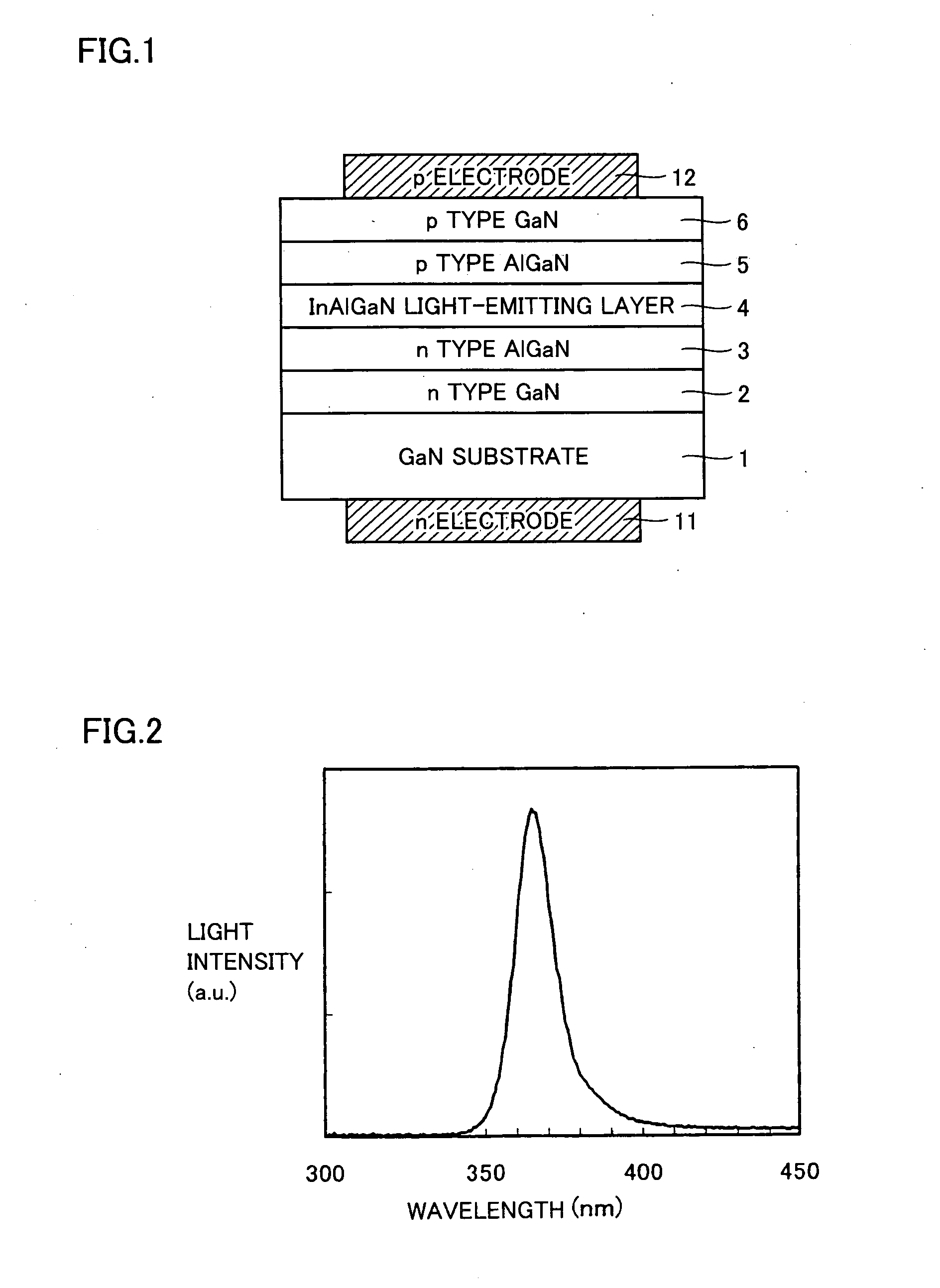

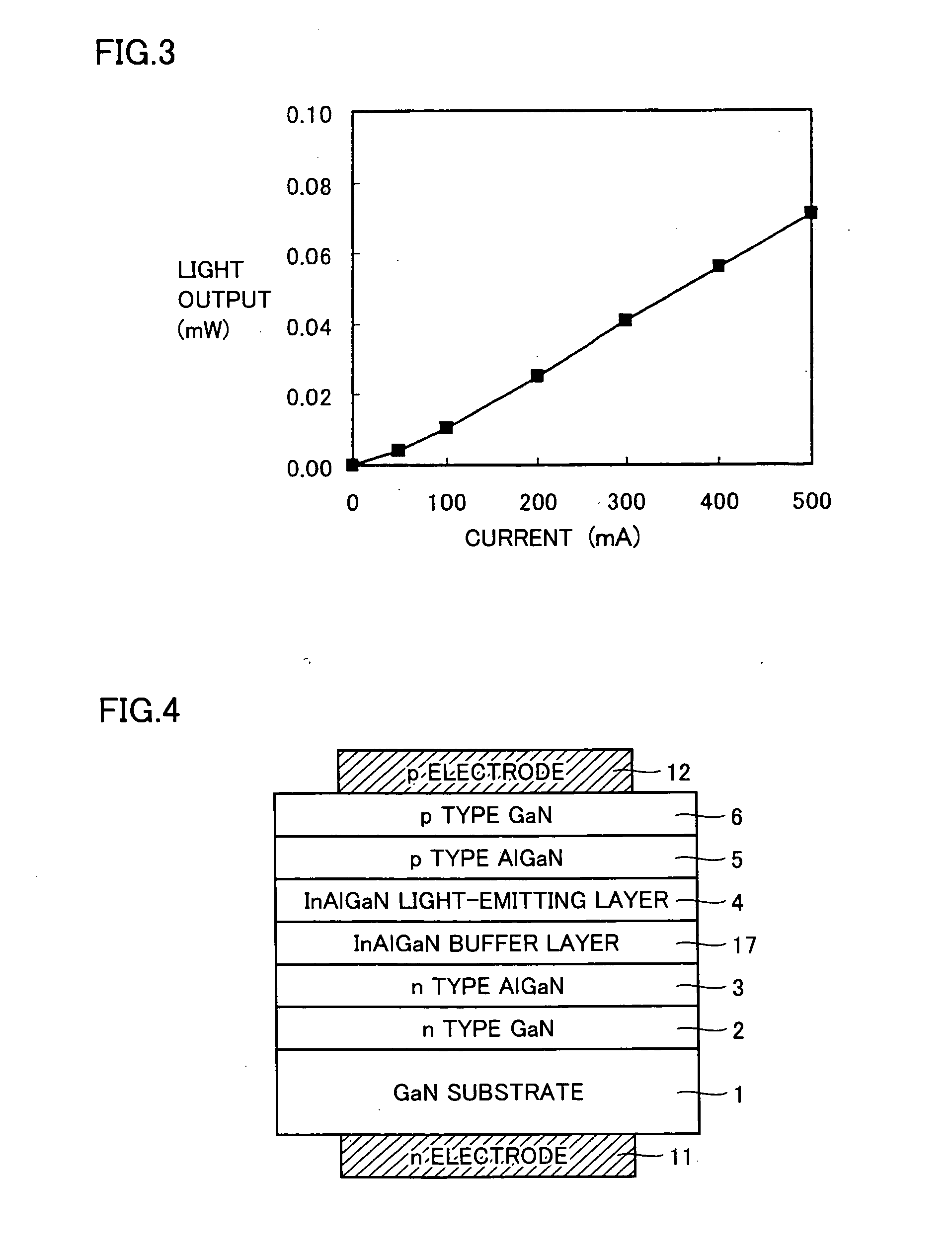

Light-emitting device and manufacturing method thereof

InactiveUS20050040414A1Highly efficient light emissionImprove emission efficiencyPhotovoltaic energy generationSemiconductor devicesLight emissionLight emitting device

To provide a light-emitting device using a nitride semiconductor which can attain high-power light emission by highly efficient light emission and a manufacturing method thereof, the light-emitting device includes a GaN substrate and a light-emitting layer including an InAlGaN quaternary alloy on a side of a first main surface of GaN substrate.

Owner:SUMITOMO ELECTRIC IND LTD +1

Nickel-free black tin cobalt alloy plating solution and electroplating technology by using same

The invention relates to a nickel-free black tin cobalt alloy plating solution and an electroplating technology by using same. The parameters and contents of all components of the plating solution are as follows: the content of tin ions in a tin salt is 0.05-6g / L; the content of cobalt ions in a cobalt salt is 0.05-0.8g / L; the content of third metallic ions is 0.02-50g / L; the content of a complexing agent is 0.1-180g / L; the content of a blacking agent is 0.1-50g / L; the content of a PH buffer is 5-300g / L; the baume degree of the plating solution is 6-250; the temperature is 20-55 DEG C; and PH is 9-13. According to the technology provided by the invention, tin is taken as a main alloy layer and few cobalt and third and fourth metal ions are added in tin to form a ternary or quaternary alloy system; the cobalt content in the common black tin cobalt alloy plating solution excesses 8g / L, but the cobalt content is reduced to 0.05g / L according to the new electroplating technology provided by the invention; the special biodegradable or non-biodegradable stabilizing complexing agent and PH buffer are used, so that the production cost is lowered; and the nickel-free black tin cobalt alloy plating solution meets the limitation requirement on CO in the European Union Rosh standard, Germany LMBG standard, Mattel children toy standard, European Oeko-Tex Standard 100 standard and the like.

Owner:杜强

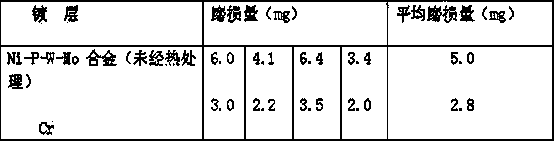

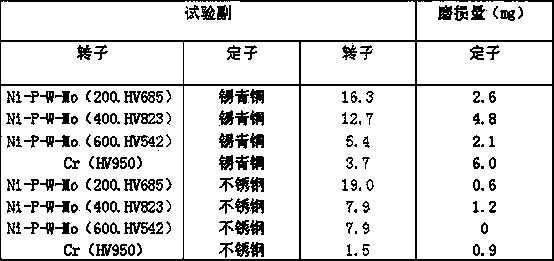

Environment-friendly type high hydrogen sulfide resistant and high wear-resistant Ni-P-W-Mo quaternary alloy plating solution and its preparation method

ActiveCN103352213AStable structureImprove corrosion resistanceLiquid/solution decomposition chemical coatingSodium acetateFood additive

Belonging to the technical field of surface treatment technologies, the invention provides a high hydrogen sulfide resistant and high wear-resistant environment-friendly type Ni-P-W-Mo quaternary alloy plating solution. Per liter of the plating solution comprises: 28-35g of nickel sulfate or nickel chloride, 35-44g of sodium hypophosphite, 11-15g of sodium acetate, 8-9ml of lactic acid, 12-15g of DL malic acid, 5-7g of succinic acid, 0.2-0.4ml of a brightening agent, 0.1-0.2ml of a complexing agent, 0.08-0.12ml of a stabilizer, and the balance water. The plating solution realizes chemical plating of W-Mo quaternary alloy, an also, except a main salt, the used materials all adopt food additives as attached salts. And there exists no heavy metal ion environmental pollution.

