Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Uniform hole size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

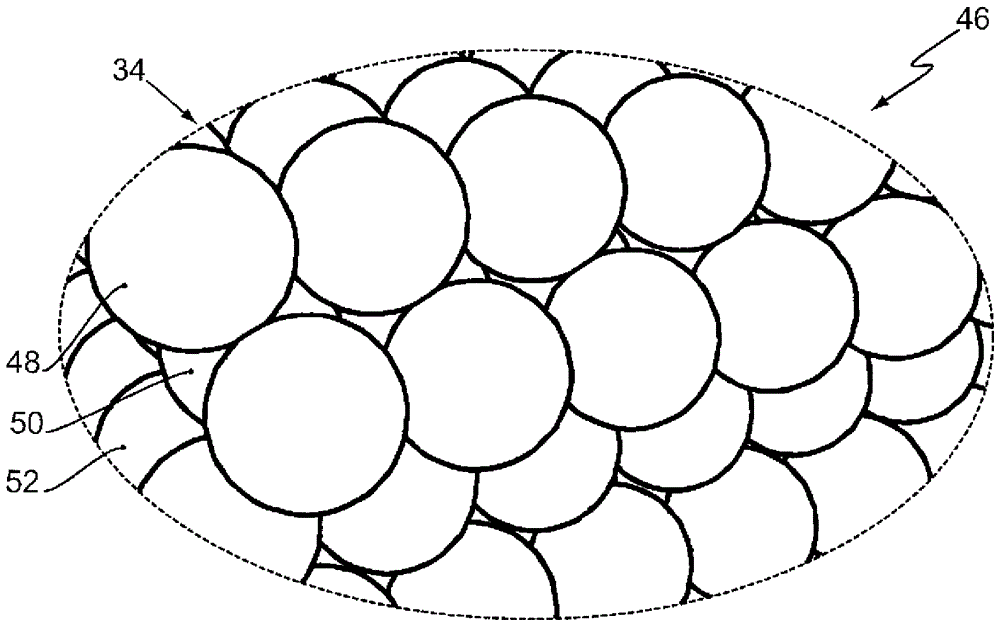

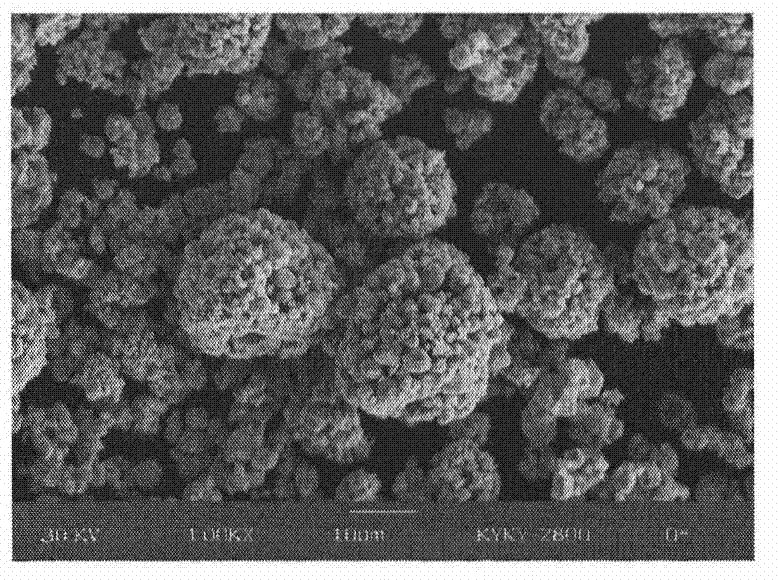

Thermo-sensitive coding microsphere carrier for drug controlled release and preparation method of microsphere carrier

InactiveCN106214644AAchieve controlled releaseHelp monitorAerosol deliveryOintment deliveryControlled releaseMedicine

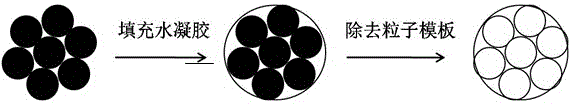

The invention discloses a thermo-sensitive coding microsphere carrier for drug controlled release and a preparation method of the microsphere carrier. The carrier is a hydrogel microsphere with an inverse opal structure. The main component of the microsphere is poly(N-isopropylacrylamide), which has a three-dimensional ordered nanometer porous structure for carrying multiple protein or polypeptide medicines. Contraction and expansion of nanometer holes can be controlled through temperature regulation, so that drug controlled release is achieved. The inverse opal hydrogel microsphere is prepared by taking a colloidal crystal microsphere as a template. The carrier is simple in preparation method, low in cost and convenient for large-scale production. The prepared coding carrier is non-toxic and is good in biocompatibility and controllability.

Owner:SOUTHEAST UNIV

Method for preparing silicon nitride bonding silicon carbide foamed ceramics

The invention discloses a method for preparing silicon nitride bonding silicon carbide foamed ceramics. The method is characterized by comprising the following steps: uniformly mixing SiC, silica powder, a phenolic resin and hydroxypropyl methyl cellulose solution so as to prepare ceramic slurry; dipping the ceramic slurry on polyurethane foam, drying, and firing in a nitrogen atmosphere, thereby obtaining the silicon nitride bonding silicon carbide foamed ceramics. The silicon nitride bonding silicon carbide foamed ceramics prepared by the method are uniform in microstructure, high in strength and uniform in pore size, and residues of carbon and free silicon are avoided, so that the strength, high temperature resistance and thermal shock resistance of the ceramics can be greatly improved.

