Preparation method of CdZnSeS/ZnS quantum dot

A technology of quantum dots and quantum dot solutions, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as unfavorable large-scale production, limitation of quantum dot application, and reduced luminous efficiency , to achieve the effects of good light stability and thermal stability, convenient implementation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of CdZnSeS / ZnS quantum dot of the present invention, comprises the steps:

[0032] Dissolve the selenium source and sulfur source in the mixed solution of phosphine compounds and long-chain olefins, and mix them uniformly by ultrasonic to obtain the Se-S precursor solution;

[0033] Dissolve the sulfur source in the mixed solution of phosphine compounds and long-chain olefins, and mix them uniformly by ultrasonic to obtain the sulfur precursor;

[0034] Add the zinc source to the mixed solution of long-chain fatty acids and long-chain olefins, stir and heat to 260°C to obtain a clear zinc precursor solution;

[0035] After mixing the cadmium source, zinc source, long-chain olefins, and long-chain fatty acids evenly, under the protection of protective gas, the above mixture is gradually heated to 150 ° C ~ 240 ° C to form a light yellow clear solution, which is cooled to room temperature to obtain Precursor of Cd-Zn;

[0036] Add the combined lig...

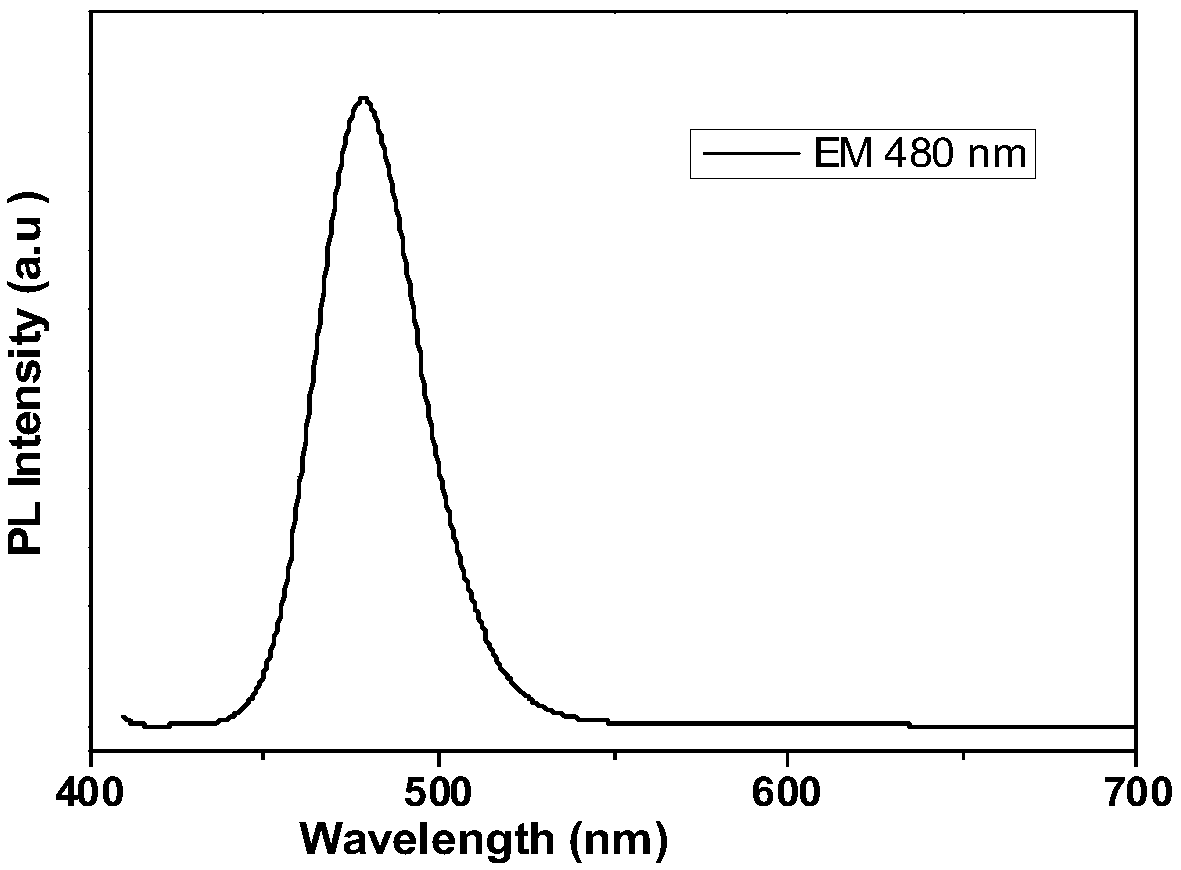

Embodiment 1

[0047] The preparation method of CdZnSeS / ZnS quantum dot of the present invention, comprises the steps:

[0048] Get 2mmol selenium powder, 20mmol sulfur powder, 40mmol tri-n-octylphosphine, 60mmol octadecene, dissolve the selenium powder and sulfur powder in the mixed solution of tri-n-octylphosphine and octadecene, and mix them uniformly by ultrasonic to obtain Se- S precursor;

[0049] Take 10mmol of sulfur powder, 30mmol of tributyl phosphate, and 15mmol of octadecene, dissolve the sulfur powder in a mixed solution of tributyl phosphate and octadecene, and mix them uniformly by ultrasonic to obtain a sulfur precursor;

[0050] Take 10mmol of zinc oxide powder, 60mmol of oleic acid, and 80mmol of octadecene, add the zinc oxide powder into the mixed solution of oleic acid and octadecene, stir and heat to 260°C to obtain a zinc precursor;

[0051] Take 2mmol cadmium oxide powder, 80mmol oleic acid, 100mmol octadecene, 30mmol zinc oxide powder, mix the cadmium oxide powder, z...