Owner:宝鸡聚和信装备技术有限公司

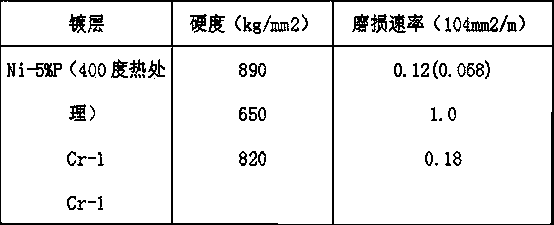

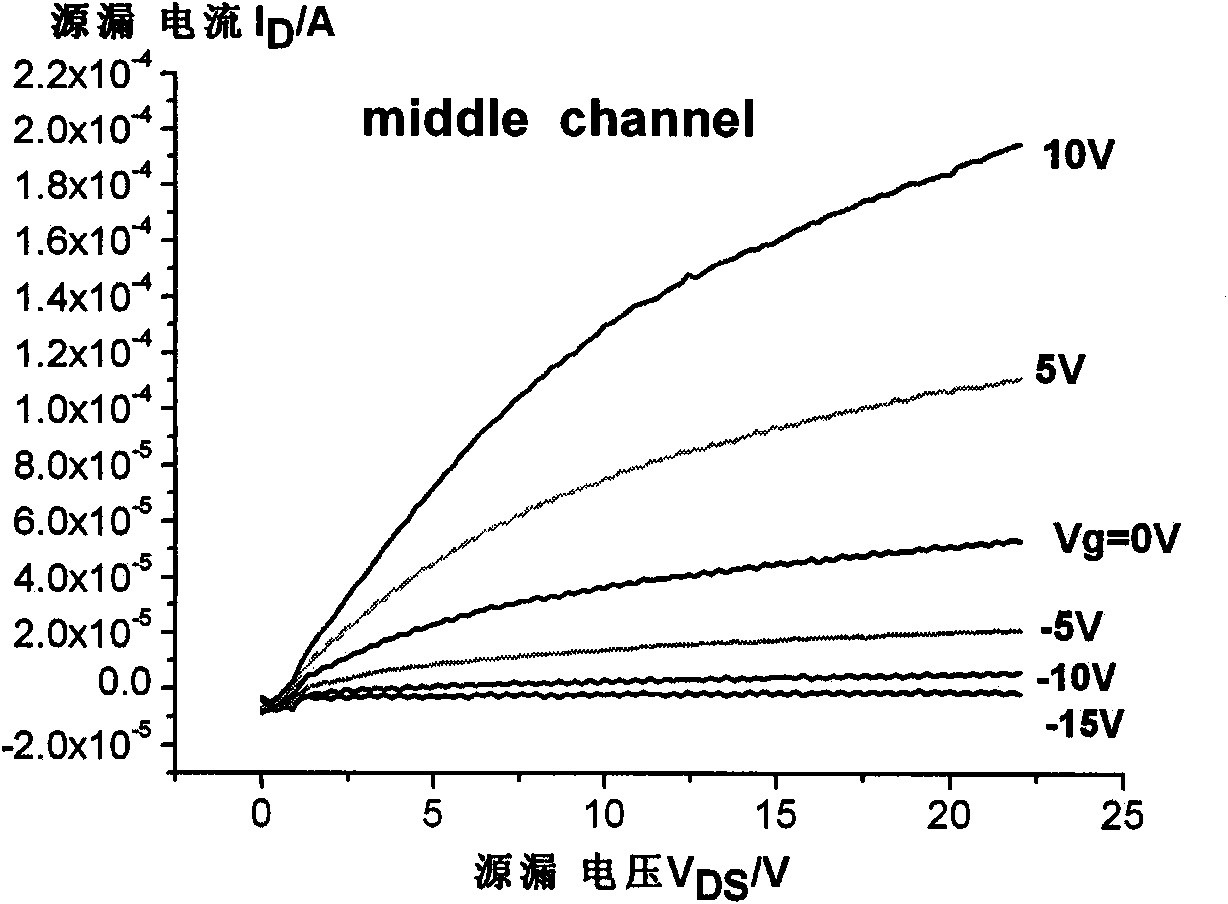

Method for preparing transparent thin-film transistor of alloyed oxide

InactiveCN101615582AImprove flexibilityHigh electron mobilitySemiconductor/solid-state device manufacturingEtchingBottom gate

The invention relates to a method for preparing a transparent thin-film transistor at low temperature. A small amount of In2O3 and SnO2 are mixed in ZnO to form a transparent ZnInSnO quaternary alloy semiconductor thin film to be a channel layer, the method is compatible with the technology for preparing flat displays and the like at low temperature, the transparent thin-film transistor is prepared by magnetron sputtering low-temperature growth, and the technology of the combinations of bottom-gate structure and lithography, chemical wet etching and stripping is adopted. Compared with the existing silicon-based TFT technology, oxide TFT has the characteristics of transparent visible light, high migration rate, low preparing temperature and the like. The transparent thin-film transistor can be applied to active-matrix liquid crystal display devices, printers, copiers and cameras and the like.

