Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Molybdenum boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-containing titanium carbide nitride based metal ceramic cutter material and preparation technique thereof

ActiveCN101255512AHigh thermal conductivityImprove high temperature strengthSingle substanceBoron carbide

The invention discloses a boracic titanium carbonitride based cermet tool bit material and the preparing method thereof. The tool bit material is based on carbonitride as the parent metal, characterized in the tool bit is composed of 0.005% to 0.25% by mass of boron, 6% to 11% by mass of C, 2% to 7% by mass of N, 35% to 70% by mass of Ti, 5% to 20% by mass of W, 0 to 12% by mass of Mo, 0 to 9% by mass of Ta, 1% to 7% by mass of Nb and 6% to 25% by mass of Co and Ni, wherein boron is prepared by adding one or more selected from single substance boron, titanium diboride, molybdenum boride, boron carbide and boric oxide which are in raw material power form. The tool bit material is prepared mainly by mixing the raw material, ball-milling dispersing, press forming, pre-sintering and high-temperature sintering, its high-temperature hardness, high-temperature strength, red hardness and inoxidability are obviously improved, the cutting speed is greatly increased, and the service life is notably entended.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

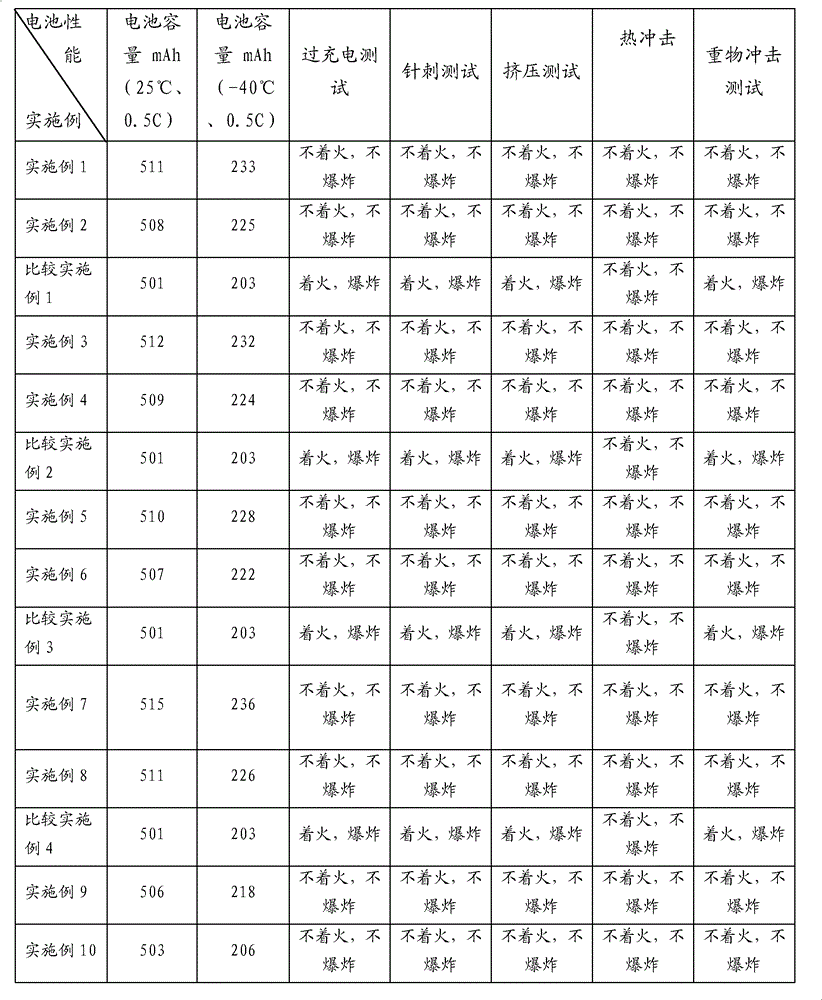

High capacity lithium ion battery containing metal conductive substances

ActiveCN102751530AImprove corrosion resistanceImprove antioxidant capacityCell electrodesSecondary cellsTitanium nitrideUranium carbide

The present invention discloses a high capacity lithium ion battery containing metal conductive substances. The battery comprises a positive electrode sheet, a negative electrode sheet, separation membranes, an electrolyte, a binder and a sealing material. A conductive substance of the positive electrode sheet comprises a metal carbide, a metal boride or a metal nitride. A conductive substance of the negative electrode sheet comprises a metal carbide, a metal boride or a metal nitride. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, or a co-melting body of tungsten carbide and titanium carbide. The metal boride is a molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conductive material of the positive electrode sheet further can contain powder metal, and the conductive material of the negative electrode sheet further can contain powdered metal, wherein the powdered metal is nickel powder, copper powder or chromium powder.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

ODS-alloy of molybdenum, silicon and boron

A Mo-Si-B alloy has a matrix of Mo or a Mo solid solution, wherein 25% by volume to 90% by volume of molybdenum silicide and molybdenum boron silicide, optionally together with molybdenum boride, are incorporated. The alloy also contains 0.1-5% by volume of one or more oxides or mixed oxides with a vapor pressure at 1500 DEG C. of <5X10-2 bar in finely dispersed form. The oxide addition not only improves the hot strength but also greatly improves the ductility.

Owner:奥地利普兰西股份公司

High capacity lithium ion battery containing metallic conducting materials

InactiveUS20140113175A1High capacity densityEasy dischargeElectrode carriers/collectorsOrganic electrolyte cellsAdhesiveElectrical battery

A lithium ion battery containing conducting materials comprises a positive electrode, a negative electrode, a separator, an electrolyte, adhesives and sealing materials. The conducting materials in the positive electrode comprise metal carbides, metal borides or metal nitrides. The conducting materials in the negative electrode comprise metal carbides, metal borides or metal nitrides. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, and eutectic of tungsten carbide and titanium carbide. The metal boride is molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conducting materials in the positive electrode may also comprise powdered metals. The conducting materials in the negative electrode comprise powdered metals. The powdered metal is nickel powder, copper powder or chromium powder.

