Method for processing organic wastewater by using MnOX/Fe0 nano composite material to activate persulfate

A nano-composite material, a technology for activating persulfate, applied in water/sewage treatment, chemical instruments and methods, reduced water/sewage treatment, etc., which can solve the problems of inability to magnetic recovery, difficulty in PMS recovery, and agglomeration of nano-zero valent iron. , to achieve the effects of complete crystallization, excellent redox activity, and improved dispersibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

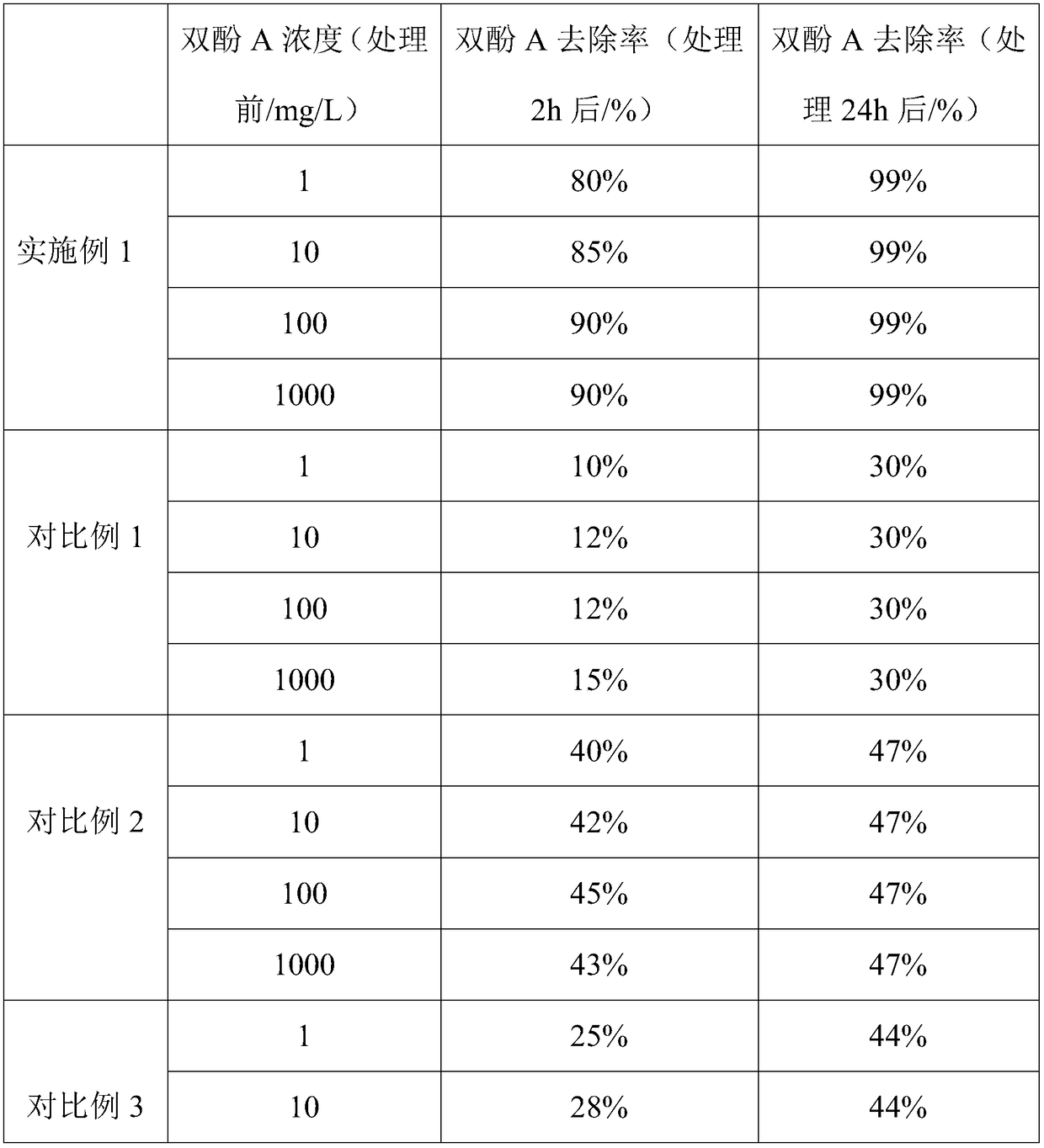

Embodiment 1

[0031] Prepare organic wastewater samples to be tested:

[0032] Add 1 mg, 10 mg, 100 mg, and 1,000 mg of bisphenol A to 1,000 ml of surface water to obtain organic wastewater samples to be tested with concentrations of 1 mg / L, 10 mg / L, 100 mg / L, and 1,000 mg / L, respectively.

[0033] Process the above organic wastewater samples to be tested:

[0034] (1) Preparation of MnO X / Fe 0 Nanocomposites:

[0035] The natural manganese ore with a manganese oxide content of 90wt% was crushed to a particle size of 3.7 μm and then calcined at 600°C for 3 hours to obtain the active ingredient MnO x The mineral powder, by weight ratio of 1:1.2 FeCl 2 4H 2 O and the active ingredient containing MnO x The mineral powder is added to the mixed solvent of water and ethanol and stirred for 24 hours, then fully mixed. The volume ratio of ethanol and water is 4:1. After filtering and drying, add an aqueous solution of sodium borohydride with a concentration of 10mol / L Carry out reduction re...

Embodiment 2

[0047] Prepare organic wastewater samples to be tested:

[0048] Add 1mg, 10mg, 100mg, 1000mg, 2000mg of 2,4-dichlorophenol to the surface water of 1000ml respectively to obtain concentrations of 1mg / L, 10mg / L, 100mg / L, 1000mg / L, 2000mg / L respectively Test organic wastewater samples.

[0049] Process the above organic wastewater samples to be tested:

[0050] (1) Preparation of MnO X / Fe 0 Nanocomposites:

[0051] The natural manganese ore with a manganese oxide content of 80wt% is ground to a particle size of 1 μm and then calcined at 300°C for 4 hours to obtain the active ingredient MnO x The mineral powder, by weight ratio of 1:1 FeSO 4 ·7H 2 O and the active ingredient containing MnO x The mineral powder is added to the mixed solvent of water and ethanol and stirred for 30 hours, then fully mixed. The volume ratio of ethanol and water is 1:1. After filtering and drying, add an aqueous solution with a concentration of 5mol / L dissolved in potassium borohydride Carry ...

Embodiment 3

[0063] Prepare organic wastewater samples to be tested:

[0064] Add 0.5mg, 10mg, 100mg, 1000mg, 3000mg of antibiotics-norfloxacin to 1000ml of surface water respectively to obtain concentrations of 0.5mg / L, 10mg / L, 100mg / L, 1000mg / L, 3000mg / L Organic wastewater samples to be tested.

[0065] Process the above organic wastewater samples to be tested:

[0066] (1) Preparation of MnO X / Fe 0 Nanocomposites:

[0067] The natural manganese ore with a manganese oxide content of 85wt% is ground to a particle size of 10 μm and then calcined at 900° C. for 2 hours to obtain the active ingredient MnO x Mineral powder, FeCl in a weight ratio of 1:1.5 3 ·6H 2 O and the active ingredient containing MnO x The mineral powder is added to the mixed solvent of water and ethanol and stirred for 30 hours, then fully mixed, filtered, and dried, and the aqueous solution with a concentration of 1mol / L dissolved in sodium borohydride is added to carry out the reduction reaction to obtain a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com