Owner:ZHEJIANG UNIV

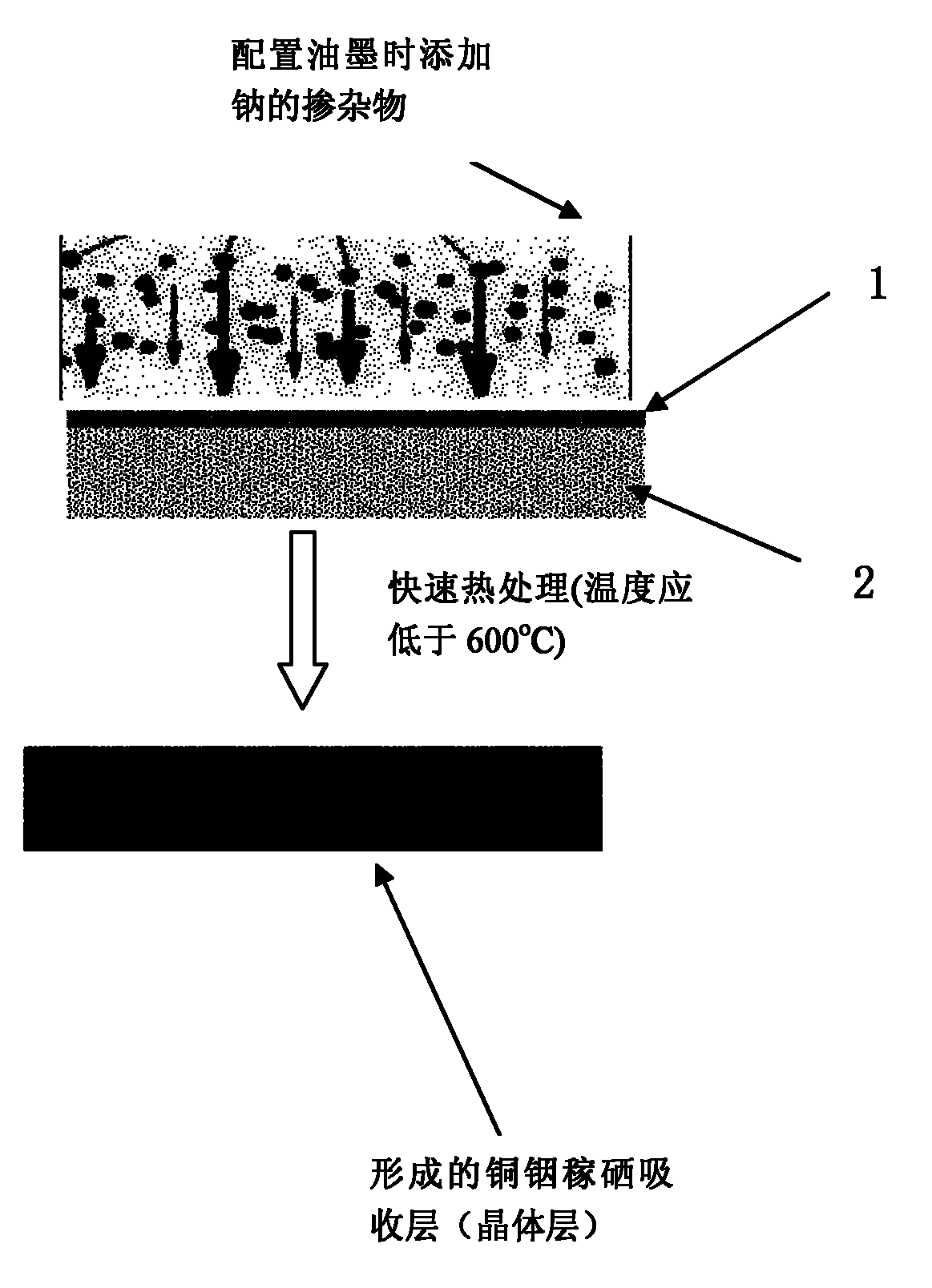

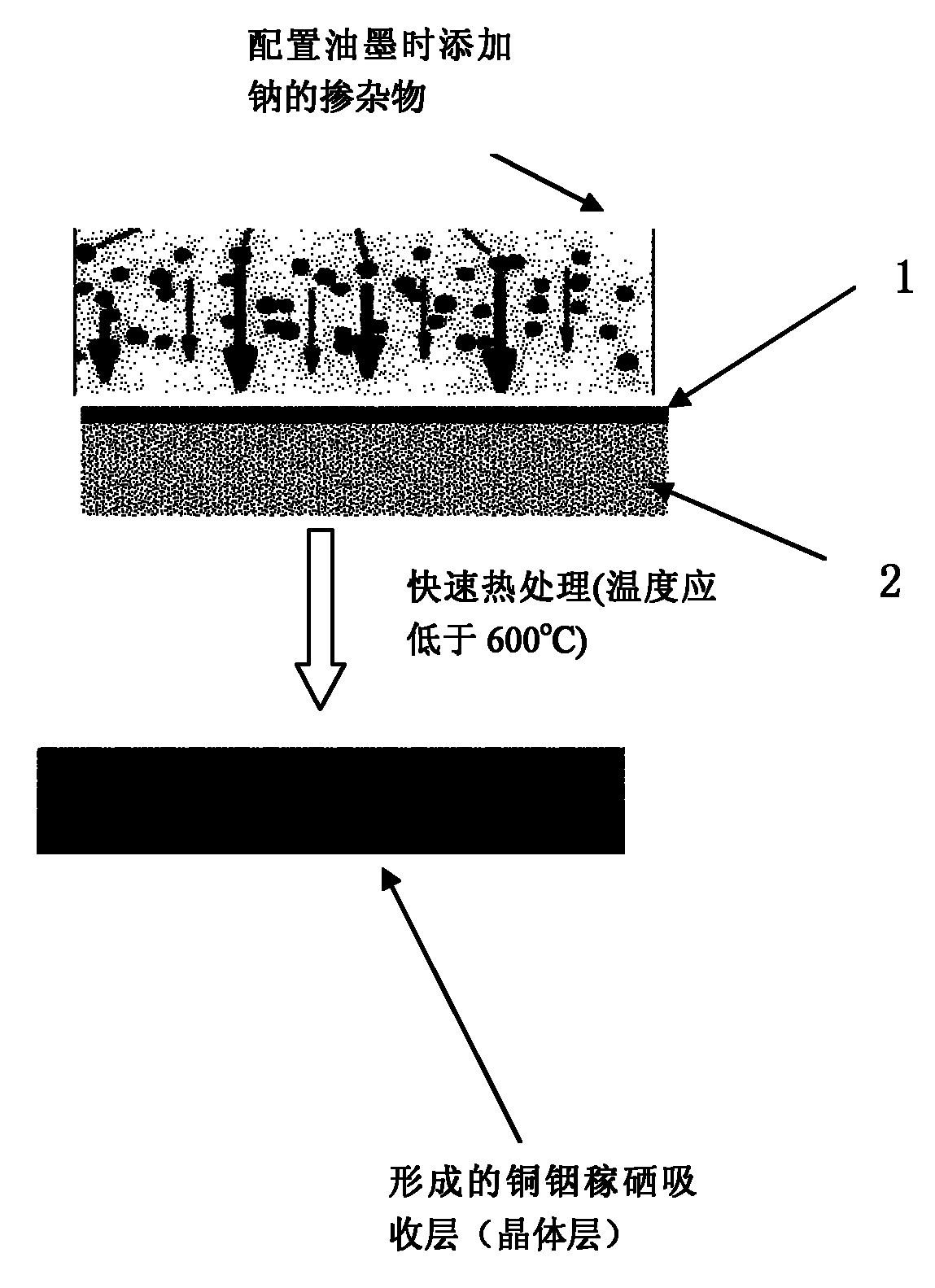

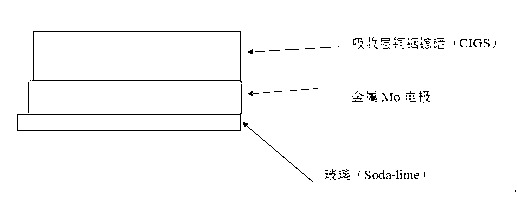

Preparation method of high-uniformity copper-indium-gallium-selenium (CIGS) absorbed layer

InactiveCN101944556AImprove uniformityIncrease the granular structureFinal product manufactureSemiconductor devicesIndiumPrinting ink

The invention discloses a preparation method of a high-uniformity copper-indium-gallium-selenium (CIGS) absorbed layer, which is characterized by comprising the following steps: preparing printing ink by using CIGS containing different particle sizes or binary, ternary and quaternary alloy nanoparticles thereof, preparing the CIGS absorbed layer of a thin film solar cell by using a simple multilayer jet-printing method, and enhancing the grain structure and film forming uniformity of the CIGS absorbed layer through rapid heat treatment. In the invention, the CIGS absorbed layer is prepared under a non-vacuum condition, thus avoiding using expensive vacuum equipment; and the preparation method has the advantages of simple process and easy control and can help obtain the high-uniformity CIGS absorbed layer.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH

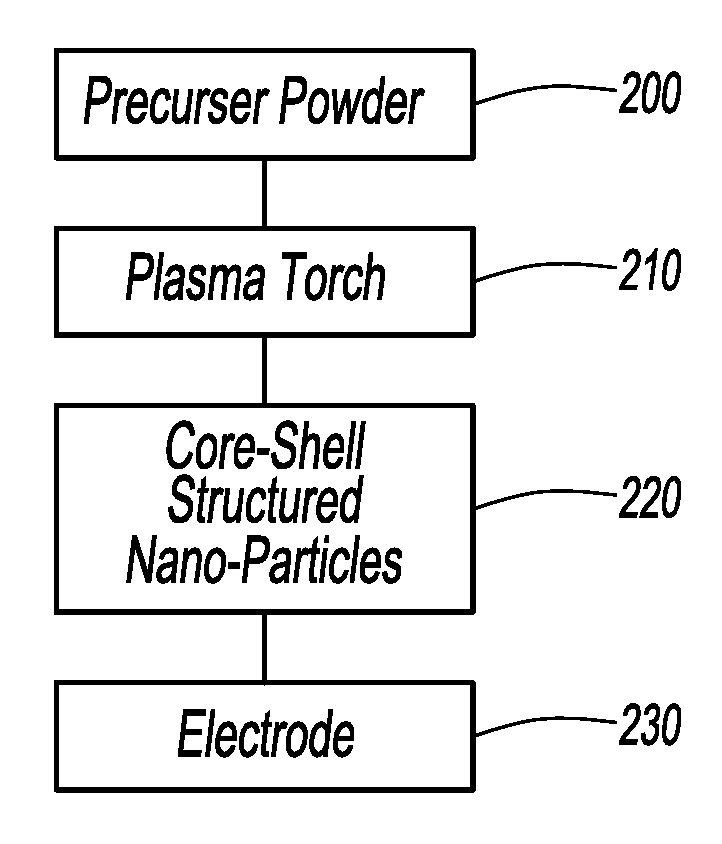

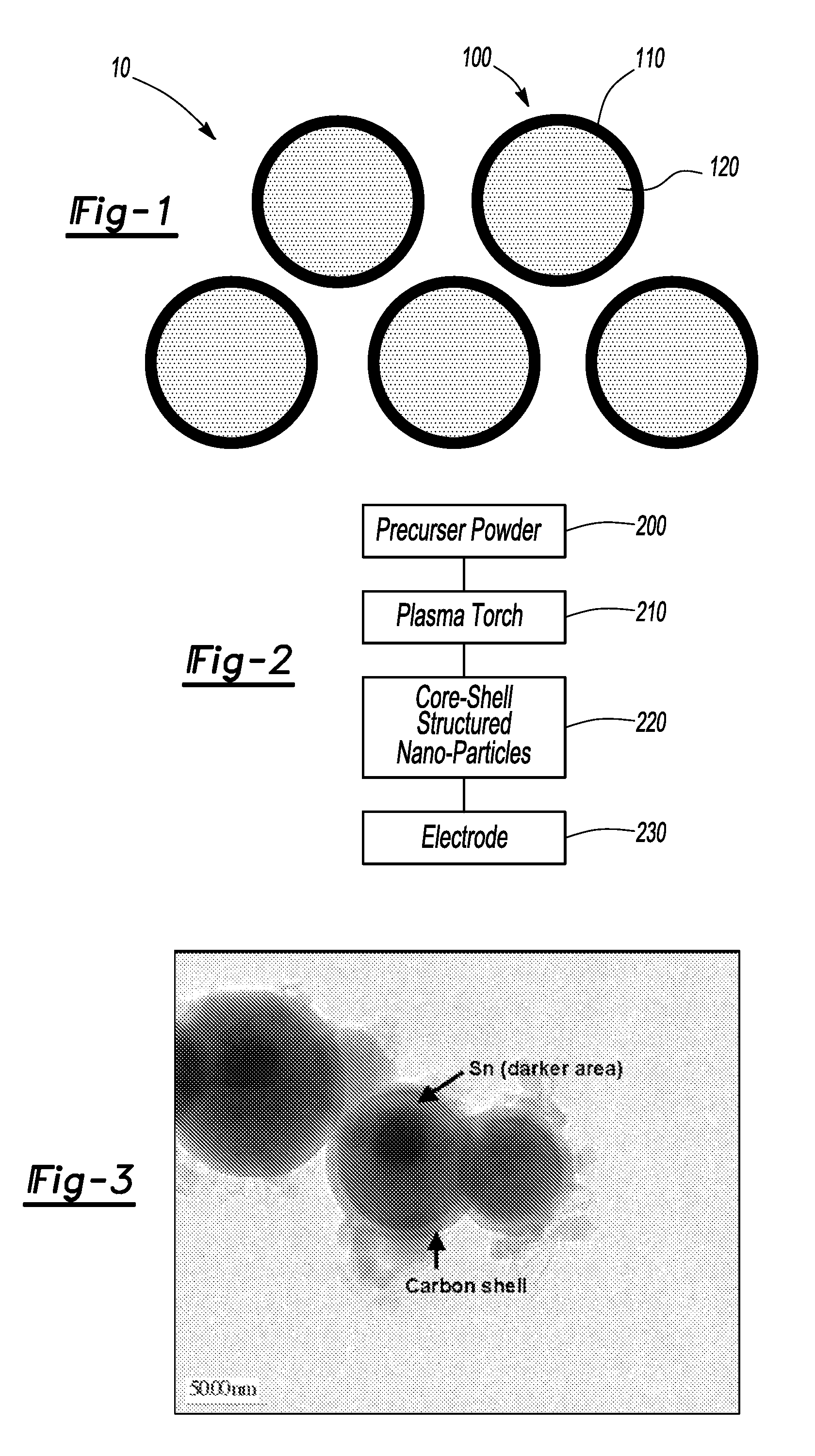

Material With Core-Shell Structure

InactiveUS20090317719A1Synthetic resin layered productsMetal-working apparatusMean diameterBinary alloy

Disclosed is a material having a composite particle. The composite particle includes an outer shell containing an element such as carbon, nitrogen, oxygen or sulfur and an inner core made from a lithium alloying material such as tin, silicon, aluminum and / or germanium. If the outer shell is made from carbon, the outer shell of the composite particle has an average thickness of less than 20 nanometers and the composite particle has an outer mean diameter of less than 100 nanometers. In some instances, the inner core is made from tin, a tin binary alloy, a tin tertiary alloy or a tin quaternary alloy.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA +1

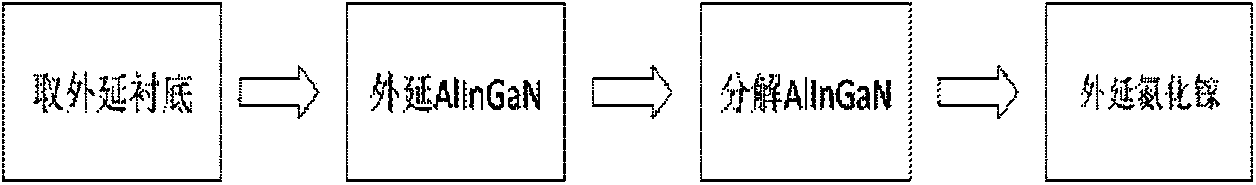

Method for manufacturing GaN epitaxial thin film by using AlInGaN

ActiveCN103489968AQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesLattice mismatchGallium nitride

A method for manufacturing a GaN epitaxial thin film by using AlInGaN includes the following steps that first, an epitaxial substrate is taken; second, a compact thin layer is arranged on the epitaxial substrate in an epitaxy mode, and the compact thin layer is used as an epitaxial nucleating layer of subsequent GaN; third, growth is suspended, and the compact thin layer is decomposed to obtain a loose thin layer; fourth, the GaN epitaxial thin film is formed on the loose thin layer in an epitaxy mode. According to the method for manufacturing the GaN epitaxial thin film by using the AlInGaN, AlInGaN quaternary alloy is used as the epitaxial nucleating layer of the GaN, an incompact AlInGaN epitaxial layer is generated by using the easy-to-dissolve characteristic of In atoms so that the stress from lattice mismatch can be released, and therefore the GaN epitaxial thin film of high quality can be obtained.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