Owner:ZHANG PANYI

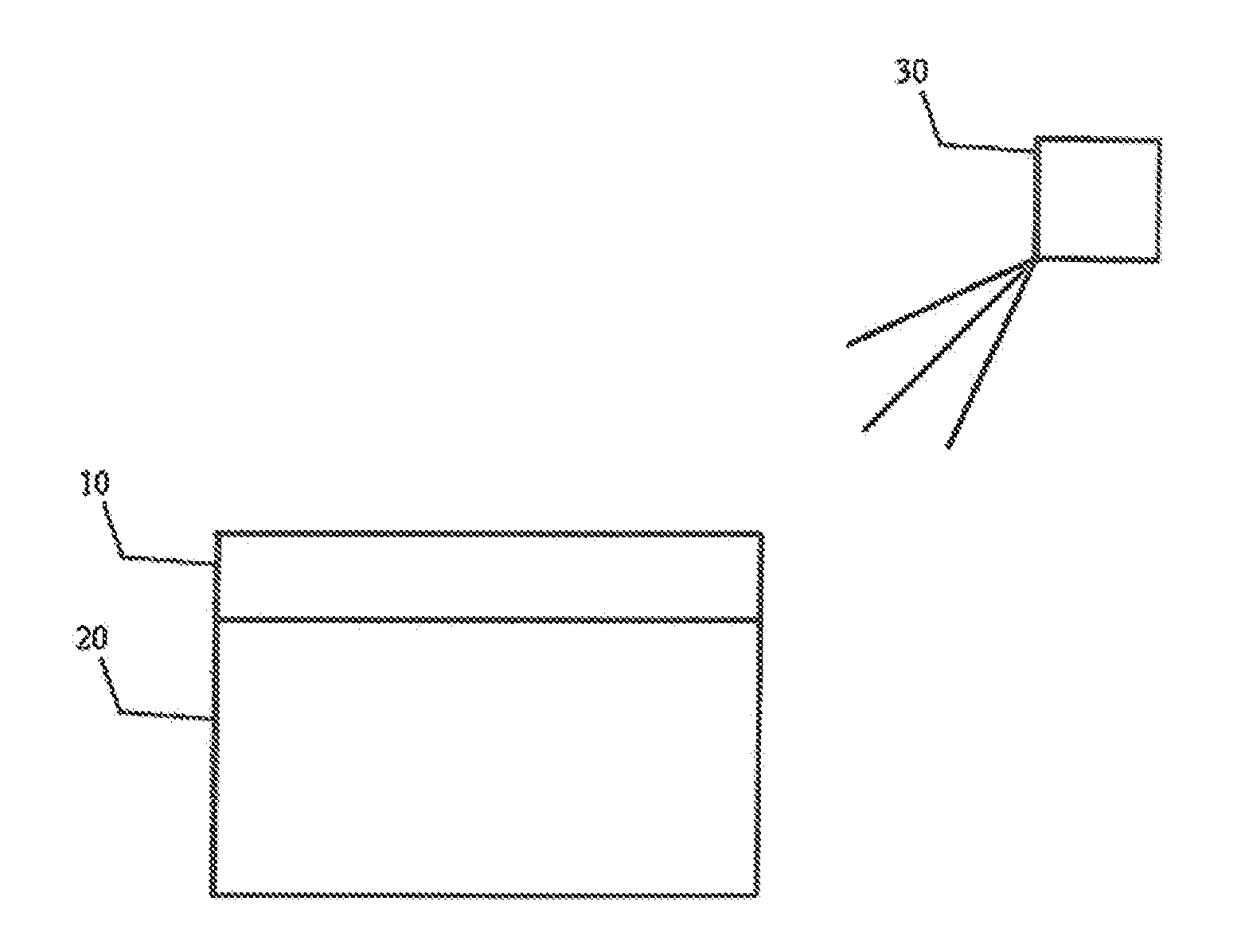

Ternary ceramic thermal spraying powder and method of manufacturing thermal sprayed coating using said powder

The invention describes a method for producing ternary and binary ceramic powders and their thermal spraying capable of manufacturing thermal sprayed coatings with superior properties. Powder contain at least 30% by weight ternary ceramic, at least 20% by weight binary molybdenum borides, at least one of the binary borides of Cr, Fe, Ni, W and Co and a maximum of 10% by weight of nano and submicro-sized boron nitride. The primary crystal phase of the manufactured thermal sprayed coatings from these powders is a ternary ceramic, while the secondary phases are binary ceramics. The coatings have extremely high resistance against corrosion of molten metal, extremely thermal shock resistance and superior tribological properties at low and at high temperatures.

