Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about How to "Crystallization intact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

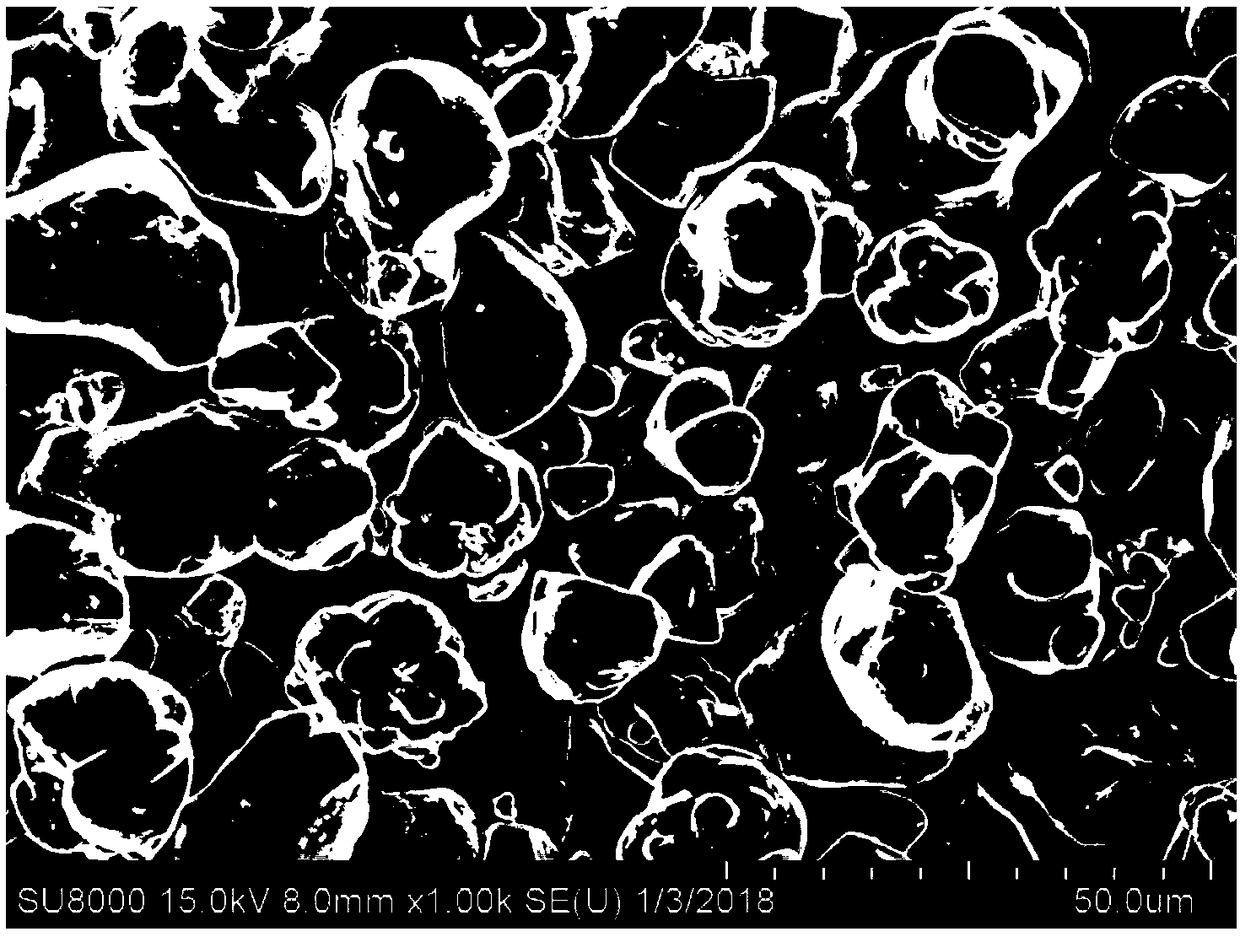

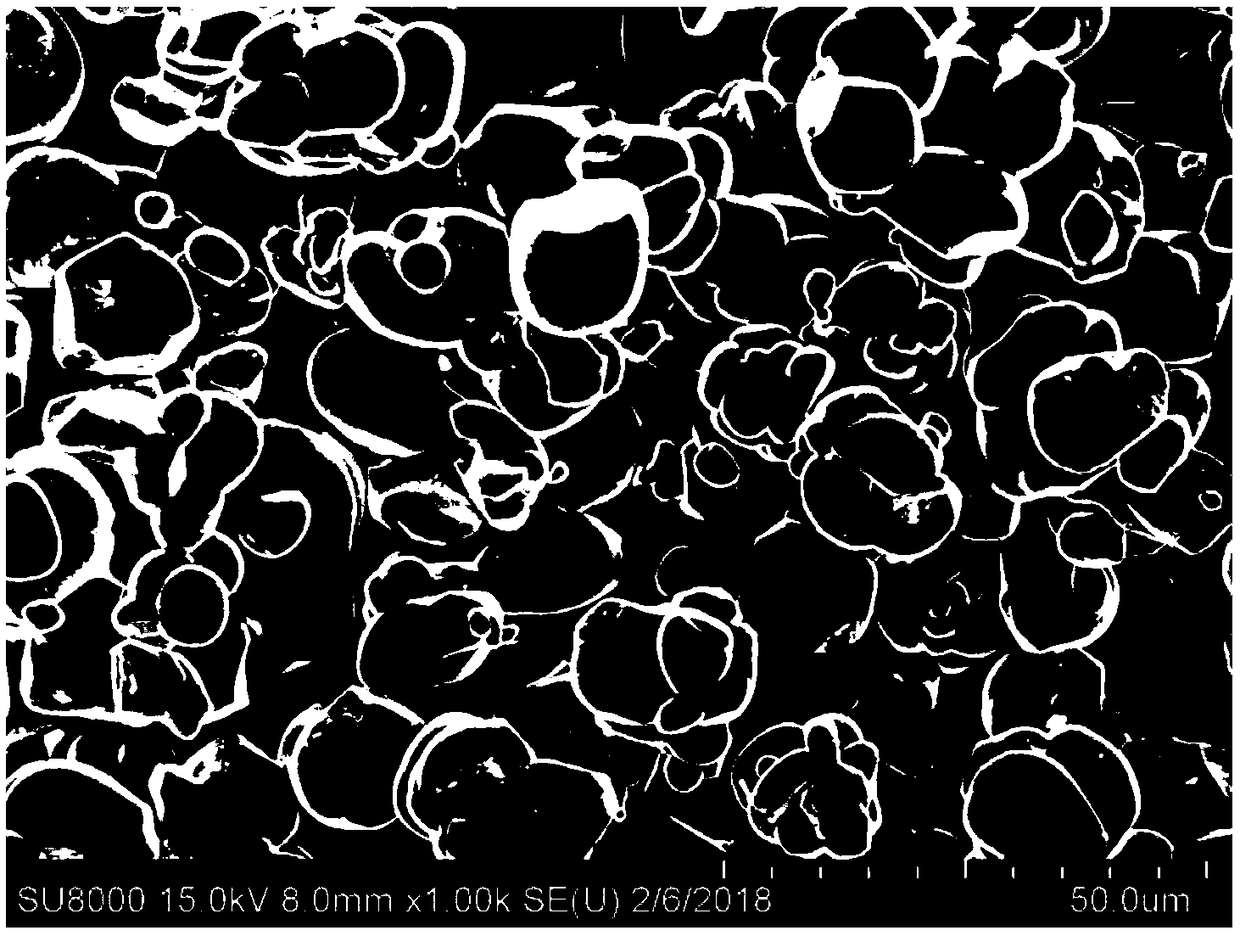

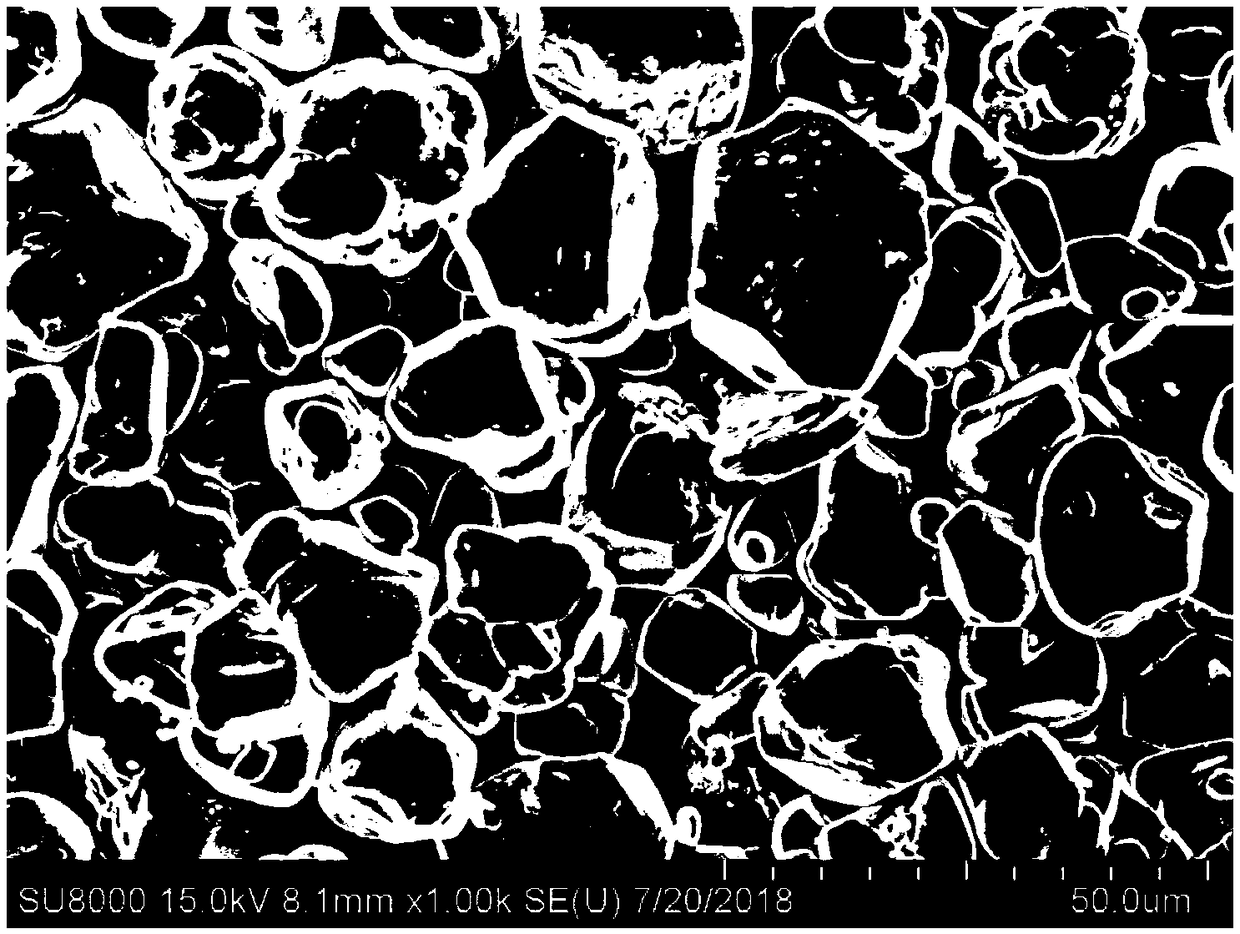

Preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN109326781AEvenly distributedWell mixedSecondary cellsPositive electrodesDual effectCobalt(II,III) oxide

The invention discloses a preparation method of a high-voltage lithium cobalt oxide cathode material which comprises the steps: (1) mixing cobaltosic oxide containing doped element M, a lithium source, oxide containing doped element M', a grain refiner and a fluxing agent to obtain a primary mixture; (2) sintering and smashing the primary mixture to obtain primary sintered powder; (3) mixing the primary sintered powder with a coating material to obtain a secondary mixture; (4) sintering and smashing the secondary mixture to obtain the lithium cobalt oxide cathode material. According to the preparation method disclosed by the invention, the problem of microscale segregation of distribution of doped elements in the product is solved by two modes of doped element premixing and dry-method mixing; a coulter type mixing technology is utilized to solve the problem of segregation of different matters in material mixing; the grain refiner and the fluxing agent are combined for use to synthesizea material in a mixed morphology; technologies such as dual effects of doped element surface crystallization catalysis and the coating material and the like are utilized; thus, performance of the high-voltage lithium cobalt oxide is obviously improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

Method for preparing high-purity calcite calcium carbonate micropowder through shell hydro-thermal treatment

InactiveCN103086414AIncrease the rate of the hydrolysis reactionImprove solubilityCalcium/strontium/barium carbonatesCalciteHigh pressure

The invention discloses a method for preparing high-purity calcite calcium carbonate micropowder through shell hydro-thermal treatment and belongs to the field of inorganic materials. The method comprises the following process steps of: (1), grinding shells into powder and sieving the shell powder; (2), adding the shell powder to an alkali aqueous solution, and putting the mixture to a high-pressure kettle to carry out hydro-thermal treatment; and (3), separating, cleaning and drying the treated shell powder to obtain the high-purity calcite calcium carbonate micropowder, wherein the grain size of the powder is 0.5 micron to 2 microns. The method for preparing high-purity calcite calcium carbonate micro powder through shell hydro-thermal treatment disclosed by the invention has the characteristics of being low in material cost, simple in production process, environment-friendly and safe in production process; and besides, the method is suitable for large-scale high-value recycling of the waste shells.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for improving mechanical properties of aramid fiber in supercritical fluid through stretching orientation

The invention relates to a method for improving mechanical properties of an aramid fiber in a supercritical fluid through stretching orientation. A supercritical carbon dioxide fluid is utilized for partially destroying interaction of a PPTA (poly-p-phenylene terephthamide) molecular chain in the aramid fiber under the action of certain tension, and the molecular chain is further oriented, so that the aramid fiber with good properties is obtained. The method for improving the mechanical properties of the aramid fiber in the supercritical fluid through stretching orientation mainly comprises the following steps: ensuring that the aramide fiber maintains certain tension in a closed container, introducing CO2 into the container at a certain temperature, so that the internal space of the closed container is in a supercritical CO2 state, carrying out swelling reaction for a period of time, and slowly releasing pressure, thus the highly stretching-oriented aramid fiber is obtained. The method for improving the mechanical properties of the aramid fiber in the supercritical fluid through stretching orientation guarantees that the aramid fiber is in a stretched state in a reaction process, so that orientation degree and crystallinity of a molecular chain are increased while stretching tension is changed, crystal particles are largened, and crystals are more and more complete.

Owner:DONGHUA UNIV +1

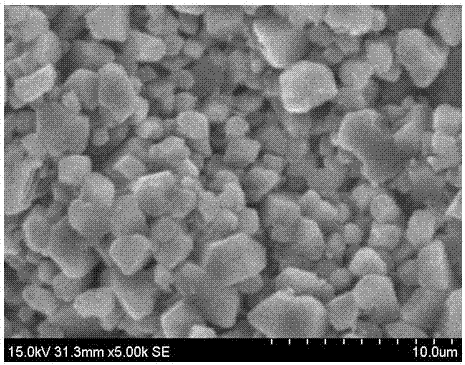

Method for preparing coarse grain hard alloy

The invention provides a coarse-grained hard alloy and a preparation method of the coarse-grained hard alloy, which mainly includes WC, Co accounting for 8.0 to 11.5 weight percent and TaC accounting for 0.4 to 0.6 weight percent; the average grain size of the WC in the coarse-grained hard alloy is 3.2 to 4.0Mu m, and the bending resistance strength is 2600 to 3100 MPa and the hardness Hv30 is 1100 to 1320. The preparation materials adopt the coarse-grained WC powder close to single crystal, with Fsss size 11.0 to 15.0Mu m and Hcp value 4.50 to 5.38 KA / m, TaC powder and Co powder; the vacuum sintering temperature is 1450 to 1520 DEG C, the ratio of TaC to Co is equal to to 0.045 to 0.055. The invention well matches the alloy strength and micro-harness, improves the over-all performance, thermal shock resistance and thermal plastic deformation resistance of the coarse-grained hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