Owner:SHANDONG UNIV OF TECH

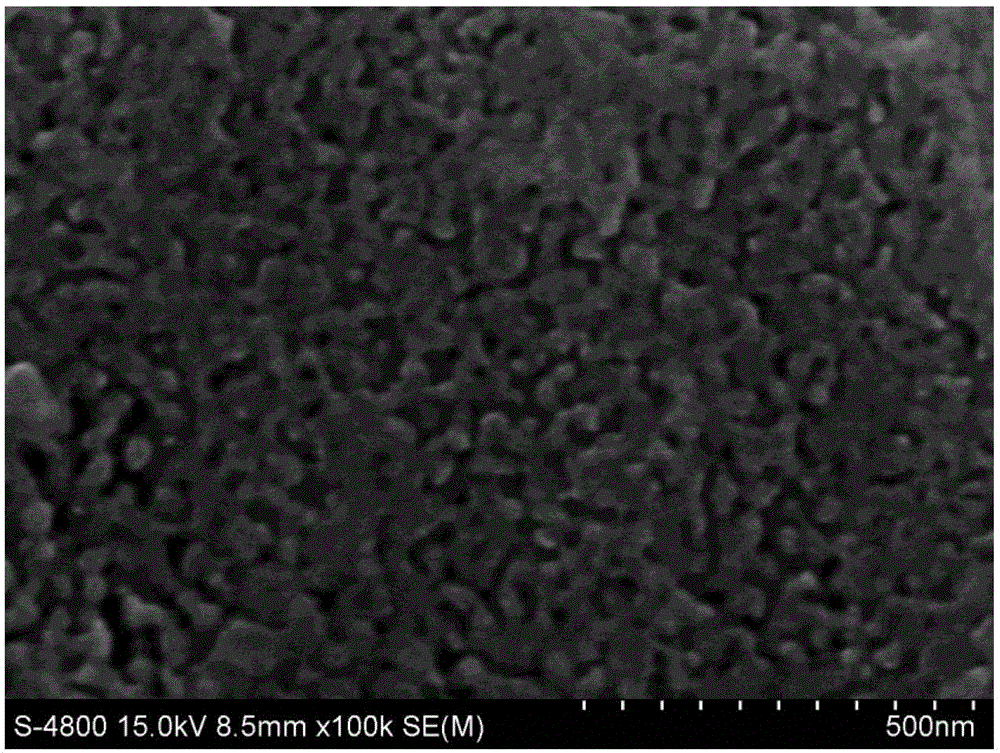

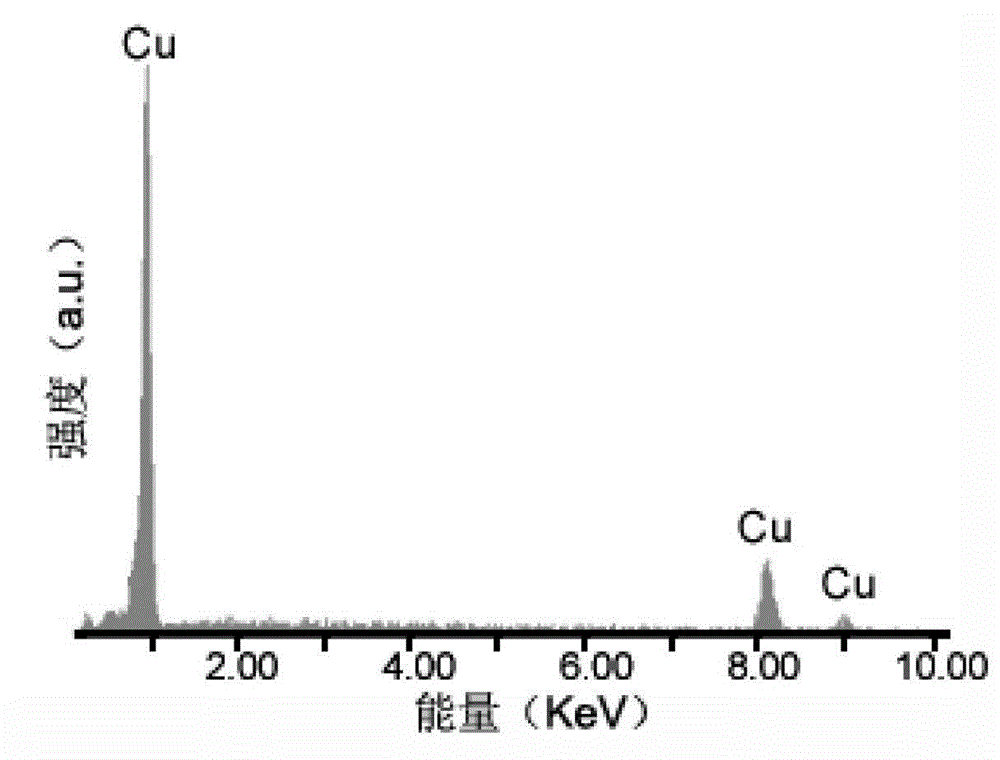

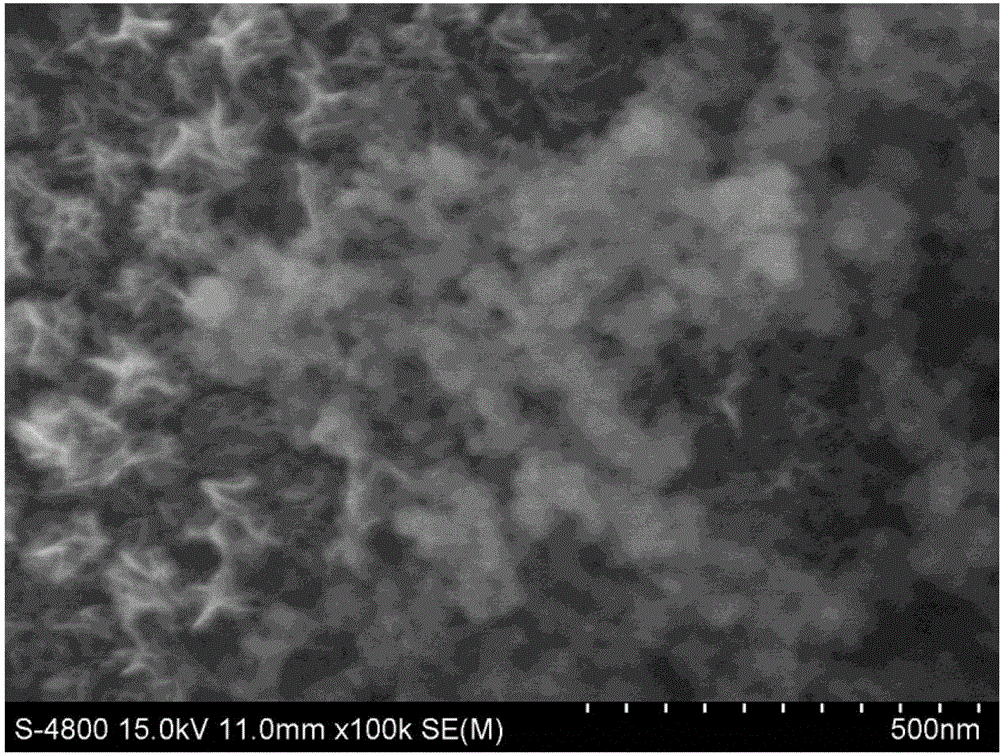

Electrode plate for super capacitor and preparation method of electrode plate

ActiveCN103337374AUniform hole sizeIncrease the areaMaterial nanotechnologyHybrid capacitor electrodesElectrolysisHigh energy

The invention relates to an electrode plate for a super capacitor and a preparation method of the electrode plate, and relates to materials for electrode components of an electrochemical capacitor. The electrode plate is made of a compound applied and pressed on a nickel screen and capable of producing MnO<2> on the surface of nano porous copper, wherein the mass percent of nano porous copper is 25 to 75. The preparation method comprises the steps as follows: the nano porous copper is prepared by a dealloying method; then nano porous copper and manganese dioxide mixed powder is prepared; finally, dried nano porous copper and manganese dioxide mixed powder is mixed with binder polytetrafluoroethylene according to the mass ratio of 95 to 5, anhydrous ethyl alcohol is taken as a dispersing agent and ground for 10 min in an agate mortar to mix to be pasty, and then evenly coated on a nickel screen with the dimension of 30 mm* 10 mm, the electrode plate is formed by the pressing of the powder tablet machine under the pressure of 10 MPa, and then drying is performed until constant weight is obtained, so that the electrode plate for the super capacitor is prepared. The defects of complex process, high energy consumption and high manufacturing cost in the manganese dioxide electrode material preparation method in the prior art can be overcome.

Owner:HEBEI UNIV OF TECH

Three-dimensional porous stent and preparation method and application thereof

ActiveCN109091705AModerate pore sizeGood biocompatibilityAdditive manufacturing apparatusProsthesisTissue repairEmulsion