Owner:HYBRID MATERIALS LLC

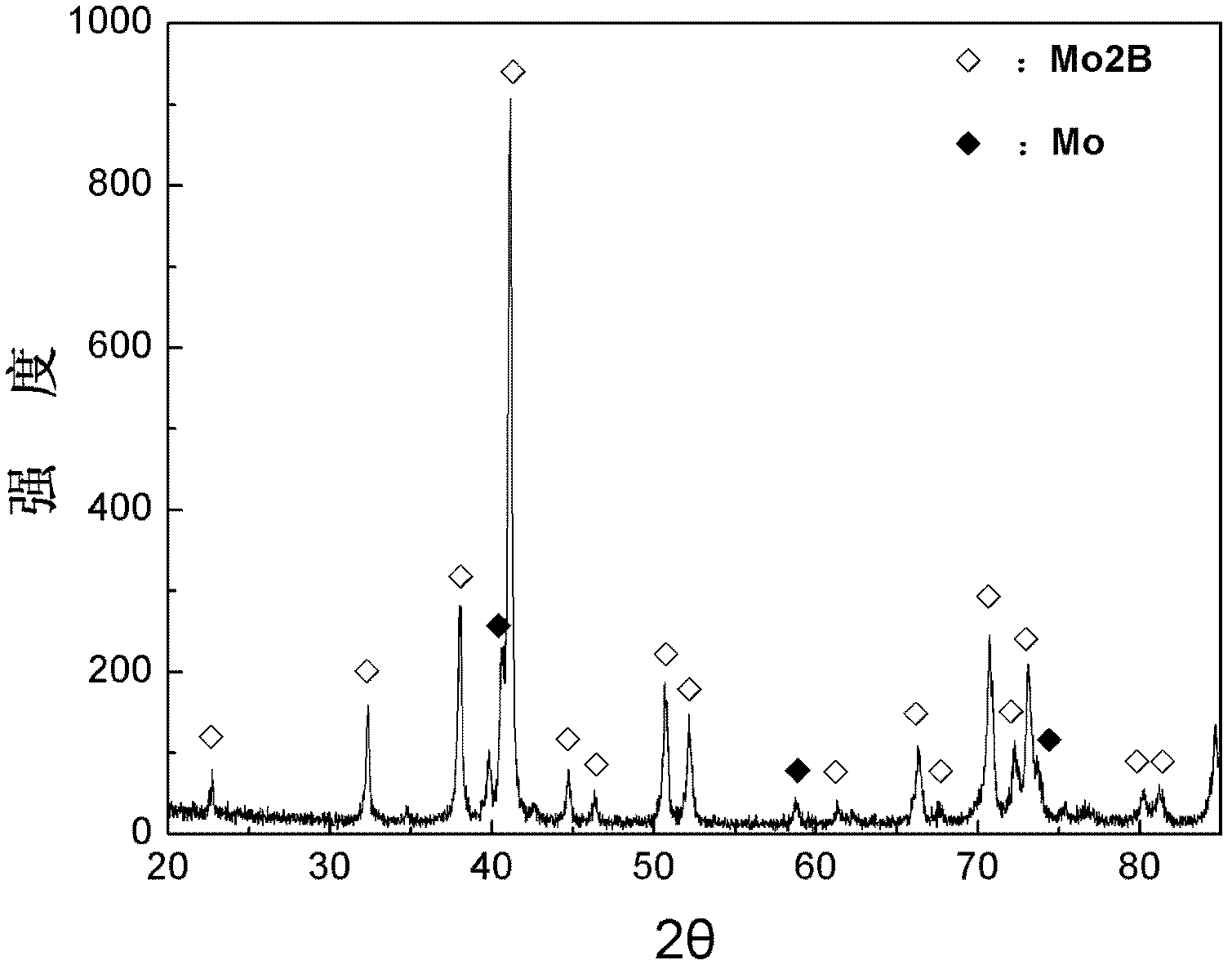

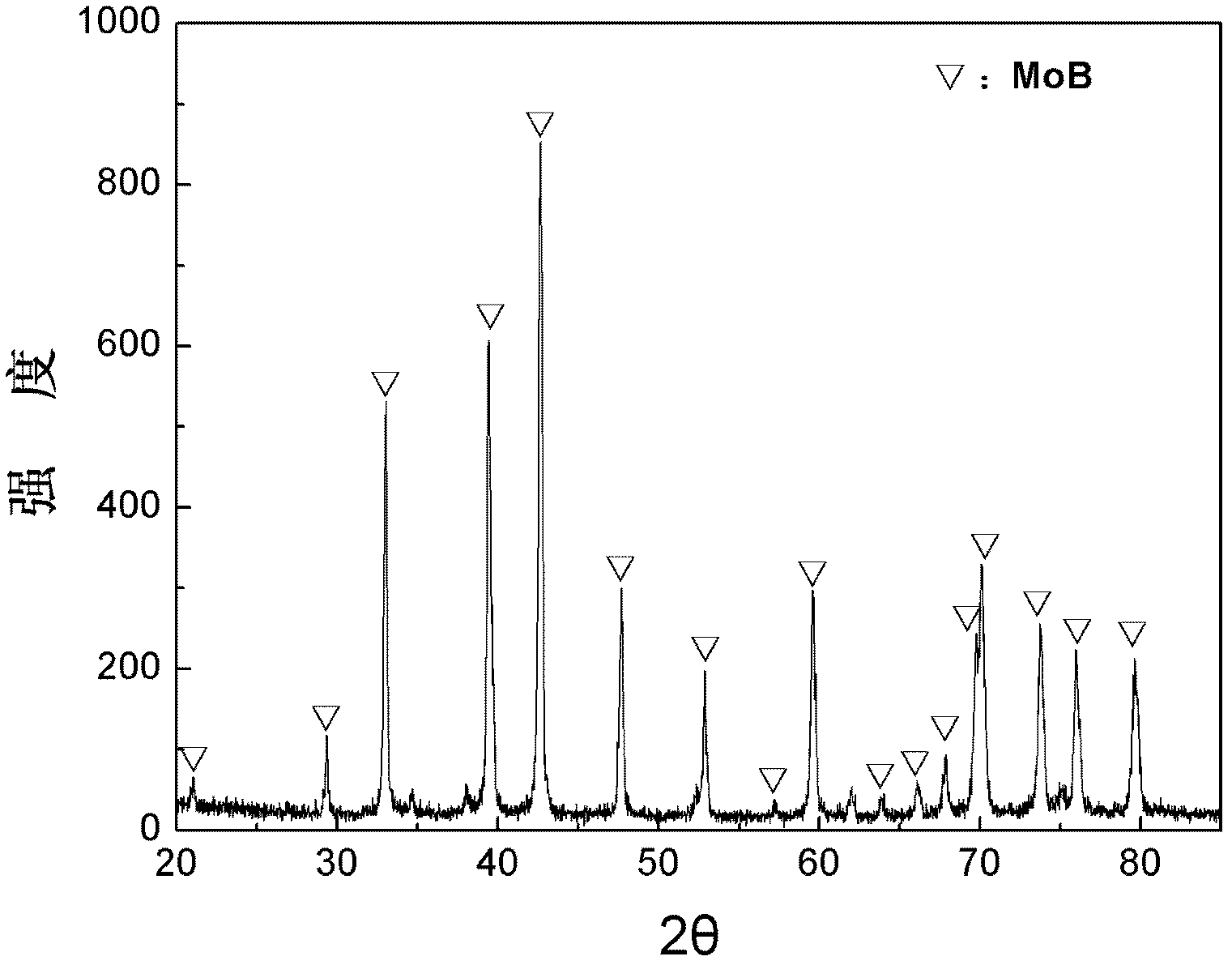

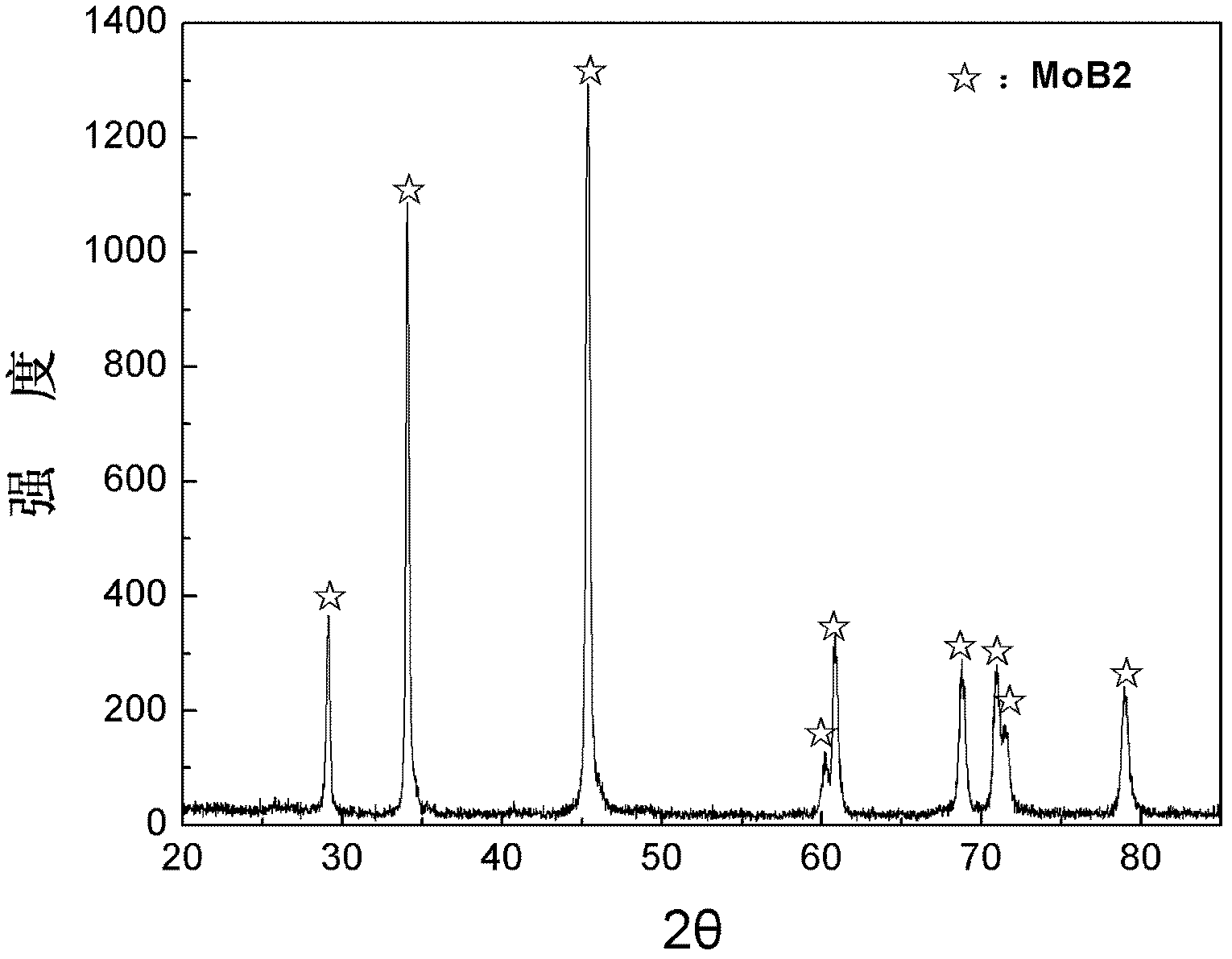

High-temperature high-pressure preparation method of molybdenum boride

The invention discloses a high-temperature high-pressure preparation method of molybdenum boride, belonging to the technical field of superhard material preparation. The method takes molybdenum powder and boron powder as raw materials and prepares the molybdenum boride material through the technological processes of mixing, briquetting, assembling, high-temperature high-pressure synthesis, cooling and pressure release, wherein in the high-temperature high-pressure synthesis, the temperature and pressure are maintained for 10-120 minutes under a pressure of 1.0-6.0GPa at a temperature of 1500-2100K; and the cooling and pressure release are performed finally to obtain the block sintered body of molybdenum boride. The method disclosed by the invention is simple and easy to implement, does not adopt any fluxing agent, and can synthesize single-phase Mo2B, MoB, MoB2 or Mo2B5 material through optimal raw material proportion, synthesis temperature, synthesis pressure and temperature / pressuremaintaining time.