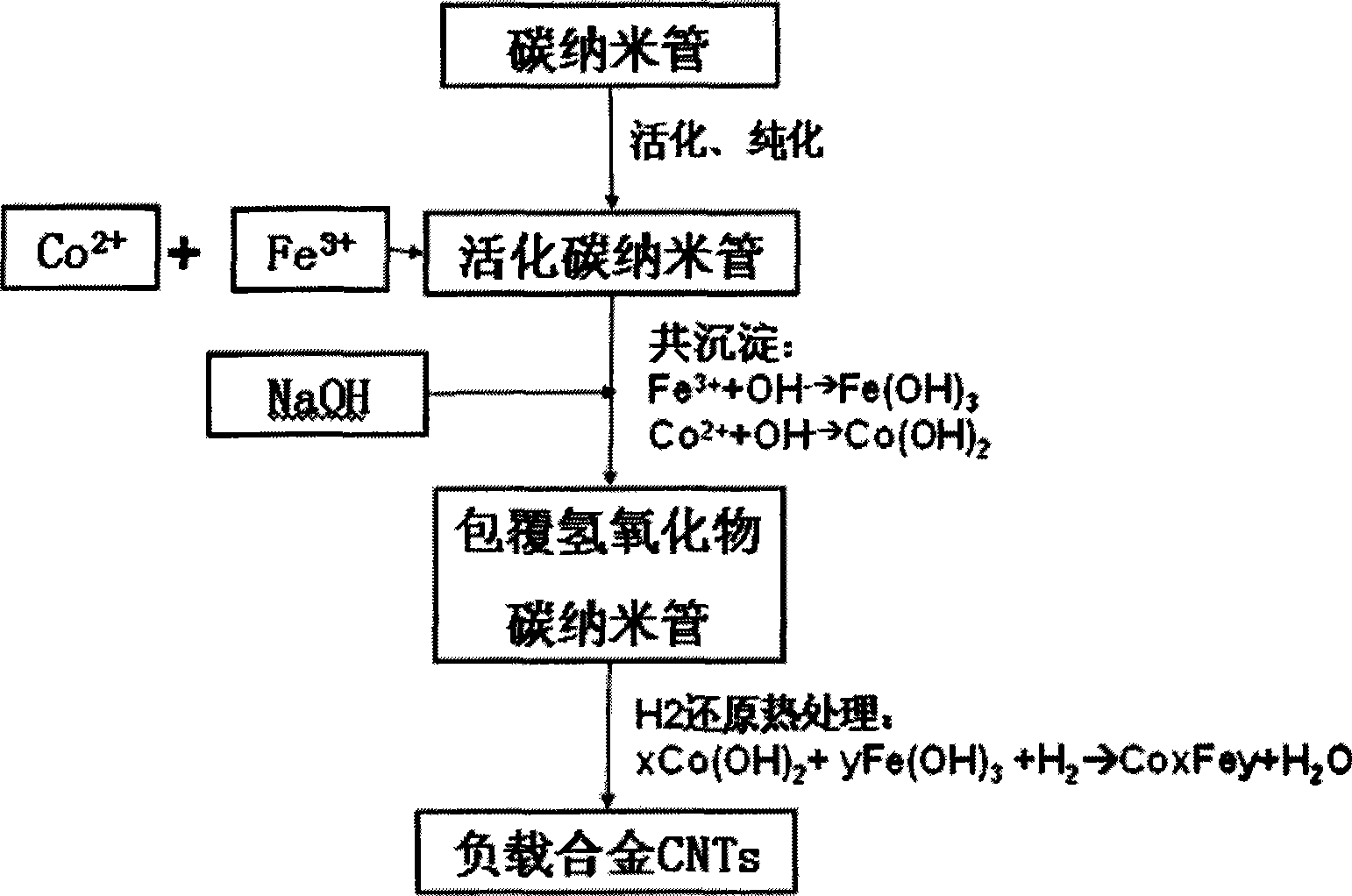

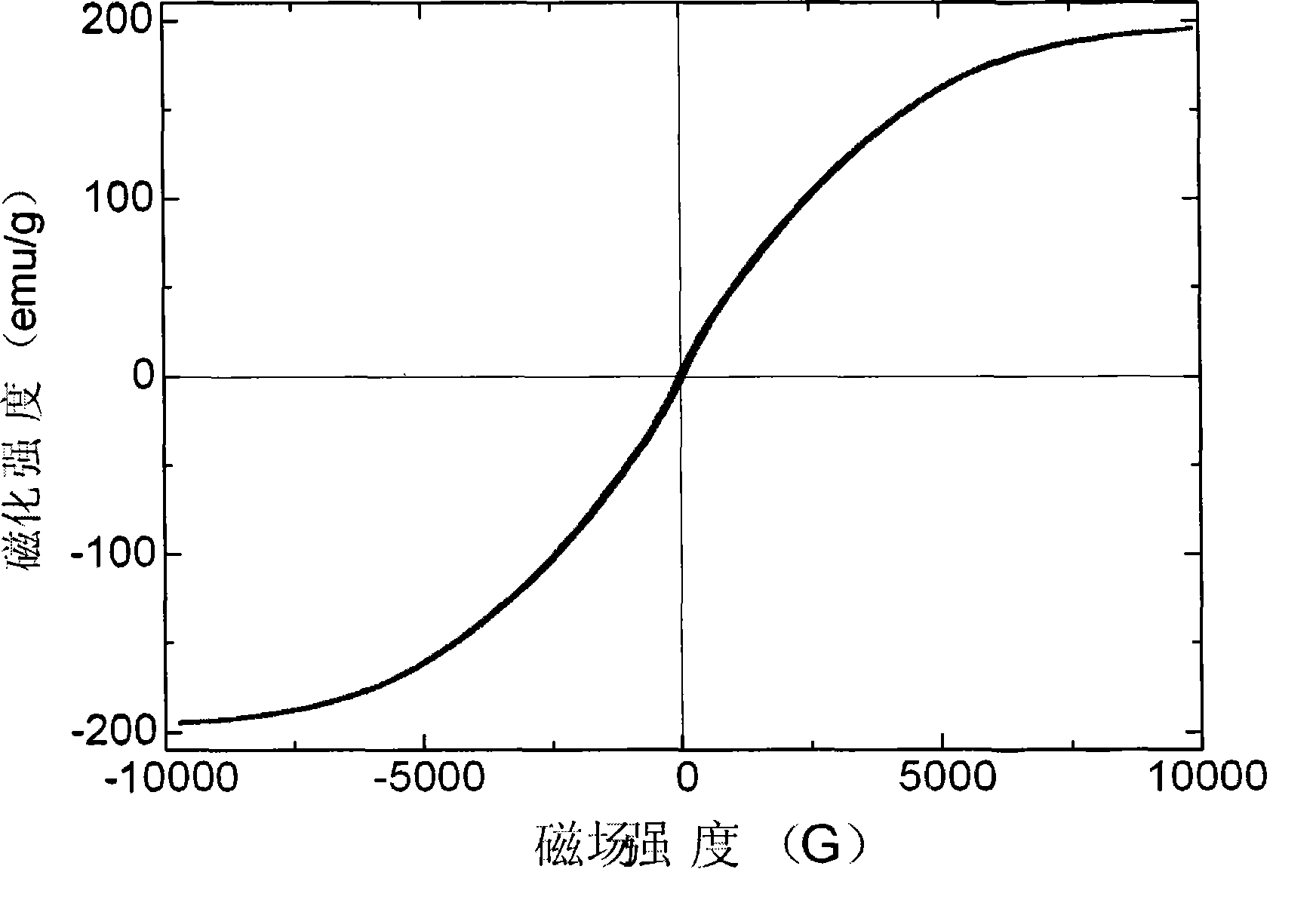

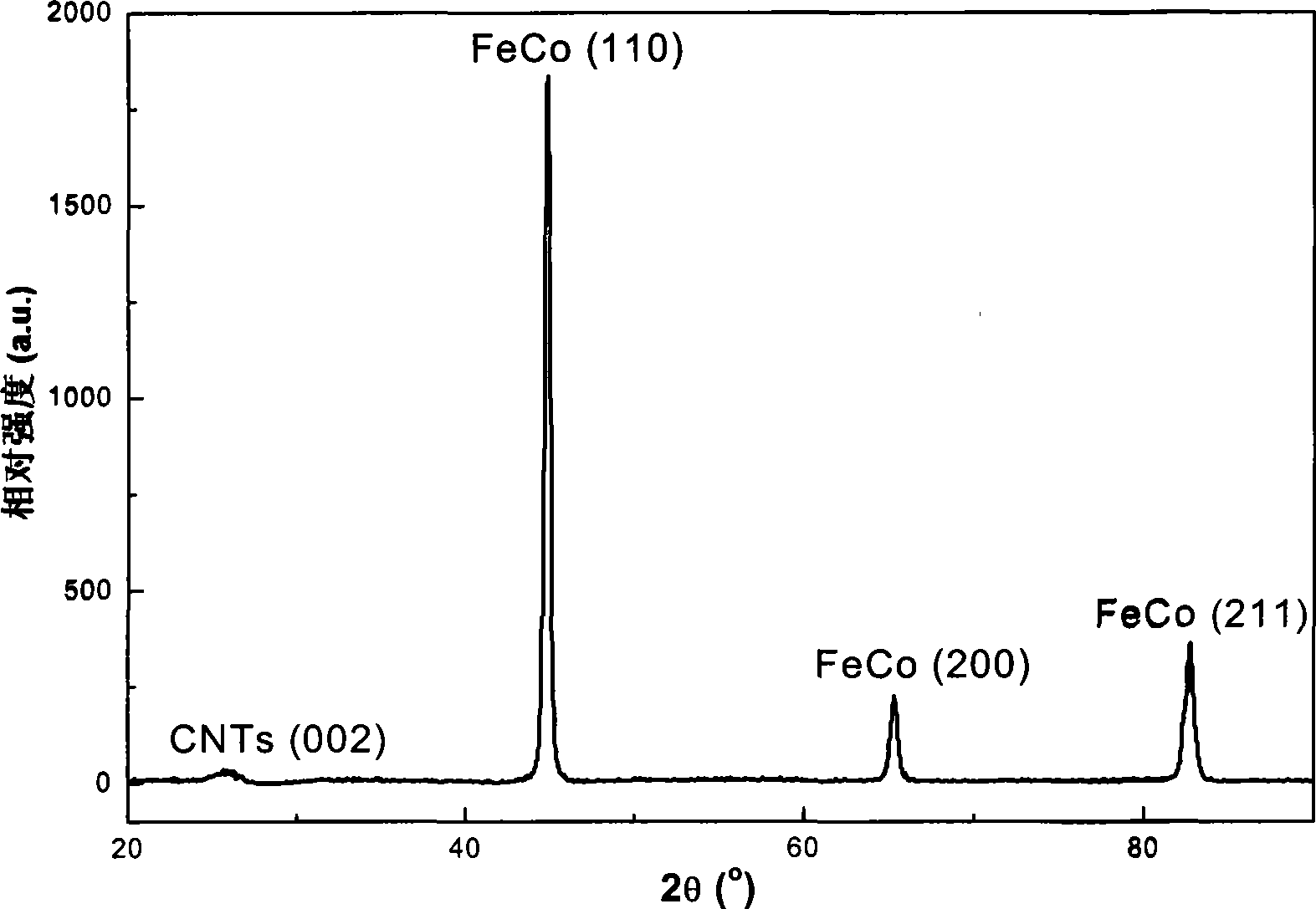

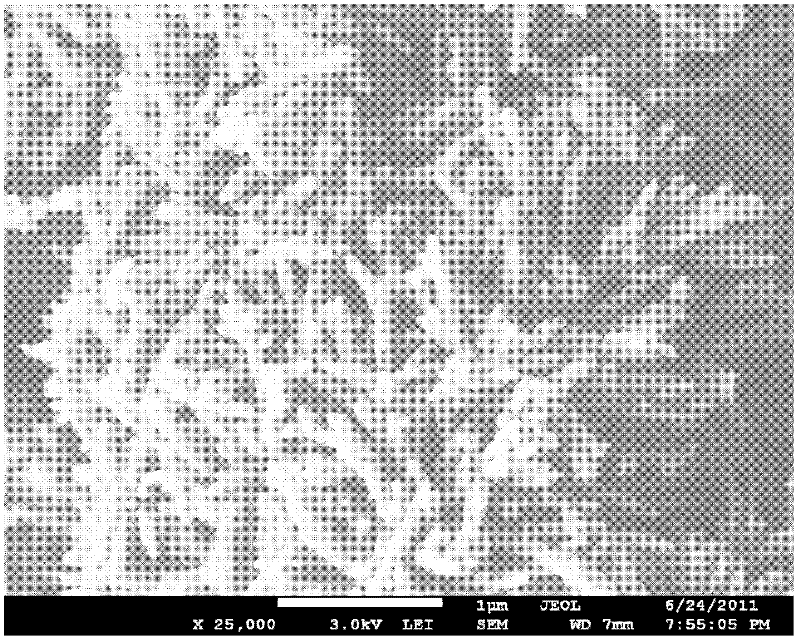

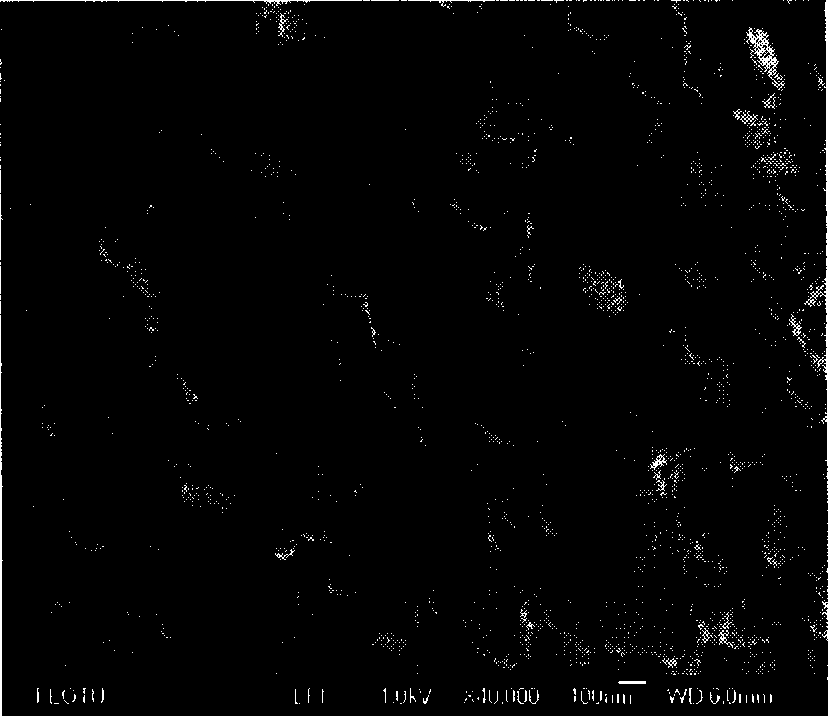

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

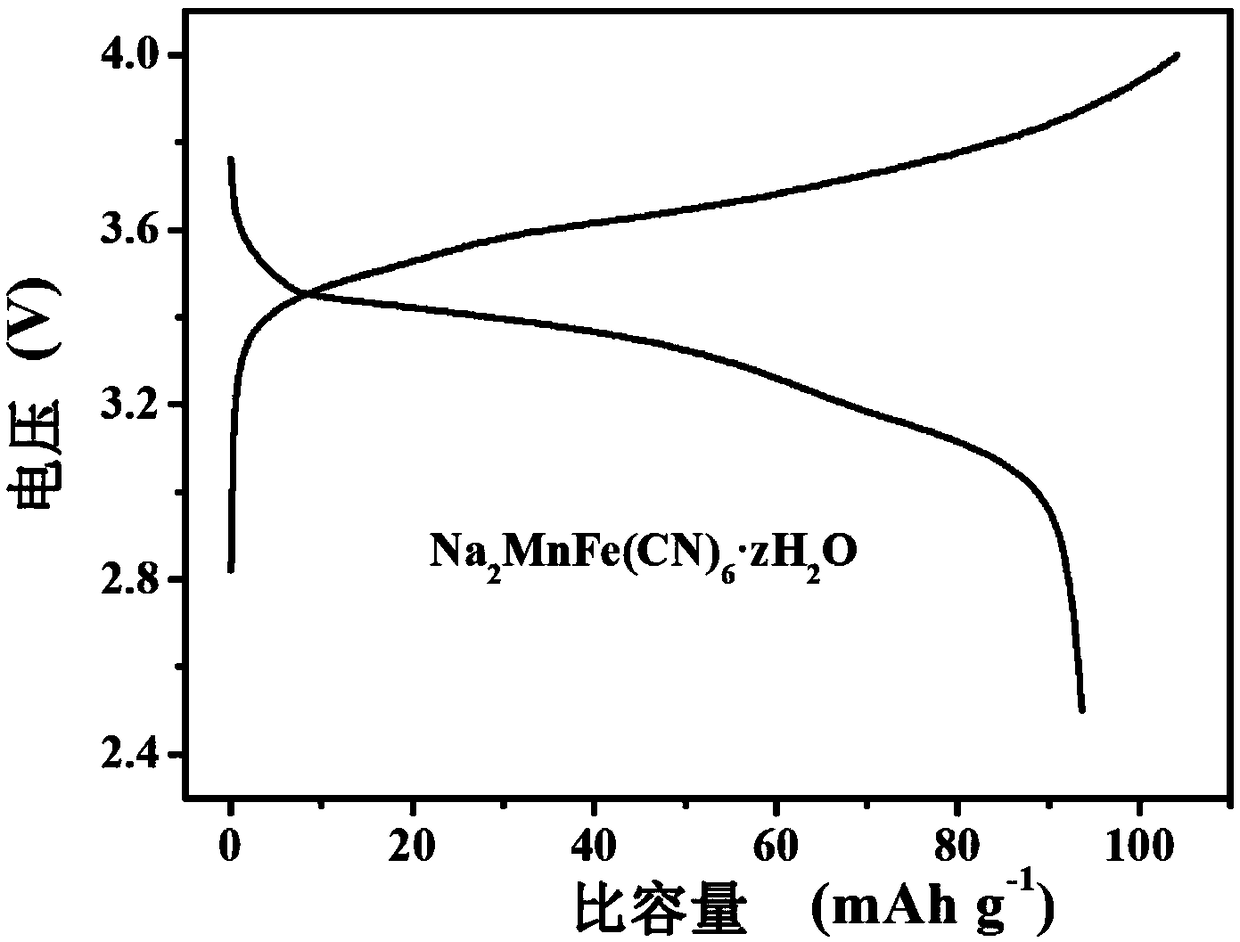

Sodium-ion battery anode material as well as preparation method and application thereof

ActiveCN108258239ALess structural defectsCrystallization intactSecondary cellsPositive electrodesIonCharge and discharge

The invention provides a sodium-ion battery anode material as well as a preparation method and application thereof. The anode material comprises doped prussian blue, wherein the prussian blue comprises a sodium element; the anode material is free of water. The preparation method of the anode material provided by the invention comprises the following steps: (1) mixing a solution A and a solution Bso as to obtain a suspension, wherein the solution A is a mixed solution of sodium ferrocyanide and sodium chloride; the solution B is a mixed solution of a doping source and a complexing agent; (2) performing solid-liquid separation on the suspension of the step (1), and collecting and drying a solid, thereby obtaining the anode material. The sodium-ion battery anode material provided by the invention has a univoltage platform, is excellent in charge and discharge property, is free of water and thus is particularly applicable to anodes of solid sodium ion batteries. The preparation method ofthe anode material provided by the invention is simple in process, low in cost and applicable to industrial application.