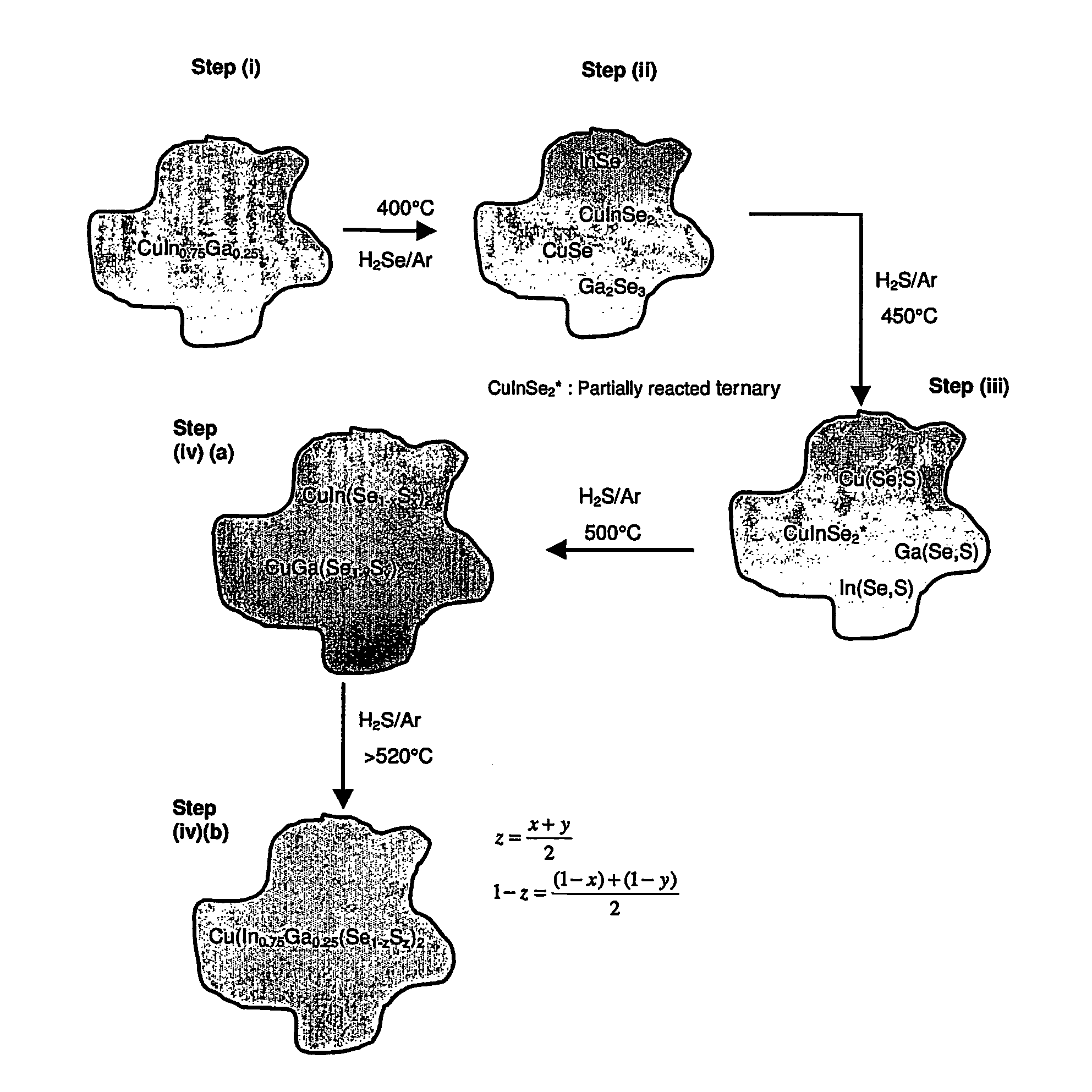

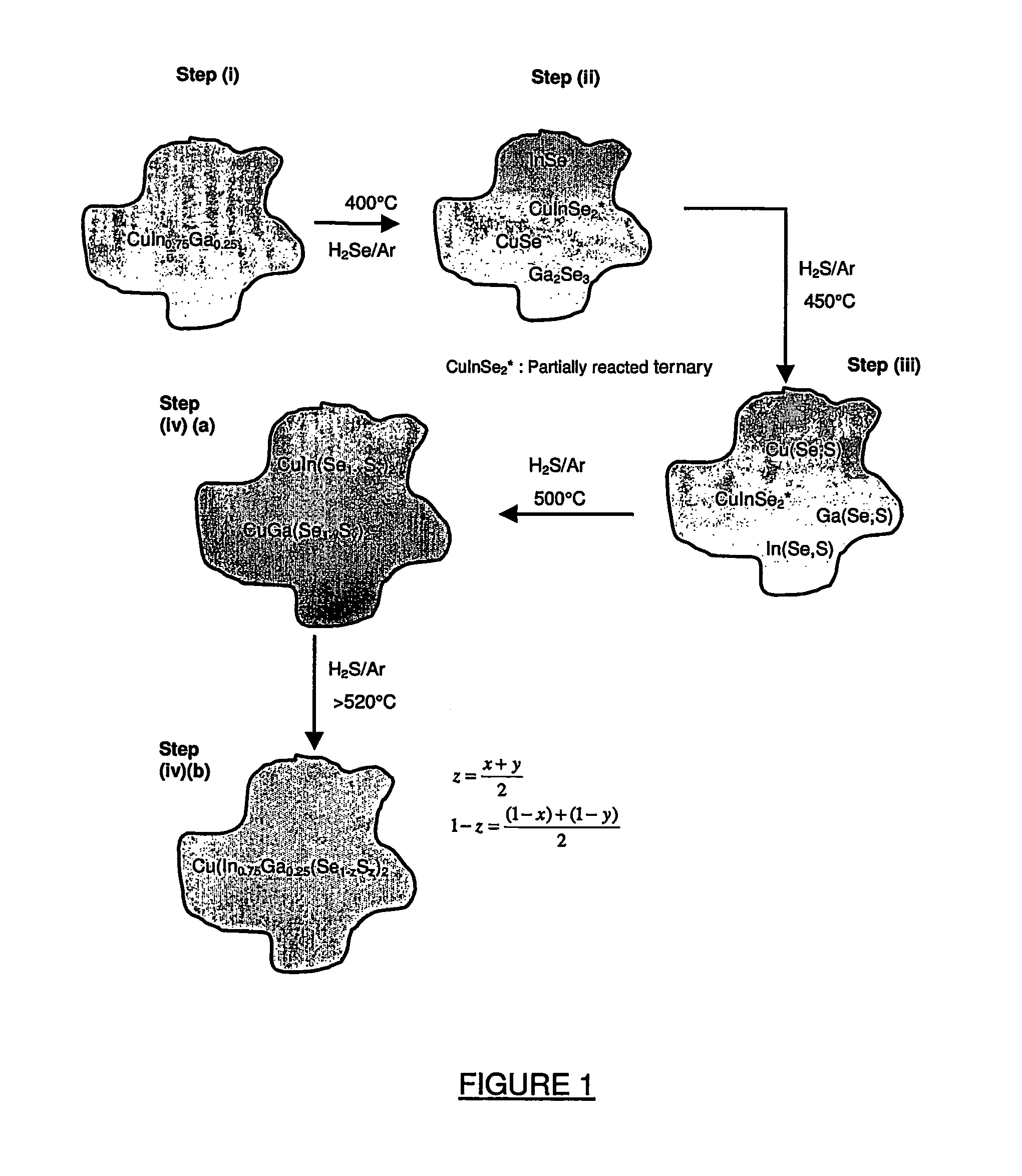

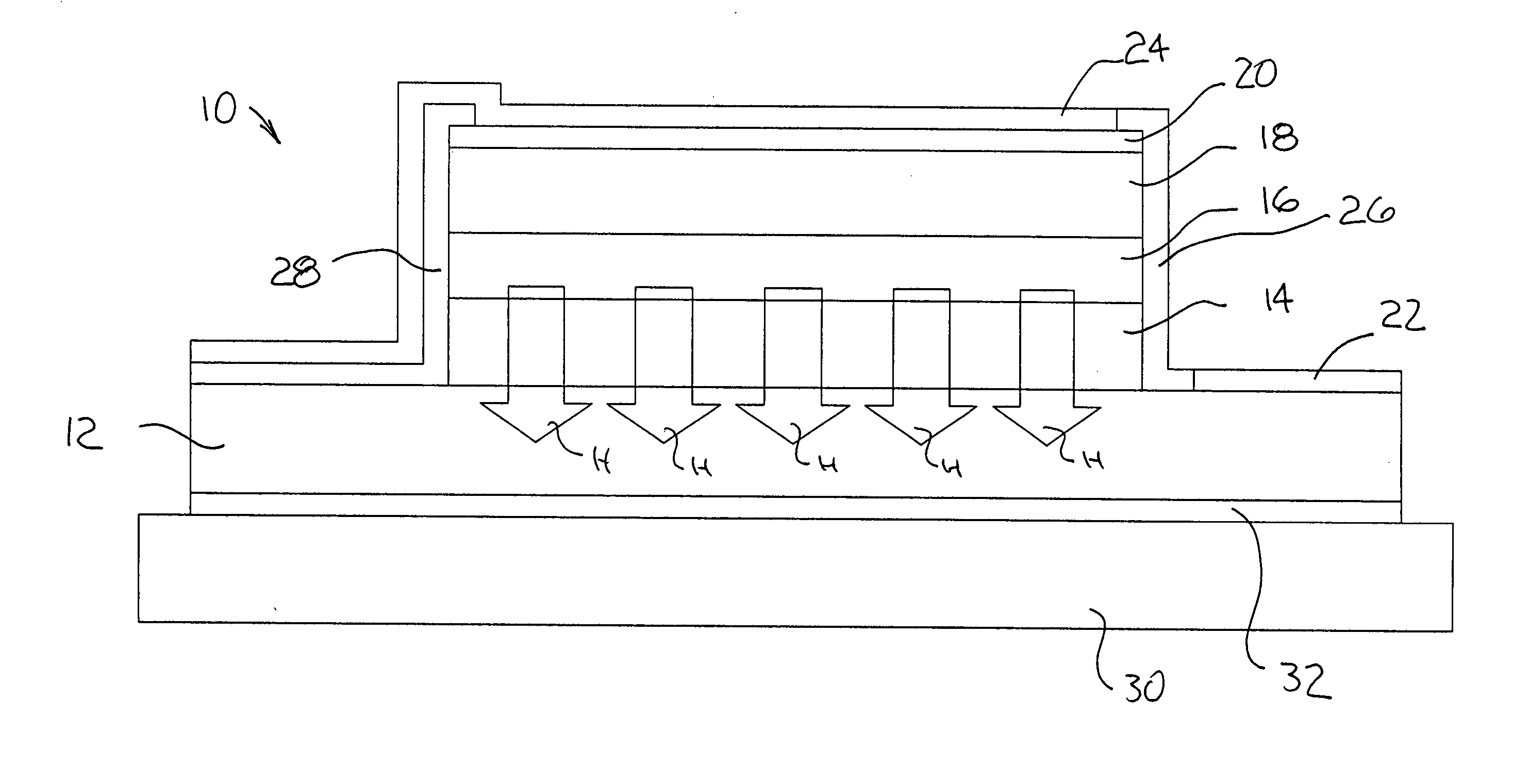

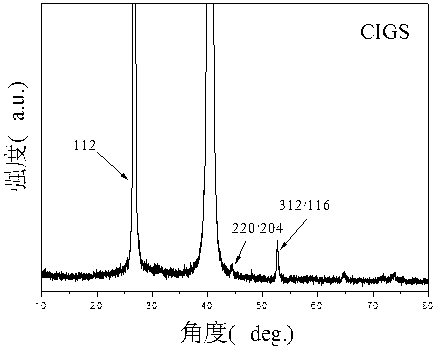

Group I-III-VI quaternary or higher alloy semiconductor films

InactiveUS20060222558A1Minimises associated disadvantageFinal product manufacturePhotovoltaic energy generationX-raySemiconductor

This invention relates to group IB-IIIA. VIA quaternary or higher alloys. More particularly, this invention relations to group IB-IIIA-VIA quaternary or pentenary alloys which are suitable for use as semiconductor films. More specifically, the invention relates to quaternary or pentenary alloys which are substantially homogeneous and are characterized by an x-ray diffraction pattern (XRD) having a main [112] peak at a 2θ angle (2θ(112)) of from 26° to 28° for Cu radiation at 40 kV, wherein a glancing incidence x-ray diffraction pattern (GIXRD) for a glancing angle of from 0.2° to 100 reflects an absolute shift in the 2θ(112) angle of less than 0.06°.

