Preparation method of austenitic stainless steel resisting high-temperature and high-concentration sulfuric acid

An austenitic stainless steel, high-concentration technology, applied in the field of austenitic stainless steel, can solve the problems of complicated construction, long manufacturing period, heavy tower body with steel shell lining bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

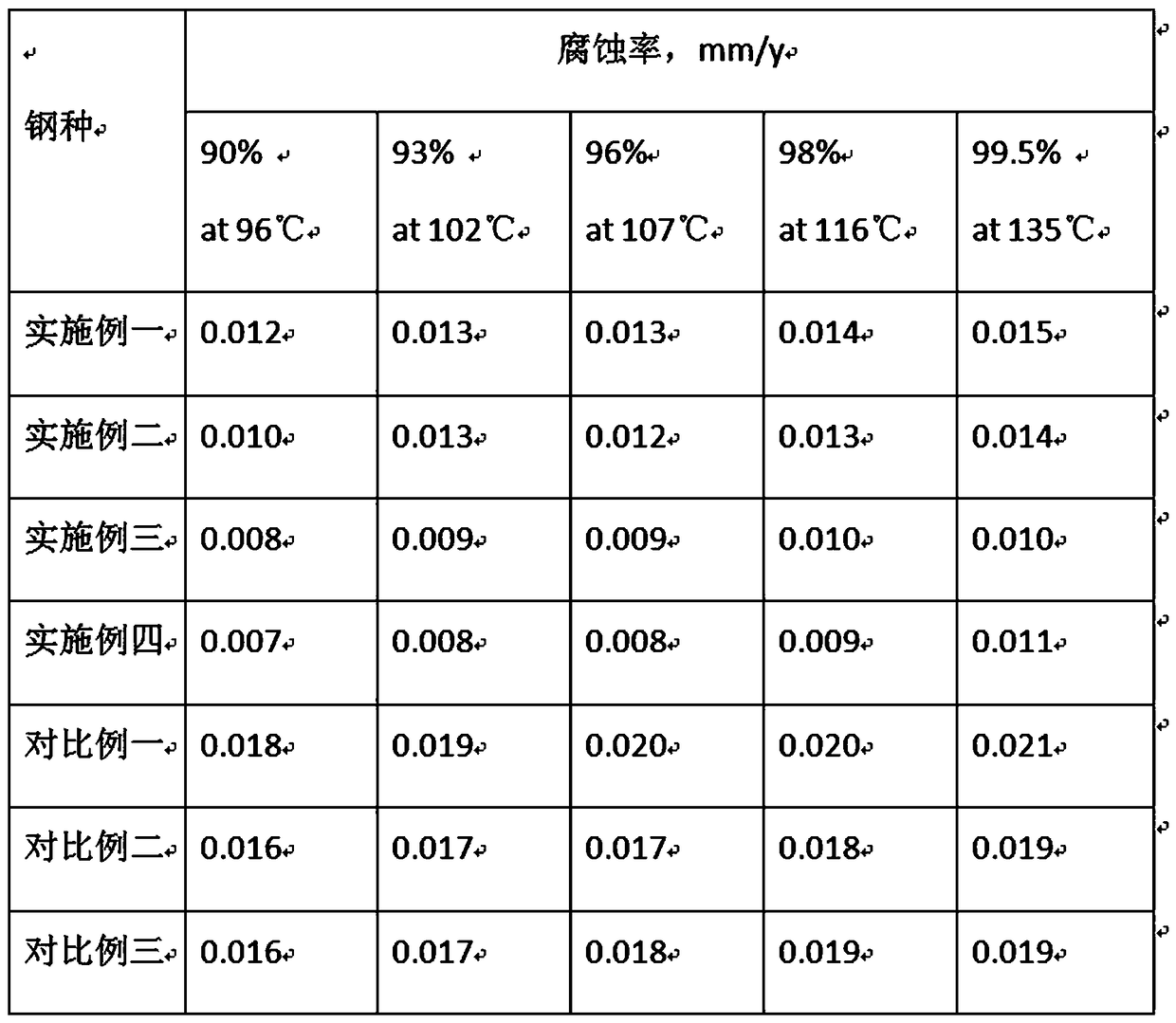

Examples

Embodiment 1

[0064] An austenitic stainless steel resistant to high temperature and high concentration of sulfuric acid, comprising the following components: Cr 13.3wt%, Ni15.2wt%, Si5.9wt%, Cu 0.98wt%, Mo 0.9wt%, C0.014wt%, Mn1.1wt% %, S 0.002wt%, P 0.022wt%, Al 0.05wt%, N 0.015wt%, B 0.004wt%, rare earth 0.03wt%, Bi 0.001wt%, As 0.002wt%, Pb0.002wt%, Sn0.005 %, Sb 0.002wt%, the balance is Fe; and the sum of Bi, As, Pb, Sn, Sb five elements <0.05wt%.

[0065] In this embodiment, the preparation method of austenitic stainless steel is as follows:

[0066] (1) Ingredients: Raw materials are prepared according to the chemical composition and burning loss of austenitic stainless steel. The main raw materials include but are not limited to low-phosphorus carbon steel, low-phosphorus ferrochrome, ferronickel, nickel plate, ferromolybdenum, metal copper, and ferrosilicon , metal silicon; send the raw materials into the electric arc furnace to melt into molten steel, add 28kg / t of slagging agent...

Embodiment 2

[0074] An austenitic stainless steel resistant to high temperature and high concentration of sulfuric acid, including the following components: Cr 13.6wt%, Ni15.7wt%, Si6.05wt%, Cu 0.95wt%, Mo 1.0wt%, C 0.012wt%, Mn 1.0wt% %, S 0.001wt%, P 0.020wt%, Al 0.03wt%, N 0.018wt%, B 0.004wt%, rare earth 0.03wt%, Bi 0.001wt%, As 0.002wt%, Pb0.002wt%, Sn0.004 %, Sb 0.001wt%, the balance is Fe; and the sum of Bi, As, Pb, Sn, Sb five elements <0.05wt%.