Owner:济宁中科恩吉科创新产业园管理有限公司

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

Quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material and preparation method

InactiveCN105958038AImprove structural stabilityImprove securityCell electrodesSecondary cellsLithiumHigh voltage

The invention relates to a preparation method of a quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material. The preparation method comprises the following steps: preparing Li<2>CO<3> and Co<3>O<4> as raw materials, adding a doping element M, adding a grain refiner and a cosolvent, and performing first sintering; and adding a grain refiner and a coating compound into a firstly-sintered material serving as a raw material, and performing surface coating and second sintering, wherein the doping element M is one or more of Ti<4+>, Zr<4+>, Mn<4+>, Sn<4+>, Ce<4+>, Ir<3+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and Co<2+>, a molecular formula of doped lithium cobaltate is LiCo<1-x>M<y>O<2-y>; and the grain refiner is one or more of oxides of Ti, Nb, V, Al and Zr. The prepared lithium cobaltate positive electrode material has the characteristics of rapid charging, high capacity, high voltage, high cycle and low cost, can be applied under a rapid-charging high-voltage condition, and has superior electrochemical performance.

Owner:湖南美特新材料科技有限公司 +1

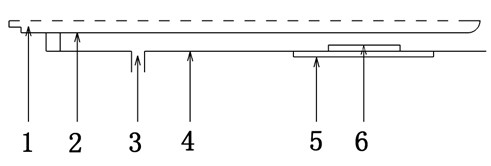

Production method for drug balloon

The invention discloses a production method for a drug balloon. The production method comprises the following steps: 1) preparing a medicinal solution; 2) spraying the medicinal solution on the surface of a balloon with layer by layer through a multi-time spraying technology. The production method has the beneficial effects that an oversaturated paclitaxel medicinal solution is prepared, and is directly applied to ultrasonic spraying to obtain a completely-crystallized medicinal coating. The multi-time spraying technology is used, and the medicinal coating is subjected to solvent steam treatment to obtain a medicinal coating with a small crystal size and a good binding effect between the crystal and a substrate. The drug balloon produced by the production method has the advantages that medicinal loss can be lowered greatly in passing and expanding processes, and the drug utilization rate is increased.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

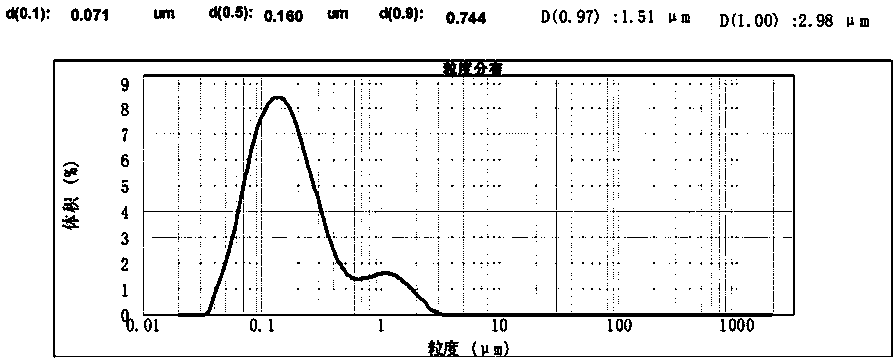

Preparation method of high-stability high-purity extra-coarse tungsten carbide powder

InactiveCN102557028ANarrow particle size distributionImprove stabilityTungsten/molybdenum carbideGranularityCarbonization

A preparation method of a high-stability high-purity extra-coarse tungsten carbide powder contains the following steps of: (1) grinding a high-purity extra-coarse tungsten carbide powdered raw material with its chemical purity being greater than or equal to 99.98 wt%, and carrying out size grading to obtain the required average granularity and a high-purity extra-coarse tungsten powder according to the particle size distribution; (2) carrying out carbon addition by the use of carbon black according to the total carbon content of the obtained tungsten carbide powder being 6.13+ / -0.05%, followed by ball milling and mixing to obtain a ball-milling mixture; (3) filling the obtained ball-milling mixture into a graphite boat and a carbide furnace, and carrying out high-temperature carbonization at 1600-2500 DEGC for the carbonization time of 1-10 hours; and (4) carrying out coarse crushing on the obtained carbonized material, followed by grinding and crushing, and carrying out size grading to obtain the high-purity extra-coarse tungsten carbide powder. The method provided by the invention can be adopted to produce the high-purity extra-coarse tungsten carbide powder with good crush resistance, morphology and structure and excellent thermal stability. The high-purity extra-coarse tungsten carbide powder is used to prepare an extra-coarse crystal cemented carbide product with high performance.