The invention discloses a three-dimensional porous stent. The three-dimensional porous stent is made from composite biomaterials consists of degradable natural biomaterials and degradable artificiallysynthesized macromolecule materials. The three-dimensional porous stent has a three-dimensional orderly porous structure in which holes are homogeneous, mutually penetrated and regular in distribution, and the hole diameter is 80-350[mu]m. The invention further discloses a preparation method and application of the three-dimensional porous stent. According to the method disclosed by the invention,the advantages of an emulsion microflow control technique and the advantages of the composite biomaterials are combined. The three-dimensional porous stent disclosed by the invention has favorable biocompatibility and biodegradability and has the characteristics that the hole diameter is appropriate, the holes are mutually penetrated, and the three-dimensional porous stent is degradable and compressible, can be shaped and can be used for performing drainage effectively, and good space is provided for medicine delivery and slow release, cell growth and metabolism and tissue repair; the proportion of ingredients of the compound materials and the holes in concentrated distribution can guarantee that the three-dimensional porous stent has favorable compression and resilience properties like sponge, so that the three-dimensional porous stent can better adapt to the shape of the uterine cavity or the shape of other positions needing prevention of adhesion, and the effect of effectively preventing the adhesion can be achieved.

Owner:南京恒华生物发展有限公司

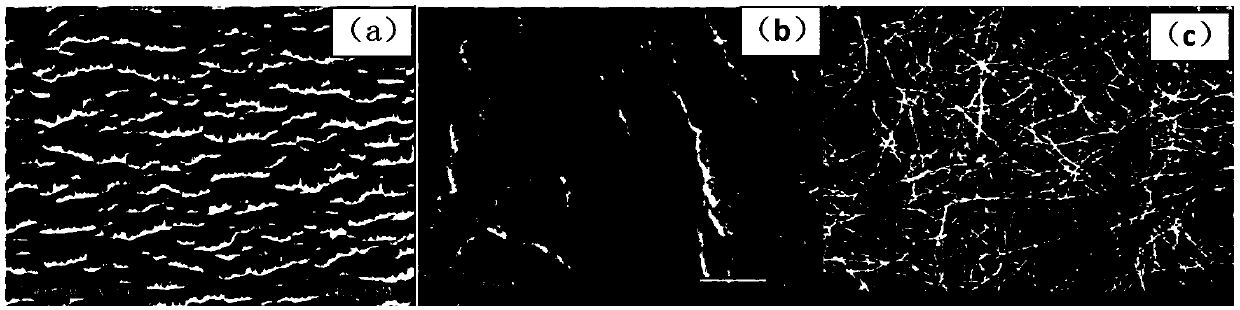

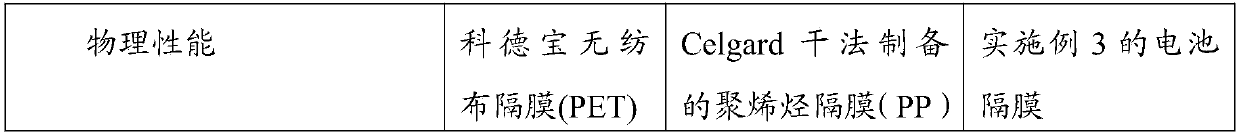

Battery diaphragm and preparation method thereof

InactiveCN109524598AIncrease specific energyGood cycle performanceCell component detailsCharge and dischargeLithium electrode

