Cutting and polishing equipment for plastic-wood plate

A board and plastic wood technology, applied in the field of plastic wood board cutting and polishing equipment, can solve the problems of fixed plastic wood board, rough and unequal cutting surface, and achieve the effect of smooth cutting surface and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

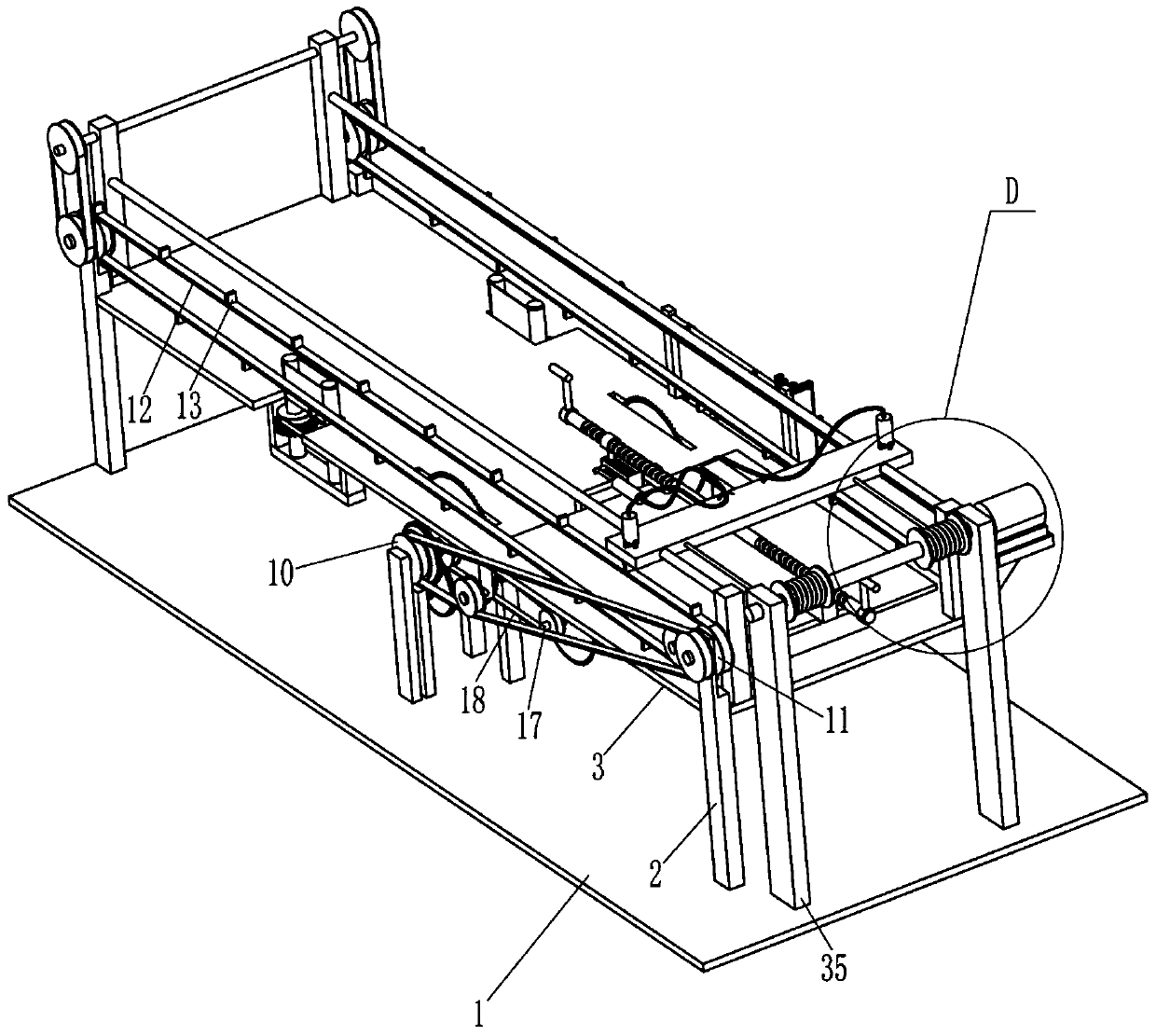

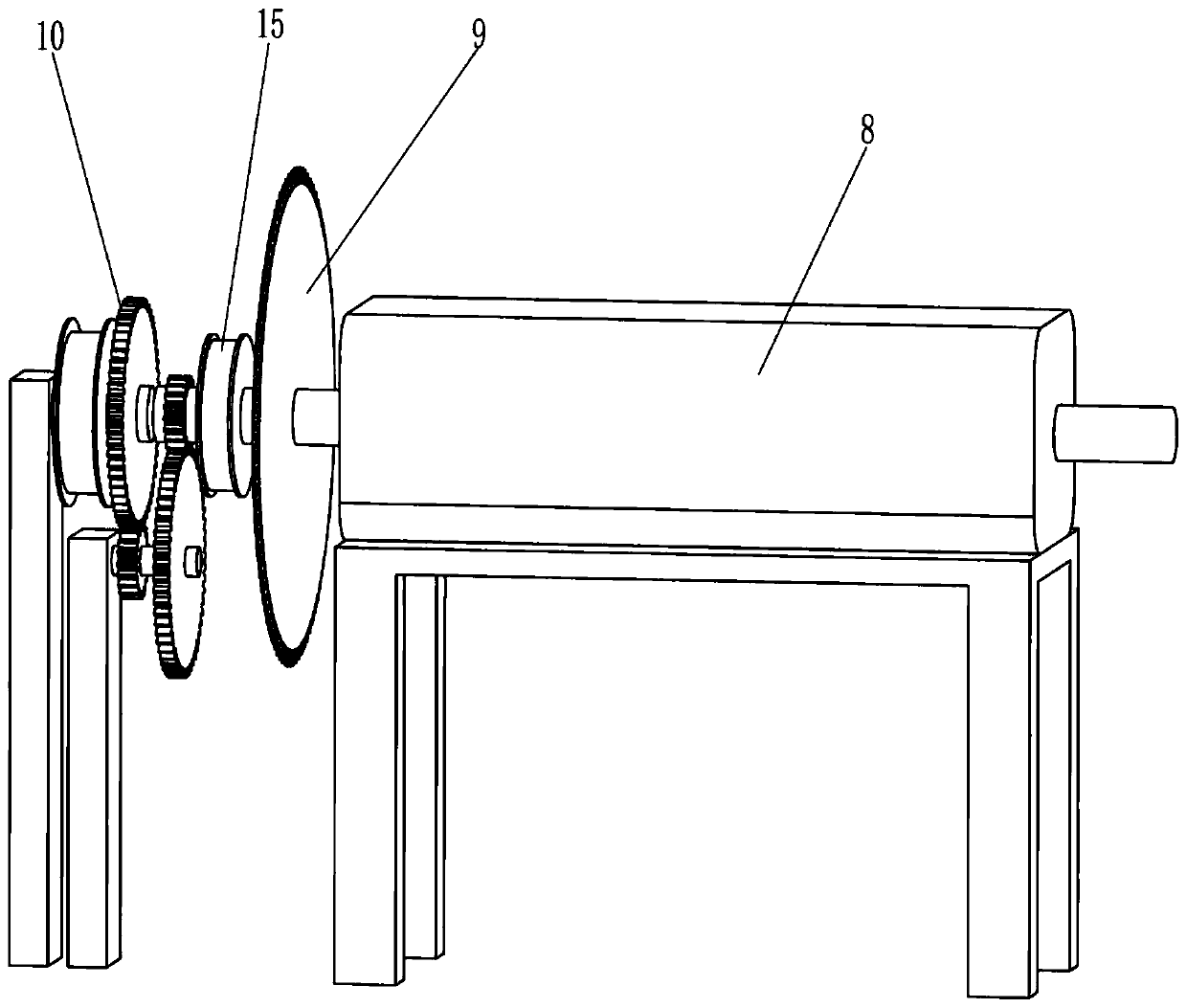

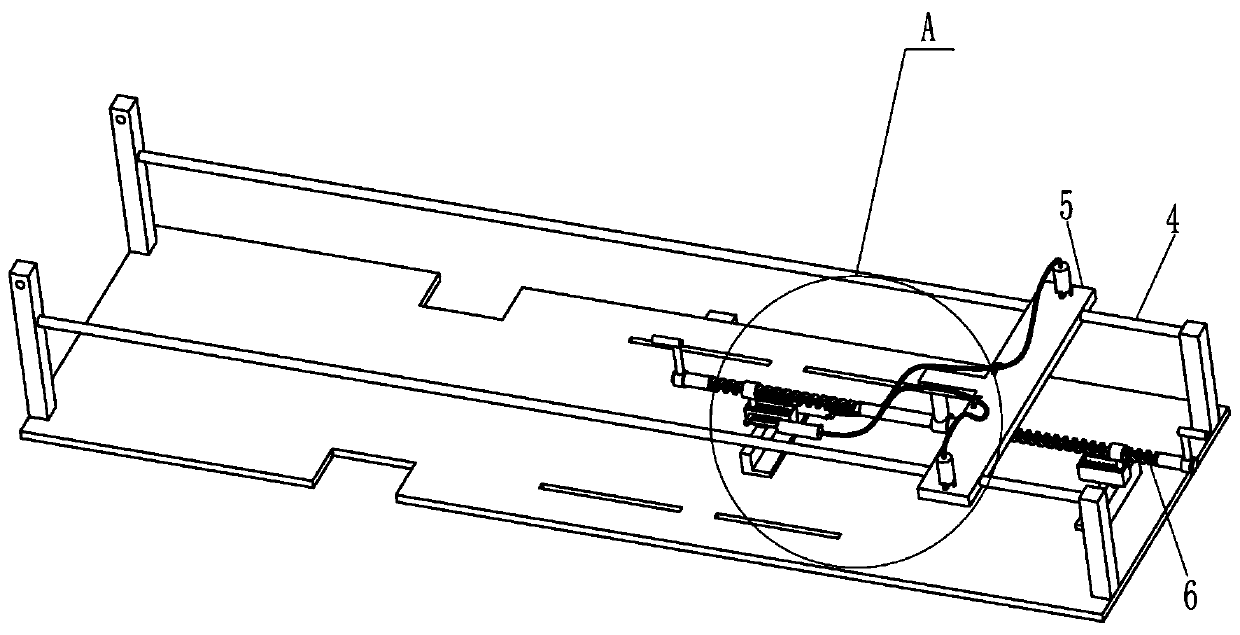

[0033] A wood-plastic plate cutting and polishing equipment, refer to Figure 1-13 , including a bottom plate 1, a first bracket 2, a placement plate 3, a first slide bar 4, a slide plate 5, a transmission block 51, a clamping assembly 6, a biaxial motor 8, a first cutting saw 9, a transmission assembly 10, a first Transmission wheel 11, the first transmission