Owner:江西耀升钨业股份有限公司 +1

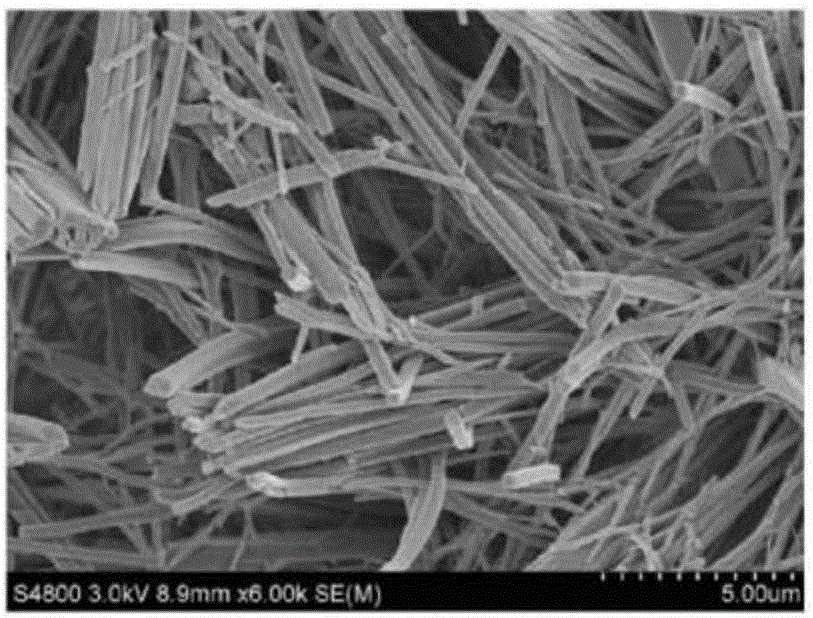

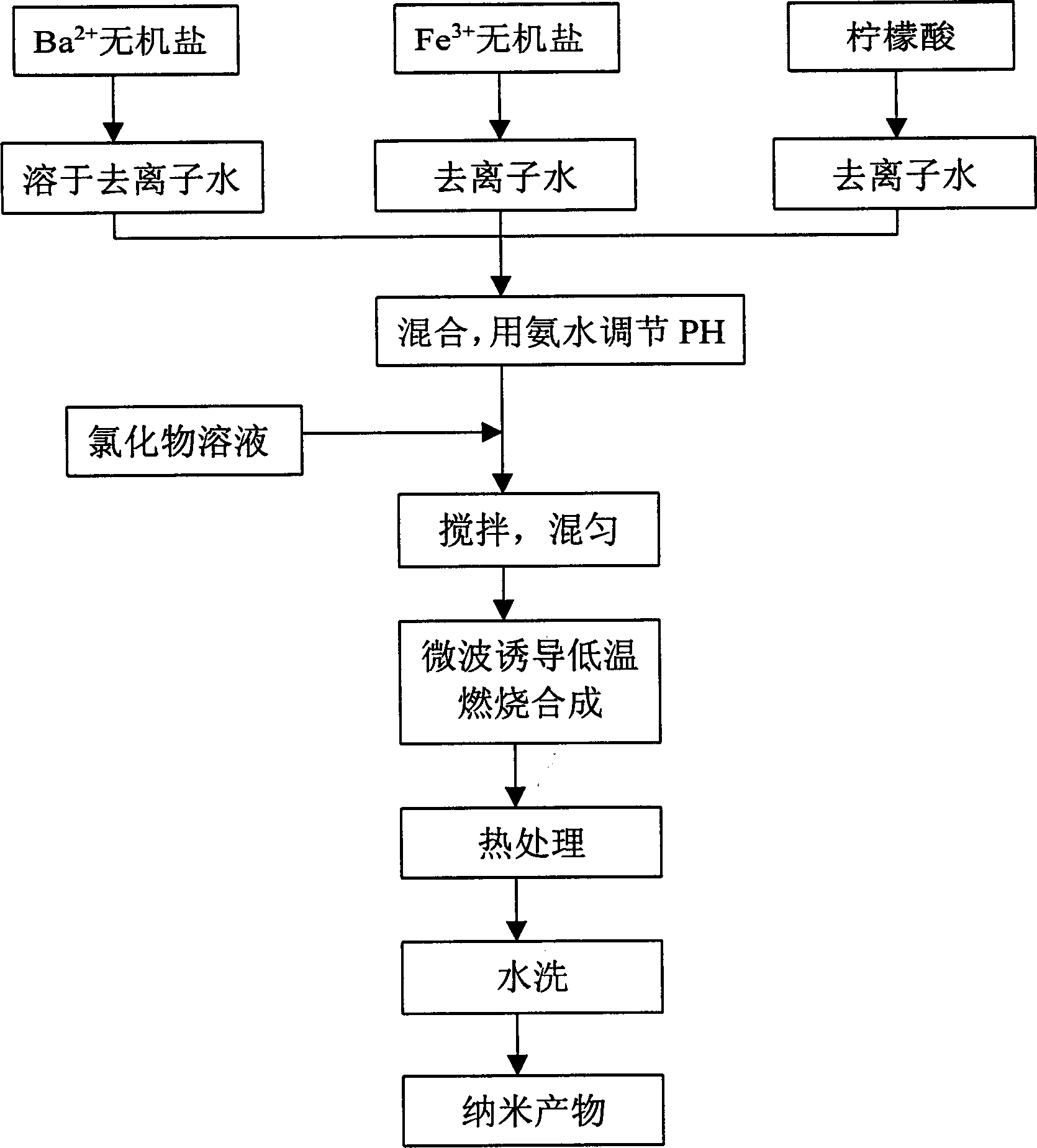

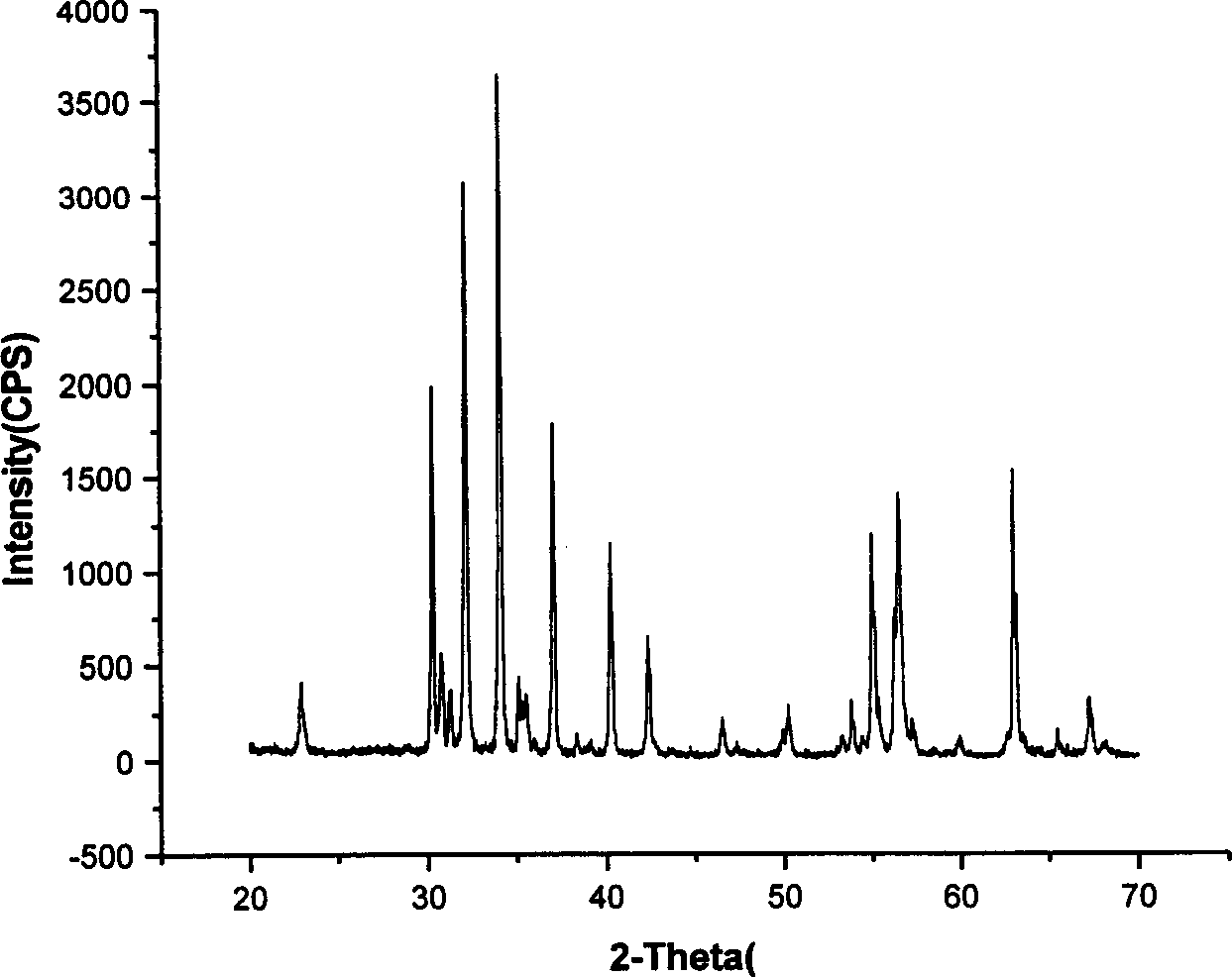

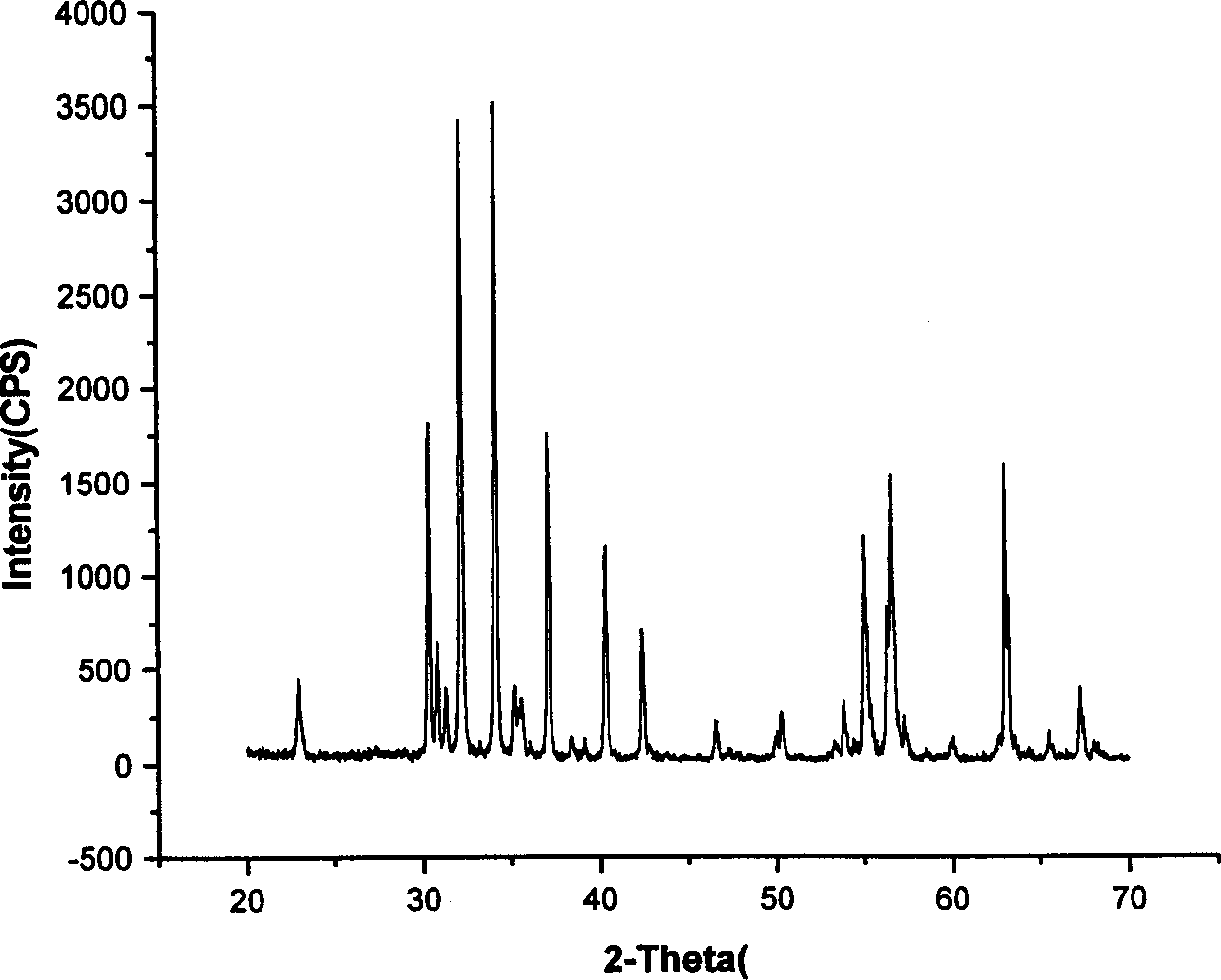

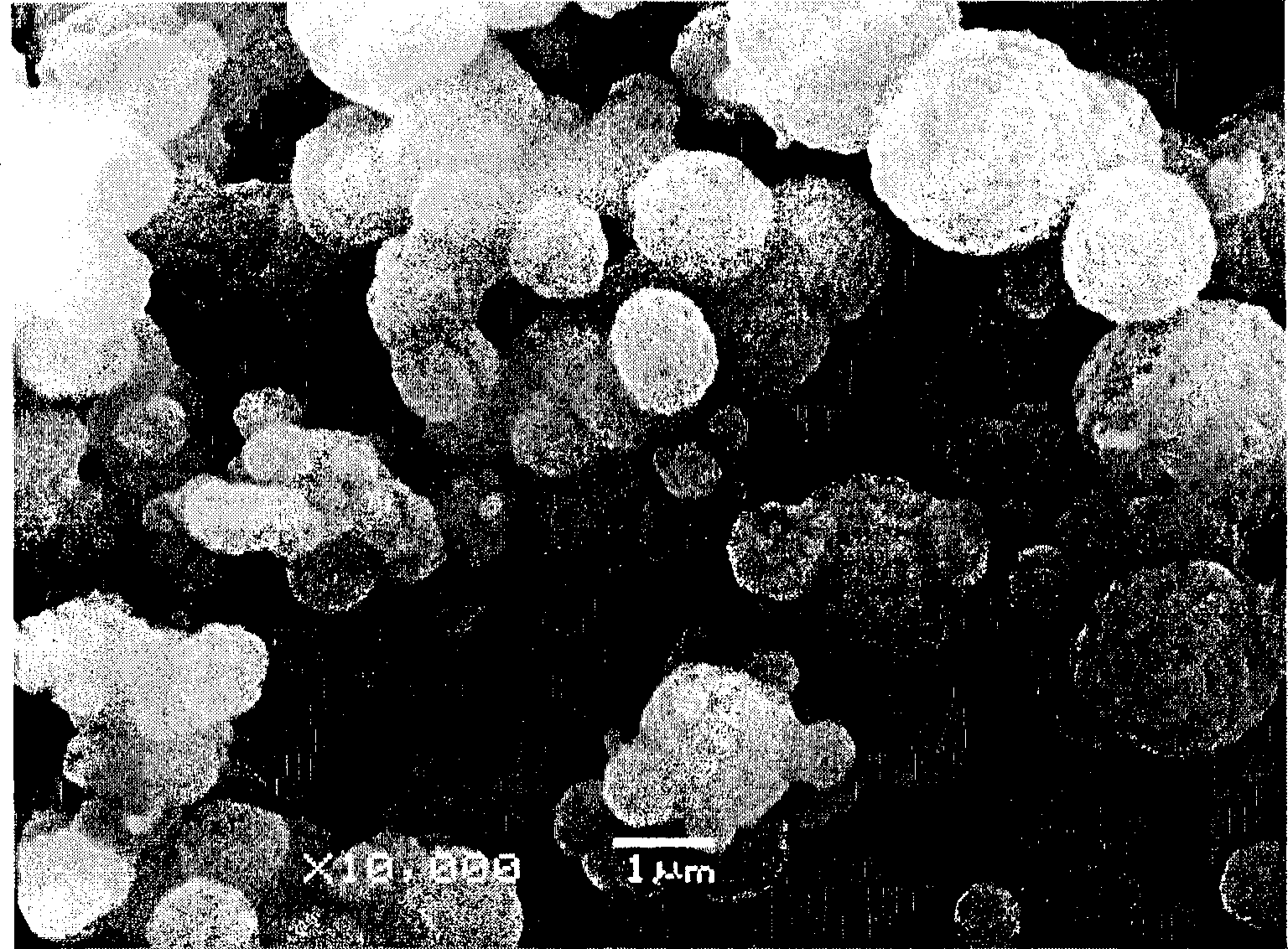

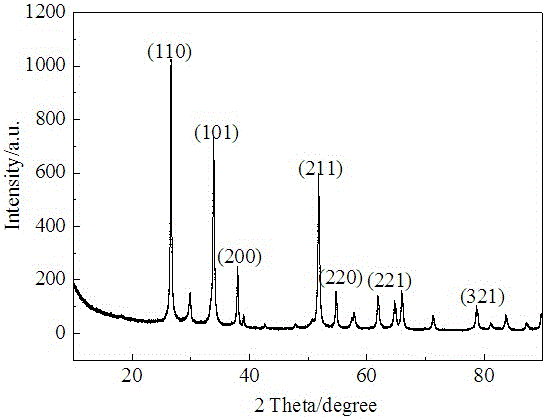

Process for synthesizing nano barium ferrite powder by microwave induction and low-temp combustion

InactiveCN1378996AThe process is simple and convenientReduce energy consumptionInorganic material magnetismPotassiumHeat treating

A process for synthesizing nanometre BaFe12O19 powder includes such steps as proportionally mixing the inorganic salt (nitrate or carbonate) of Ba2+ or Fe3+, citric acid and chloride (potassium chloride, sodium chloride, or their combination in mol ratio of NaCl / KCl=1:0.5-1.5), microwave inducing, low-temp. combustion for 2-10 min, heat treating under 900 deg.c for 0.2-10 hr and water washing to obtain nanometre hexagonal crystal of BaFe12O19. Its advantages are simple process, low energy consumption, and regulatable magnetic performance of product.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

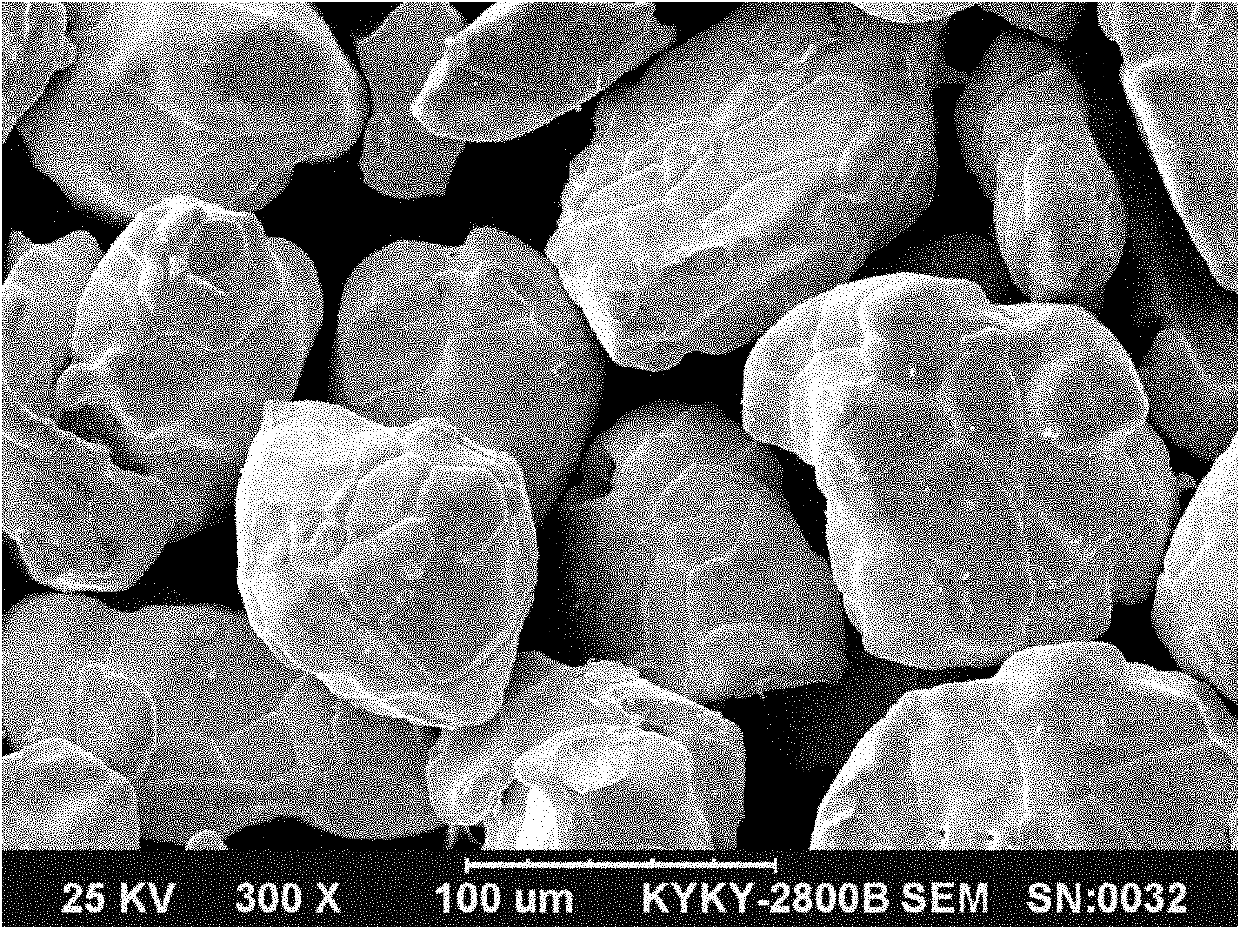

Carbon nano tube/chitosan mesoporous spherical composite material as well as preparation method thereof

ActiveCN103933949AWon't fall offEasy separationOther chemical processesAlkali metal oxides/hydroxidesCarbon nanotubeSpherical form

The invention relates to a carbon nano tube / chitosan mesoporous spherical composite material as well as a preparation method thereof. The preparation method of the spherical composite material comprises the following steps: (1) carrying out acid treatment and dispersion treatment on carbon nano tube raw materials; (2) preparing a chitosan solution with the degree of deacetylation of 80-100%; (3) adding the carbon nano tube which is treated by the step (1) into the chitosan solution obtained by the step (2), and mixing uniformly so as to a spherical liquid; (4) dissolving alkaline solute into water so as to obtain a solidified liquid; (5) dropwise adding the spherical liquid into the solidified liquid so as to prepare a composite sphere; (6) placing the composite sphere generated by the step (5) into a crosslinking agent solution to crosslink, and stirring so as to obtain a crosslinking composite sphere; (7) refrigerating and drying the crosslinking composite sphere obtain by the step (6) so as to obtain the carbon nano tube / chitosan mesoporous spherical composite material. The carbon nano tube / chitosan mesoporous spherical composite material disclosed by the invention is nontoxic, and has favorable adsorption performance.

Owner:梁吉 +1

Phosphatizing liquid and preparation method thereof

InactiveCN101935831AReduce construction difficultyIncrease productivityMetallic material coating processesSodium fluoridePhosphoric acid

The invention discloses phosphatizing liquid. The phosphatizing liquid comprises the following components in percentage by weight: 7 percent of starter liquid, 0.38 to 0.4 percent of neutralizer, 0.2 to 0.6 percent of accelerator and the balance of water, wherein the starter liquid comprises the following components in percentage by weight: 30 to 36 percent of 85 percent phosphoric acid, 16 to 20 percent of 68 percent nitric acid, 15.6 to 18.4 percent of 99.7 percent zinc oxide, 0.4 to 0.6 percent of citric acid, 0.4 percent of sodium fluoride, 0.6 to 1 percent of nickel nitrate, 0.16 to 0.24 percent of ferric nitrate, 0.004 to 0.01 percent of copper nitrate and the balance of water.

Owner:景阳富

Cemented carbide for composite matrix and preparation method of cemented carbide

The invention discloses cemented carbide for a composite matrix and a preparation method of the cemented carbide. According to a formula, a WC (wolfram carbide) powder mixture is a mixture of conventional WC powder and cast WC powder whose mass ratio is (33-40) : (60-67); the mass ratio of cobalt powder and the WC powder mixture is (8-17) : (83-92); the preparation process comprises steps as follows: material preparation, wet grinding, dry granulation, press forming and low-pressure vacuum integrated sintering. The average WC grain size of the cemented carbide prepared with the preparation method according to the formula is 2.0-3.2 microns, the bending strength is 3,200-3,400 MPa, and the hardness is HRA 85.0-90.8.

