Novel liquid metal, and preparation method and application thereof

A liquid metal, a new type of technology, applied in the field of alloys that are liquid at room temperature and their preparation, can solve the problems of high alloy entropy, inability to use liquid metal, and inability to use, and achieve high heat transfer coefficient and stable microstructure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

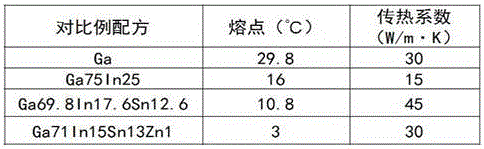

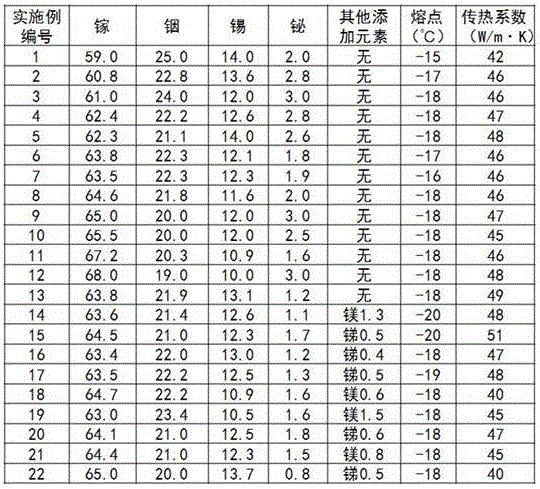

[0029] Prepare the liquid metal according to the element composition and percentage content in the table below, and test the melting point and heat transfer coefficient of the liquid metal after preparation.

[0030] The preparation process is as follows:

[0031] Step 1, the alloy raw material is selected from an alloy powder raw material with a purity greater than 99.9%, and the alloy raw material is weighed according to the formula;

[0032] Step 2: mix the alloy raw materials except gallium evenly in the preparation container, heat over 200°C, then pour metal gallium into it, heat to 255°C, until the raw materials are fully melted and mixed;

[0033] Step 3: Stir the alloy raw materials in Step 2 evenly, keep it warm for 2.5 hours, and then naturally cool to room temperature to obtain the required liquid metal.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com