Owner:JOHANNESBURG UNIV OF

Semiconductor laser cladding layers

Cladding layers for semiconductor lasers provide improved heat transfer and optical confinement properties. The cladding layers may comprise superlattices such as AlSb / GaAs, AlSb / AlAs, AlSb / GaSb / AlAs, AlGaSb / AlGaAs and AlSb / AlGaAs. The cladding layers may also comprise Al-As-Sb ternary alloys or Al-Ga-As-Sb quaternary alloys. Such cladding layers may be used in interband cascade lasers or other types of semiconductor lasers to significantly increase heat flow out of the active light-emitting region of the device, while providing improved optical confinement characteristics.

Owner:MAXION TECH

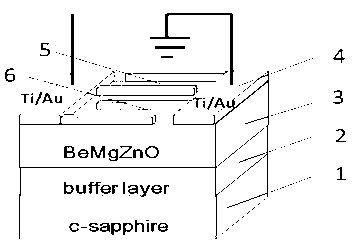

BeMgZnO-based MSM solar blind detector and preparation method thereof

InactiveCN103022217ASimple preparation processGood light responseFinal product manufactureSemiconductor devicesUltraviolet detectorsAlloy thin film

The invention discloses a BeMgZnO-based MSM structure ultraviolet detector and a preparation method thereof. The ultraviolet detector comprises a substrate, and is characterized in that a buffer layer is deposited on the substrate, and a film layer grows on the buffer layer; interdigital electrode patterns as metallic contacts are formed on the film layer, and a clearance part between the interdigital electrodes is a photosensitive area; the film layer is a BeMgZnO quaternary alloy film layer, and the thickness of the BeMgZnO quaternary alloy film layer is in the range of tens of nanometers to several microns; and the forbidden bandwidth of the BeMgZnO quaternary alloy film layer is regulated by regulating the atom proportioning of the three elements Be, Mg and Zn, and the forbidden bandwidth is 3.37 eV-6.2 eV. According to the invention, by adopting the BeMgZnO quaternary alloy film layer as the absorption layer, the ultraviolet detector responding in the solar blind range of 200nm-375 nm is obtained, thus covering the whole solar blind region.