Owner:HUNAN CENTURY SPECIAL ALLOY

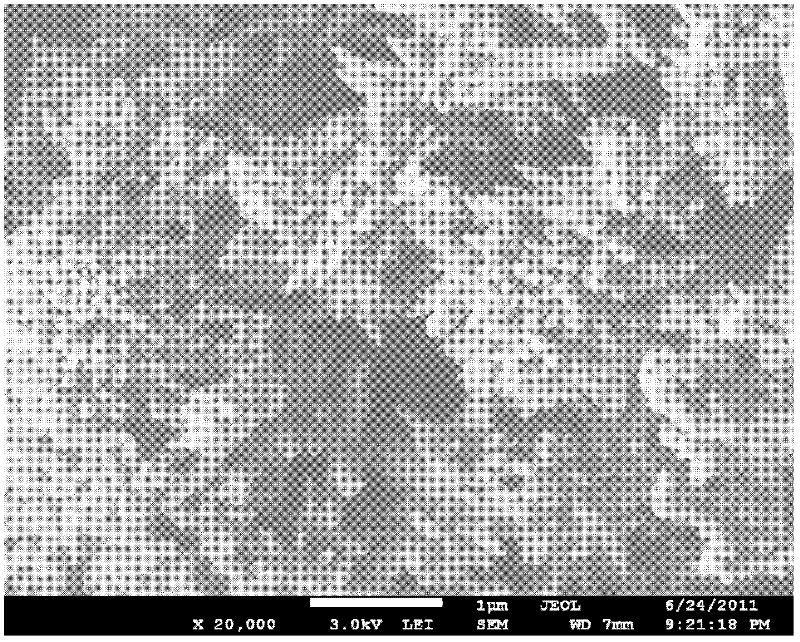

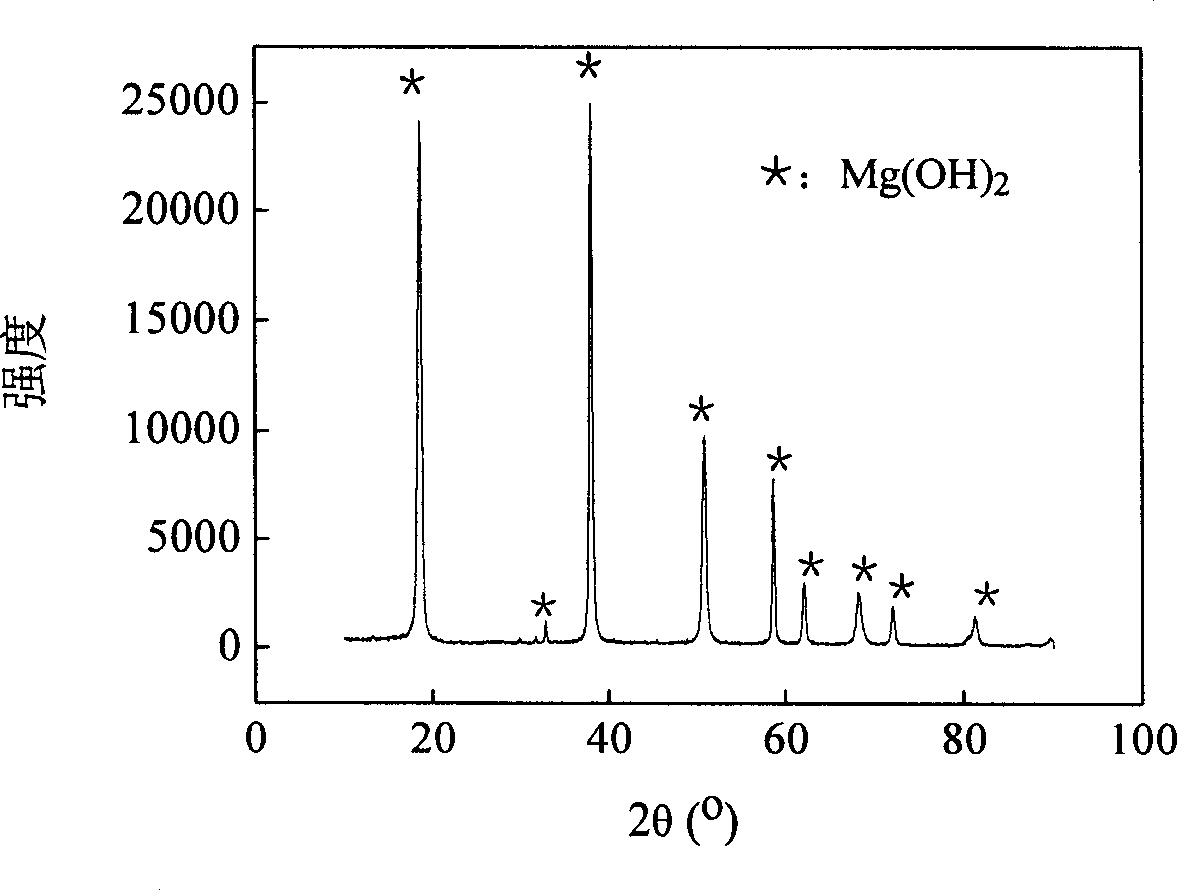

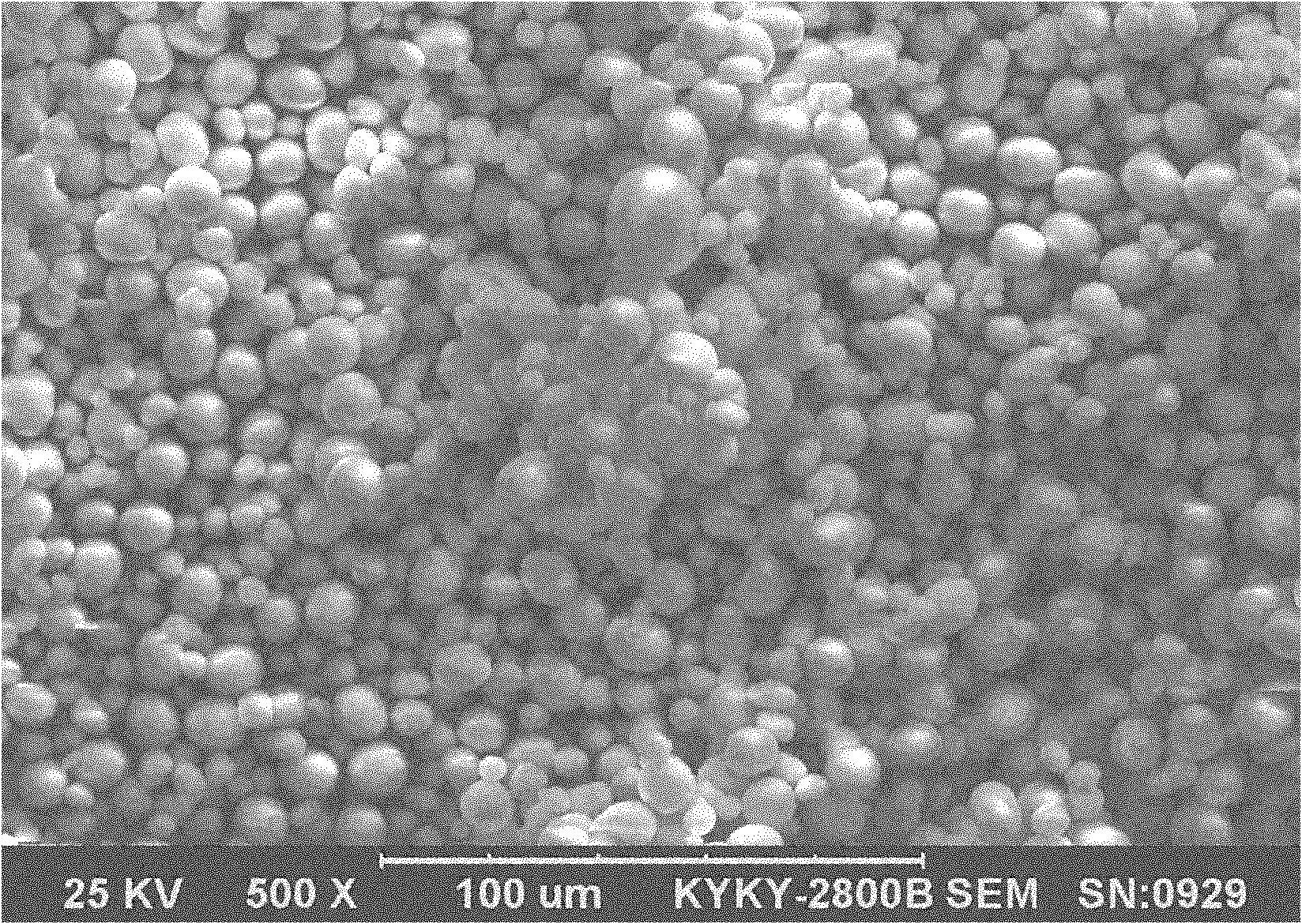

Water heat modification method for high dispersion magnesium hydroxide nanometer sheet

The invention discloses a substrate double-injection- hydrothermal modified method of high-dispersed magnesium hydroxide nanometer piece in the organic chemical technique domain, which is characterized by the following: adapting inorganic magnesium salt as raw material and inorganic alkaline as precipitant and inorganic chlorine salt as substrate solution; injecting the magnesium salt and inorganic chlorine salt solution at 10-80 deg.c; disposing the atmospheric product for 1-6 hours at 100-200 deg.c; improving the product structure through chlorine salt and hydrothermal environment to produce topographic regulation and good dispersion property magnesium hydroxide nanometer piece with 10-50nm even thickness, 30-300nm even diameter and 100 -600nm birdnesting particle size. The invention makes regular topographic, even grain size and good dispersing magnesium hydroxide nanometer piece, which is used in the plastic and rubber industry as high-property inorganic flame-proof brusque.

Owner:TSINGHUA UNIV

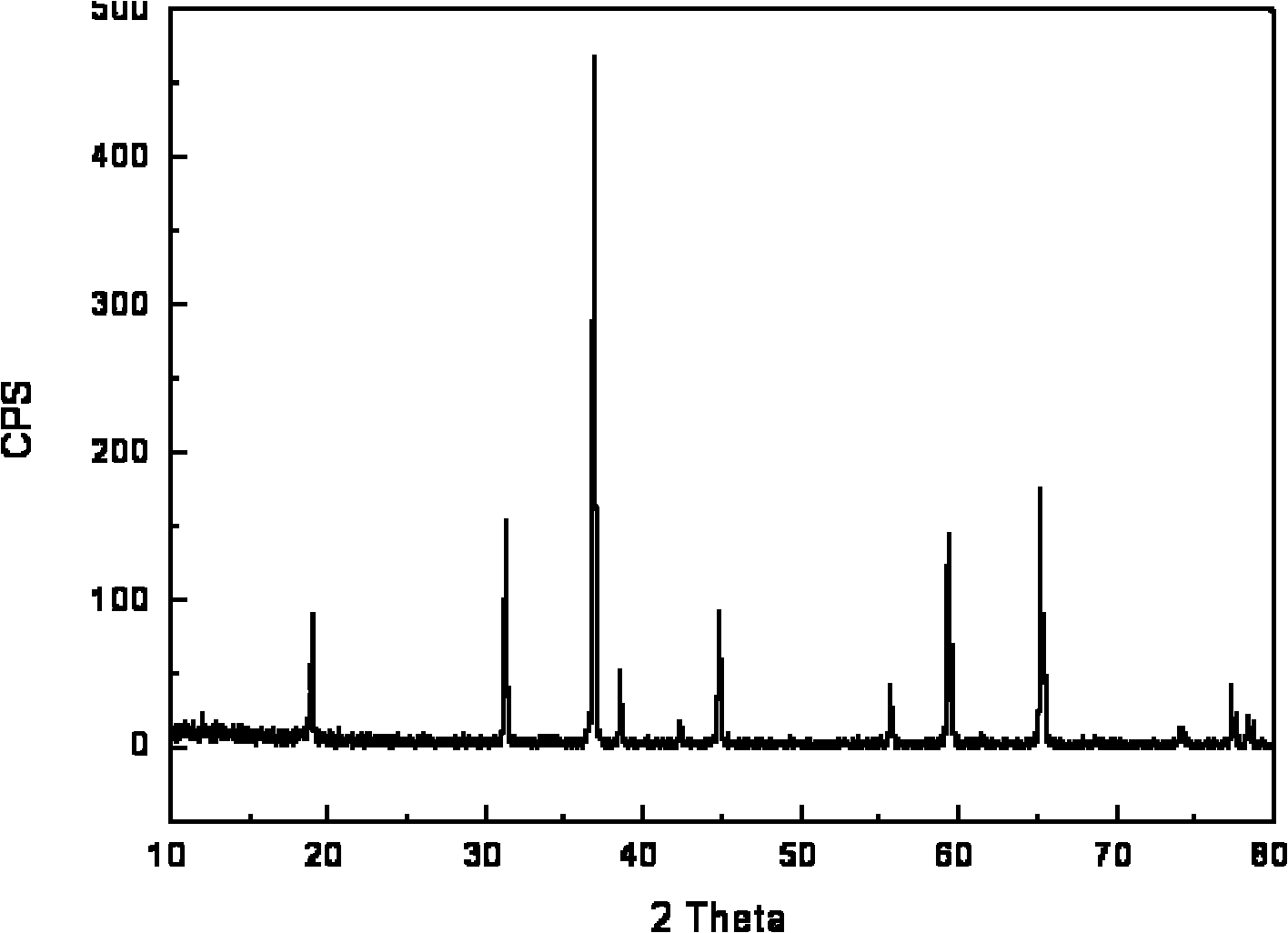

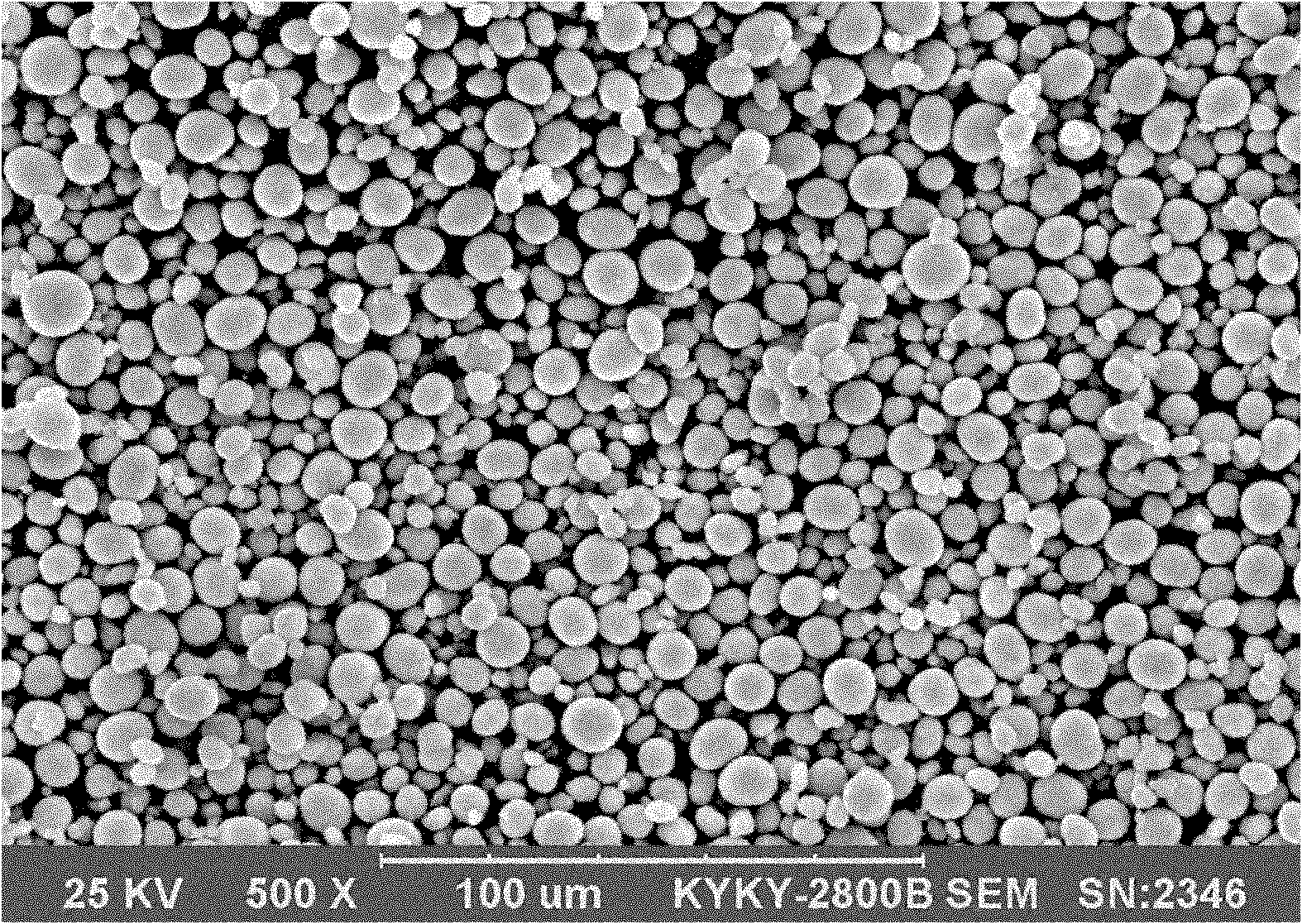

Nickel-cobalt composite oxide, nickel-cobalt doped oxide and preparation method thereof

The invention discloses a nickel-cobalt composite oxide and a nickel-cobalt doped oxide. The molecular formula of the nickel-cobalt composite oxide can be represented by a general formula NixCo(3-x)O4+ / -z, wherein x is more than or equal to 1.8 and less than or equal to 2.7, and z is more than or equal to 0 and less than or equal to 0.5; and the molecular formula of the nickel-cobalt doped oxide can be represented by a general formula NixCo(3-x-y)MyO4+ / -z, wherein the x is more than or equal to 1.8 and less than or equal to 2.7, y is more than or equal to 0.03 and less than 0.3, and z is morethan or equal to 0 and less than or equal to 0.5. The invention also discloses a method for preparing the nickel-cobalt composite oxide and the nickel-cobalt doped oxide. The nickel-cobalt composite oxide and the nickel-cobalt doped oxide have the advantages of excellent sphericility degree, high density, complete crystal and good activity.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

