Method for manufacturing GaN epitaxial thin film by using AlInGaN

An epitaxial thin film, gallium nitride technology, used in semiconductor/solid state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

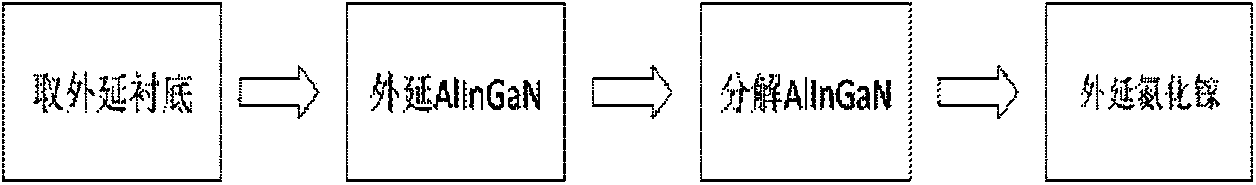

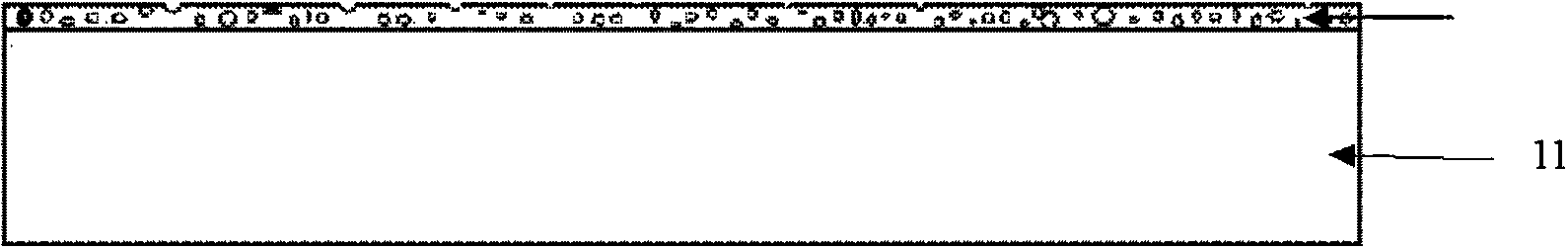

[0015] see Figure 1 to Figure 4 Shown, the present invention provides a kind of method utilizing AlInGaN to make gallium nitride epitaxial film, comprises the following steps:

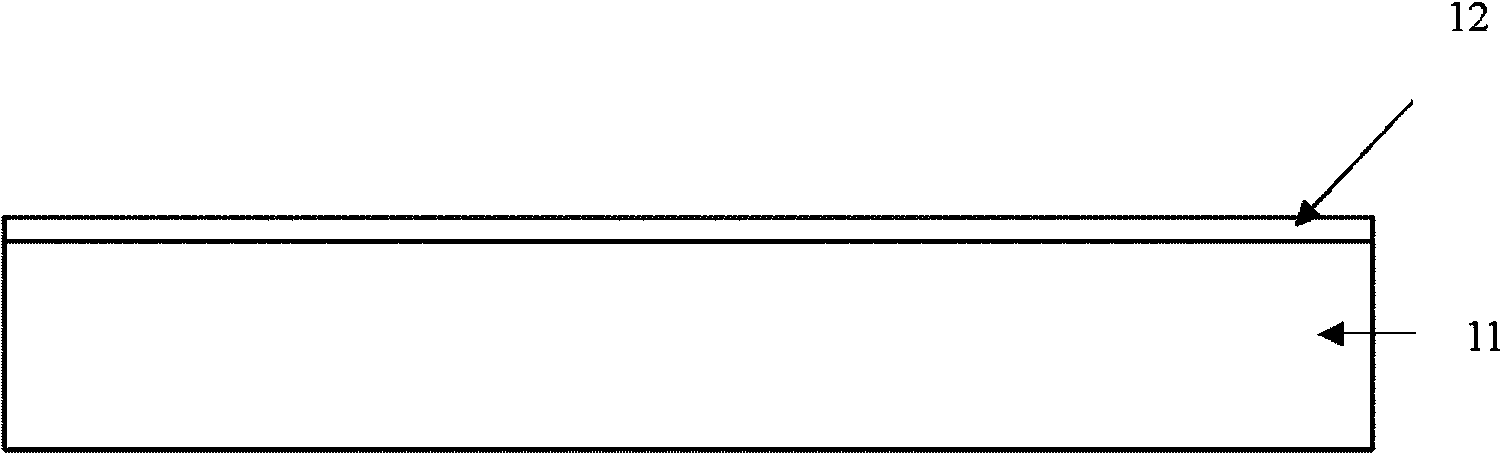

[0016] Step 1: take an epitaxial substrate 11, the material of the epitaxial substrate 11 is an epitaxial substrate such as sapphire, silicon or silicon carbide, and the epitaxial substrate 11 is a planar substrate, which provides a nucleation platform for subsequent epitaxial growth ;

[0017] Step 2: Epitaxially develop a dense thin layer 12 on the epitaxial substrate 11, the material of the dense thin layer 12 is AlInGaN, its thickness is 5-100nm, the epitaxial temperature of the dense thin layer 12 is 600-1000°C, grow The time is between 5-1000s. The dense thin layer 12 is used as the nucleation layer for the subsequent gallium nitride epitaxy, which provides raw materials for the subsequent generation of the sparse thin layer 13. It is most important to select the appropriate source gas flow of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com