Owner:SUN YAT SEN UNIV

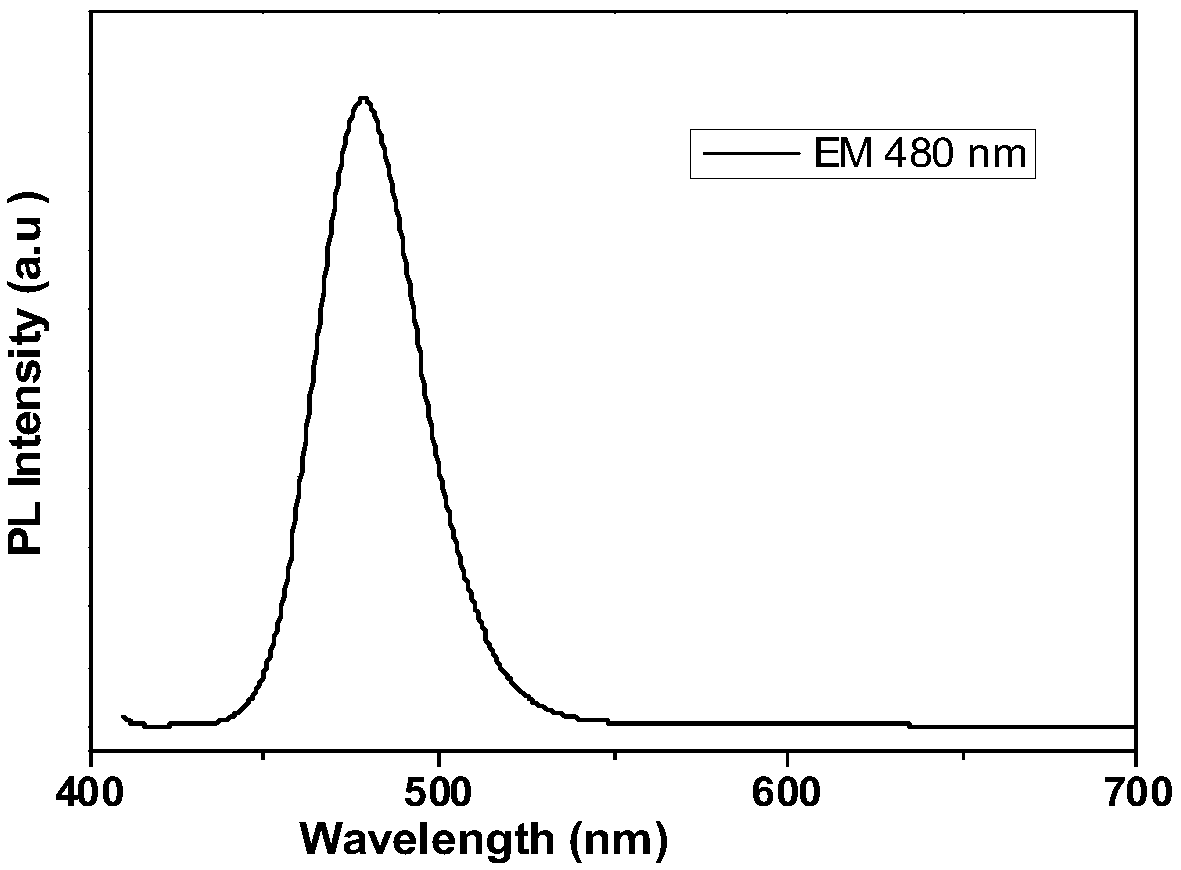

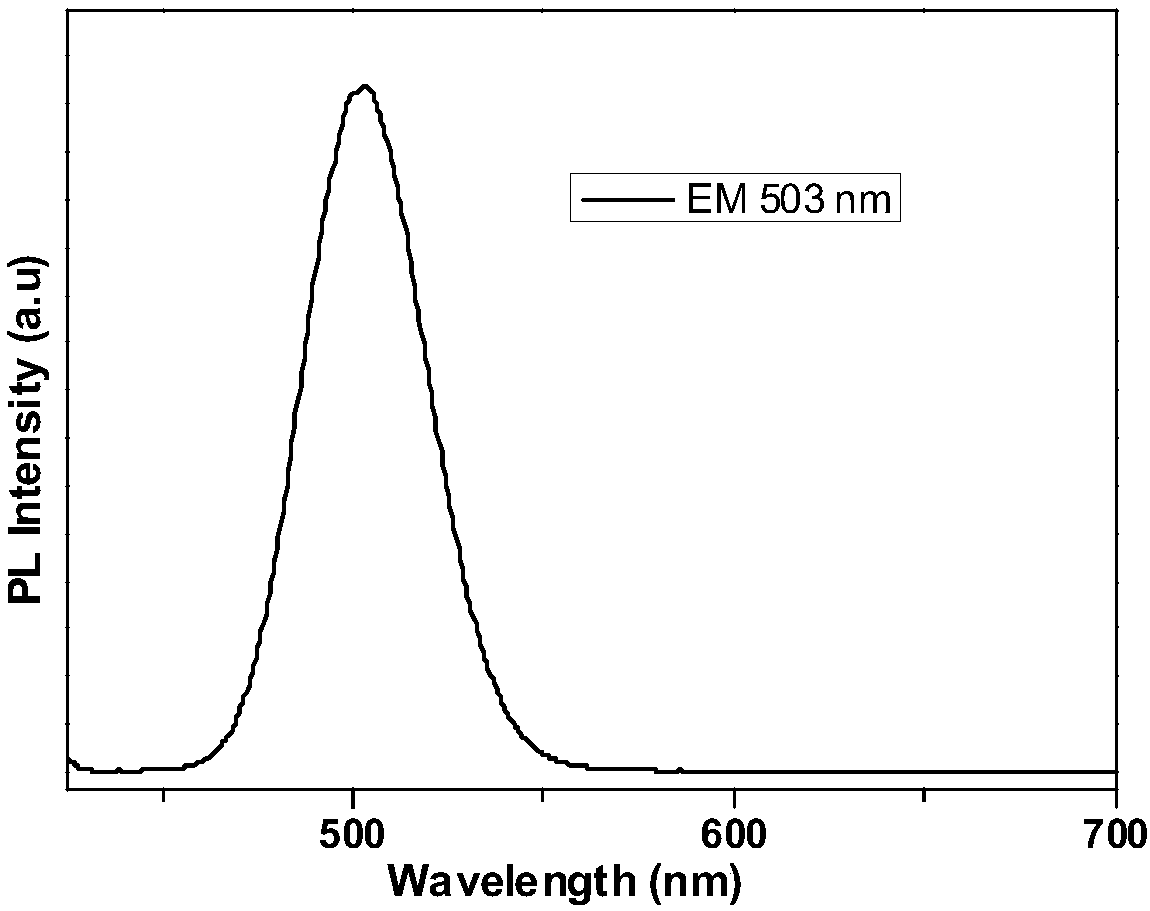

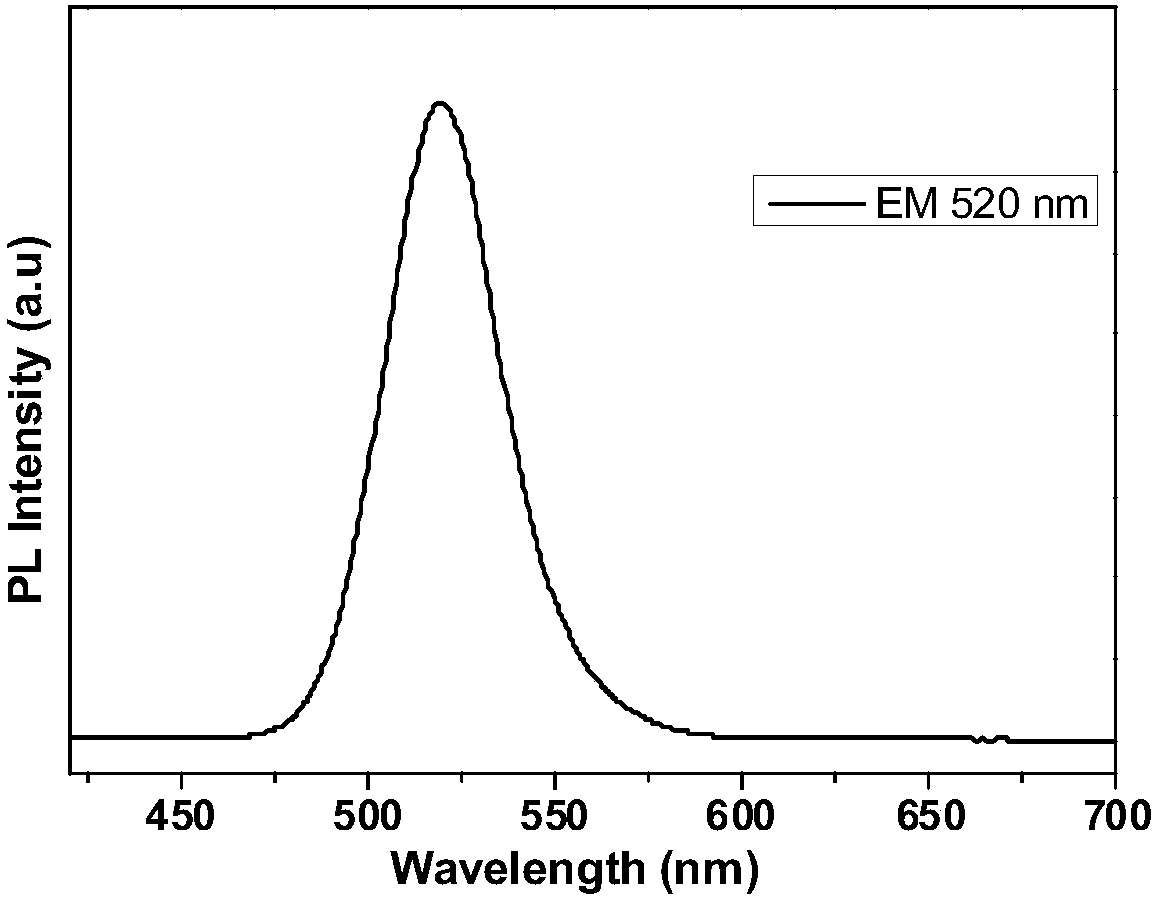

Preparation method of CdZnSeS/ZnS quantum dot

InactiveCN107903900AGood light stabilityImprove thermal stabilityMaterial nanotechnologyNanoopticsFluorescenceQuantum dot

The invention relates to a preparation method of a CdZnSeS / ZnS quantum dot. The preparation method of the CdZnSeS / ZnS quantum dot comprises the following steps of adding and uniformly mixing combinedligand into Cd-Zn precursor, under protection of shielding gas, heating to 240-310 DEG C, rapidly filling Se-S precursor, and performing mixed reaction for 5-30 min; sequentially slowly filing S precursor and Zn precursor into the obtained CdZnSeS quantum dot solution for reaction for 30-120 min to obtain the CdZnSeS / ZnS quantum dot. According to the preparation method of the CdZnSeS / ZnS quantum dot, core ZnCdSeS excellent in performance and good in stability is formed under the influence of the ligand, and then through the S precursor and the Zn precursor, a quaternary alloy core-shell structured quantum dot can be formed. The CdZnSeS / ZnS quantum dot is good in photostability and thermal stability, reaches a fluorescent yield up to higher than 80% and meanwhile, the preparation of the CdZnSeS / ZnS quantum dot is simple in operation and convenient to implement.

Owner:DONGGUAN XUANLANG IND

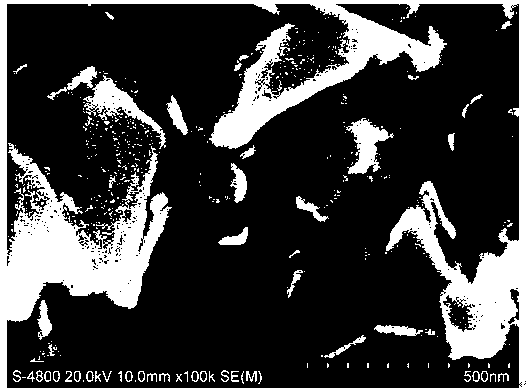

Preparation method of CIGS (copper indium gallium selenide) thin-film solar cell absorbing layer

InactiveCN103296139AImprove uniformityGood repeatabilityFinal product manufactureVacuum evaporation coatingRadio frequency magnetron sputteringElectrical battery

The invention discloses a preparation method of a CIGS (copper indium gallium selenide) thin-film solar cell absorbing layer. The method includes adopting a direct-current magnetron sputtering method for depositing a double-layer metal Mo electrode on soda-lime glass, and then using a radio-frequency magnetron sputtering method for sputtering a single CIGS quaternary alloy target (CuIn0.7Ga0.3Se2) to deposit a CIGS thin film on the Mo electrode. Certain substrate temperature and sputtering power are kept in the sputtering process, the CIGS thin film obtained by sputtering is provided with a chalcopyrite structure and suitable for serving as the absorbing layer of a solar cell, and the method is low in cost, simple in process, capable of omitting selenization annealing and more beneficial to environment protection.