Owner:JILIN UNIV

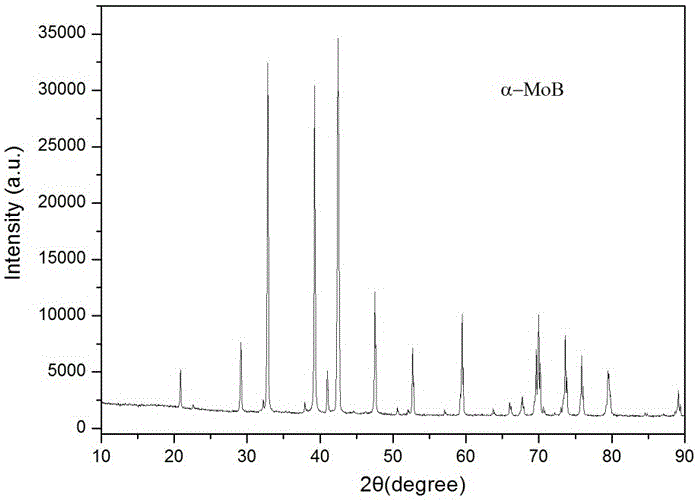

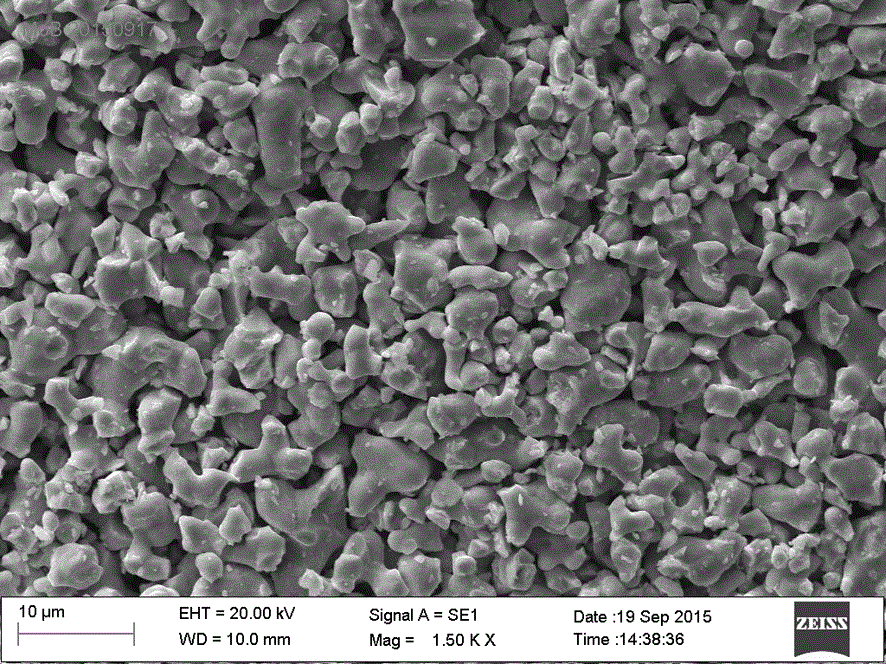

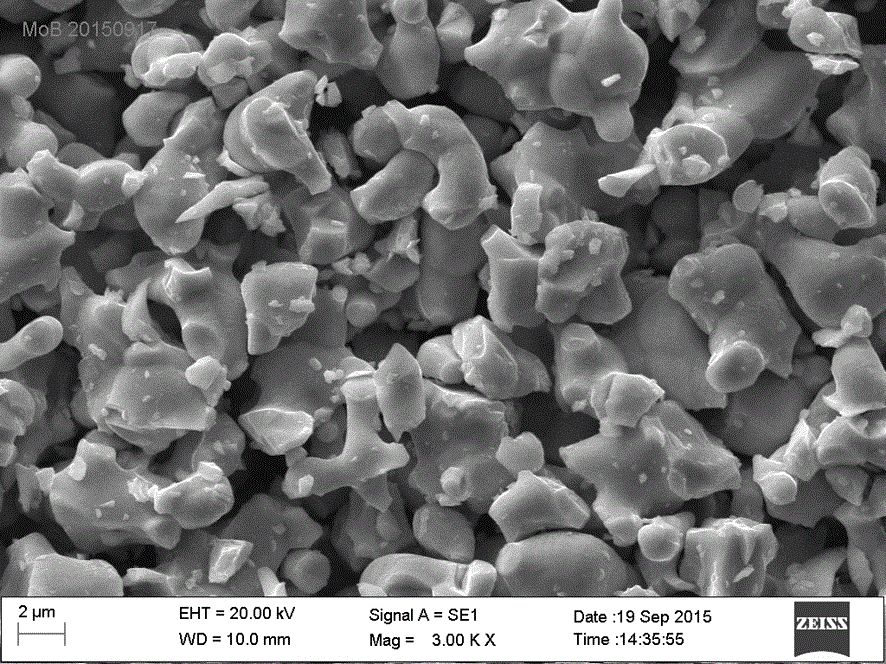

Preparation method of molybdenum boride powder

ActiveCN106276941AUniform particle sizeImprove performanceChemical industryMetal boridesMaterial DesignHigh pressure

The invention provides a preparation method of molybdenum boride powder. In the preparation steps, the molybdenum boride powder which completely accords with material design phase compositions can be controlled to be prepared by means of a high-temperature and high-pressure synthesis mode according to setting of the B / Mo mole ratio n (n=0.5, 1, 2, 2.5, 4) before synthesis, controllable synthesis of target molybdenum boride material phase compositions is achieved, and the synthesized molybdenum boride powder is uniform in particle size, complete in grain crystallization and excellent in property. The method is controllable in technological process, short in technological route, high in targeted property, convenient to operate, efficient, economical in energy, safe and good in reliability. The finished molybdenum boride powder is uniform in particle size distribution and complete in grain crystallization, the chemical purity is higher than or equal to 99.8%, and the product quality stability is good, the properties are obviously improved compared with a molybdenum boride material synthesized through a conventional method, and therefore the produced molybdenum boride material shows excellent physical and chemical properties in industrial application.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

Molybdenum base alloy surface oxidation-resistant coating and preparation method thereof

InactiveCN107523785ADeposition tightSmall particlesSolid state diffusion coatingCoated surfaceOxidation resistant

The invention discloses a molybdenum base alloy surface oxidation-resistant coating and a preparation method thereof. The method includes the steps that a molybdenum boride layer is formed on the surface of molybdenum base alloy through an in-situ chemical vapor deposition method; and then the in-situ chemical vapor deposition method is further adopted to form a molybdenum disilicide layer on the molybdenum boride layer. According to the molybdenum base alloy surface oxidation-resistant coating and the preparation method thereof, the surface of the composite coating is flat, particle deposition is formed on the coating surface, deposited particles are tiny, and the particles can be stacked compactly. The molybdenum base alloy surface oxidation-resistant coating is of a double-layer structure, and the interface between the layers is obvious.

Owner:张家港市思杰五金工具有限公司

Composite biological ceramic material and preparation method thereof

The invention belongs to the field of biological materials and discloses a composite biological ceramic material and a preparation method thereof. The biological ceramic material is prepared from the following components: 12-18 parts of calcium aluminate, 10-16 parts of silicon oxide, 14-20 parts of aluminum phosphate, 10-15 parts of magnesium aluminum silicate, 5-8 parts of calcium oxide, 3-7 parts of zirconium silicate, 6-11 parts of niobium silicide, 5-13 parts of vanadium silicide, 4-9 parts of boron nitride and 6-10 parts of molybdenum boride. The preparation method comprises the following steps: (1) uniformly mixing the materials at a high speed; (2) performing ball-milling through a ball mill; (3) pressing and molding in a hot pressing furnace, heating the hot pressing furnace to 760-800 DEG C and keeping the temperature for one hour, heating to 1230-1430 DEG C and sintering at a high temperature, and cooling to the room temperature, thereby obtaining the composite biological ceramic material.

Owner:深圳市四鼎华悦科技有限公司

Thermal insulation waterproof paint

The invention discloses thermal insulation waterproof paint which consists of the following raw materials in parts by weight: 70-76 parts of silicone acrylic emulsion, 0.7-1 part of triterpenoid saponin, 2-3 parts of hexafluorobutyl acrylate, 1-2 parts of ammonium polyphosphate, 0.7-1 part of N-hydroxymethyl acrylamide, 0.1-0.3 part of polybenzimidazole, 1.3-2 parts of hydrogenated castor oil, 3-4 parts of ceramic powder, 1-2 parts of diacetone alcohol, 0.1-0.2 part of molybdenum boride, 1-2 parts of saturated stearamide, 0.8-1 part of dibutyl maleate, 6-8 parts of quartz sand, 0.5-1 part of ammonium trimolybdate, 6-8 parts of coalescing agents and 10-30 parts of deionized water. The waterproof paint has high fluidity and adhesiveness; and due to the addition of the ammonium trimolybdate and ceramic powder, the gas tightness, elasticity and wear resistance of the film can be effectively improved, and the water resistance of the film is further enhanced.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Biological ceramic material and preparation method

