Method for preparing rose calcium carbonate from low-grade limestone

A low-grade limestone and calcium carbonate technology, applied in calcium carbonate/strontium/barium, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of coarse particles, poor hiding power, poor dispersion, etc., and achieve smoothness The effect of improving degree and air permeability, increasing opacity, and enhancing mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

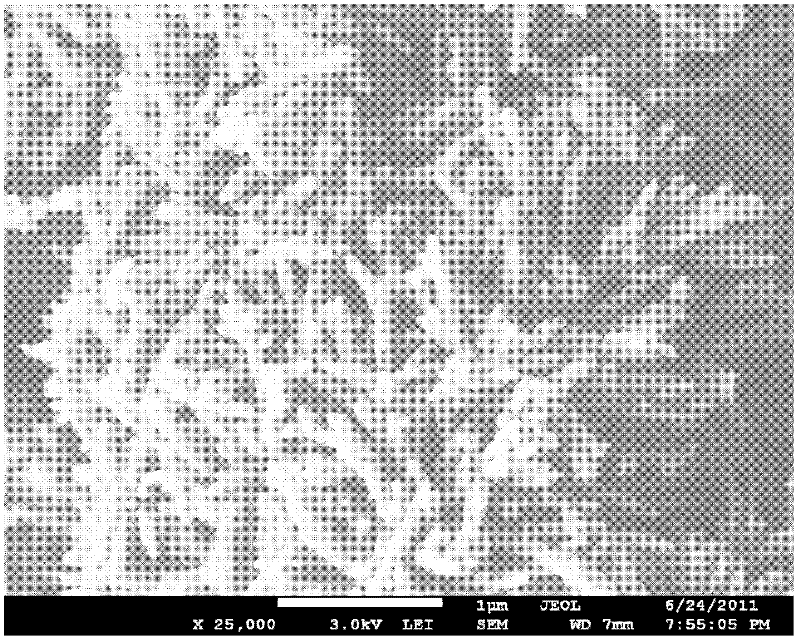

[0033] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. The calcination is carried out in an environmentally friendly and energy-saving steel mechanized shaft kiln. The ratio of limestone and anthracite is 10:1. The calcination temperature and calcination time are automatically controlled. The calcination temperature is controlled between 1000 ° C and the calcination time is 25 hours; High activity. The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of water for digesting lime is controlled at about 40°C, and the water consumption is 7 times of lime mass. The primary lime slurry contains some coarse slag, and the concentration of calcium hydroxide in the slurry is 12-14%. It passes through a 60-mesh sieve, a hydrocyclone, a 150-mesh sieve and a 250-mesh s...

Embodiment 2

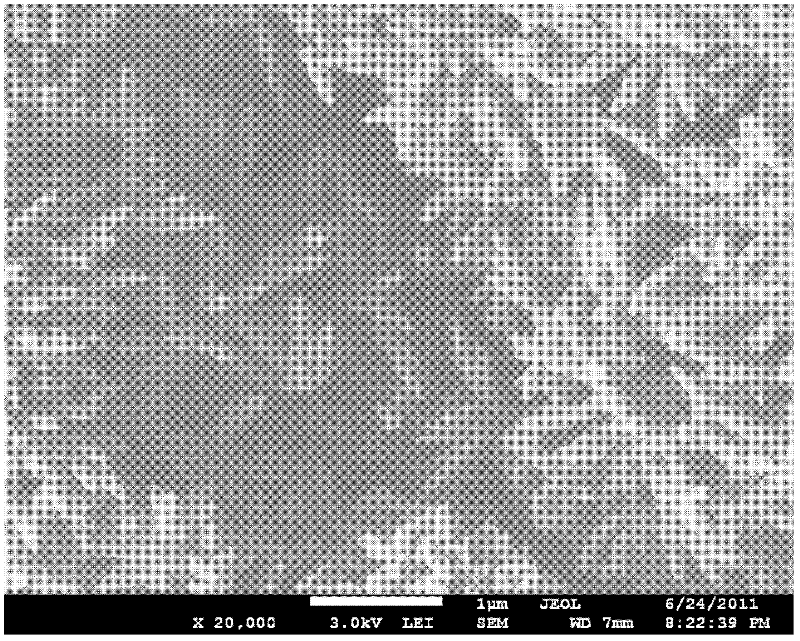

[0037] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. The calcination is carried out in an environmentally friendly and energy-saving steel mechanized shaft kiln. The ratio of limestone and anthracite is 10:0.95. The calcination temperature and calcination time are automatically controlled. The calcination temperature is controlled between 950 ° C and the calcination time is 36 hours; the burned lime has high active. The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of the water for digesting lime is controlled at about 30°C, and the water consumption is 7 times the mass of lime. The primary lime slurry contains some coarse slag, and the calcium hydroxide concentration in the slurry is 11-13%. It passes through a 60-mesh sieve, a hydrocyclone, a 150-me...

Embodiment 3

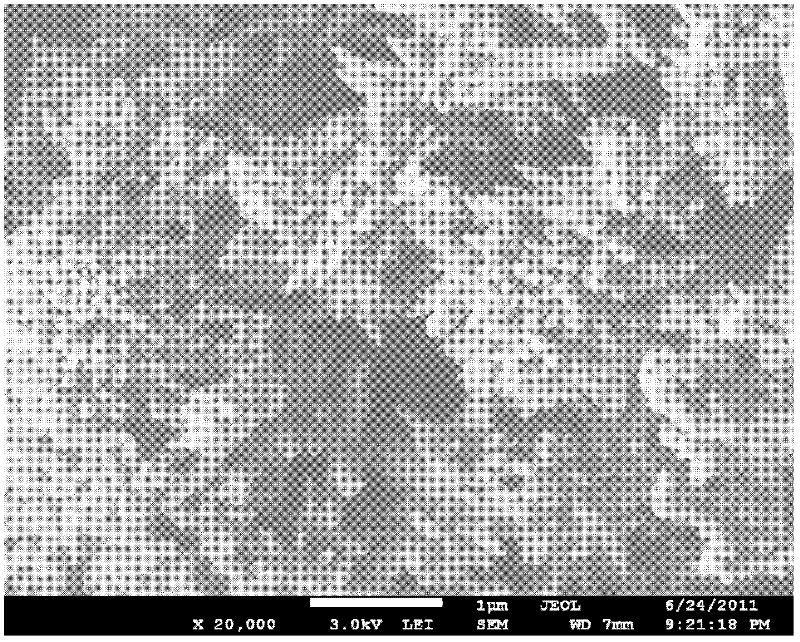

[0041] The limestone is crushed to a size of 40×120mm by a jaw crusher, and then conveyed to the top hopper of the mechanical shaft kiln by a conveyor belt. Calcination is carried out in an environmentally friendly and energy-saving steel-made mechanized shaft kiln. The ratio of limestone and anthracite is 10:1.1. The calcination temperature and calcination time are automatically controlled. The calcination temperature is controlled between 1050 ° C and the calcination time is 18 hours; Has high activity. The calcined lime is sieved to remove coal slag and small lime powder, and the obtained high-quality block lime enters the rotary digester for lime digestion. The temperature of water for digesting lime is controlled at about 50°C, and the water consumption is 4 times of lime mass. The primary lime slurry contains some coarse slag, and the calcium hydroxide concentration in the slurry is 11-13%. It passes through a 60-mesh sieve, a hydrocyclone, a 150-mesh sieve and a 250-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com