The invention belongs to the technical field of lithium ion batteries and particularly relates to a battery diaphragm and a preparation method thereof. The preparation method of the battery diaphragmcomprises the steps of putting battery diaphragm fiber filaments into a textile machine, and weaving by virtue of the textile machine, so as to obtain the battery diaphragm, wherein the battery diaphragm fiber filaments are electronically insulated battery diaphragm fiber filaments which do not react with electrolyte, and the diameters of the battery diaphragm fiber filaments are 5-40 microns. Theinvention aims at providing the battery diaphragm with uniform small pore diameter and high porosity, so that dendritic crystals are produced in the charging and discharging processes of the battery,and the cycle performance of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

Air electrode and preparation method and application thereof

ActiveCN110890550AReduce energy consumptionHigh porosityFuel and secondary cellsCell electrodesPtru catalystPolyvinyl alcohol

The invention provides a preparation method of an air electrode. The preparation method comprises the following steps of 1) preparing a gas diffusion slurry from C powder, industrial alcohol and PTFEemulsion; 2) enabling the gas diffusion slurry to form a gas diffusion film at one side of a current collector; 3) preparing the catalytic slurry from the C powder, industrial alcohol, a catalyst, a pore-forming agent and PTFE emulsion, wherein the pore-forming agent is selected from any one of ammonium oxalate, ammonium bicarbonate, polyethylene glycol 200 and polyvinyl alcohol; 4) forming a catalytic membrane from the catalytic slurry at the other side of the current collector; and 5) sintering the current collector of which the two sides are respectively provided with the gas diffusion filmand the catalytic film to prepare the air electrode which has the relatively higher porosity, relatively longer electrode service life and relatively more excellent electrical property. In addition,the invention also provides the air electrode prepared by the preparation method of the air electrode and the application of the air electrode in the field of membrane electrodes.

Owner:蔚蓝(广东)新能源科技有限公司

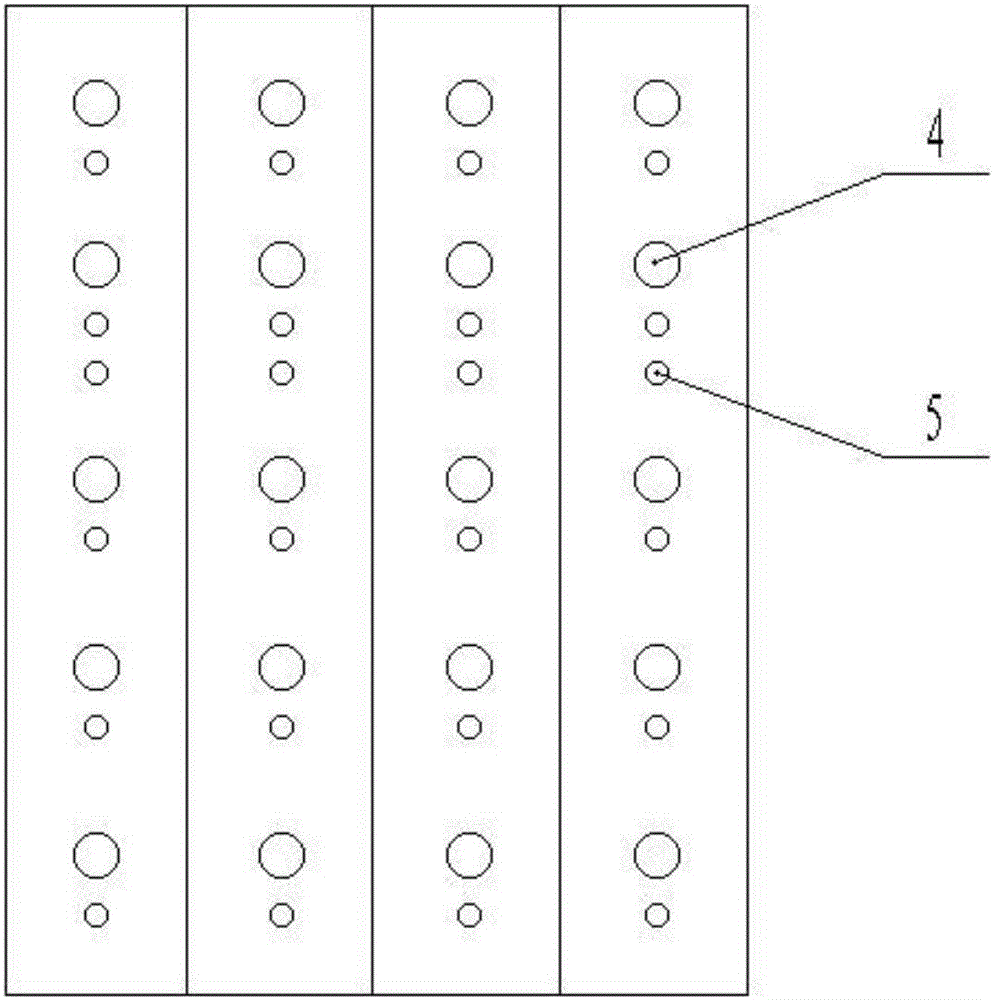

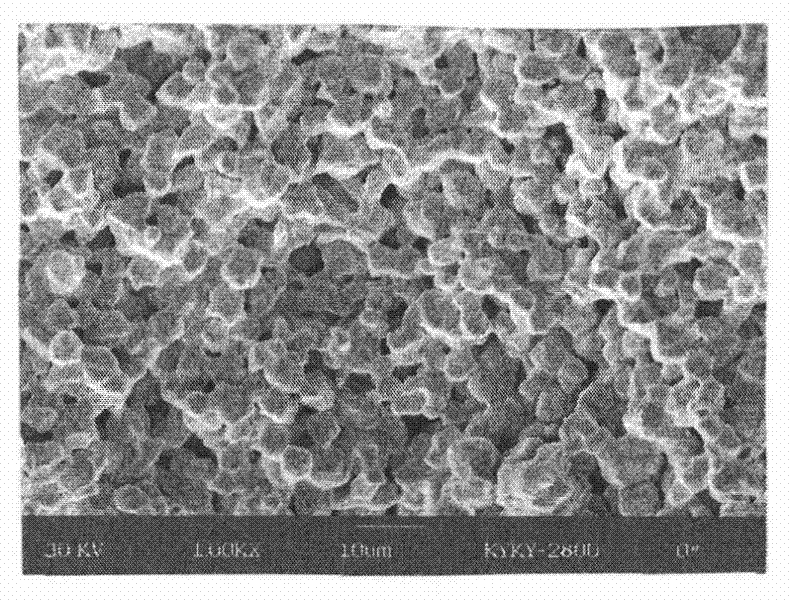

Method for preparing impregnated cathode matrix

InactiveCN102024640AUniform hole sizeWell distributed holesThermionic cathode manufactureMicrowavePrill