Owner:TIANJIN NORMAL UNIVERSITY

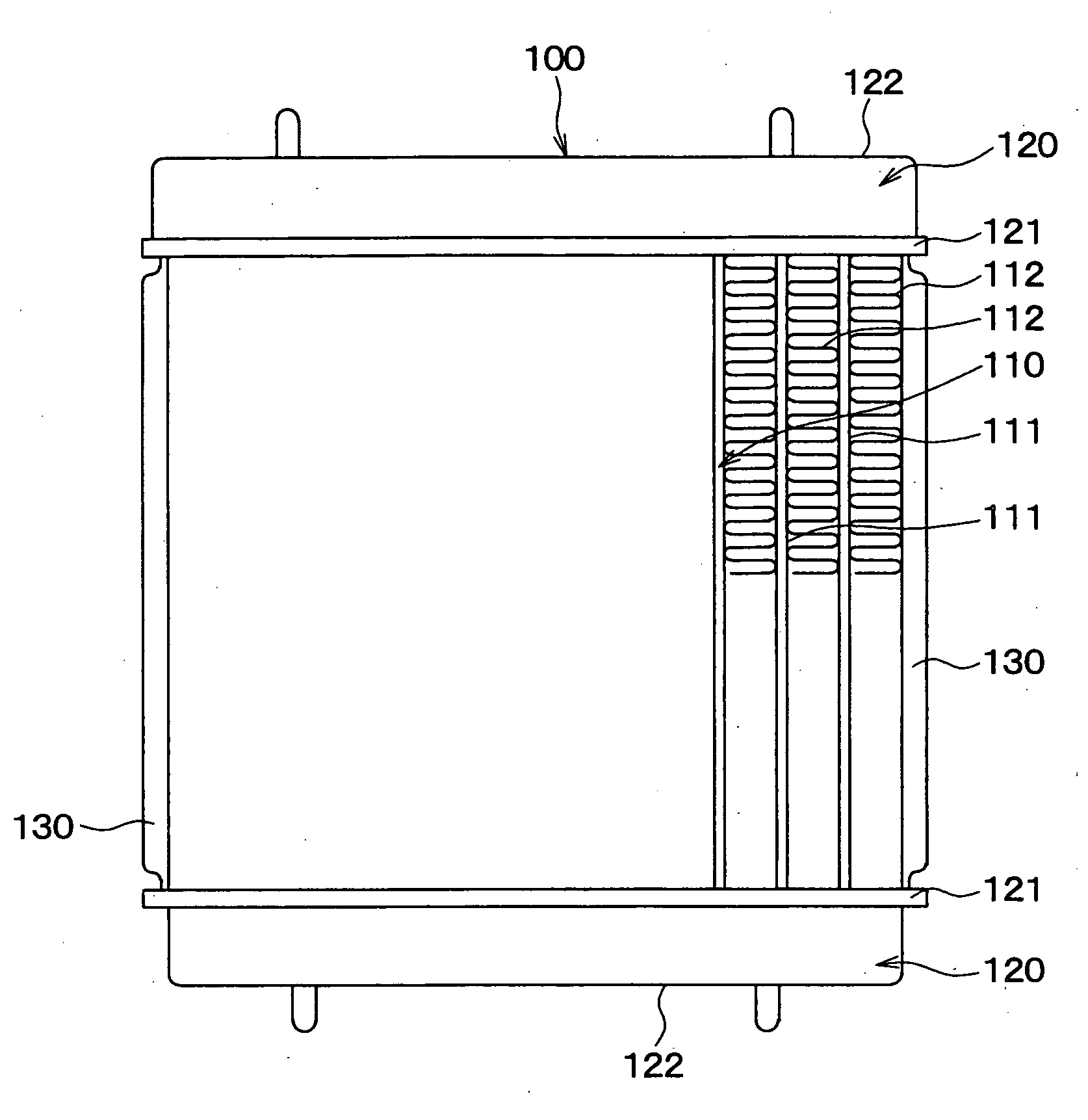

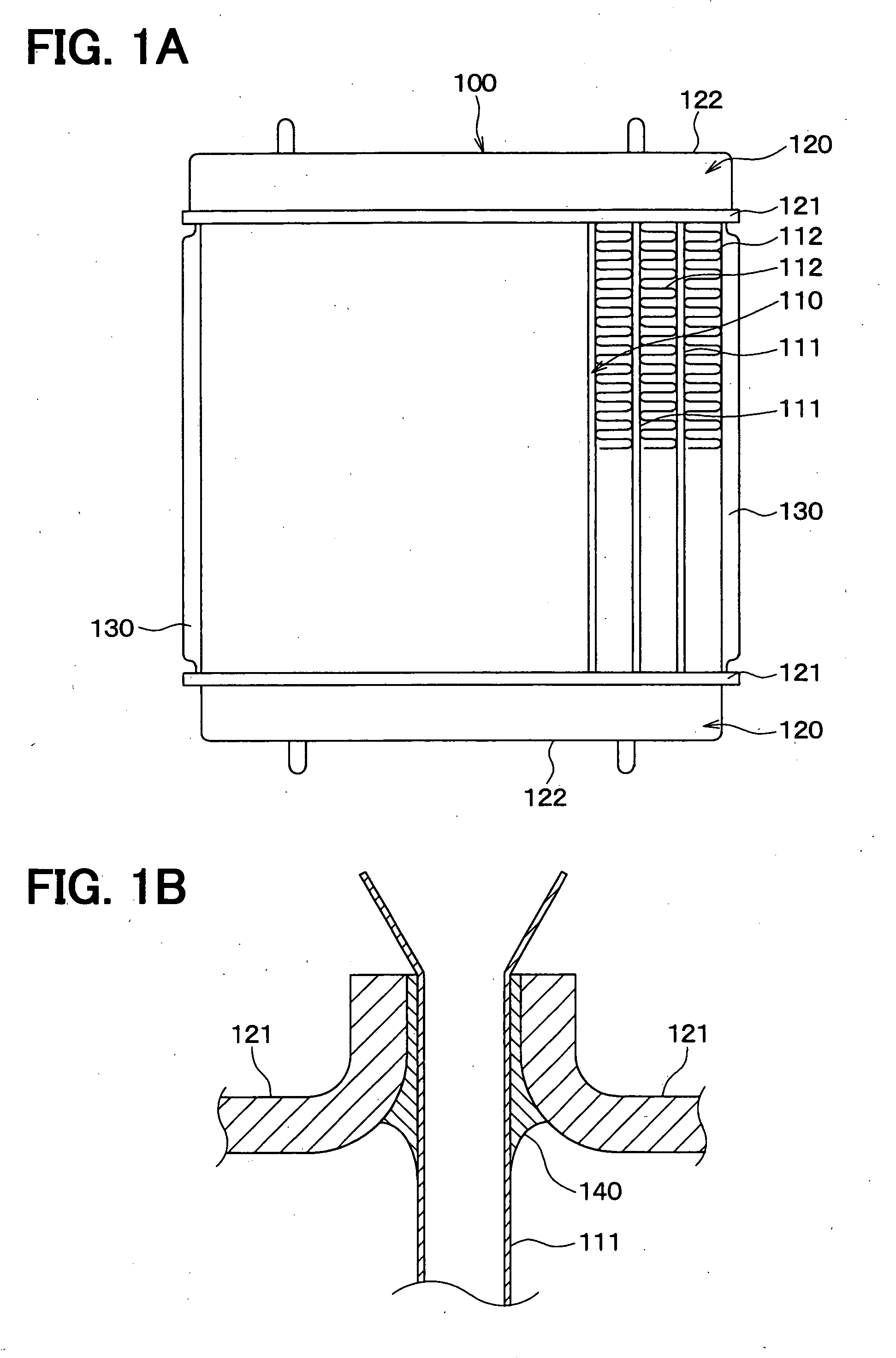

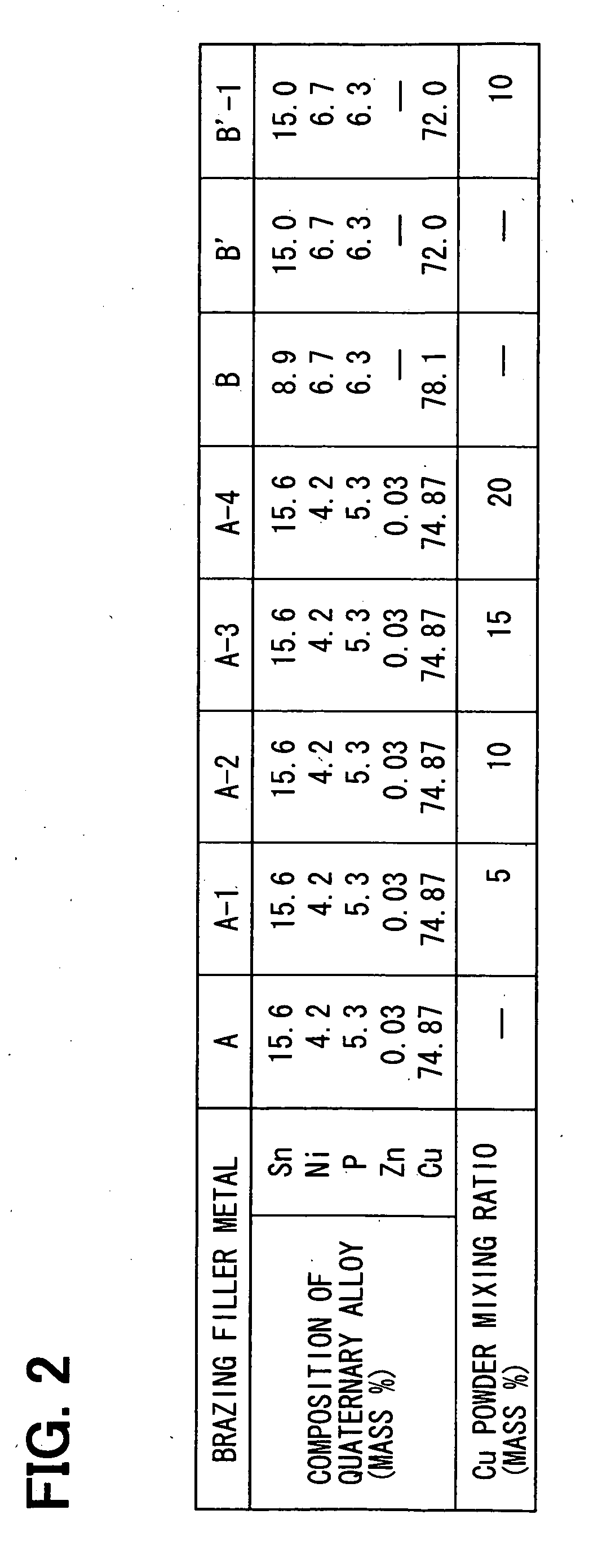

Brazing filler metal, brazing filler metal paste, and heat exchanger

InactiveUS20090297882A1Reduce tin contentImprove joint strengthWelding/cutting media/materialsThin material handlingOrganic solventPlate heat exchanger

A brazing filler metal includes quaternary alloy powder and copper powder. The quaternary allow powder consists of from 0.1 to 27.4 mass percent tin, from 0.8 to 5.1 mass percent nickel, from 2.2 to 10.9 mass percent phosphorous and a balance including copper and any unavoidable impurity. The brazing filler metal can be used in a form of paste by being mixed with an organic binder and an organic solvent. The brazing filler metal and the brazing filler metal can be used for joining members made of copper or copper alloy, such as members of a heat exchanger.