belt 12, the first push block 13, polishing assembly 14 and cutting assembly, the left and right sides of bottom plate 1 top all are equipped with first support 2 by bolt, are connected between the first support 2 of left and right sides Place plate 3 and two first slide bars 4, place plate 3 is positioned at below two first slide bars 4, two first slide bars 4 slide type is provided with slide plate 5, slide plate 5 front and rear all have The two openings are provided with transmission blocks 51, the top of the bottom plate 1 is connected with a mounting frame, the top of the mounting frame is equipped with a double-ax...

Embodiment 2

[0042] On the basis of embodiment 1, with reference to Figure 4 , Figure 5 , Figure 6 and Figure 14 , also includes a clutch assembly 7, the clutch assembly 7 includes a first compression cylinder 701, an intake valve 702, an outlet valve 703, a first push rod 704, a first piston 705, an air pipe 706, a second compression cylinder 707, a second The piston 708 and the second spring 709 are connected with the first compression cylinder 701 on the front and rear sides of the housing 604 on the left side, the two first compression cylinders 701 are connected with the intake valve 702, and the first sliding sleeve 603 on the left side The front and rear sides are connected with a first push rod 704, the first push rod 704 runs through the left housing 604, the first compression cylinder 701 is provided with a first piston 705, and the first push rod 704 runs through the left side of the first compression cylinder 701. side and is connected with the left side of the first pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com