The invention discloses a method for preparing an impregnated cathode matrix and relates to technology of microwave devices. The method is used for preparing a tungsten sponge matrix of an impregnated barium and tungsten cathode. Tungsten particles of different sizes are prepared into uniform spherical particles by particle spray drying powder treating technology, so that the flowability of tungsten powder is enhanced; and after being filled into a rubber sleeve, the treated tungsten powder can be beat, tamped or vibrated to form a close-packed structure, and then the close-packed structure is pressed and sintered to prepare the tungsten sponge matrix. The method is simple and practicable, the prepared impregnated cathode matrix has the advantages of uniform hole size, uniformly distributed holes, few closed holes and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

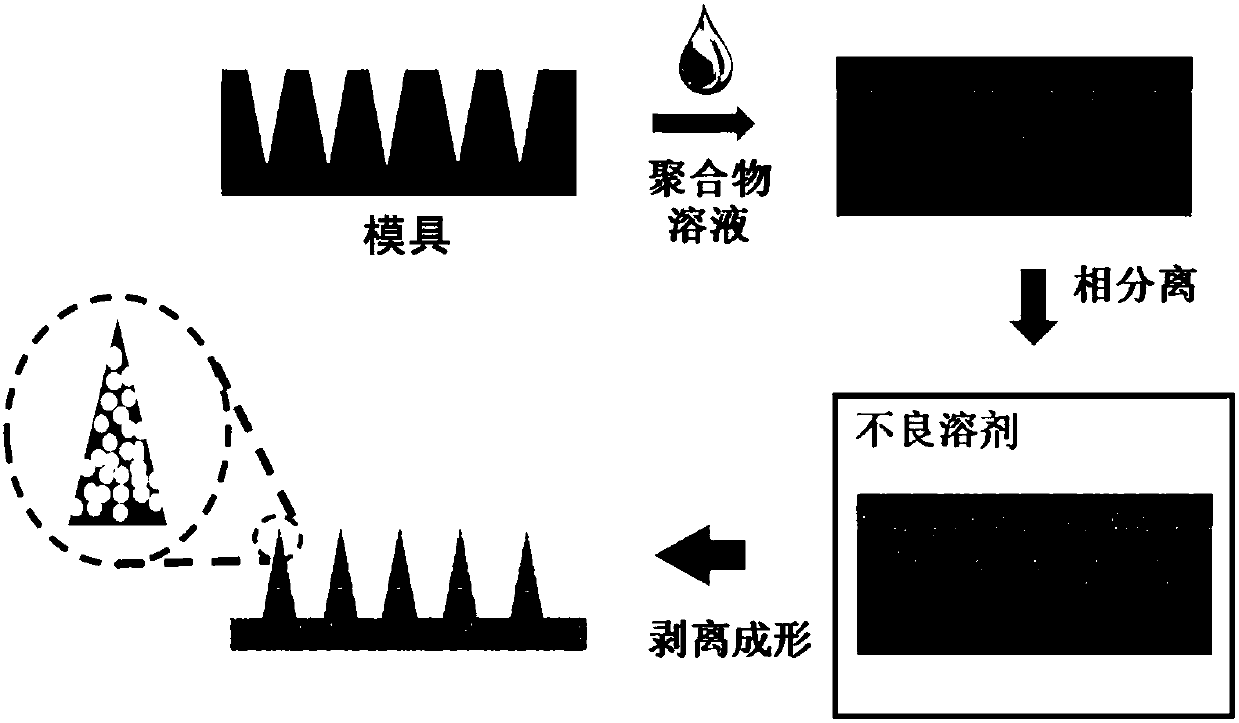

Method for preparing porous polymer microneedle based on phase separation technology and application of method

ActiveCN110115707ASmall apertureRegular hole structureMetabolism disorderMicroneedlesPolymer dissolutionPolymer science

The invention discloses a method for preparing a porous polymer microneedle based on a phase separation technology and application of the method. The method comprises the following steps that 1, a polymer is dissolved into a solvent A to obtain a polymer solution; 2, the polymer solution is put into a microneedle mould; 3, the microneedle mould is placed in a poor solvent B, so that phase separation of the polymer in the microneedle mould is facilitated; 4, the poor solvent B is removed, and then the porous polymer microneedle can be obtained. Through the simple and mild phase separation technology, the porous polymer microneedles can be prepared on a large scale, and therefore, the technical problems can be solved that the preparation process of the porous polymer microneedle is complicated, the conditions are harsh, the technology is tedious, the price is high, the pore structure, the size and the distribution are difficult to control, and it is difficult for large-scale production and application. The prepared porous polymer microneedle can be used for interstitial fluid extraction and transdermal drug delivery.

