High-temperature-resistant aluminum alloy material and preparation method thereof

An aluminum alloy material, high temperature resistance technology, applied in the field of alloys, can solve the problems of low strength and poor high temperature resistance, and achieve the effects of low mismatch degree, stable substructure and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a high-temperature-resistant aluminum alloy material, which comprises the following mass ratios: Al is 81%, Si is 9%, Mg is 5%, Fe is 2%, B is 1%, Ti is 1%, and Ce is 1%. .

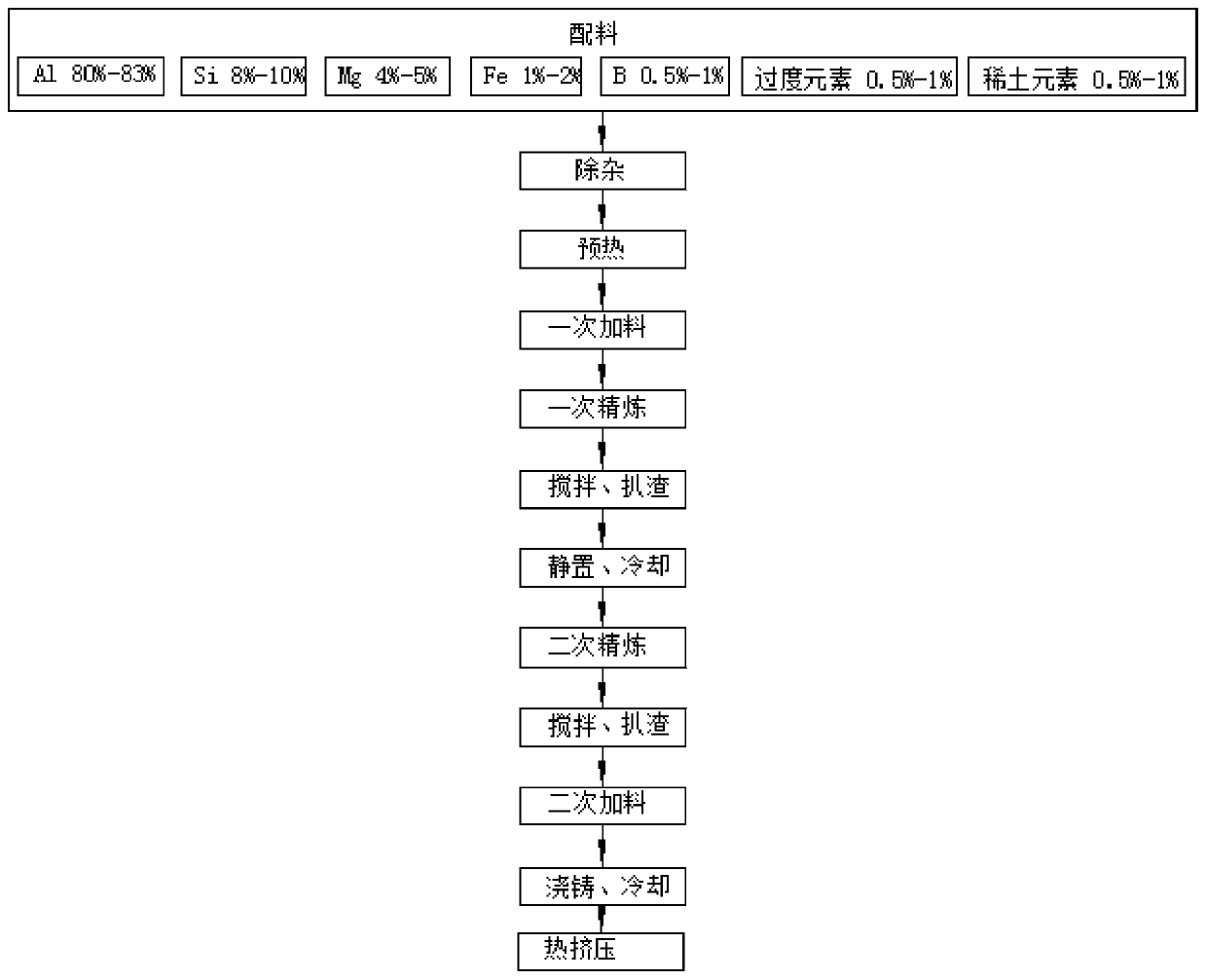

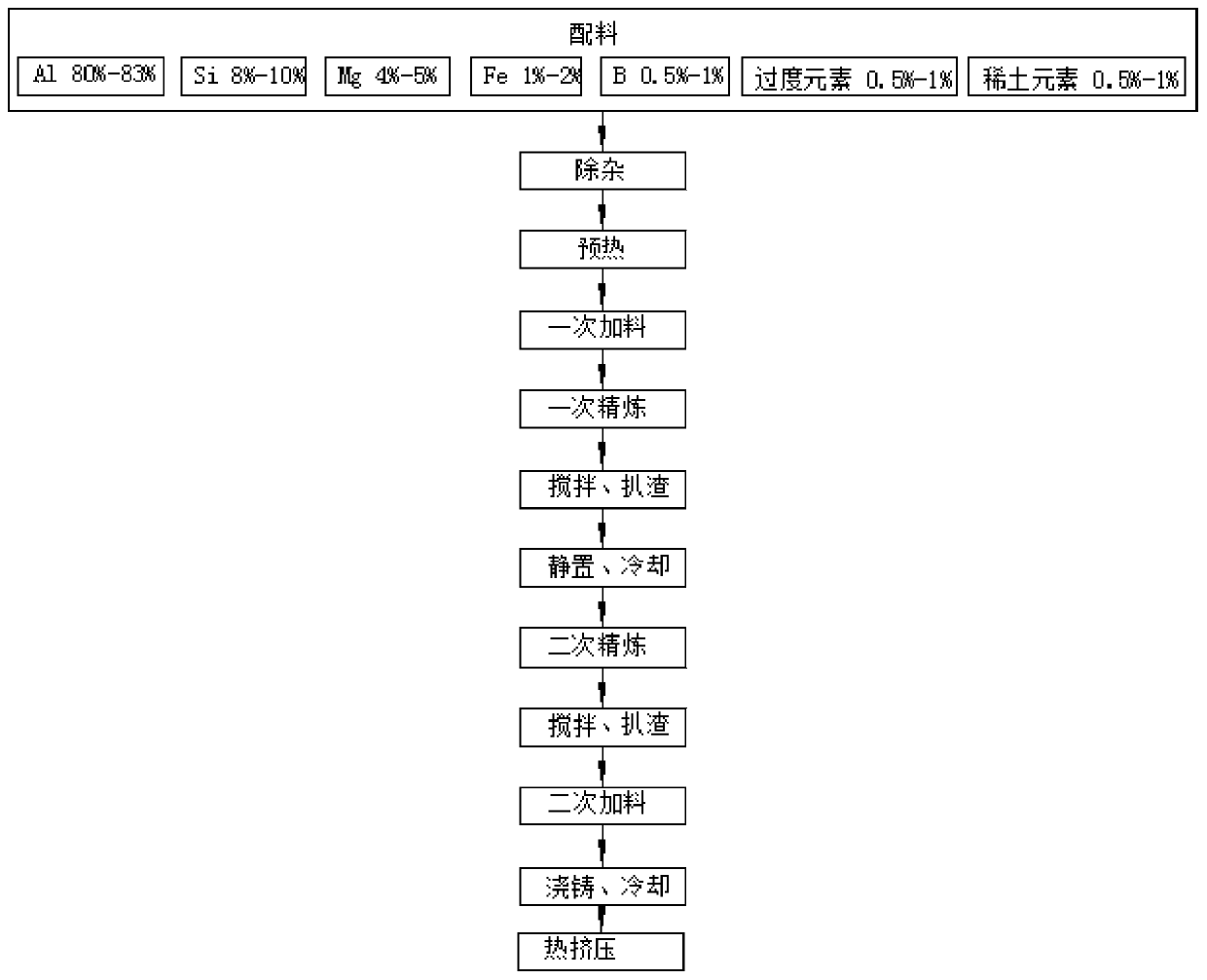

[0032] The preparation method of a kind of high temperature resistant aluminum alloy material of embodiment one, please refer to figure 1 , including the following steps:

[0033] 1), first carry out batching, and weigh the raw materials according to each proportion through the weighing device, and crush them;

[0034] 2) Place the weighed raw materials inside the material frame, and then use an ultrasonic cleaning device to remove impurities and dust on the surface;

[0035] 3), after the removal of impurities is completed, the raw materials in step 2) are preheated through the waste heat recovery device;

[0036] 4) After step 3) is completed, put the preheated Al, Si, Mg and Fe into the furnace together, and carry out refining at a high temperature of 900-1000°C. When t...

Embodiment 2

[0045] A high temperature resistant aluminum alloy material, comprising the following mass ratios: 81% Al, 9% Si, 5% Mg, 2% Fe, 1% B, 1% Zr, and 1% Sc.

[0046] For a preparation method of a high temperature resistant aluminum alloy material in embodiment two, please refer to figure 1 , including the following steps:

[0047] 1) Firstly, batching is carried out, and the raw materials are weighed and proportioned according to various proportions through the weighing device;

[0048] 2) Place the weighed raw materials inside the material frame, and then use an ultrasonic cleaning device to remove impurities on the surface to remove dust on the surface. When removing impurities, the raw materials need to be stirred;

[0049] 3), after the removal of impurities is completed, the raw materials in step 2) are preheated through the waste heat recovery device;

[0050] 4) After step 3) is completed, put the preheated Al, Si, Mg and Fe into the furnace together, and carry out refinin...

Embodiment 3

[0055] A high temperature resistant aluminum alloy material, comprising the following mass ratios: 81% for Al, 10% for Si, 4.5% for Mg, 1.5% for Fe, 1% for B, 1% for Ni, 1% for each of Sc and Ce .

[0056] For a preparation method of a high-temperature-resistant aluminum alloy material in Embodiment 3, please refer to figure 1 , including the following steps:

[0057] 1) Firstly, batching is carried out, and the raw materials are weighed and proportioned according to various proportions through the weighing device;

[0058] 2) Place the weighed raw materials inside the material frame, and then use the ultrasonic cleaning device to remove impurities and remove the dust on the surface;

[0059] 3), after the impurity removal is completed, the raw materials in step 2 are preheated through the waste heat recovery device;

[0060] 4) After step 3) is completed, put the preheated Al, Si, Mg and Fe into the furnace together, and carry out refining at a high temperature of 900-1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com