Electroplated quaternary alloys

a technology of electroplating and quaternary alloys, applied in the field of electroplating quaternary alloys, can solve the problems of restricted use of chromium (vi) and its compounds in certain applications, and achieve the effects of increasing the bright plating range, and facilitating deposition of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

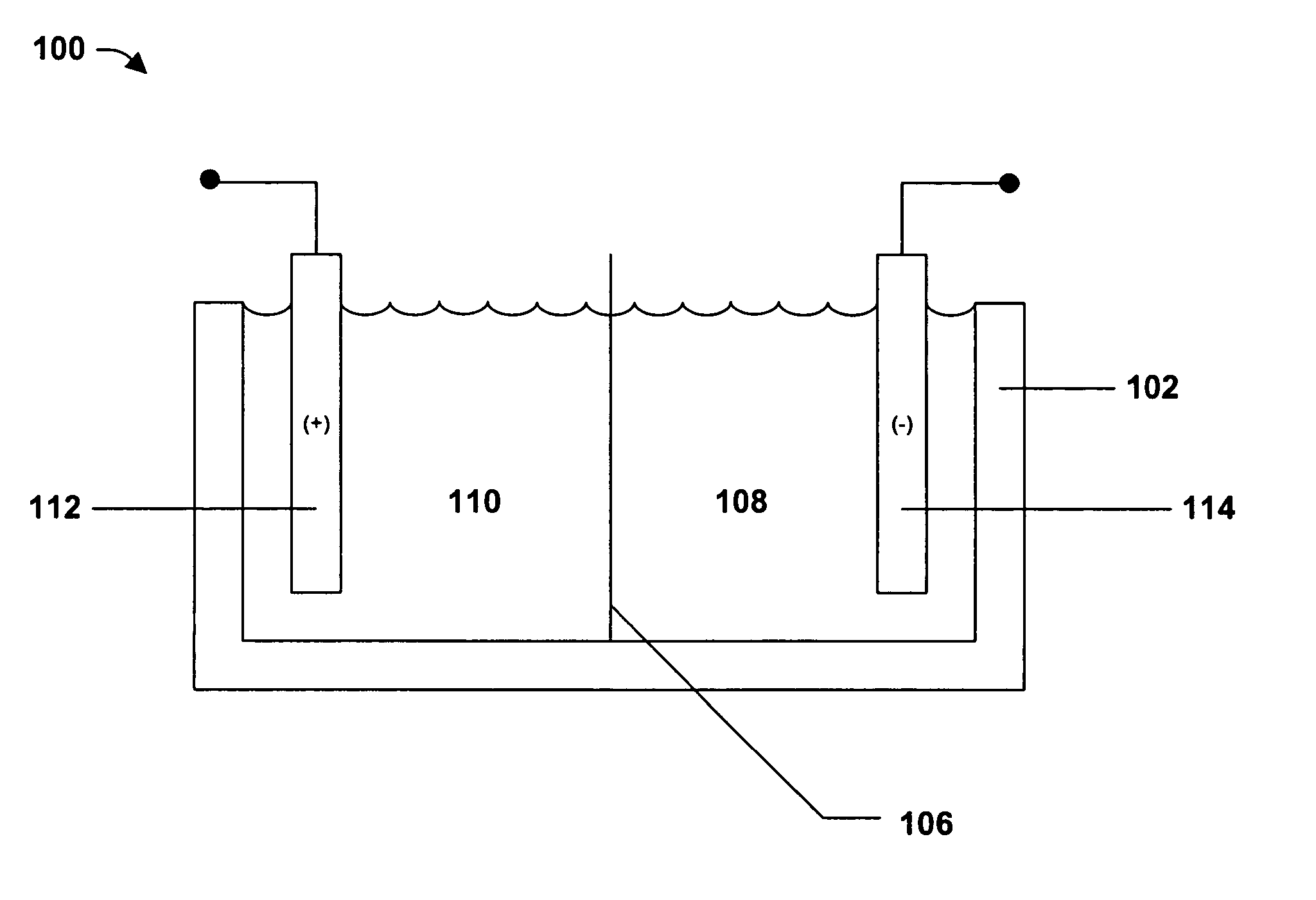

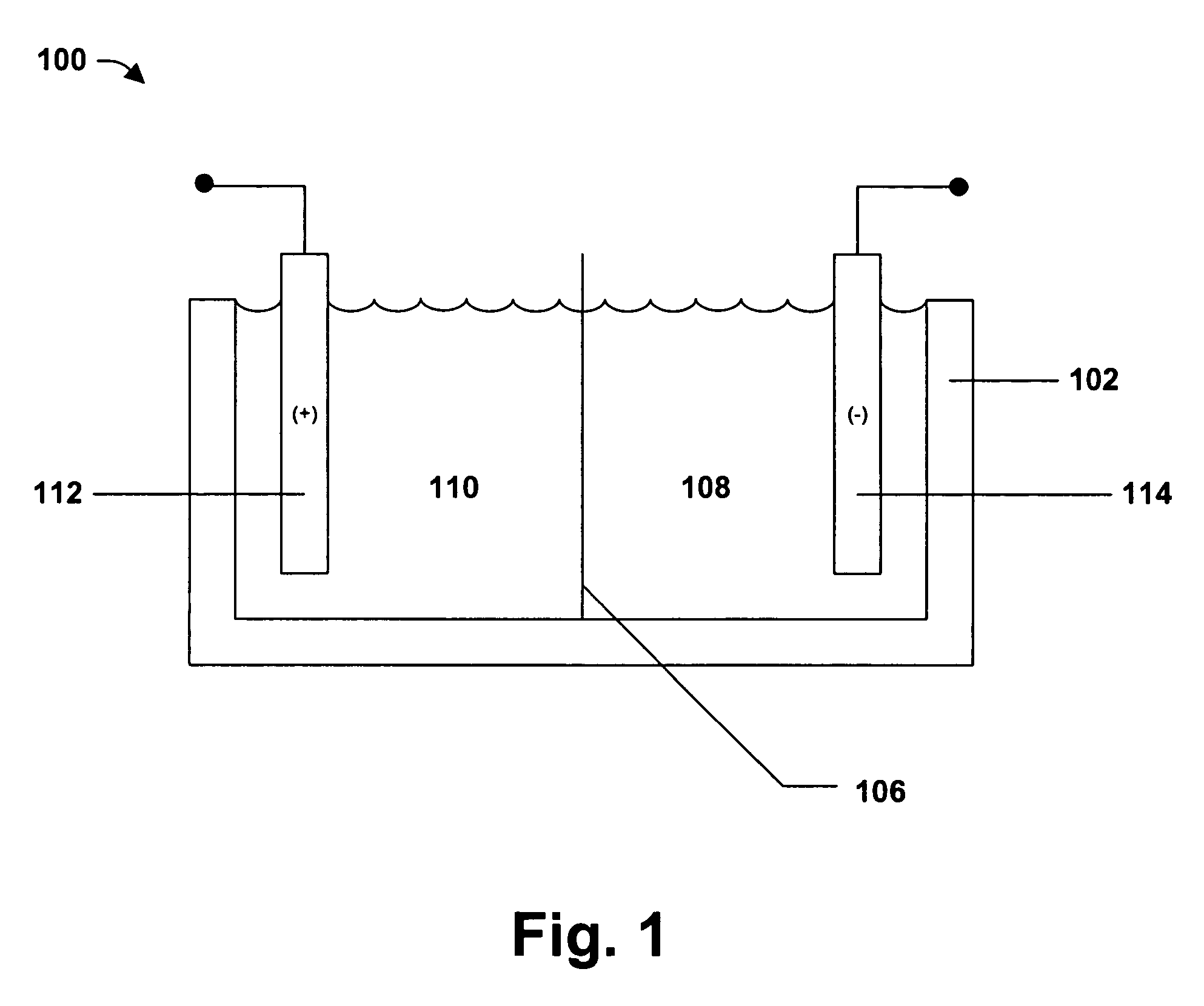

[0009] The present invention provides quaternary alloys made by electroplating that exhibit two or more of high brightness, high luster, level / smoothness, uniform thickness, high hardness, high reflectivity, ductile, high density, resistant to corrosion, resistant to heat, and resistant to wear. Typically, the quaternary alloys made in accordance with the present invention have a mirror bright deposit and a hardness on par with chrome. Electroplating involves metal in ionic form migrating in solution from a positive electrode (anode) to a negative electrode (cathode). The anode and cathode are connected to a power source and an electrical current is passed through the electroplating bath or solution causing substrates at the cathode to be coated by the metal (nickel, cobalt, and at least two alloy metals) in solution. In most embodiments, the substrate to be plated is the cathode.

[0010] The cathodes are any electrically conductive material that can accommodate a nickel cobalt quate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com