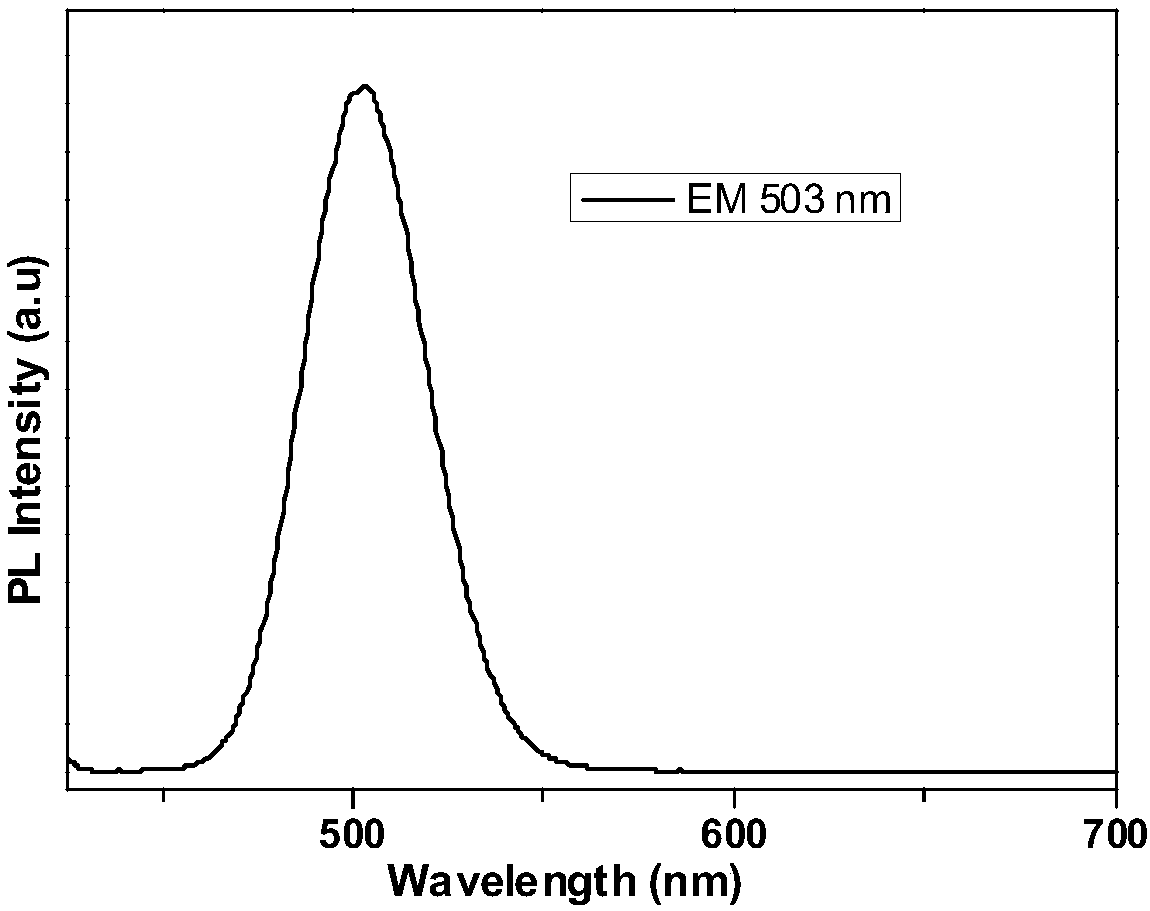

Embodiment 2

[0058] The preparation method of CdZnSeS / ZnS quantum dot of the present invention, comprises the steps:

[0059] Take 3.5mmol selenium powder, 20mmol sulfur powder, 40mmol tri-n-octylphosphine, and 60mmol octadecene, dissolve the selenium powder and sulfur powder in the mixed solution of tri-n-octylphosphine and octadecene, and mix them uniformly by ultrasonic to obtain Se -S precursor;

[0060] Take 10mmol of sulfur powder, 30mmol of tributyl phosphate, and 15mmol of octadecene, dissolve the sulfur powder in a mixed solution of tributyl phosphate and octadecene, and mix them uniformly by ultrasonic to obtain a sulfur precursor;

[0061] Take 40mmol of zinc oxide powder, 40mmol of oleic acid, and 60mmol of octadecene, add the zinc oxide powder into the mixed solution of oleic acid and octadecene, stir and heat to 260°C to obtain a zinc precursor;

[0062] Take 2.5mmol of cadmium oxide powder, 80mmol of oleic acid, 100mmol of octadecene, and 30mmol of zinc oxide powder. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com