Method for preparing Fe film with pyramid structure

A technology of pyramid structure and thin film, applied in metal material coating process, ion implantation plating, coating and other directions, to achieve the effect of low cost, complete crystallization and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

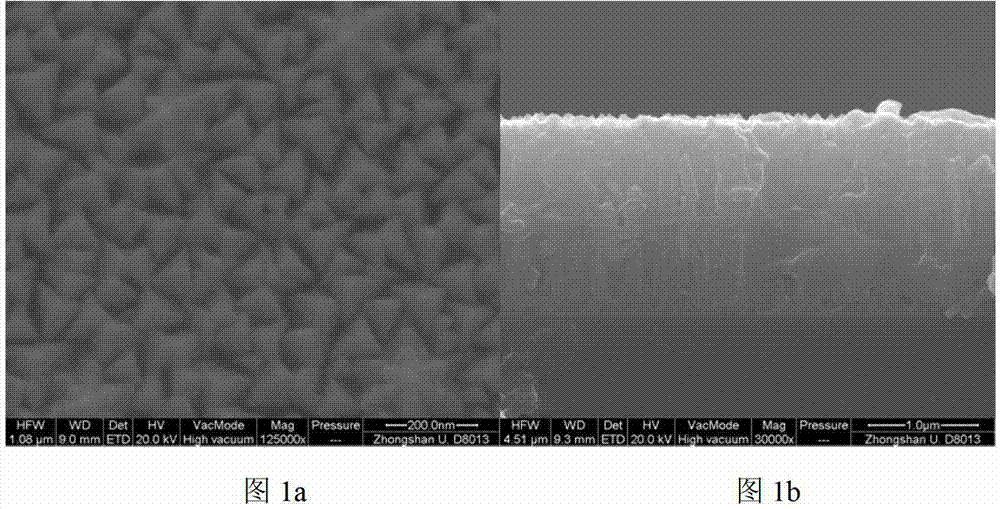

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step (1): target selection

[0029] Select a high-purity metal iron target (purity 99.99%) as the sputtering target, and put the target into the magnetron sputtering chamber;

[0030] Step (2): Substrate Processing

[0031] A single crystal silicon wafer with a single-sided polished (100) crystal surface is selected as the growth substrate; the single crystal silicon substrate is ultrasonically cleaned with acetone, alcohol and deionized water in sequence, and the processed single crystal silicon substrate is placed in Magnetron sputtering room sample table;

[0032] Step (3): Preparation of Fe thin film

[0033] Pyramid structure Fe film is prepared by sputtering; the vacuum degree of the magnetron sputtering chamber is less than or equal to 3×10 -4 Pa, the working gas is argon with a purity of 99.999%, the sputtering pressure is 2.0Pa, the argon flow rate is 20sccm, the excitation current is 3.5A, the sputteri...

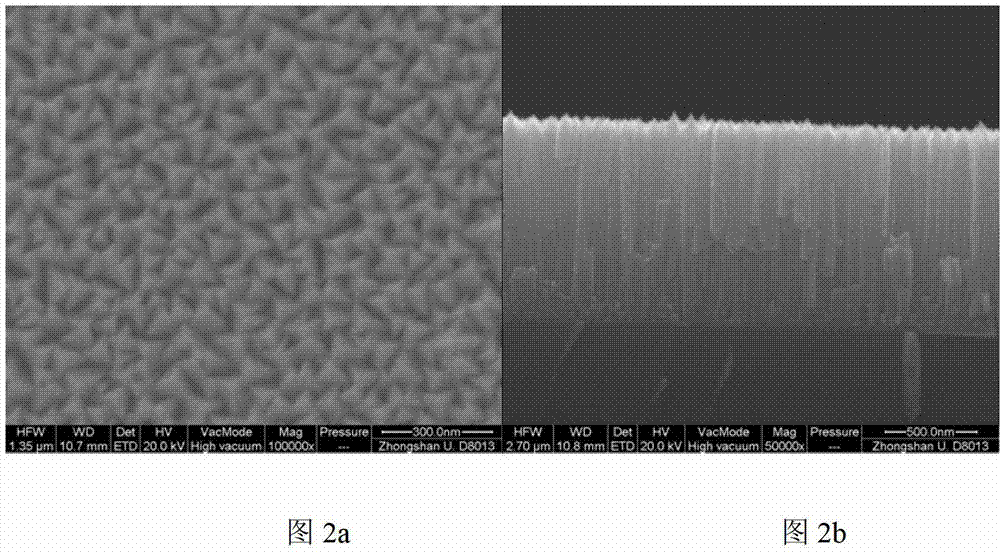

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step (1): target selection

[0037] Select a high-purity metal iron target (purity 99.99%) as the sputtering target, and put the target into the magnetron sputtering chamber;

[0038] Step (2): Substrate Processing

[0039] A single-crystal silicon wafer with a single-sided polished (100) crystal plane is selected as the growth substrate. The single crystal silicon substrate is ultrasonically cleaned with acetone, alcohol and deionized water in sequence, and the processed single crystal silicon substrate is placed on the sample stage of the magnetron sputtering chamber;

[0040] Step (3): Preparation of Fe thin film

[0041] Pyramid structure Fe films were prepared by sputtering. The vacuum degree of the magnetron sputtering chamber is less than or equal to 3×10 -4 Pa, the working gas is argon with a purity of 99.999%, the sputtering pressure is 2.0Pa, the argon flow rate is 20sccm, the excitation current is 3....

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] Step (1): target selection

[0045] Select a high-purity metal iron target (purity 99.99%) as the sputtering target, and put the target into the magnetron sputtering chamber;

[0046] Step (2): Substrate Processing

[0047] A single-crystal silicon wafer with a single-sided polished (100) crystal plane is selected as the growth substrate. The single crystal silicon substrate is ultrasonically cleaned with acetone, alcohol and deionized water in sequence, and the processed single crystal silicon substrate is placed on the sample stage of the magnetron sputtering chamber;

[0048] Step (3): Preparation of Fe thin film

[0049] Pyramid structure Fe films were prepared by sputtering. The vacuum degree of the magnetron sputtering chamber is less than or equal to 3×10 -4Pa, the working gas is argon with a purity of 99.999%, the sputtering pressure is 2.0Pa, the argon flow rate is 20sccm, the excitation current is 3.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com