The invention belongs to the technical field of biological ceramics and provides a biological ceramic material and a preparation method. The biological ceramic material comprises the following components in parts by weight: 25-40 parts of zirconium silicate, 10-26 parts of molybdenum boride, 13-29 parts of zirconium dioxide, 8-17 parts of attapulgite, 8-23 parts of selenium dioxide, 12-25 parts of calcium citrate, 7-19 parts of kieselguhr, 11-15 parts of tricalcium phosphate and 10-15 parts of collagen. According to the invention, the product is formed according to the steps of ball-milling, molding, controlling collagen and cross-linking collagen. The biological ceramic material has better mechanical properties and biological properties for boosting the cell growth.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

Ceramic material used for mouth rehabilitation and preparation method thereof

InactiveCN105906334AImprove the lack of brittleness and brittlenessImprove clinical successImpression capsDentistry preparationsNano al2o3Rare earth

The invention discloses a ceramic material used for mouth rehabilitation. The ceramic material is prepared from the following components in parts by weight: zirconia, nanometer aluminum oxide, niobium pentoxide, rare earth oxide, rectorite, molybdenum boride, aluminium borate, calcium-magnesium silicate whisker and fluorapatite. The invention also discloses a preparation method of the ceramic material used for the mouth rehabilitation. The Vickers hardness of the ceramic material used for the mouth rehabilitation exceeds 21.4GPa, the bending strength of the ceramic material exceeds 963.2MPa, and the breaking tenacity of the ceramic material is higher than 16.3MPa.m1 / 2. The defect of the traditional ceramic material that the traditional ceramic material is likely to be subjected to brittle failure since the traditional ceramic material is crisp is eliminated, a clinic success rate is improved, and the ceramic material can be used as a mouth rehabilitation material and has a wide application prospect.

Owner:王泽陆

High-temperature-resistant and anti-burst tempered glass material

The invention discloses a high-temperature-resistant explosion-proof tempered glass material, which is composed of the following components in parts by weight: 100 parts by weight of silicon dioxide, 6 parts by weight of aluminum oxide, 2 parts by weight of dimolybdenum boride, glass 5-10 parts by weight of fiber, 1-5 parts by weight of potassium aluminum sulfate, 2-8 parts by weight of polychloroacetic acid, 3-7 parts by weight of aluminum oxide, 10-15 parts by weight of mica powder, 1-part by weight of polyoxyethylene alkylphenol ether 5 parts by weight, 4-8 parts by weight of nano calcium carbonate, 1-5 parts by weight of nano-zinc oxide, 0.3-0.9 parts by weight of manganese, 0.1-0.5 parts by weight of cobalt, 0.2-0.6 parts by weight of strontium, 0.3-0.7 parts by weight of tungsten, Gallium 0.2-0.8 parts by weight. The composition of the invention is reasonably formulated, has excellent impact resistance, explosion-proof, mechanical damage resistance, high and low temperature resistance, etc., has the effects of explosion-proof and high-temperature resistance, improves the comprehensive performance of the glass, and has high safety.

Owner:明光市富域玻璃有限公司

Nano carbon rubber material

The invention discloses a nano carbon rubber material which is prepared from the following raw materials in parts by weight: 0.5 to 1 part of potassium citrate, 0.2 to 0.6 parts of 8 to 10 percent sulfuric acid, 26 to 30 parts of melamine, 5 to 8 parts of 37 percent formaldehyde solution, 7 to 10 parts of urea, 6 to 10 parts of microcrystalline cellulose, 1 to 1.2 parts of isopropanol, 2 to 3 parts of sulfur, 3 to 4 parts of maleic anhydride, 3 to 4 parts of molybdenum boride, 210 to 230 parts of chloroprene rubber S40V, 2 to 3 parts of aluminium potassium sulfate, 2 to 3 parts of phosphate, 6 to 10 parts of dioctyl phthalate, 0.4 to 1 part of nonylphenol polyoxyethylene ether, 40 to 43 parts of nano carbon powder, 2 to 3 parts of a promoting agent CA and 3 to 4 parts of an anti-aging agent TNP. Under the crosslinking action of maleic anhydride, a closer network structure is formed by microcrystalline cellulose in melamine resin formed by melamine, urea and formaldehyde, so that the viscosity and the tensile deformation resistance of the resin are well improved; certain reinforcement and viscosity increase effects are achieved in a rubber material, and the deflection, cracking, hot air aging resistance performances and the stability are improved.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Boron-based metal ceramic material and preparation method thereof