[0075] In this embodiment, the preparation method of austenitic stainless steel is as follows:

[0076] (1) Ingredients: Raw materials are prepared according to the chemical composition and burning loss of austenitic stainless steel. The main raw materials include but are not limited to low-phosphorus carbon steel, low-phosphorus ferrochrome, ferronickel, nickel plate, ferromolybdenum, metal copper, and ferrosilicon , metal silicon; send the raw materials into the electric arc furnace to melt into molten steel, add 30kg / t of slagging age...

Embodiment 3

[0084] An austenitic stainless steel resistant to high temperature and high concentration of sulfuric acid, including the following components: Cr17.8wt%, Ni 20.wt%, Si5.4wt%, Cu 0.92wt%, Mo 1.95wt%, C 0.015wt%, Mn 1.1 wt%, S 0.002wt%, P0.022wt%, Al 0.04wt%, N≤0.016wt%, B 0.003wt%, rare earth 0.02wt%, Bi 0.001wt%, As0.002wt%, Pb 0.002wt%, Sn0 .005%, Sb 0.002wt%, the balance is Fe; and the sum of Bi, As, Pb, Sn, Sb five elements <0.05wt%.

[0085] In this embodiment, the preparation method of austenitic stainless steel is as follows:

[0086] (1) Ingredients: Raw materials are prepared according to the chemical composition and burning loss of austenitic stainless steel. The main raw materials include but are not limited to low-phosphorus carbon steel, low-phosphorus ferrochrome, ferronickel, nickel plate, ferromolybdenum, metal copper, and ferrosilicon , metal silicon; send the raw materials into the electric arc furnace to melt into molten steel, add 32kg / t slagging agent lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com