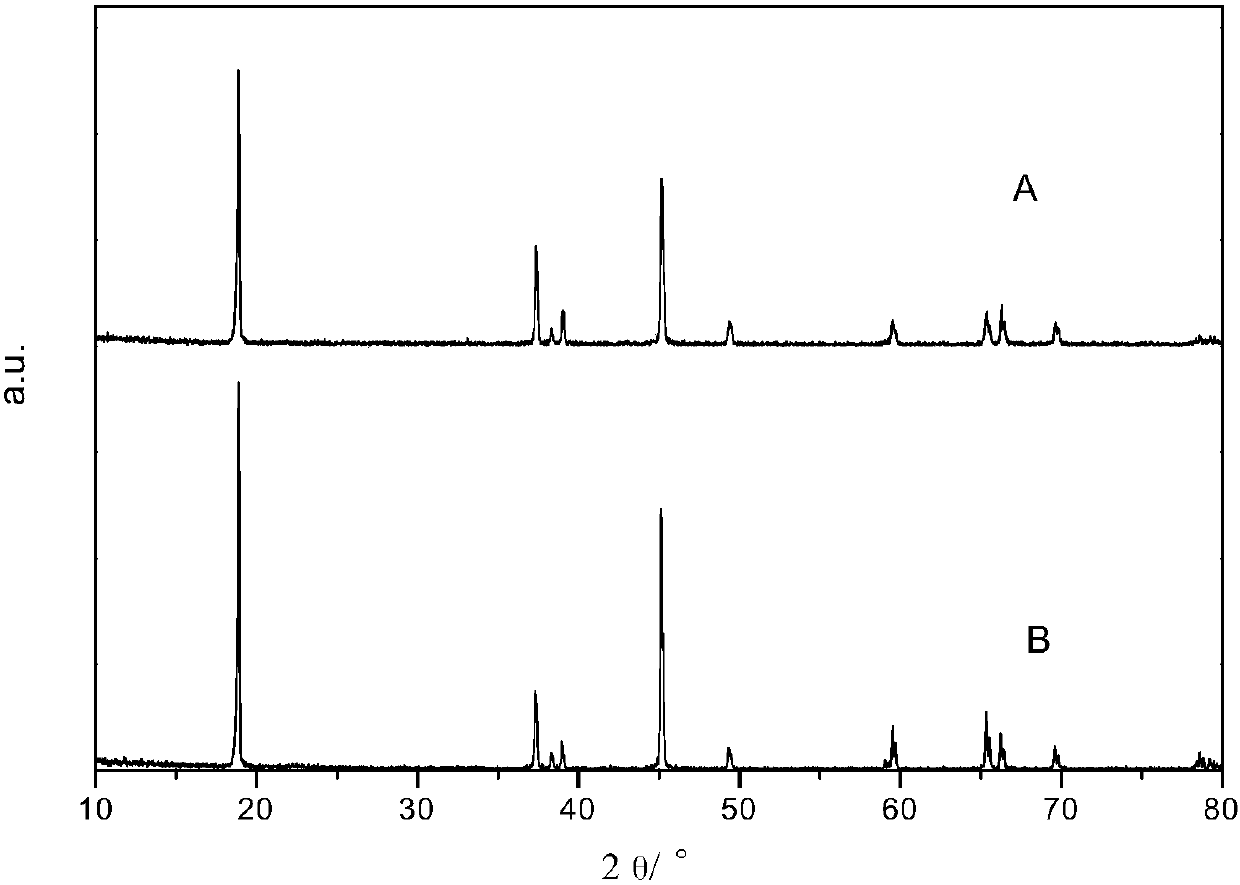

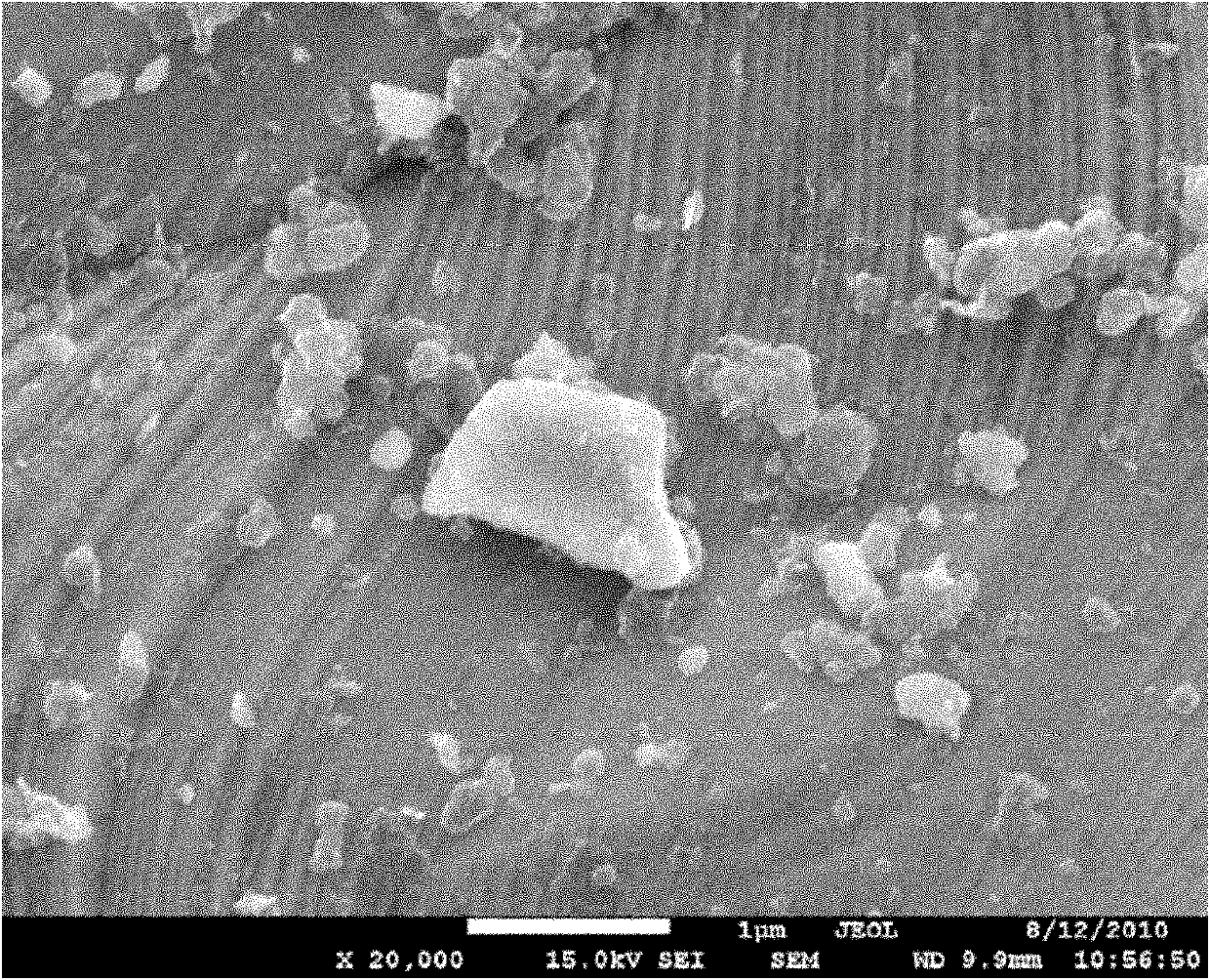

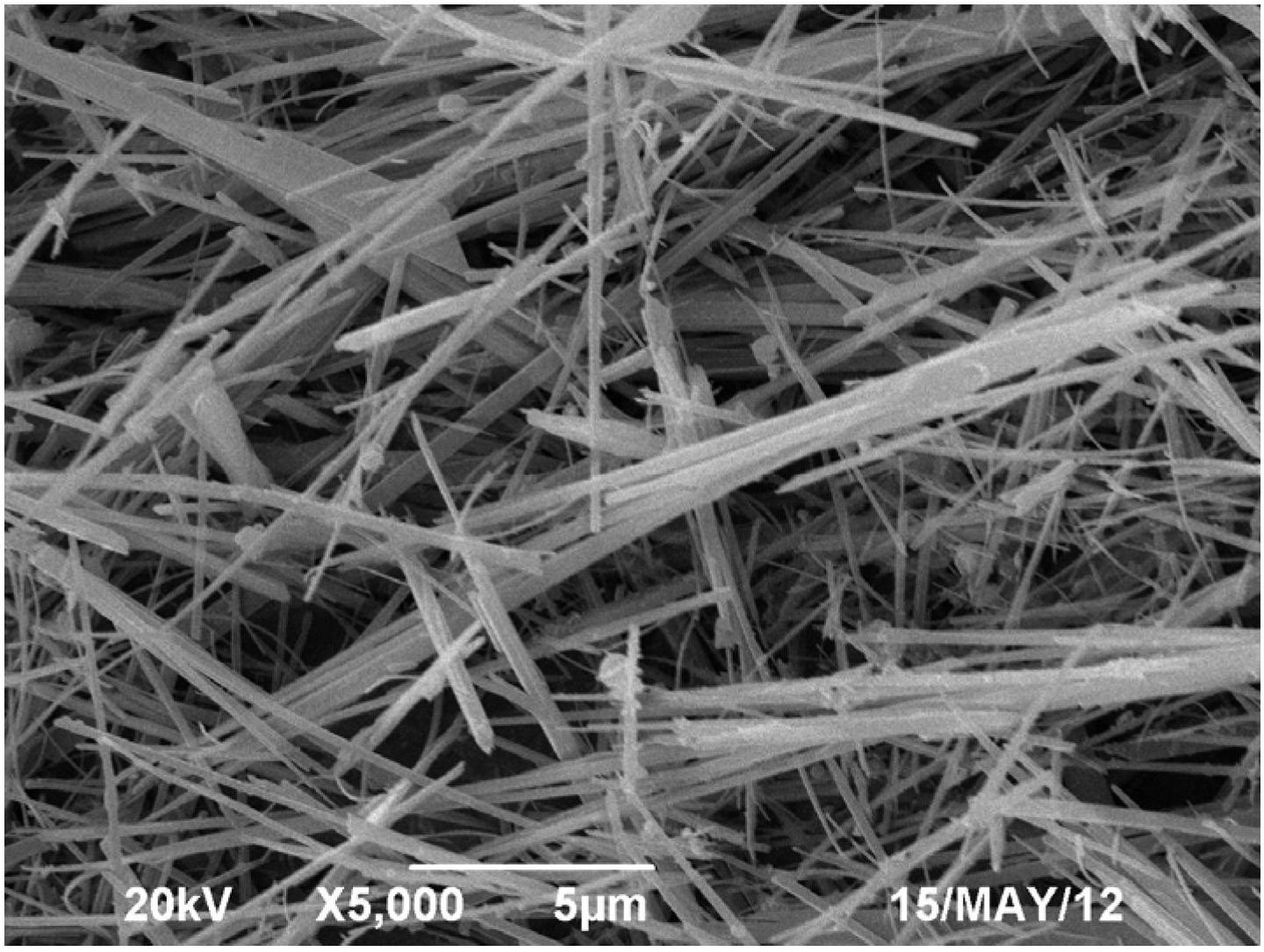

Method for synthesizing tobermorite whiskers by sodium silicate

ActiveCN102674380APromote generationHigh purityAlkaline-earth metal silicatesSodium silicateCalcium EDTA

The invention discloses a method for synthesizing tobermorite whiskers by sodium silicate, comprising the following steps of: preparing sodium silicate and caustic alkali into solution with a certain concentration; dissolving a chlorine-containing compound and an aluminum-containing compound according to a certain silicon-chlorine mol ratio and a certain silicon-aluminum mol ratio; mixing the prepared solution and lime milk according to a certain calcium-silicon mol ratio, using a dynamic hydrothermal method to perform constant-temperature and constant-pressure reaction in a reaction kettle; after reaction; and cooling and filtering the product to obtain the tobermorite whiskers. The method has a simple process and low energy consumption, and the purity of the synthesized tobermorite whiskers is high; the tobermorite whiskers prepared by the invention is needle-like, have complete crystallization surfaces, and can be applied in fields such as the building material, the petrifaction, the ceramic, the biological material, and the like. The comprehensive recovery of high-alkalinity sodium silicate waste liquid produced during the industrial production can be achieved. The method is suitable for industrial application.

Owner:CENT SOUTH UNIV

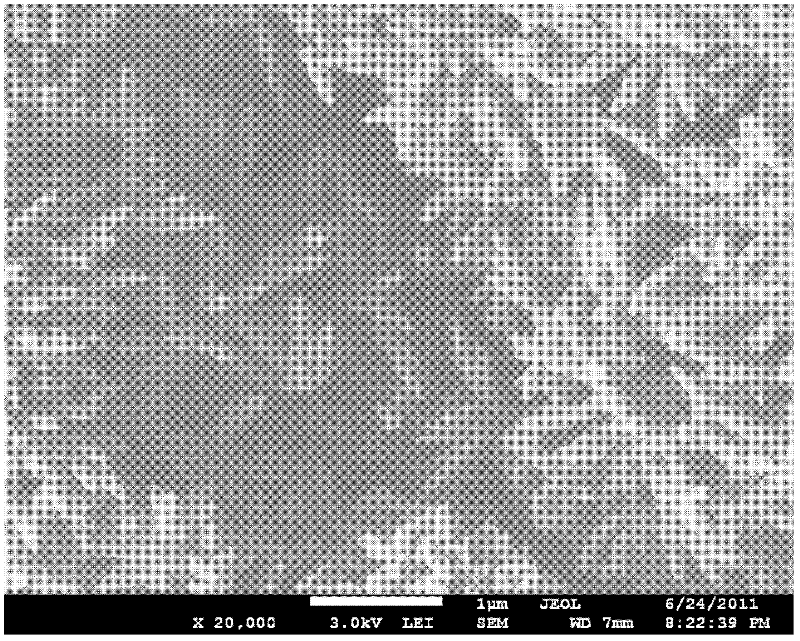

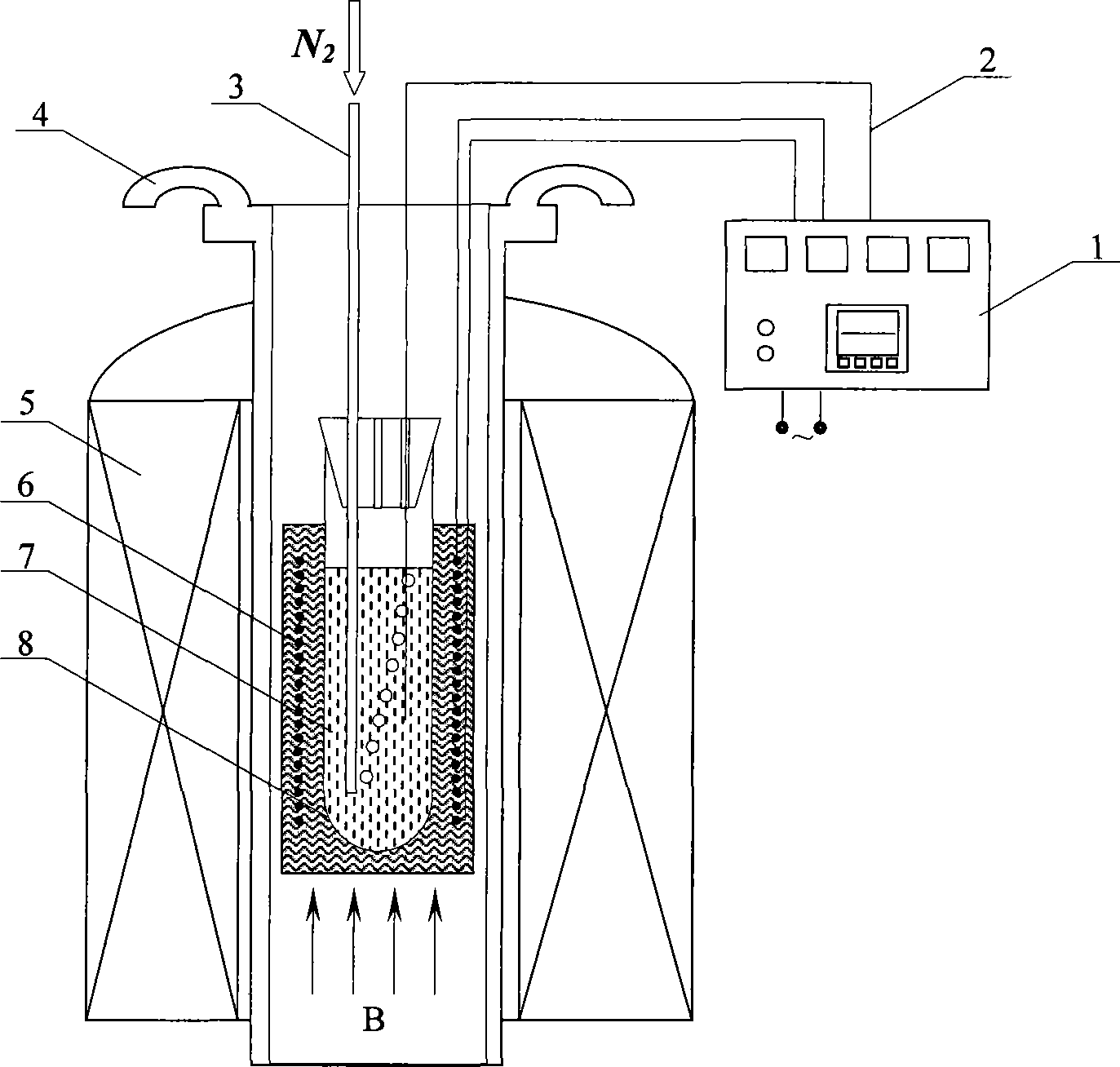

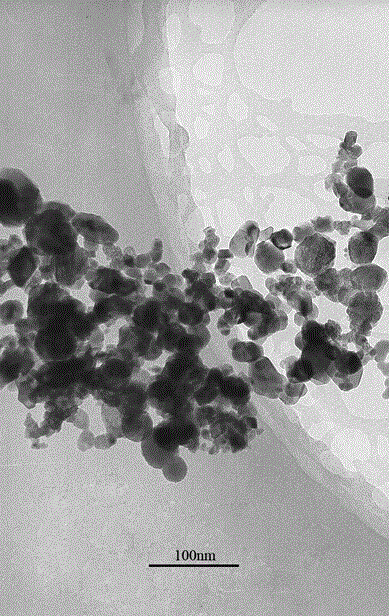

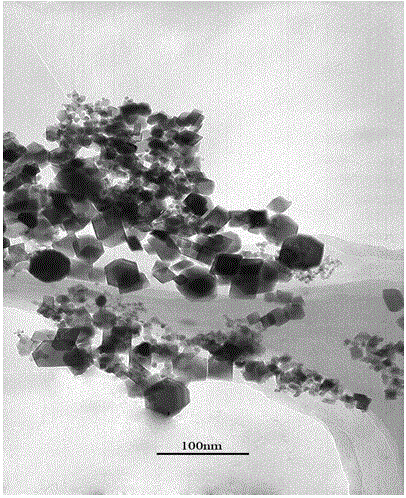

Method for preparing magnetic nano particles of anisotropy cobalt ferrite

InactiveCN101071670AImprove performanceCrystallization intactInorganic material magnetismIonMagnetic stirrer

This invention involves an anisotropic cobalt ferrite magnetic nanoparticle for the preparation methods and devices, nano-magnetic material is a preparation of technical fields. The characteristics of the present invention are to co-precipitation - Preparation phase transformation process of nano-cobalt ferrite placed in a strong magnetic field in a reactor. Will ion containing cobalt and iron ions in the mixture solution by adding containers of sodium hydroxide precipitation, stirring mixture with magnetic stirrer, and 60 Deg.C to respond fully, cobalt hydroxide by ferric hydroxide precipitation and the suspension and then transfer its Xeon magnetic field reactor, the strong magnetic field of magnetic field intensity of 6 to 7 T, slurry temperature is 60 to 95 Deg.C, in strong magnetic field heat treatment two hours, then pumped filter isolated precipitation powder, The cobalt ferrite particles have excellent magnetic properties.

Owner:SHANGHAI UNIV

Powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics and preparation method of powder material

The invention discloses a powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics. The powder material is prepared from zirconia and yttrium oxide, wherein the content of the yttrium oxide is 1.4-2.6mol% of the total amount of Zr<4+>; and the average grain size of raw crystal of the powder material is 50-110nm. Moreover, the invention further discloses a preparation method of the powder material. According to the zirconia powder material, the doping amount of yttrium is reduced, the tetragonal polycrystal ceramics prepared by using the powder are capable of realizing full tetragonal phase stable existence of zirconia at room temperature to guarantee the characteristic of high strength, activating the tetragonal phase in TZP (tetragonal zirconia polycrystalline), improving the transformation toughening performance and further optimizing the fracture toughness of TZP ceramics. The preparation method is safe and reliable, has the advantages of wide raw material source, low energy consumption and remarkable effect on energy conservation and emission reduction, is convenient for popularization and application, is suitable for industrial large-scale production, and can be used for effectively promoting application and development of zirconia materials.