Owner:武汉楚颜生物科技有限公司

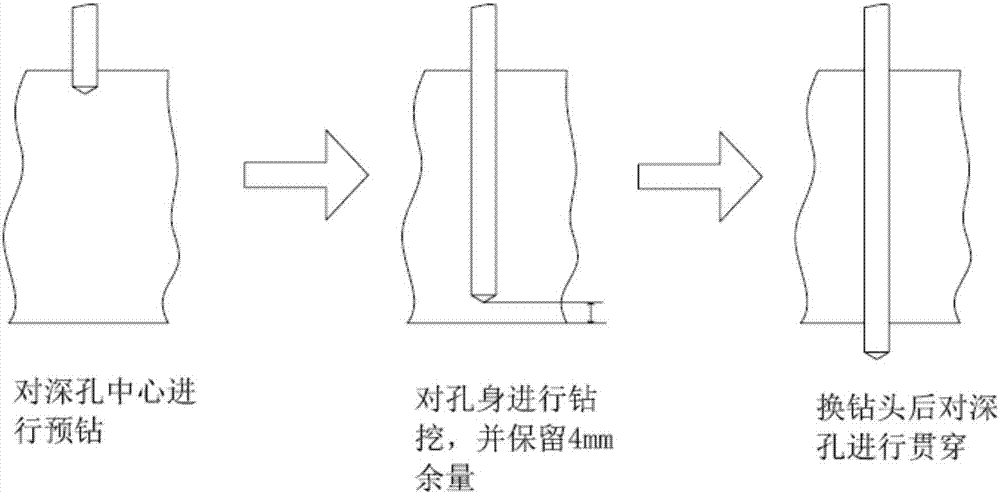

Drilling process for deep hole machining for hard material

ActiveCN107414117AReduce manufacturing costIncrease productivityBoring/drilling machinesDrill holeDrill bit

The invention relates to a drilling process for deep hole machining for a hard material. A pre-drilling process is carried out at first, a pre-drilling bit is chosen to carry out pre-drilling on hole positions of a product, and during a pre-drilling process, tool setting is carried out at first, a pre-drilled hole with a depth of 0.5mm is machined for all the hole positions after the tool setting, foundations of the machined hole positions are moved by 0.5mm up and down after the operation is completed, the operation is repeated for many times, depths of 1-4mm, of the pre-drilled holes, are guaranteed, and pre-drilling operation is completed. The drilling process disclosed by the invention has the characteristics of avoiding breakage of the drilling bit, reducing a wear degree of the drilling bit and then lowering a production cost, omitting a wire wrapping process and then greatly increasing a machining speed of drilling, avoiding different hole diameters and then ensuring accuracy of the product, avoiding offset of the hole positions, and reducing consumption of the drilling bit and then prolonging the service life of the drilling bit, and the like.