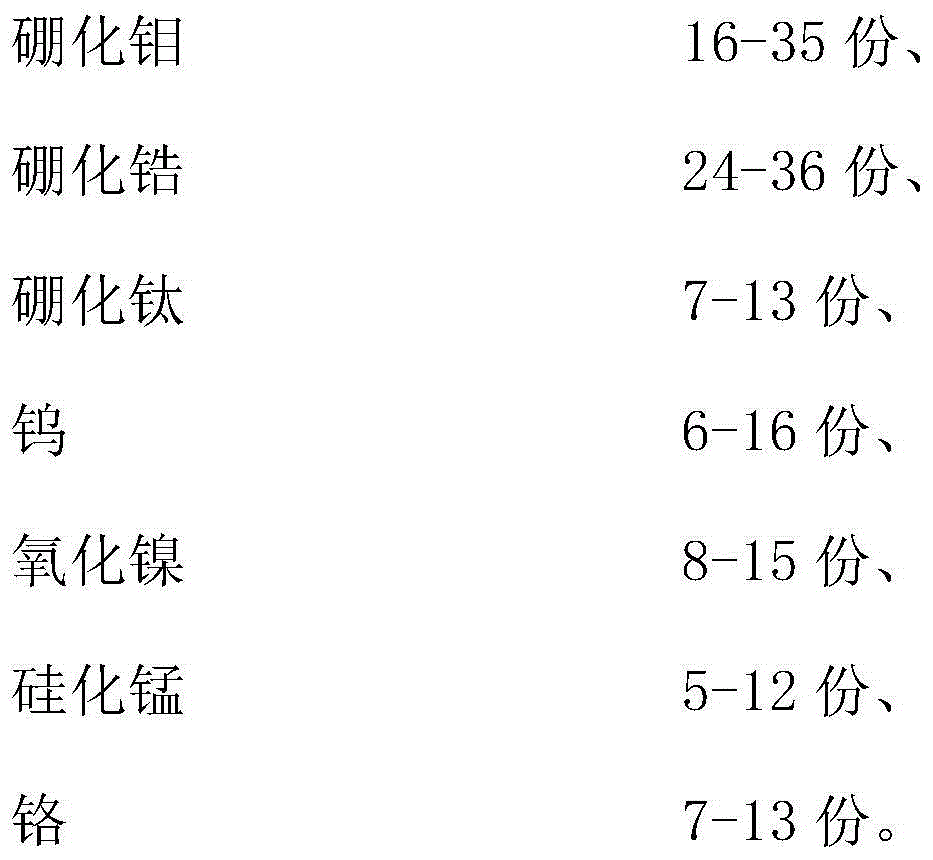

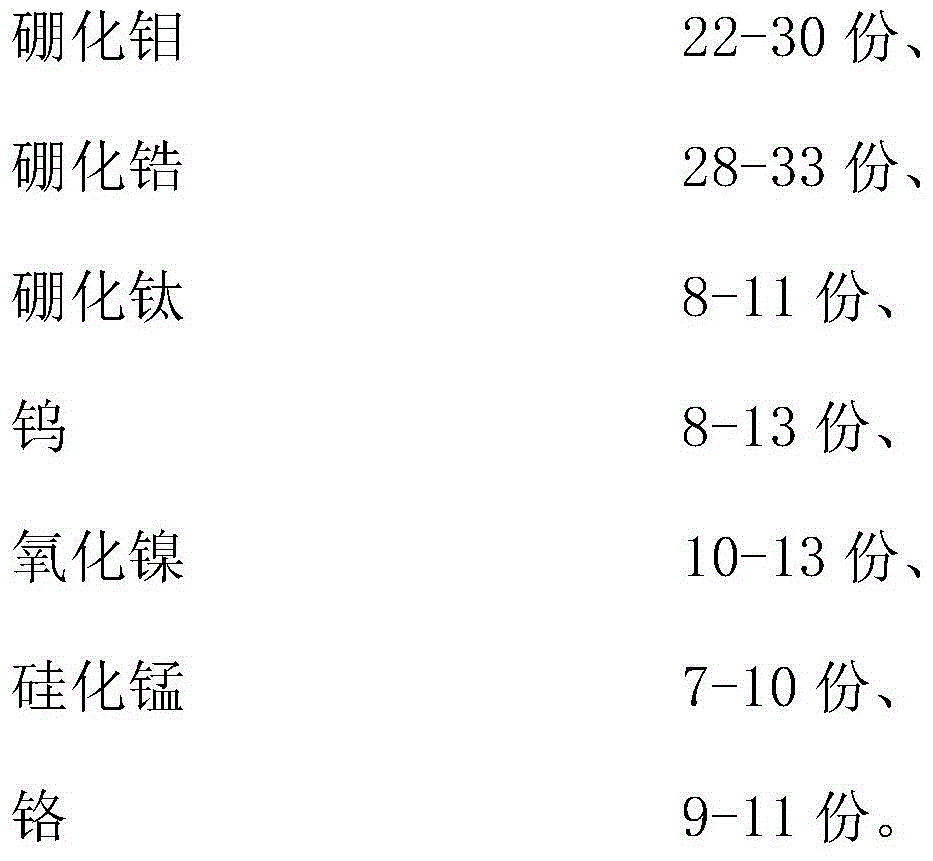

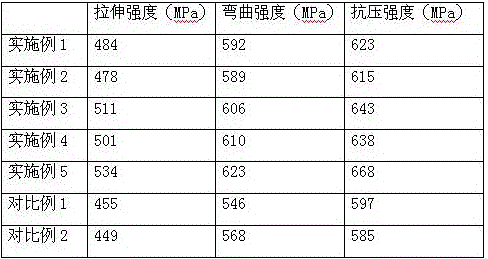

The invention discloses a boron-based metal ceramic material and a preparation method thereof. The metal ceramic material comprises the following components in parts by weight: 16-35 parts of molybdenum boride, 24-36 parts of zirconium boride, 7-13 parts of titanium boride, 6-16 parts of tungsten powder, 8-15 parts of nickel oxide, 5-12 parts of manganese silicide and 7-13 parts of chromium powder. The preparation method comprises the following steps: (1) respectively weighing 16-35 parts of molybdenum boride, 24-36 parts of zirconium boride, 7-13 parts of titanium boride, 6-16 parts of tungsten powder, 8-15 parts of nickel oxide, 5-12 parts of manganese silicide and 7-13 parts of chromium powder according to weights, and mixing uniformly; (2) then performing ball milling on mixed materials which are uniformly mixed; (3) pressing a metal ceramic material in a pressing mold after ball milling; and (4) then performing high-temperature sintering under the conditions that the sintering temperature is 910-940 DEG C and the sintering time is 3-7 hours, and cooling to room temperature to prepare the boron-based metal ceramic material.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

High-temperature-resistant sealant and preparation method thereof

InactiveCN105885729AImprove high temperature resistanceGood oil resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesEpoxyFiber

The invention discloses a high-temperature-resistant sealant and a preparation method thereof. The high-temperature-resistant sealant comprises, by weight, 50-70 parts of natural rubber, 5-6 parts of styrene butadiene rubber, 5-10 parts of acrylonitrile butadiene rubber, 5-7 parts of calcium sulfate crystal whisker, 10-30 parts of ceramic fiber, 10-13 parts of rice bran vinegar, 30-40 parts of cashew nut shell oil, 5-6 parts of gas-phase white carbon black, 5-8 parts of nano calcium carbonate, 10-15 parts of sepiolite powder, 10-12 parts of epoxy linseed oil, 6-8 parts of coumarone resin, 0.5-1.5 parts of dibutyl tin diacetate, 3-5 parts of 2-mercaptobenzothiazole, 5-10 parts of triethyl acetyl citrate, 1-2 parts of molybdenum boride, 6-10 parts of modified dolerite powder and 5-12 parts of a binding auxiliary. The high-temperature-resistant sealant has excellent resistance to high temperature, oil and radiation, has the advantages of high crack resistance and impact resistance and is high in compactness and comprehensive performance.

Owner:杨玉双

Improved ultraviolet-light ultralow-temperature-curable powdery paint

InactiveCN103497628AStrong impact resistanceStrong weather resistancePowdery paintsEpoxy resin coatingsEpoxyUltraviolet lights

The invention discloses an improved ultraviolet-light ultralow-temperature-curable powdery paint composed of the raw materials of, by weight: 50-60 parts of E-12 epoxy resin, 4-6 parts of polysiloxane resin, 1-2 parts of white carbon black, 25-30 parts of montmorillonite powder, 4.5-5.5 parts of activated carbon powder, 0.1-0.3 parts of cobalt oxide, 2-3 parts of molybdenum boride, 10-16 parts of dimethylaminopropylamine, 0.2-0.4 parts of dimethyl isooctyl thioglycolate tin, 0.8-1 part of 2-hydroxy-4-n-octyloxy benzophenone, and 10-20 parts of a composite filling material. The powdery paint provided by the invention has good impact strength and high weatherability, and can be applied in the coating fields of heat sensitive substrates such as plastics, wood, paper, and various heat sensitive electronic elements. The paint can also be used in the fields such as hardware, electrical appliances, household appliances, automobiles, furniture, decoration, machinery equipment, and the like.

Owner:BENGBU DEMO FILTRATION TECH

Super wear-resistant and corrosion-resistant coating and preparation method thereof

ActiveCN110747425ASimple processWide variety of sourcesMolten spray coatingSS - Stainless steelCobalt

The invention relates to a super wear-resistant and corrosion-resistant coating and a preparation method thereof. The technical scheme adopted by the preparation method of the super wear-resistant andcorrosion-resistant coating is that the super wear-resistant and corrosion-resistant coating comprises the chemical composition and content of molybdenum boride powder 40 to 60wt%, chromium boride powder 10-25wt% and Ni 60 alloy powder 24-42wt%. According to the chemical composition and content of the super wear-resistant and corrosion-resistant coating, a mixture is obtained through proportioning and mixing; the mixture is wet ground in a ball mill until the particle size is less than 5 micrometer, the mixture is dried in a vacuum drying oven at 80 to 120 DEG C for 12 to 48 hours, then spraying materials are obtained; and then the surface of a matrix is sprayed with the spraying materials through using spraying process, and the super wear-resistant and corrosion-resistant coating is prepared. The matrix material is one of hard alloy, carbon steel, stainless steel, cast iron, iron-based alloy, nickel based alloy, cobalt-base alloy, chromium-base alloy and titanium base alloy. The super wear-resistant and corrosion-resistant coating and the preparation method thereof has the advantages of simple preparation process and low cost, the super wear-resistant and corrosion-resistant coating has the advantages of high hardness, excellent wear-resistance, good corrosion-resistance, long service life and wide range of the matrix, can meet harsh service conditions.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of silicon nitride, silicon carbide combined molybdenum boride foamed ceramics

InactiveCN104311133AHomogeneous microstructureUniform hole sizeCeramicwareCarbide siliconMethyl cellulose

The invention relates to a preparation method of silicon nitride, silicon carbide combined molybdenum boride foamed ceramics. The preparation method is characterized by comprising the following steps: uniformly mixing Mo2B, micro silicon powder, phenolic resin and hydroxypropyl methyl cellulose to obtain a ceramic sizing agent, then soaking the ceramic sizing agent on polyurethane foam, drying the ceramic sizing agent, and burning the ceramic sizing agent in a nitrogen atmosphere to form the silicon nitride, silicon carbide combined molybdenum boride foamed ceramics. The silicon nitride, silicon carbide combined molybdenum boride foamed ceramics prepared in the method is uniform in micro structure, high in strength, uniform in porous size and capable of avoiding the residue of carbon and free silicon; moreover, the strength, high temperature resistance and thermal impact resistance can be greatly improved.