Owner:江西赛瓷材料有限公司 +1

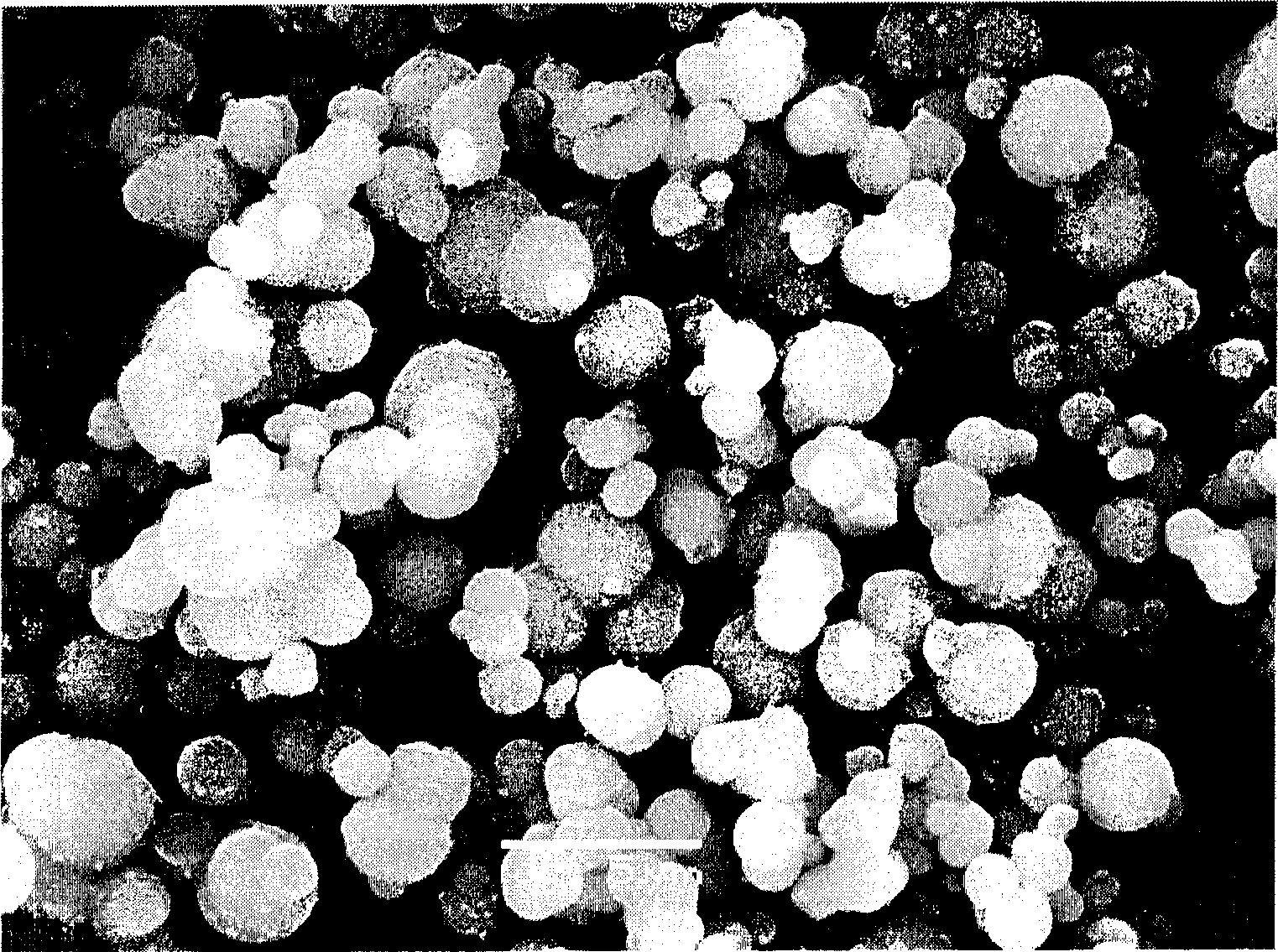

Method for preparing alumina powder for polishing solution

InactiveCN101391788ACrystallization intactGood liquidityOther chemical processesAluminium oxides/hydroxidesUreaAluminium salts

The invention discloses a preparation method for polishing liquid used alumina powder, relates to a preparation method for alumina, in particular to a preparation method for polishing liquid and polishing powder used for spherical alumina powder by liquid phase precipitation method. The preparation method is characterized by the preparation process thereof, comprising: adding urea and catalyst in 0.2-0.4M ammonium aluminum sulfate solution for carrying out reaction under the temperature of 60 to 80 DEG C till the precipitation appears; carrying out aging, and then filtering, washing, and drying so as to obtain the precursor of the alumina powder which is calcined for 2 to 6 hours at 1200 to 1600 DEG C; later calcined alumina is obtained; finally, by screening, spherical alumina which has integral crystallization, high purity (the alumina content reaches 99.5 percent), good mobility, and uniform particle diameter, and is suitable to be used for the polishing liquid is obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Technology for preparing nano-metallic oxide powder with DC (direct-current) plasma method

ActiveCN106044849ASimple processReduce manufacturing costGallium/indium/thallium compoundsNanotechnologyAtomic clusterOxygen

A technology for preparing nano-metallic oxide powder with a DC (direct-current) plasma method comprises steps as follows: a high-purity metal block is put into a smelting furnace and is melted, and a melt delivery tube connected with the smelting furnace is heated; a reaction chamber is subjected to vacuum pumping until the pressure reaches 2-10 MPa, cooling air is introduced into the reaction chamber, and cooling water is introduced into a reactor interlayer arranged in the reaction chamber; an arc plasma gasification system power source of a reactor is switched on, gasification current is adjusted to 10-2,000 A, and voltage is adjusted to 5-400 V; inert gas is introduced into the metal melt, the melt delivery tube is adopted for flow guidance, the gasification reaction is performed, and metal jet is formed; the metal jet is gasified under the action of arc plasma so as to form atomic clusters, the atomic clusters are subjected to a reaction with oxygen, oxide nanoparticles are formed, is condensed under cold-air negative pressure and enters a powder collecting chamber with cold air flow, and the nano-metallic oxide powder is obtained. The technology is simple, does not need a plasma source and has high yield, and the prepared nano-metallic oxide powder is not prone to agglomeration, is high in purity and facilitates large-scale production.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for preparing ultra-coarse-grain tungsten-cobalt hard alloy

The invention discloses a method for preparing a high-tenacity super-coarse-grained tungsten and cobalt hard alloy. The method comprises the following process steps of: mixing raw materials, performing wet grinding, drying, pre-sintering, performing wet mixing, drying, adding a forming agent, palletizing, performing compression moulding and performing integral sintering in vacuum under low pressure, wherein in the step of mixing the raw materials, cobalt powder and tungsten carbide powder are blended in the mass ratio of 2.4-2.6:97.4-97.6; metal cobalt powder and Co2W4C nanoparticles are added into the pre-sintered mixture in which the mass ratio of cobalt to tungsten carbide is 8-13:87-92; and the adding amount of the Co2W4C nanoparticles is accordant with the condition that the mass ratio of the cobalt to the Co2W4C nanoparticles is 1:0.045-0.055. The WC average grain size of the prepared hard alloy is up to 4.0 to 5.2mu m; the bending strength is up to 3,000 to 3,400MPa; and the hardness HRA is up to 88.0 to 90.8.

Owner:HUNAN CENTURY SPECIAL ALLOY

Modified lithium titanate material used for lithium ion battery and manufacturing method thereof

The invention relates to a modified lithium titanate material used for a lithium ion battery and a manufacturing method thereof. The modified lithium titanate material is manufactured by the following steps through a molten-salt growth method: adopting a lithium source and a titanium source as raw materials and taking a molten salt as a fusing agent; doping a compound containing a magnesium element, an aluminum element, a neodymium element, a rubidium element, a gallium element, a cesium element, a silicon element, a tin element or a carbon element for modification; and grinding and calcining. The modified lithium titanate material has the advantages of nano particles, clear crystal structure and integral crystallization shape; the manufacturing method using the molten-salt growth method is used to ensure the homogeneity of products; and the electrical conductivity and cycle performance of the lithium ion battery with the modified lithium titanate cathode can be improved greatly.

Owner:青岛瀚博电子科技有限公司

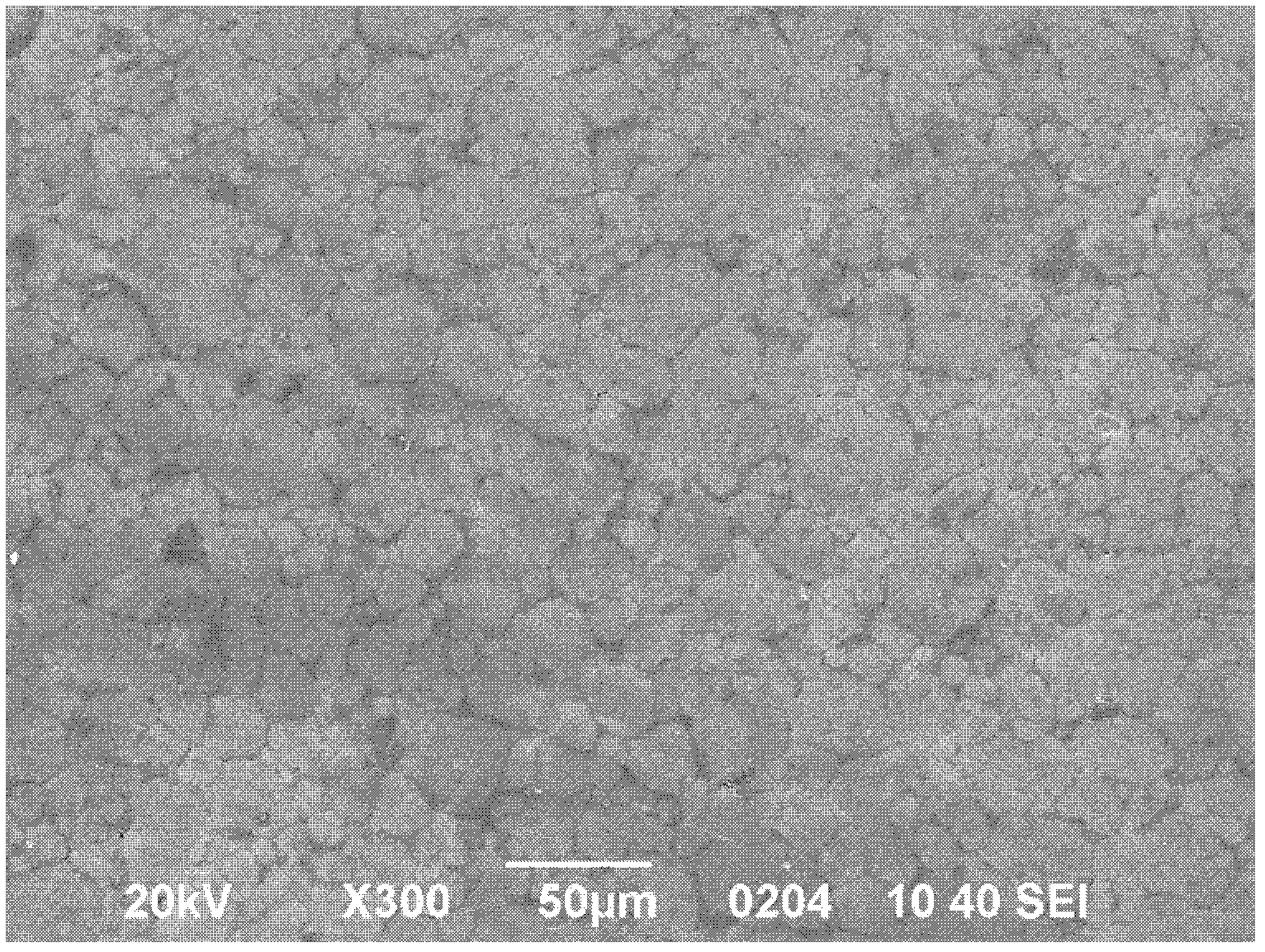

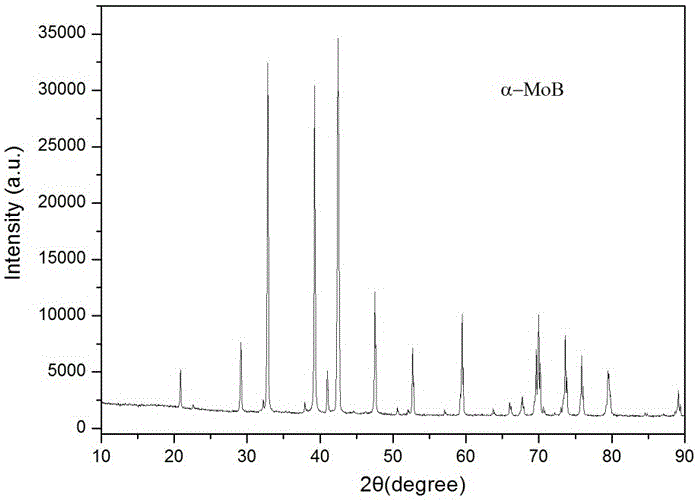

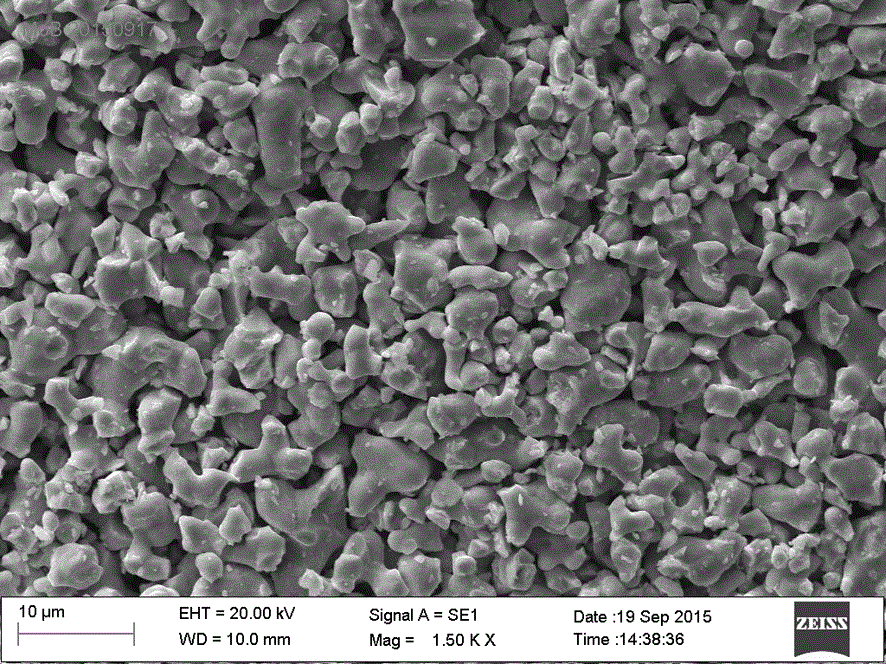

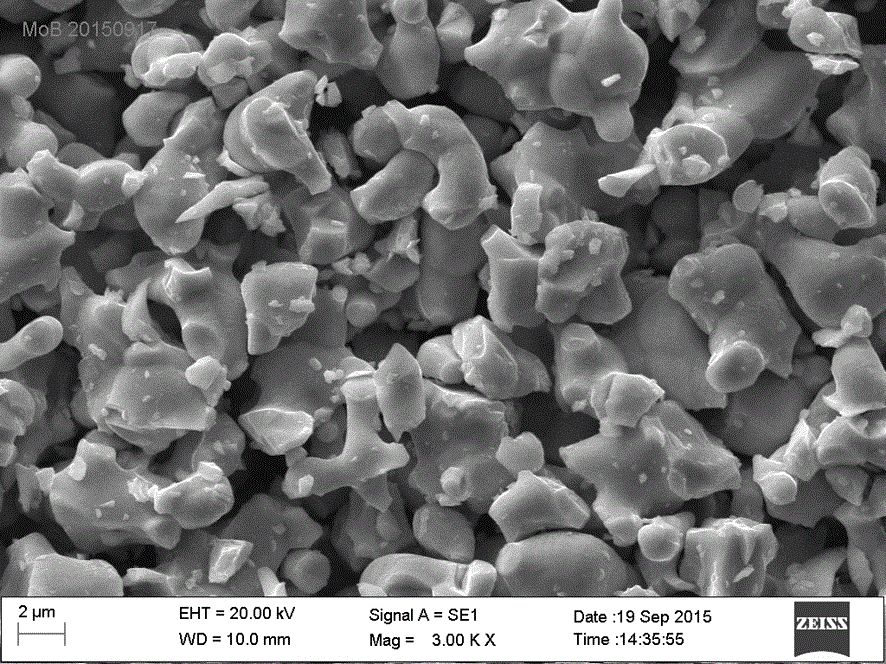

Preparation method of molybdenum boride powder

ActiveCN106276941AUniform particle sizeImprove performanceChemical industryMetal boridesMaterial DesignHigh pressure

The invention provides a preparation method of molybdenum boride powder. In the preparation steps, the molybdenum boride powder which completely accords with material design phase compositions can be controlled to be prepared by means of a high-temperature and high-pressure synthesis mode according to setting of the B / Mo mole ratio n (n=0.5, 1, 2, 2.5, 4) before synthesis, controllable synthesis of target molybdenum boride material phase compositions is achieved, and the synthesized molybdenum boride powder is uniform in particle size, complete in grain crystallization and excellent in property. The method is controllable in technological process, short in technological route, high in targeted property, convenient to operate, efficient, economical in energy, safe and good in reliability. The finished molybdenum boride powder is uniform in particle size distribution and complete in grain crystallization, the chemical purity is higher than or equal to 99.8%, and the product quality stability is good, the properties are obviously improved compared with a molybdenum boride material synthesized through a conventional method, and therefore the produced molybdenum boride material shows excellent physical and chemical properties in industrial application.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

Heat-conductive and flame-retardant PET composite material and preparation method thereof

InactiveCN108822506AAlso has heat conduction functionWith flame retardant functionHeat-exchange elementsAntioxidantThermal coefficient

The invention relates to a heat-conductive and flame-retardant PET composite material and a preparation method thereof. The composite material comprises 80-100 parts of PET, 16-18 parts of a heat-conductive and flame-retardant boehmite composite filler, 1-3 parts of nanometer titanium dioxide, 0.2-0.4 part of a compatibilizer and 0.1-0.5 part of an antioxidant. The heat-conductive flame-retardantboehmite composite filler is used, and boehmite is a small white crystal, and has the characteristics of completeness in crystallization, fine crystal grains, few crystal structure defects and high thermal coefficient, so the heat conductivity of the PET composite material is improved; and the boehmite generates water and Al2O3 in the thermal decomposition process, the water can dilute flammable gas, and the Al2O3 solid covers the surface of a PET substrate to block and delay the burning rate, so the effects of flame retardant and smoke suppression are achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Modified lithium iron phosphate material for lithium ion battery and preparation method thereof

InactiveCN102390825AImprove consistencyEnsure consistencyCell electrodesNanotechnologyRubidiumLithium-ion battery

The invention relates to a modified lithium iron phosphate material for a lithium ion battery and a preparation method thereof. The modified lithium iron phosphate material is prepared by a molten salt method: adding a compound containing magnesium, aluminum, neodymium, rubidium, gallium, cesium, silicon, tin or carbon element for modification by taking a lithium source, an iron source and a phosphorus source as raw materials and molten salt as a flux; and grinding and then calcining. The modified lithium iron phosphate material has nano-sized granularity, a clear crystal structure and a complete crystal shape; the electron conductivity and ion diffusivity are high; and the lithium ion battery using the modified lithium iron phosphate material as a positive electrode has high cycle performance.

