Yak milk residue cake production system

A production system and technology of yak milk, applied in the field of yak milk dregs cake production system, can solve problems such as unsuitable for large-scale production, high defective rate, weak continuity, etc., to achieve enhanced system continuity, high production efficiency, Reduce the effect of transit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

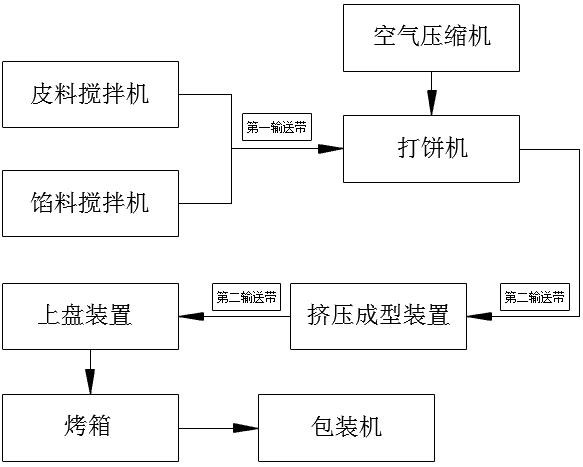

[0023] refer to figure 1 Shown, a kind of yak milk dregs cake production system comprises leather material mixer, stuffing mixer, first conveyor belt, cake making machine, second conveyor belt, extruding molding device, loading device, oven, packaging machine; The leather mixer is used to stir and mix the leather to make the leather; the filling mixer is used to stir and mix the filling to make the filling; the first conveyor belt includes two, respectively The leather of the material mixer and the filling of the filling mixer are delivered to the cake maker; the cake maker is used to make cakes and wrap the filling in the leather; the second conveyor belt is used to connect the cake maker to the top Disk device; The extrusion molding device is arranged on one side of the second conveyor belt between the cake making machine and the upper disk device, and is used to extrude the semi-finished yak milk slag cake; The upper disk device is used to make the semi-finished yak The mi...

Embodiment 2

[0030] refer to figure 1 Shown, a kind of yak milk dregs cake production system comprises leather material mixer, stuffing mixer, first conveyor belt, cake making machine, second conveyor belt, extruding molding device, loading device, oven, packaging machine; The leather mixer is used to stir and mix the leather to make the leather; the filling mixer is used to stir and mix the filling to make the filling; the first conveyor belt includes two, respectively The leather of the material mixer and the filling of the filling mixer are delivered to the cake maker; the cake maker is used to make cakes and wrap the filling in the leather; the second conveyor belt is used to connect the cake maker to the top Disk device; The extrusion molding device is arranged on one side of the second conveyor belt between the cake making machine and the upper disk device, and is used to extrude the semi-finished yak milk slag cake; The upper disk device is used to make the semi-finished yak The mi...

Embodiment 3

[0036] refer to figure 1 Shown, a kind of yak milk dregs cake production system comprises leather material mixer, stuffing mixer, first conveyor belt, cake making machine, second conveyor belt, extruding molding device, loading device, oven, packaging machine; The leather mixer is used to stir and mix the leather to make the leather; the filling mixer is used to stir and mix the filling to make the filling; the first conveyor belt includes two, respectively The leather of the material mixer and the filling of the filling mixer are delivered to the cake maker; the cake maker is used to make cakes and wrap the filling in the leather; the second conveyor belt is used to connect the cake maker to the top Disk device; The extrusion molding device is arranged on one side of the second conveyor belt between the cake making machine and the upper disk device, and is used to extrude the semi-finished yak milk slag cake; The upper disk device is used to make the semi-finished yak The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com