Display method for precipitation condition of ferrite along original austenite

A display method and a technology for displaying conditions, applied in the field of iron and steel structure analysis, can solve the problems of inability to study and analyze ferrite precipitation, observe the original austenite structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for displaying ferrite precipitation along prior austenite, comprising:

[0060] S1. Sample preparation: Prepare a sample made of 20CrMnTi steel, and polish the detection surface of the sample.

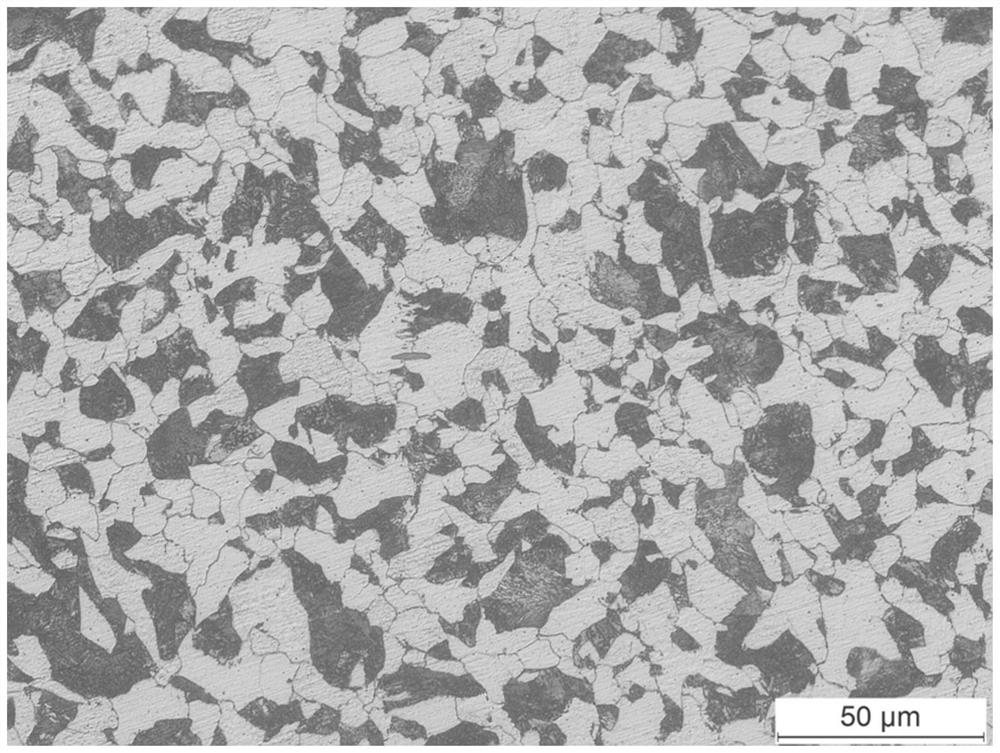

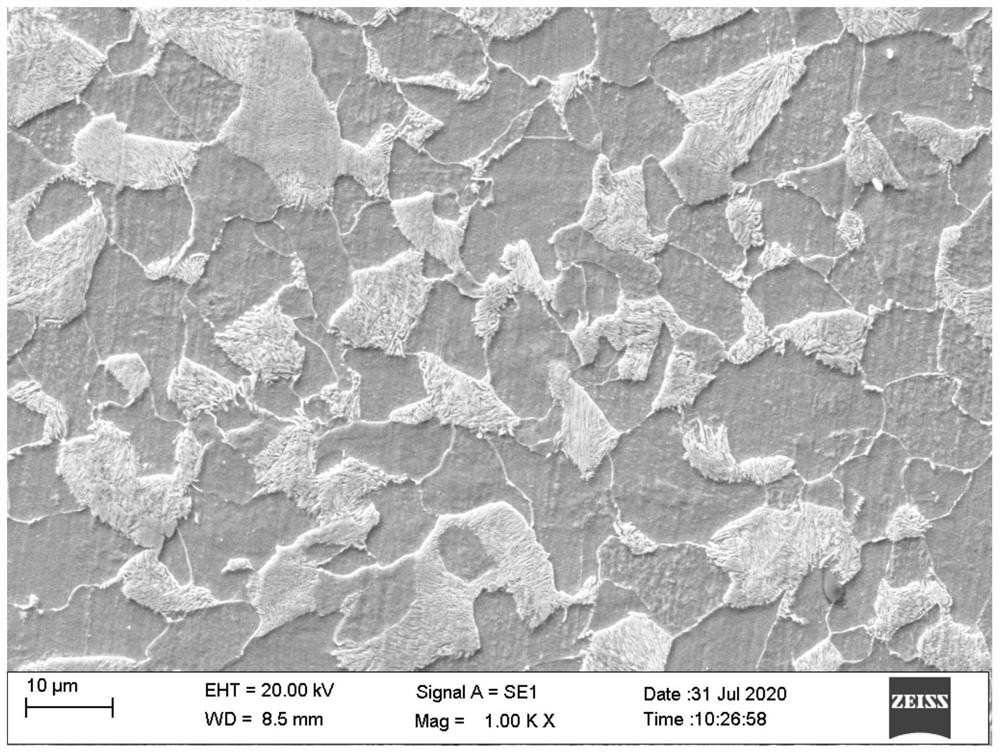

[0061] S2. Microstructure treatment: put the sample into the heat treatment furnace with the polished detection surface facing up, heat it to 890°C, and keep it for 60 minutes to completely austenitize the sample and form an iron oxide layer on the detection surface; then The samples were taken out of the heat treatment furnace for air cooling, so that the austenite under the iron oxide layer was transformed into ferrite and pearlite.