Owner:青岛瀚博电子科技有限公司

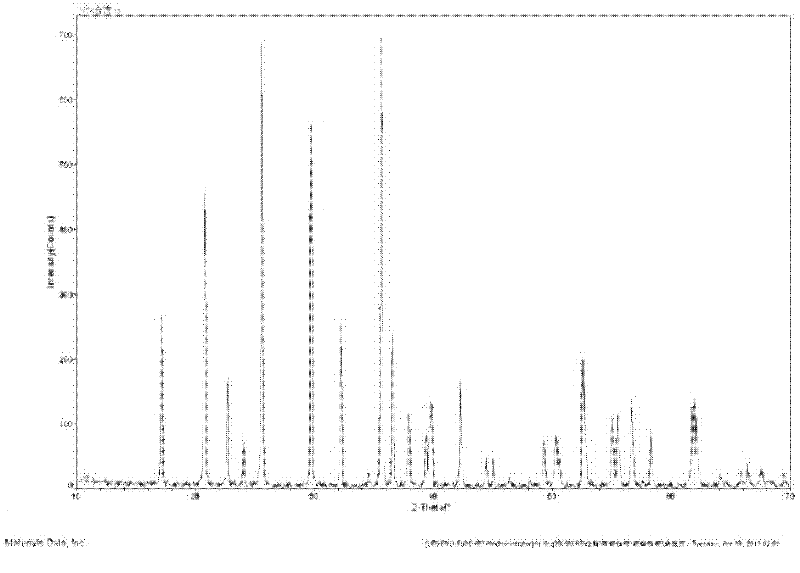

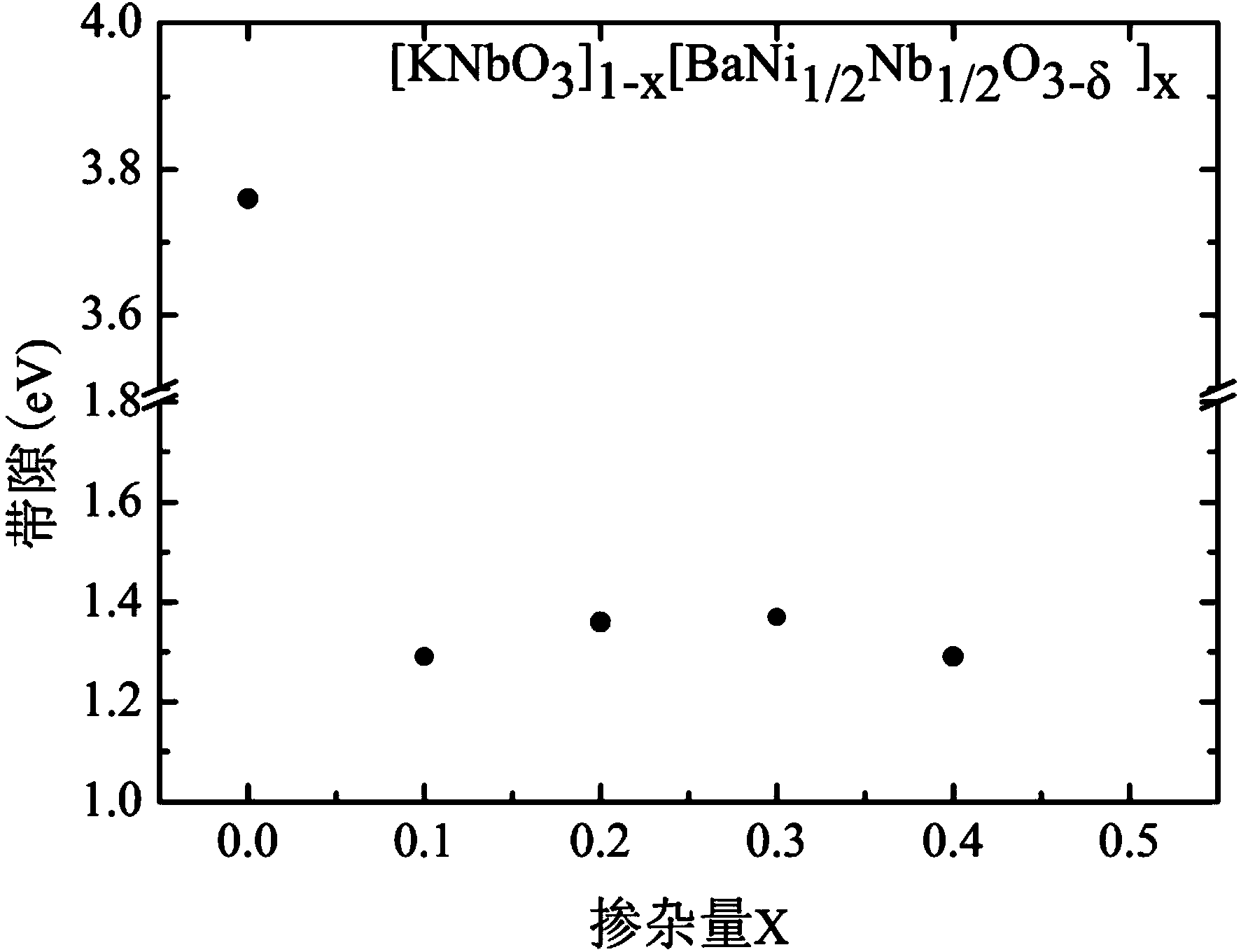

Preparation method of KNbO3 nano solid solution with adjustable optical band gap

InactiveCN104163627AHigh visible light photocatalytic performanceLower sintering temperatureAir atmosphereNiobium

The invention discloses a preparation method of KNbO3 nano solid solution with adjustable optical band gap. The preparation method is as follows: adding citric acid monohydrate into deionized water for completely dissolving, then adding basic nickel carbonate, heating and stirring to form a transparent solution A; adding niobium oxalates into the deionized water for completely dissolving to form a solution B; slowly adding dropwise the solution B into the solution A, fully stirring, successively dissolving anhydrous potassium carbonate and barium carbonate into a mixed solution of the solution A and the solution B for full reaction and stirring to form a transparent solution C; finally adding ethylene glycol, and fully stirring to form a solution D; heating the D solution for evaporation and promotion of citric acid and ethylene glycol esterification, drying to form a dark yellow solid precursor; grinding the precursor, and calcining in air atmosphere to eventually obtain the nano solid solution with the chemical formula of [KNbO3] 1-x [BaNi1 / 2Nb1 / 2O3-Delta] x. The product exhibits better photocatalytic effect in visible region.

Owner:SOUTH CHINA UNIV OF TECH

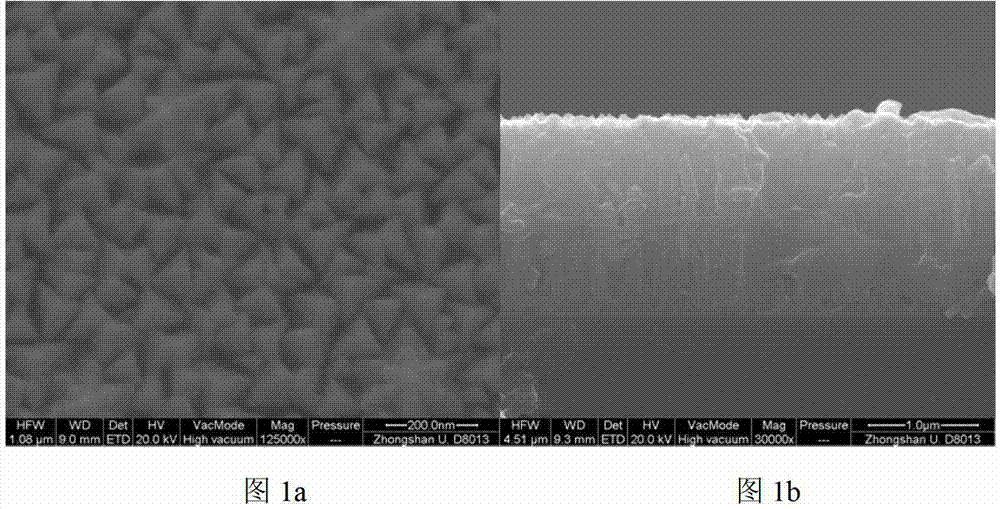

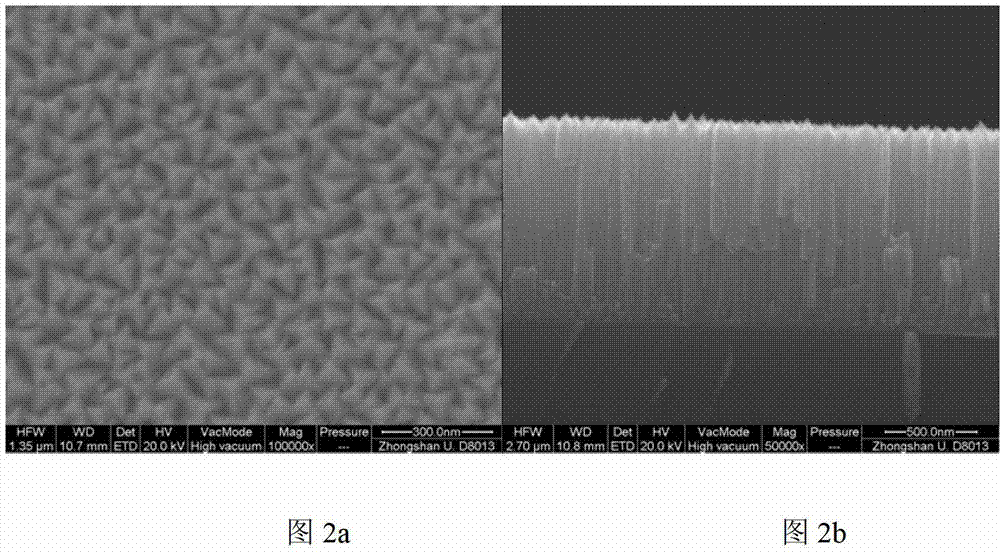

Preparation method of three-dimensional TiO2 crystal film

InactiveCN102418089AEasy to manufactureStrong visible fluorescenceChemical vapor deposition coatingPlasma jetFluorescence

The invention provides a preparation method of a three-dimensional TiO2 crystal film. The method comprises steps of: letting discharge gas in medium block discharge plasma reactor by employing a normal pressure low temperature radio frequency medium block glow discharge method; the discharge gas discharging to generate plasma jet by radio frequency alternating current; sending a precursor and carrying gas to a plasma zone to carry out reaction and precipitate on a substrate, so as to obtain the three-dimensional TiO2 crystal film. The method is characterized in that the precipitate is inner glow precipitate. The TiO2 obtained by the invention has a large proportion of {001} active surface and a unique three-dimensional structure forming by intersecting growth of a {101} surface, a {001} surface and a {101} surface; and the titanium dioxide film irradiates strong visible fluorescence by excitation of laser of 325 nm wavelength at room temperature.

Owner:DONGHUA UNIV

Method for processing organic wastewater by using MnOX/Fe0 nano composite material to activate persulfate

ActiveCN109292951AHigh crystallinityGood dispersionWater contaminantsWater/sewage treatment by reductionSulfateActive component

The invention provides a method for processing organic wastewater by using a MnOX / Fe0 nano composite material to activate persulfate. The method comprises the following steps: pulverizing natural manganese ore and calcining the material to obtain mineral powder containing an active component MnOx, fully mixing the iron salt and the mineral powder containing the active component MnOx, and then adding a reducing agent to carry out a reduction reaction to obtain the MnOX / Fe0 nano composite material; adding the obtained MnOX / Fe0 nano composite material and persulfate to the organic wastewater, andprocessing the organic wastewater under stirring condition. The method for processing the organic wastewater by using the MnOX / Fe0 nano composite material to activate persulfate can perform catalyticdegradation on various organic substances in organic wastewater, and has high purification efficiency, simple method, and easy operation, few types of reagents required, and the cost is low.

Owner:HEFEI UNIV

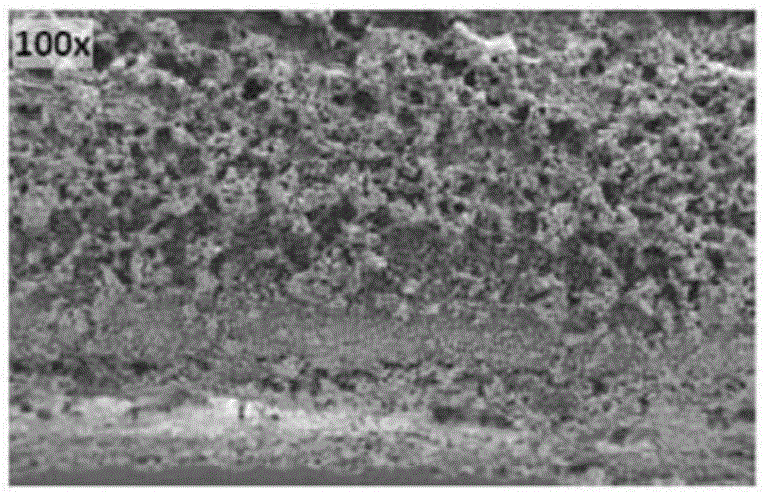

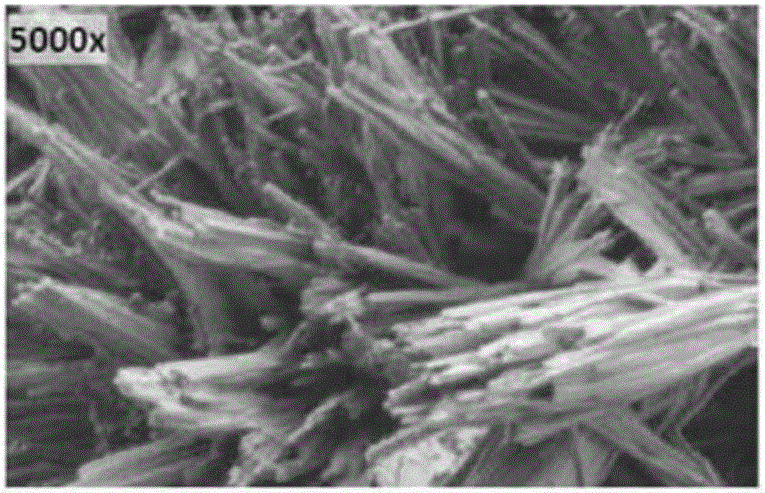

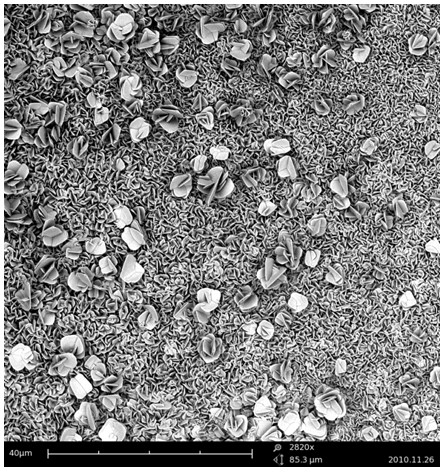

Method for preparing Fe film with pyramid structure

InactiveCN102864414ACrystallization intactClear crystallographic featuresVacuum evaporation coatingSputtering coatingExcitation currentThin membrane

The invention discloses a method for preparing a Fe film with a pyramid structure. The method comprises the steps of (1) selecting high-purity metallic iron target (the purity is 99.99%) as a sputtering target material and placing the target material into a magnetron sputtering chamber; (2) sequentially using acetone, alcohol and deionized water to perform ultrasonic cleaning to a monocrystalline silicon substrate and placing the processed monocrystalline silicon substrate into a magnetron sputtering chamber sample table; and (3) using argon gas as working gas as, adjusting sputtering pressure, exciting current, sputtering current and rotary rate of the sample table and performing sputtering for certain time to prepare the Fe film. Under the condition that direct current bias voltage is not exerted, the Fe film with the pyramid structure is prepared on the monocrystalline silicon substrate by appropriately controlling the sputtering pressure, the exciting current, the sputtering current and the like. The Fe film with the pyramid structure prepared on the monocrystalline silicon substrate is simple in preparation process and has wide industrialization prospect.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com