Owner:NINGBO HUIWANG MACHINERY

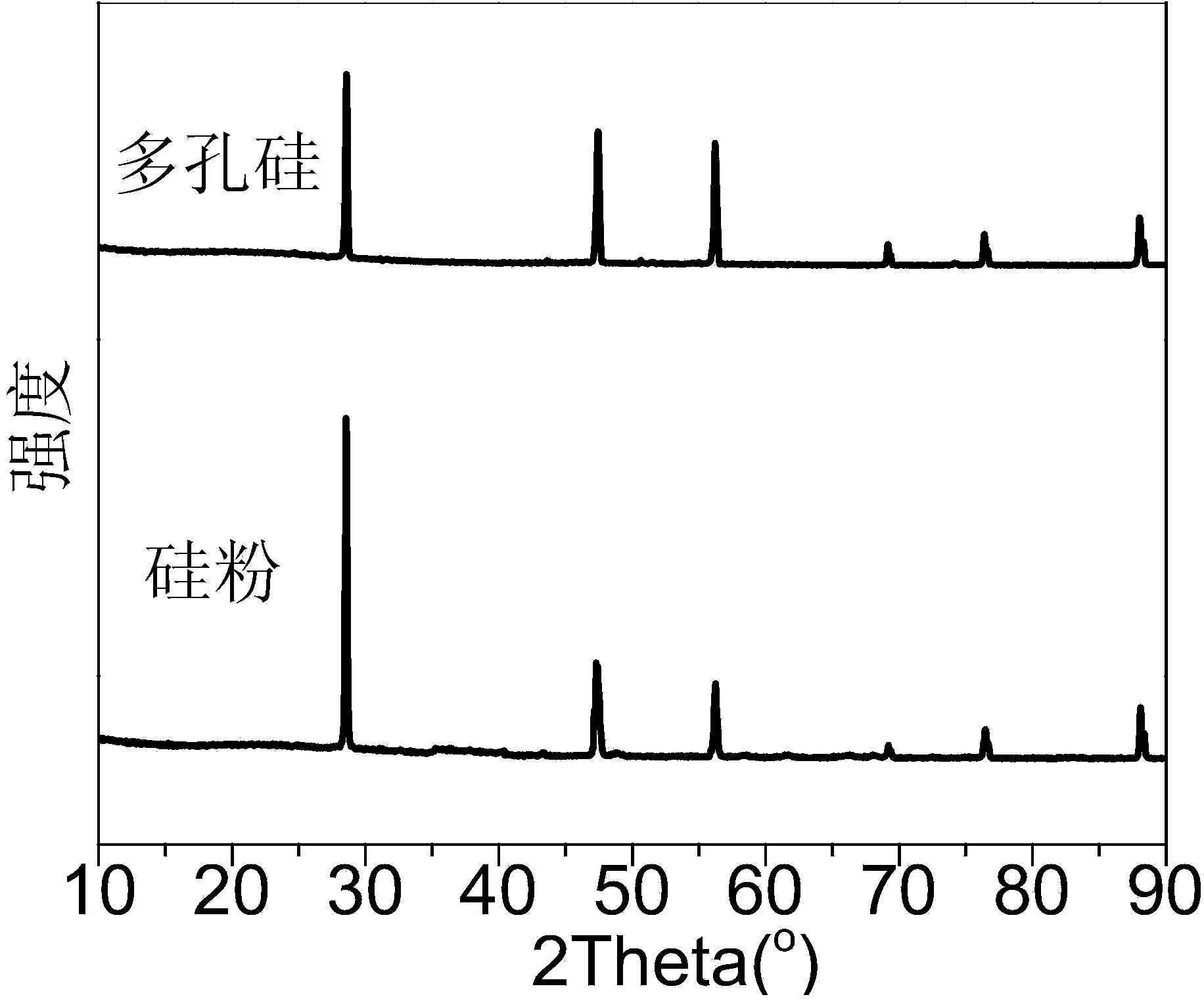

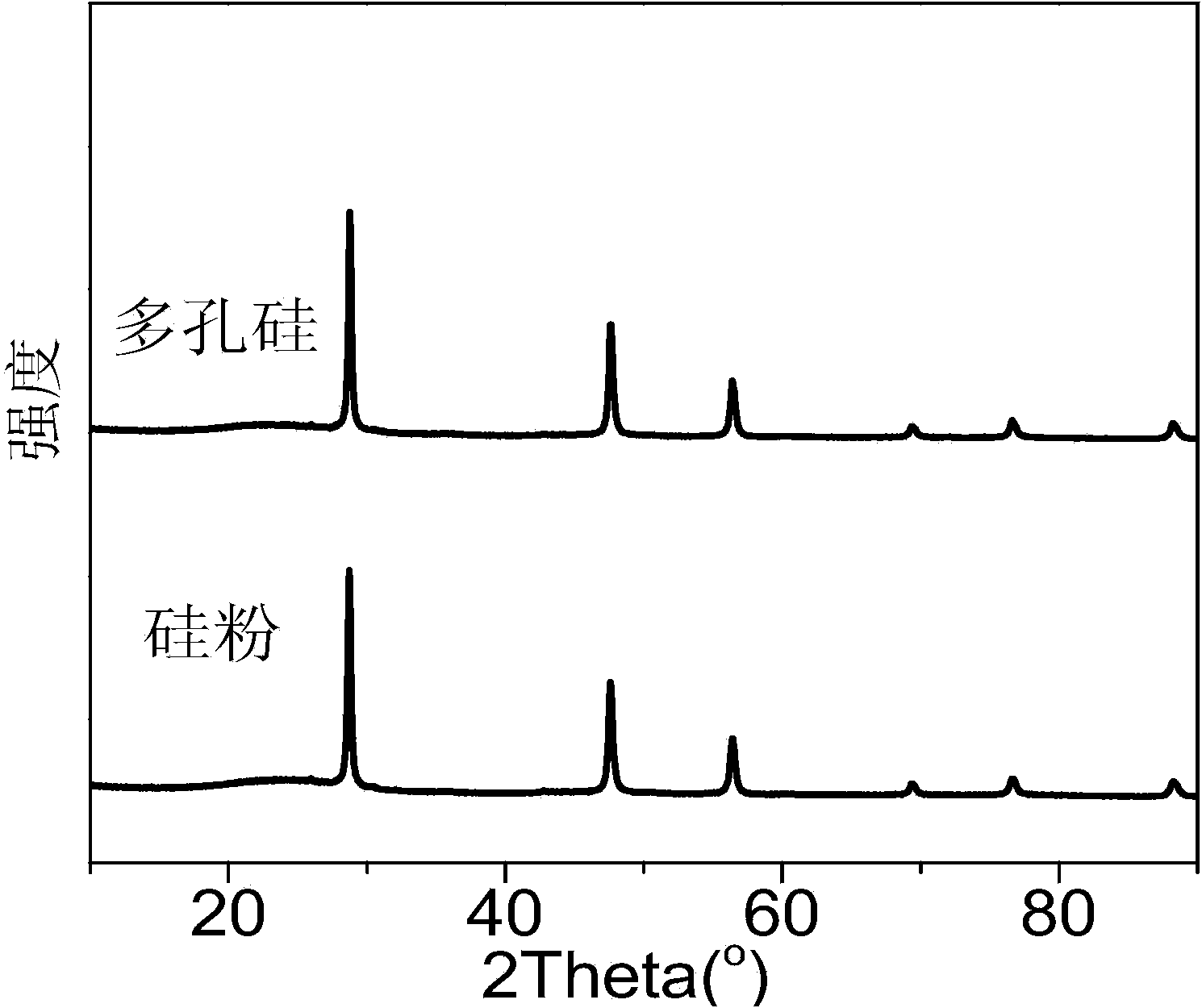

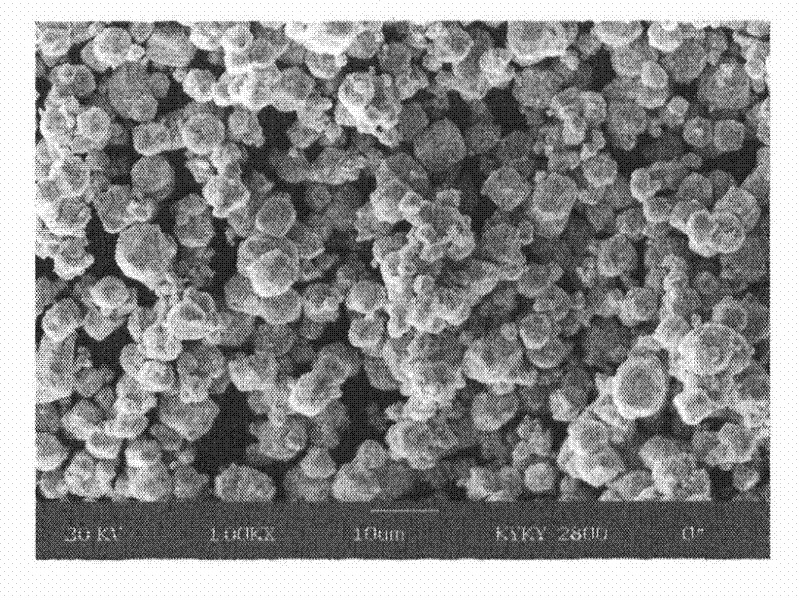

Porous silicon material and preparation method thereof

The invention relates to a porous silicon material and a preparation method thereof. The method for preparing the porous silicon material comprises the following steps: carrying out an in-situ catalytic reaction between a silicon material and chloromethane at the temperature of 401 to 800 DEG C in the presence of a solid copper-based catalyst, and preparing the porous silicon material through calcining, acid pickling, alkaline washing and other after-treatment impurity removal technologies, wherein the solid copper-based catalyst comprises one or a mixture of more than two in primary catalysts such as CuOx, CuCl and CuCl2, x is more than or equal to 0 and less than or equal to 1, as well as a small amount of secondary catalysts. Reaction condition parameters are regulated, so that the pore size, pore size distribution and porosity of the silicon material can be regulated. According to the method, a porous silicon material which is difficultly obtained in the patented technology at present is obtained, and important organic silicon monomer chemicals can be obtained. The porous silicon material prepared by the method is uniform in pore size, low in production cost, simple in process and suitable for industrial production and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Porous silicon material and preparation method of porous silicon material