Owner:SHANDONG UNIV OF TECH

Alumina bioceramics material and preparation method therefor

The invention belongs to the field of medical materials and discloses an alumina bioceramics material and a preparation method therefor. The ceramic material is prepared from the ingredients in parts by weight: 16-28 parts of alumina, 3-6 parts of molybdenum boride, 3-5 parts of boron nitride, 2-5 parts of chromium boride, 3-7 parts of tungsten silicide, 4-8 parts of cobalt silicide, 2-4 parts of magnesia, 2-4 parts of copper, 1-3 parts of zirconium, 2-5 parts of rubidium and 1-3 parts of nickel. The preparation method disclosed by the invention comprises the following steps: (1) carrying out mechanical ball-milling on the ingredients (in parts by weight) in a ball mill; (2) after ball-milling, uniformly mixing a mixed cermet material; and (3) carrying out high-temperature sintering on the mixture, which is uniformly mixed in the step (2), in a high-temperature sintering furnace for 3 hours at the temperature of 800 DEG C to 900 DEG C, then, heating the mixture to the temperature of 950 DEG C to 1,050 DEG C, carrying out sintering for 4 hours, and cooling the mixture to room temperature, thereby preparing the alumina bioceramics material.

Owner:SUZHOU COSMETIC MATERIALS

Antioxidant coating and method of preparing molybdenum boride on surface of molybdenum-based alloy

InactiveCN107523784AHigh hardnessIncrease elasticitySolid state diffusion coatingOxidation resistantBall mill

The application discloses an antioxidant coating and a method of preparing molybdenum boride on the surface of a molybdenum-based alloy. The method comprises the following steps of: (1) mixing boron powder, sodium fluoride and aluminum oxide, and putting the mixture in a ball mill to be mixed for 24h to obtain mixed powder; (2) drying the mixed powder at a constant temperature of 50-60 DEG C for 10-12h to obtain a powder feed; (3) performing molybdenum-based alloy surface treatment, including abrasive blasting, ultrasonic cleaning and deoiling, successively; and (4) putting the powder feed and the molybdenum-based alloy in a tubular furnace, raising the temperature to 900-1000 DEG C at 8-10 DEG C / min for pretreatment for 15-20h, cooling the temperature to room temperature, and preparing the molybdenum boride coating on the surface of a molybdenum base. The molybdenum boride coating obtained by the invention has very high hardness and elastic modulus which are separately HV3130 and 520GPa. The oxidation rate constant is 0.22mg<2>(cm<4>.h) after the molybdenum boride coating is oxidized for 100h at 600 DEG C, and the low-temperature antioxidant performance of molybdenum is improved.

Owner:张家港市思杰五金工具有限公司

Explosion-proof film for mobile phone screen glass

The invention relates to a plastic film, in particular to an explosion-proof film for mobile phone screen glass, which belongs to the technical field of mobile phone protective films. Explosion-proof film, including the following components by weight: 20-30 parts of acrylic resin, 40-50 parts of polyvinyl chloride, 6-10 parts of calcium phosphate, 2-12 parts of silicon dioxide, 1-7 parts of benzyl alcohol, boron 5-10 parts of dimolybdenum chloride, 3-8 parts of glass cellulose, 2-6 parts of 2-hydroxy-4-methoxybenzophenone, 2-5 parts of polyphenylene sulfide, and 4-9 parts of titanium dioxide. The present invention uses acrylic resin, polyvinyl chloride, calcium phosphate, silicon dioxide, benzyl alcohol, dimolybdenum boride, glass cellulose, 2-hydroxy-4-methoxybenzophenone, polyphenylene sulfide, titanium dioxide Through the synergy between the raw materials, the explosion-proof film provided by the invention has the advantages of high transparency, good anti-ultraviolet effect, high surface hardness, etc., and also has the function of mitigating impact, which can protect the screen from breaking.

Owner:芜湖辉灿电子科技有限公司

Glass film

The invention discloses a glass film which is composed of the following components in parts by weight: 12 parts of acrylic resin, 1-2 parts of benzyl alcohol, 1.3 parts of poly chloroacetic acid, 2.3 parts of molybdenum boride, 1.3 parts of tetraethoxysilane, 1.2 parts of polyxyethylated alkylphenol, 4.5 parts of ethyltrimethoxysilane and 3.4 parts of glycerol. The glass film disclosed by the invention can improve a heat-insulating property, an insulation property, cold resistance, an explosionproof property, corrosion resistance, an antibacterial property, and an anti-static property of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

Anti-tensile metallic nickel ceramic coating and manufacturing method thereof

InactiveCN105039966AImprove permeabilityWith strengthHeat inorganic powder coatingInterfacial reactionCeramic coating

The invention discloses an anti-tensile metallic nickel ceramic coating. The surface of matrix metal is coated with the ceramic coating manufactured by selecting metallic nickel as a metallic matrix and adopting refractory materials such as cobaltous oxide and molybdenum boride as ceramic phases. Alloying elements in the matrix metal diffuse towards the interface and are subjected to interfacial reactions with substances such as NiO in the coating, wherein one interfacial reaction follows the equation that NiO+M->MO+Ni. Reduced and precipitated active nickel atoms and the matrix metal M form Ni-M metallic bonds. Thus, the adherence of the metallic ceramic coating and the matrix metal is improved. Moreover, because rare-earth nano cerium dioxide is high in activity, the atomic orbital interaction of the rare-earth nano cerium dioxide with absorbed molecules is improved, the reactions are enhanced, adherence can be built soon, and added boron powder and nickel powder are combined so that the permeability of the coating can be improved. The manufactured coating has the strength and toughness of the metal, is anti-tensile, also has the high-temperature-resistant, antioxidant, abrasion-resistant and corrosion-resistant advantages of ceramic materials, and is a novel composite material.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Composite high-strength zirconia ceramic material and preparation method thereof

The invention discloses a composite high-strength zirconia ceramic material and a preparation method thereof.The ceramic material comprises 20-40 parts of zirconium oxide, 5-12 parts of silicon carbide, 4-10 parts of tungsten carbide, 3-7 parts of boron nitride, 3-7 parts of zirconium boride, 2-7 parts of molybdenum boride, 2-6 parts of tungsten silicide, 2-6 parts of barium silicide, 2-4 parts of vanadium silicide and 3-6 parts of tantalum boride.The preparation method includes the following steps that 1, all ingredients are subjected to mechanical milling in a ball mill; 2, after ball milling is conducted, the ceramic material is subjected to high-temperature sintering in a sintering furnace, the temperature raising rate is 30-70 DDG C / min, the temperature is raised to 900-950 DEG C in the first place, the temperature is maintained unchanged for 2 hours, then the temperature is raised to 1250-1350 DEG C, the temperature is maintained unchanged for 3 hours and then lowered to the room temperature, and the composite high-strength zirconia ceramic material is prepared.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Reflective water-resistant paint

InactiveCN104263135AImprove waterproof performanceImprove washabilityReflecting/signal paintsAluminum silicateWater resistant

The invention discloses a reflective water-resistant paint which is prepared from the following raw materials in parts by weight: 72-80 parts of polyvinyl acetate emulsion, 0.3-1 part of potassium ferrocyanide, 0.3-1 part of tea tree oil, 0.5-1 part of octadecamethacrylate, 2-3 parts of binary vinyl chloride-vinyl acetate resin, 1-2 parts of inositol, 2-3 parts of alkenyl succinate, 1-2 parts of molybdenum boride, 2-3 parts of anhydrous calcium chloride, 1-2 parts of aluminum silicate, 1-2 parts of magnesium silicate, 10-14 parts of reflective glass microbead, 1-2 parts of terpineol, 2-3 parts of chlorinated paraffin, 5-7 parts of film forming assistant and 11-20 parts of deionized water. The water-resistant paint has the advantages of favorable water resistance, favorable washing fastness, enduring and bright color and high reflection ratio, is mainly used for making various reflecting signs, vehicle number plates, reflective clothes, safety devices and the like, and has favorable safety and protectiveness.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

