Modified lithium iron phosphate material for lithium ion battery and preparation method thereof

A lithium-ion battery and lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as hindering practical application, low Li+ diffusion coefficient, and limiting large-scale commercial application of lithium iron phosphate materials. To achieve the effect of ensuring the control of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

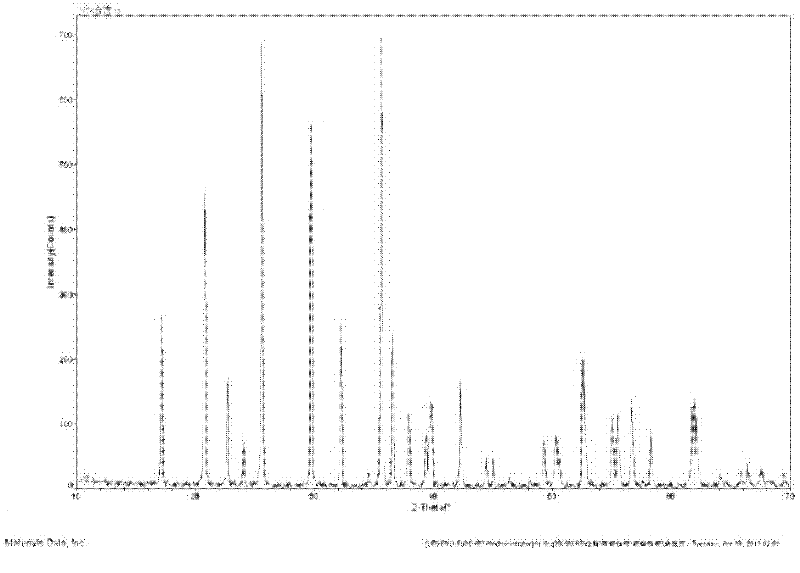

Image

Examples

Embodiment 1

[0051] Weigh 90g of potassium phosphate, 90g of lithium carbonate, 90g of ferrous sulfate, 110g of natural graphite, 20g of magnesium oxide, and 1000g of sodium chloride, and add them into a ball mill jar for grinding for 2 hours; The cake-shaped grinding material was placed in a tube-type sintering furnace, and calcined for 5 hours at a temperature of 900 ° C, and then the sample was cooled to room temperature with the furnace temperature; the sintered block was placed in a ball mill and ground into a Powders with a diameter of less than 10 microns are washed twice with 5000g of water each time; after filtration, they are dried with a blower at 200°C for 2 hours to obtain the product modified lithium iron phosphate.

Embodiment 2

[0053] Take by weighing ammonium phosphate 110g, lithium hydroxide 110g, ferrous ammonium sulfate 100g, artificial graphite 110g, silicon oxide 10g, potassium chloride 1500g respectively, add in ball mill tank and grind 8 hours; Press into cake shape with cake press machine; Under the protection of nitrogen, put the cake-shaped grinding material in a tubular sintering furnace and calcinate it at a temperature of 600°C for 10 hours, then cool the sample to 150°C with the furnace temperature; put the sintered block in a ball mill Grind it into a powder with a diameter of less than 10 microns, add water to wash twice, each time with 6000g of water; after filtering, use a blower to dry at 100°C for 6 hours to obtain the product modified lithium iron phosphate.

Embodiment 3

[0055] Take by weighing 100g of sodium dihydrogen phosphate, 90g of lithium chloride, 110g of iron nitrate, 90g of graphite, 5g of neodymium nitrate, and 1200g of lithium chloride, and add them into a ball mill jar for grinding for 6 hours; press them into a cake shape with a cake press; Under protection, put the cake-shaped grinding material in a tube-type sintering furnace and calcinate it for 7 hours at a temperature of 800°C, and then cool the sample to room temperature with the furnace temperature; place the sintered block in a ball mill to grind Form into a powder with a diameter of less than 10 microns, add water to wash twice, each time with 6500 g of water; after filtering, use a blower to dry at 150 ° C for 4 hours to obtain the product modified lithium iron phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com