Preparation method of austenitic heat-resistant steel with high durable strength and steam corrosion resistance

A technology for austenitic heat-resistant steel and lasting strength, applied in the field of austenitic heat-resistant steel preparation, can solve problems such as inapplicability, improve oxygen supply strength, reduce burning loss and slag, and reduce chromium burning. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

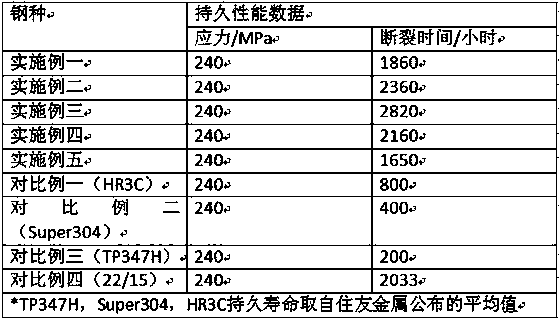

Examples

Embodiment 1

[0032] In this embodiment, the chemical composition of the austenitic heat-resistant steel is as follows:

[0033] Cr 21wt%, Ni 10wt%, Cu 2.5wt%, N 0.18wt%, C 0.04wt%, Nb 0.20wt%, V0.10wt%, Mo 0.15wt%, Si 0.6wt%, Mn 0.8wt%, S< 0.01wt%, P<0.025wt%, B0.003wt%, Bi<0.015wt%, As<0.015wt%, Pb<0.015wt%, Sn<0.015wt%, Sb<0.015wt%, the balance is Fe; And the sum of the five elements of Bi, As, Pb, Sn, and Sb is <0.05wt%.

[0034] In this embodiment, the preparation method of austenitic heat-resistant steel is as follows:

[0035] (1) Ingredients: Prepare raw materials according to the chemical composition and burning loss of austenitic heat-resistant steel, send the raw materials into the electric arc furnace to melt into molten steel, add 25kg / t of slagging agent lime for initial smelting in the electric furnace, and reduce with the reducing agent For oxidized metals in molten steel, adjust the Cr content in molten steel to be 0.30% higher than the lower limit of the target value spe...

Embodiment 2

[0044] In this embodiment, the chemical composition of the austenitic heat-resistant steel is as follows:

[0045] Cr 23wt%, Ni 15.5wt%, Cu 3.6wt%, N 0.25wt%, C 0.07wt%, Nb 0.50wt%, V0.12wt%, Mo 0.15wt%, Si 0.3wt%, Mn 0.6wt%, S <0.005wt%, P<0.025wt%, B0.002wt%, Bi<0.015wt%, As<0.015wt%, Pb<0.015wt%, Sn<0.015wt%, Sb<0.015wt%, the balance is Fe .

[0046] In this embodiment, the preparation method of austenitic heat-resistant steel is as follows:

[0047] (1) Ingredients: prepare raw materials according to the chemical composition and burning loss of austenitic heat-resistant steel, send the raw materials into the electric arc furnace to melt into molten steel, add 27kg / t of slagging agent lime for the initial refining of the electric furnace, and reduce with the reducing agent For oxidized metals in molten steel, adjust the Cr content in molten steel to be 0.30% higher than the lower limit of the target value specified for the type of steel being made; when the temperature of...

Embodiment 3

[0056] Cr 22.5wt%, Ni 15wt%, Cu 3.5wt%, N 0.25wt%, C 0.07wt%, Nb 0.45wt%, V0.20wt%, Mo 0.35wt%, Si 0.3wt%, Mn 0.7wt%, S <0.005wt%, P<0.025wt%, B0.003wt%, Bi<0.015wt%, As<0.015wt%, Pb<0.015wt%, Sn<0.015wt%, Sb<0.015wt%, the balance is Fe .

[0057] In this embodiment, the preparation method of austenitic heat-resistant steel is as follows:

[0058] (1) Ingredients: prepare raw materials according to the chemical composition and burning loss of austenitic heat-resistant steel, send the raw materials into the electric arc furnace to melt into molten steel, add 28kg / t of slagging agent lime for the initial smelting of the electric furnace, and reduce with the reducing agent For oxidized metals in molten steel, adjust the Cr content in molten steel to be 0.30% higher than the lower limit of the target value specified for the type of steel being made; when the temperature of molten steel reaches 1630°C, the molten steel is released from the furnace;

[0059] (2) Oxygen blowing dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com