Cermet material for high-strength mold and preparation method of cermet material

The invention discloses a cermet material for a high-strength mold and a preparation method of the cermet material. The cermet material is prepared from the following materials in parts by weight: 5-13 parts of magnesium oxide, 12-20 parts of tungsten boride, 10-16 parts of molybdenum boride, 6-15 parts of nickel silicide, 5-10 parts of titanium silicide, 4-8 parts of silicon nitride, 3-7 parts of cobalt silicide, 2-5 parts of nitridedferrochrome, 2-6 parts of nickel, 2-5 parts of vanadium and 2-4 parts of iron. The preparation method comprises the following steps: (1) weighing according to the weight parts, and mixing in a large mixing and stirring tank; (2) ball milling the materials after being mixed in a ball mill for 1-3h, wherein the ratio of grinding media to material in the ball mill is 20: (1-35): 1; and (3) taking the cermet material out of the ball mill, and sintering in a sintering furnace by raising the temperature to prepare the cermet material for the high-strength mold. The prepared cermet material is good in compression and shock resistances.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

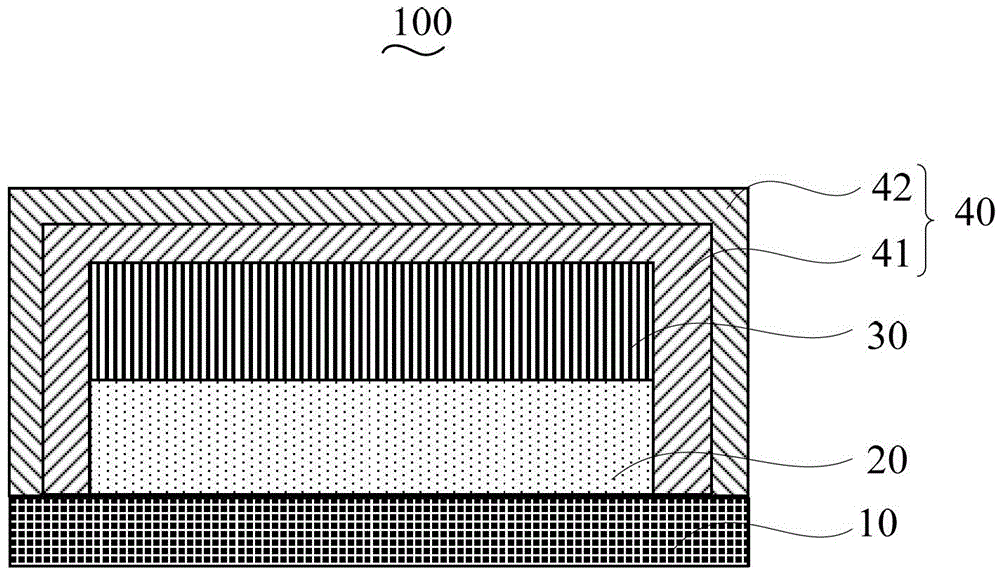

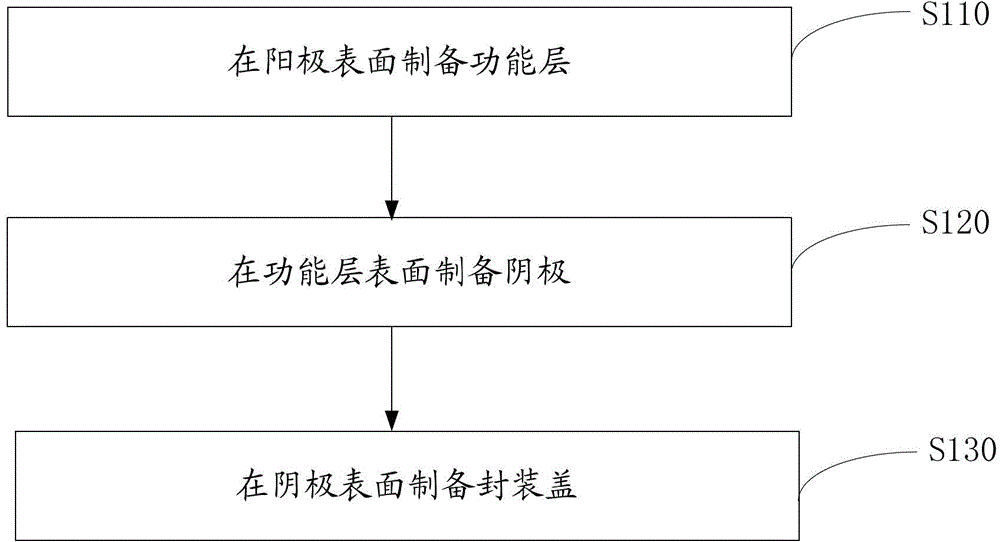

Organic light-emitting device and preparation method for same

InactiveCN104425752ASolution to short lifeCorrosion protectionSolid-state devicesSemiconductor/solid-state device manufacturingNiobiumTitanium nitride

The invention discloses an organic light-emitting device. The organic light-emitting device comprises an anode, a luminous layer, a cathode and a packaging cover, which are sequentially laminated, wherein the luminous layer and the cathode are packaged on the anode by virtue of the packaging cover; the packaging cover comprises a silicon carbonitride layer and a barrier layer formed on the surface of the silicon carbonitride layer; a material for the barrier layer comprises nitride and boride; the nitride is at least one of trisilicon tetranitride, aluminum nitride, boron nitride, hafnium nitride, tantalum nitride and titanium nitride; the boride is at least one of aluminum boride, lanthanum hexaboride, vanadium boride, niobium boride, titanium diboride and molybdenum boride. The organic light-emitting device is longer in service life. The invention also provides a preparation method for the organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Nanometer environmentally friendly pbt material

ActiveCN104140652APromote environmental protectionImprove wear resistancePolytetramethylene terephthalateBrick

The invention discloses a nanometer environmentally friendly pbt material. The nanometer environmentally friendly pbt material comprises, by weight, 92-100 parts of polybutylene terephthalate, 0.7-1 part of methyl ethyl ketone oxime, 1-2 parts of tricalcium silicate, 1-2 parts of butylmercaptooxo stannane, 1-2 parts of sebacic dihydrazide, 1-2 parts of polyhexamethylene guanidine, 1-2 parts of sodium fluoride, 2-4 parts of nanometer brick slag powder, 1-2 parts of aluminum dihydrogen phosphate, 1-2 parts of molybdenum boride, 2-3 parts of phosphate ester, 2-4 parts of dioctyl phthalate, 0.1-0.2 part of cross-linking agents TAC and 1-2 parts of processing agents. The nanometer environmentally friendly pbt material is good in environmental protection performance, compatibility among the materials is well promoted due to the added nanometer materials, and the comprehensive performance of products is increased. The finished product is good in anti-abrasion performance and tensile resistance, high in heat resistance and acid and alkali resistance, wide in application range and good in safety and environmental protection performance.

Owner:广东森绅实业有限公司

Anti ultraviolet, heat aging resistance and heat radiation paint for LED lamp and preparation method thereof

The invention provides an anti-ultraviolet, heat aging resistant and heat radiative paint for an LED lamp, wherein the paint is prepared by the raw materials by weight: 35-40 parts of E-12 epoxy resin, 4-5 parts of vinyl triamine DETA, 1-4 parts of triallyl isocyanurate, 1-2 parts of antioxidant MB, 4-6 parts of amino propyl triethoxysilane, 2-3 parts of nano-silica, 1-2 parts of emery powder, 1-2 parts of lemon oil, 5-8 parts of triglycidyl isocyanurate, 1-2 parts of boron nitride, 2-3 parts of nano hollow bead, 19-22 parts of ethyl acetate, 2-3 parts of molybdenum boride, 14-16 parts of aluminum nitride powder, and 4-5 parts of film forming auxiliary agent. Aluminum nitride powder is added to make the paint have high heat conduction rate and good heat radiation effect; nano silica is added to make that the paint has excellent ultraviolet ray-shielding and infrared ray-reflecting functions, is beneficial to human health, resists heat aging, obviously improves the pot-opening effect, and has advantages of no delamination and thixotropy.

Owner:天长市天泰光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com