Owner:DENSO CORP +1

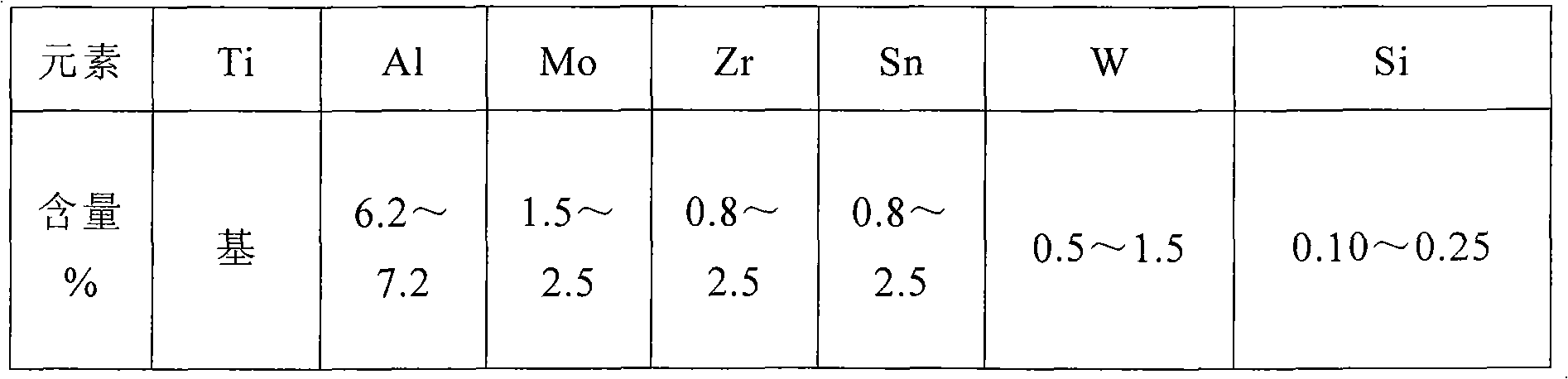

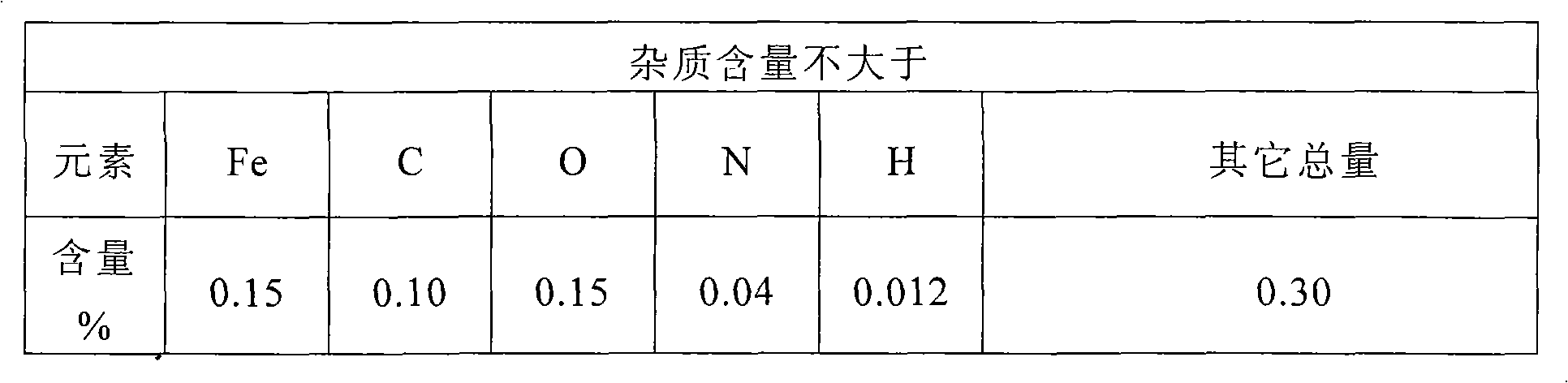

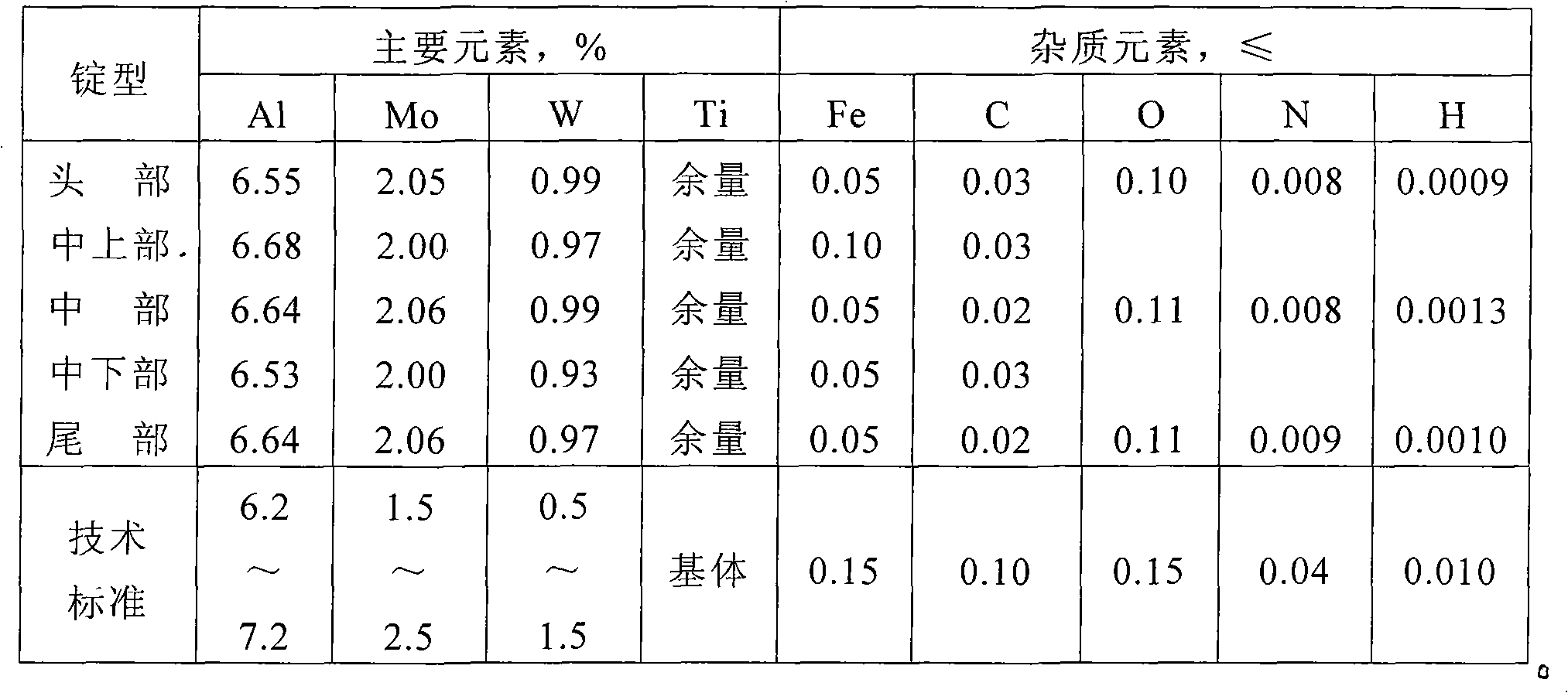

Al-Mo-W-Ti quaternary alloy

The invention discloses an Al-Mo-W-Ti quaternary alloy, which comprises the following components in percentage by mass: 10 to 15 percent of W, 20 to 30 percent of Mo, 45 to 60 percent of Al, 5 to 15 percent of Ti, and the balance of inevitable impurities. The Al-Mo-W-Ti quaternary alloy can solve segregation of impurities and components of W and Mo high-melting-point alloy in TC25, and effectively avoid the problem of part failure caused by metal impurities in TC25 titanium alloy.

Owner:宝武特冶钛金科技有限公司

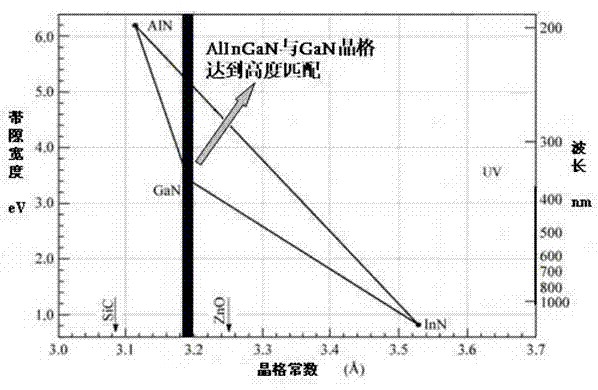

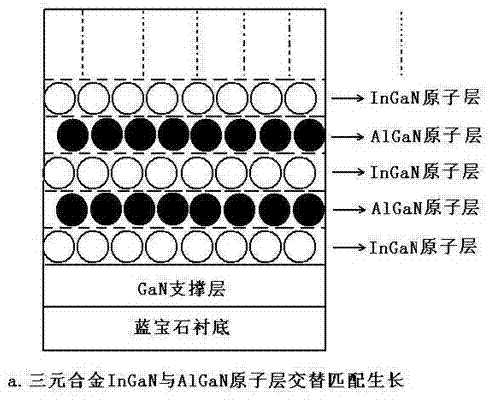

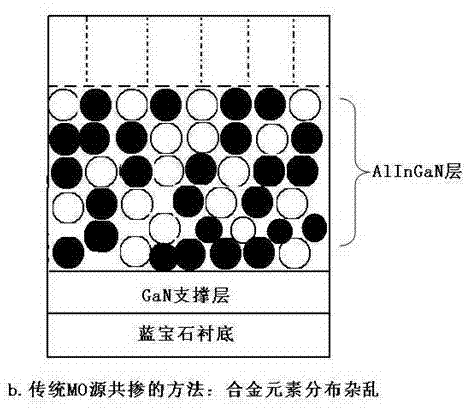

MOCVD epitaxy processing method of AlInGaN quaternary alloy thin-film material

InactiveCN103715071AImprove migration abilityImprove the efficiency of incorporationSemiconductor/solid-state device manufacturingSemiconductor devicesGas phaseX-ray

An MOCVD epitaxy processing method of an AlInGaN quaternary alloy thin-film material belongs to the technical field of semi-conductors. The AlInGaN quaternary alloy thin-film material is formed by virtue of using a metal organic chemical vapor deposition (MOCVD) epitaxy technology and employing a method of alternatively matching and growing ternary alloy InGaN and AlGaN materials in a thickness of atomic level. The AlInGaN quaternary alloy thin-film material prepared by using the aforementioned technology can achieve the following parameter indexes: (1) the half-peak height and width of an X-ray diffraction (XRD) (002) symmetry plane < 240 seconds; (2) the material surface roughness < 1 nm; and (3) the c-face lattice constant mismatch degree with respect to GaN < 0.5%.

Owner:南京大学扬州光电研究院

Elongated steel element comprising a ternary or quaternary brass alloy coating and corresponding method

InactiveUS20140378597A1Improved adhesion resultAdhesion performanceConductive materialPneumatic tyre reinforcementsIndiumManganese

An elongated steel element adapted for the reinforcement of rubber products is covered with a ternary or quaternary alloy coating of copper-M-zinc. M is one or two metals selected from the group consisting of cobalt, nickel, tin, indium, manganese, iron, bismuth and molybdenum. The copper content inside the coating ranges from 58 weight percent to 75 weight percent, the content of said one or two metals inside the coating ranges from 0.5 weight percent to 10 weight percent, the remainder is zinc and unavoidable impurities. The one or two metals are present throughout the coating. The phosphorus is present on and / or in the coating in an amount ranging from 0.3 milligram per square meter to 1 milligram per square meter of the coating. The coating further lacks triazole residues. Good results for under cure adhesion have been obtained. Furthermore, a corresponding method for manufacturing such an elongated steel element is disclosed.

Owner:NV BEKAERT SA

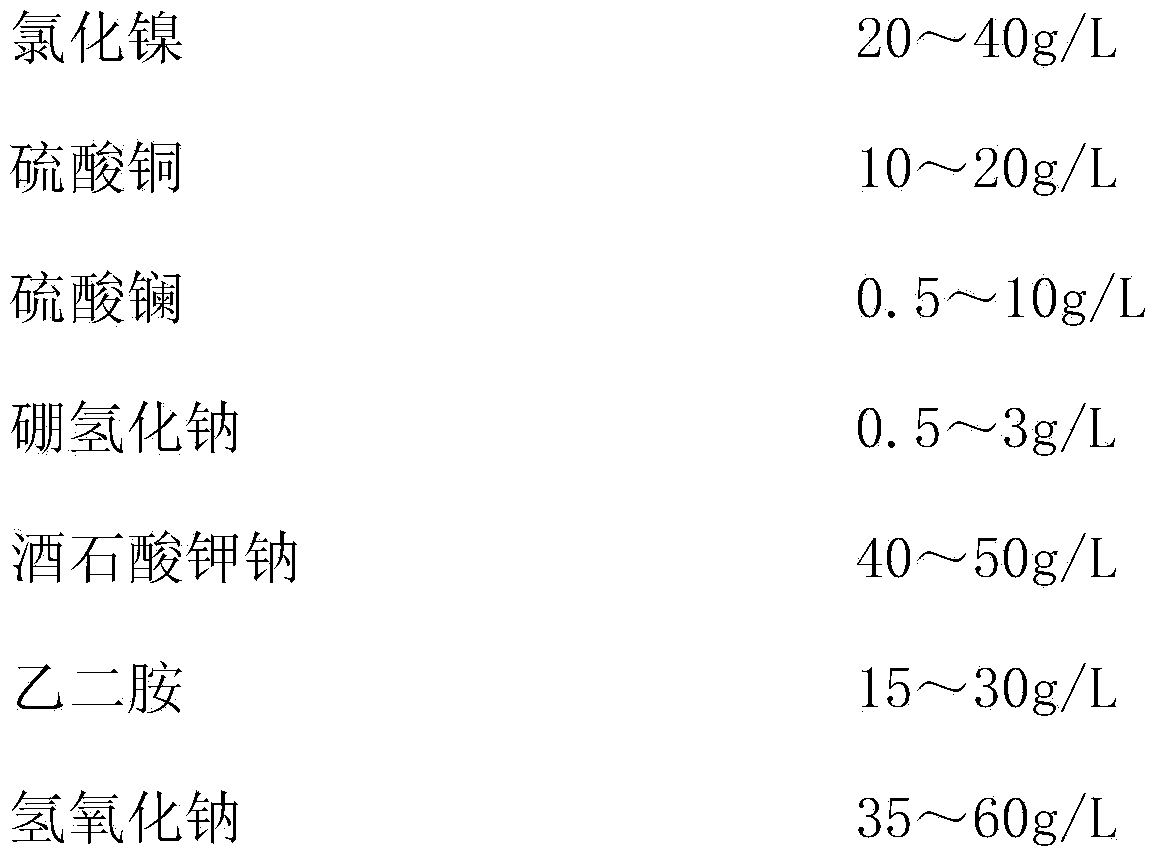

Ni-Cu-La-B quaternary alloy plating solution and method for chemically plating glass fibers by using same

ActiveCN103757617AReduce contentIncreased nickel contentLiquid/solution decomposition chemical coatingEthylenediamineMicroscopic observation

The invention discloses a Ni-Cu-La-B quaternary alloy plating solution. The Ni-Cu-La-B quaternary alloy plating solution comprises the following components: 20-40g / L of nickel chloride, 10-20g / L of copper sulfate, 0.5-10 g / L of lanthanum sulfate, 0.5-3 g / L of sodium borohydride, 40-50g / L of potassium sodium tartrate, 15-30g / L of ethylenediamine and 35-60g / L of sodium hydroxide. A method for chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution comprises the following steps: using sodium borohydride as a reducing agent, adding the water-soluble lanthanum sulfate, and chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution under the conditions of strong base and low temperature; plating layers are Ni-Cu-La-B alloy plating layers, wherein the content of boron is low (only about 0.5-5wt%), the content of nickel in the plating layers is high; the plating layers have good bonding force, electrical conductivity and wear resistance. Through observation with microscopes, the plating layers of the Ni-Cu-La-B quaternary alloy plated glass fibers prepared by using the method are compact; testing with an X-ray energy dispersive spectrometer shows that the surface chemistry components of the Ni-Cu-La-B quaternary alloy plated glass fibers contain 15-50wt% of Ni, 2-15wt% of Cu, 0.5-5wt% of La and 0.5-5wt% of B. The electric conducting glass fibers can be applied to the special fields of electromagnetic wave shielding, microwave absorption, invisibility, anti-static electricity and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com