[0062] S3. Grinding and polishing of the detection surface: knock out the iron oxide scale on the detection surface of the sample; then finely grind the sample so that the area of the iron oxide layer retained on the detection surface accounts for 5%; and then polish the detection surface to make it form a mirror.

[0063] S4. Corro...

Embodiment 2

[0065] A method for displaying ferrite precipitation along prior austenite, comprising:

[0066] S1. Sample preparation: Prepare a sample made of 35 steel, and polish the detection surface of the sample.

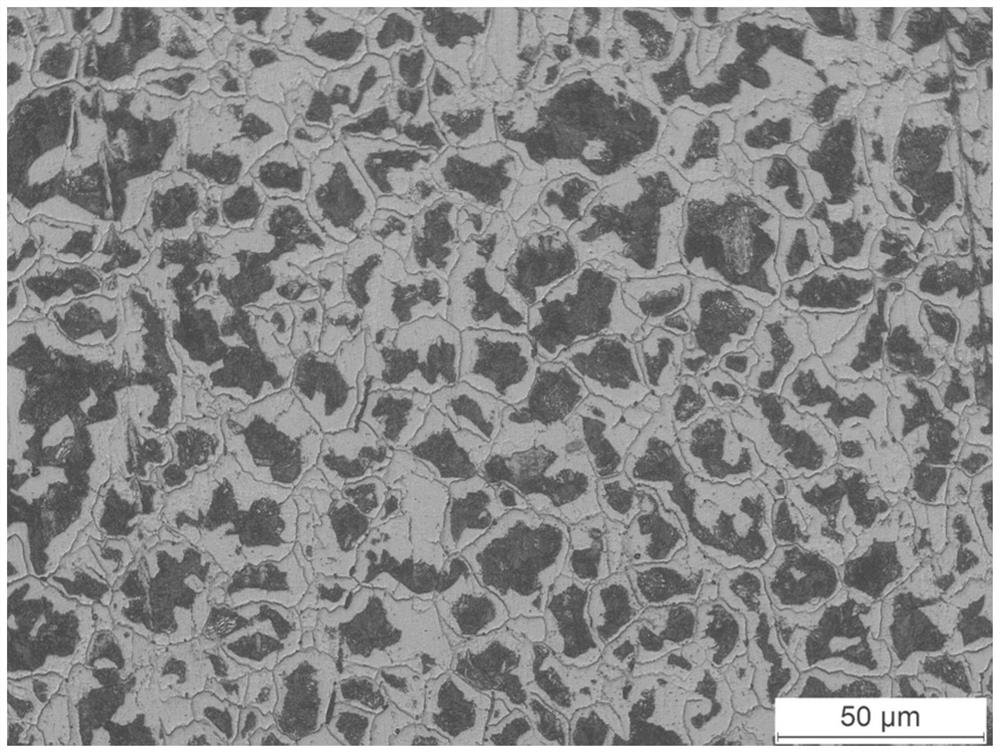

[0067] S2. Microstructure treatment: put the sample into the heat treatment furnace with the polished detection surface facing up, heat it to 860°C, and keep it for 30 minutes to completely austenitize the sample and form an iron oxide layer on the detection surface; then The samples were taken out of the heat treatment furnace for air cooling, so that the austenite under the iron oxide layer was transformed into ferrite and pearlite.

[0068] S3. Grinding and polishing of the detection surface: knock out the iron oxide scale on the detection surface of the sample; then finely grind the sample so that the area of the iron oxide layer retained on the detection surface accounts for 50%; and then polish the detection surface to make it form a mirror.

[0069] S4. Corrosion ...

Embodiment 3

[0071] A method for displaying ferrite precipitation along prior austenite, comprising:

[0072] S1. Sample preparation: Prepare a sample made of 20Cr steel, and polish the detection surface of the sample.

[0073] S2. Microstructure treatment: put the sample into the heat treatment furnace with the polished detection surface facing up, heat it to 890°C, and keep it for 30 minutes to completely austenitize the sample and form an iron oxide layer on the detection surface; then The samples were taken out of the heat treatment furnace for air cooling, so that the austenite under the iron oxide layer was transformed into ferrite and pearlite.

[0074] S3. Grinding and polishing of the detection surface: knock out the iron oxide scale on the detection surface of the sample; then finely grind the sample so that the area of the iron oxide layer retained on the detection surface accounts for 95%; and then polish the detection surface to make it form a mirror.

[0075] S4. Corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com