InactiveCN104229804AUniform hole sizeSize fine-tuningSilicon compoundsMetal/metal-oxides/metal-hydroxide catalystsAlcoholCopper

The invention provides a porous silicon material and a preparation method of the porous silicon material. The preparation method of the porous silicon material comprises the following steps: carrying out in-situ catalytic reaction on silicon and alcohol at 60-400 DEG C under the action of a solid copper-based catalyst, and preparing the porous silicon material by post-treatment and purification technologies such as burning, and pickling and alkali washing. The porous silicon material prepared by the method is uniform in aperture, and the pore structure, size and porosity of silicon can be regulated and controlled by adjusting reaction parameters. The method is low in production cost, simple in process, easy to operate, clean in preparation process, and suitable for industrial production, and has a wide application prospect. In addition, the process can be combined with an alkoxy silane production process, and the process is expected to achieve double-win of porous silicon material and alkoxy silane production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of silicon nitride, silicon carbide combined molybdenum boride foamed ceramics

InactiveCN104311133AHomogeneous microstructureUniform hole sizeCeramicwareCarbide siliconMethyl cellulose

The invention relates to a preparation method of silicon nitride, silicon carbide combined molybdenum boride foamed ceramics. The preparation method is characterized by comprising the following steps: uniformly mixing Mo2B, micro silicon powder, phenolic resin and hydroxypropyl methyl cellulose to obtain a ceramic sizing agent, then soaking the ceramic sizing agent on polyurethane foam, drying the ceramic sizing agent, and burning the ceramic sizing agent in a nitrogen atmosphere to form the silicon nitride, silicon carbide combined molybdenum boride foamed ceramics. The silicon nitride, silicon carbide combined molybdenum boride foamed ceramics prepared in the method is uniform in micro structure, high in strength, uniform in porous size and capable of avoiding the residue of carbon and free silicon; moreover, the strength, high temperature resistance and thermal impact resistance can be greatly improved.

Owner:SHANDONG UNIV OF TECH

Preparation method of silicon nitride, silicon carbide and tantalum carbide combined foam ceramic

The invention relates to a preparation method of silicon nitride, silicon carbide and tantalum carbide combined foam ceramic. The preparation method is characterized by comprising the following steps: uniformly mixing TaC, silicon micropowder and phenolic resin in addition to a hydroxypropyl methyl cellulose solution to prepare ceramic slurry; then, impregnating the ceramic slurry on polyurethane foam; and drying and firing in a nitrogen polyurethane to prepare the silicon nitride, silicon carbide and tantalum carbide combined foam ceramic. The silicon nitride, silicon carbide and tantalum carbide combined foam ceramic prepared by the invention is uniform in micro-structure, high in strength and uniform in pore size, and carbon and residue of free silicon are avoided, so that the strength, high-temperature resistance and hot impact resistance are greatly improved.

Owner:SHANDONG UNIV OF TECH

Preparation method of foam ceramic of silicon nitride and silicon carbide combined with titanium carbide

The invention relates to a preparation method of foam ceramic of silicon nitride and silicon carbide combined with titanium carbide. The preparation method is characterized by comprising the following steps: uniformly mixing TiC, silicon micropowder, and phenolic resin in addition to a hydroxypropyl methyl cellulose solution to prepare ceramic slurry; then, impregnating polyurethane foam with the ceramic slurry; and drying and firing in a nitrogen atmosphere to obtain the foam ceramic of silicon nitride and silicon carbide combined with titanium carbide. The foam ceramic of silicon nitride and silicon carbide combined with titanium carbide provided by the invention is uniform in microstructure, high in strength and uniform in size of pore and avoids residues of carbon and free silicon, so that the strength, high-temperature resistance and heat impact resistance of the ceramic are greatly improved.

Owner:SHANDONG UNIV OF TECH

Preparation method of silicon nitride and silicon carbide combined lanthanum hexaboride foamed ceramic

InactiveCN104311102AHomogeneous microstructureHigh strengthCeramicwareCarbide siliconMethyl cellulose

The invention discloses a preparation method of a silicon nitride and silicon carbide combined lanthanum hexaboride foamed ceramic. The preparation method is characterized by comprising the following steps: uniformly mixing LaB6, silica powder, phenolic resin and hydroxypropyl methyl cellulose solution to prepare ceramic slurry, soaking the ceramic slurry in a polyurethane foam, drying and sintering in nitrogen atmosphere to prepare the silicon nitride and silicon carbide combined lanthanum hexaboride foamed ceramic. The prepared silicon nitride and silicon carbide combined lanthanum hexaboride foamed ceramic has a uniform microscopic structure, high strength and uniform hole size, and is capable of avoiding the residue of carbon and free silicon so as to greatly improve the strength, the high temperature resistance and the thermal shock resistance.

Owner:SHANDONG UNIV OF TECH

Perforating device for plastic films

The invention discloses a perforating device for plastic films. The perforating device comprise a device body and is characterized in that device legs are arranged on two sides of the bottom of the device body, driven rollers are arranged inside the device body through rotary shafts, each driven roller is connected with a drive roller through a conveying belt, a roller motor is arranged on one side of each drive roller, a feed disc and a discharge disc are arranged in the middle of the top of the device body, a back plate is arranged at the back of the device body, a power switch is arranged in the middle of the top of the back plate, spindle motors are arranged inside the back plate, and the outer surface of the back plate is provided with rotary spindles. The perforating device has the advantages that the perforating device adopting mechanical perforating is simple to operate, perforating speed can be increased by utilizing double-side perforating, the size of perforated holes is unchanged, uniform hole size is achieved, regular and rhythmed perforating can be achieved through the mechanical performance, hole intervals are identical, and perforating efficiency is increased.

Owner:吴敏

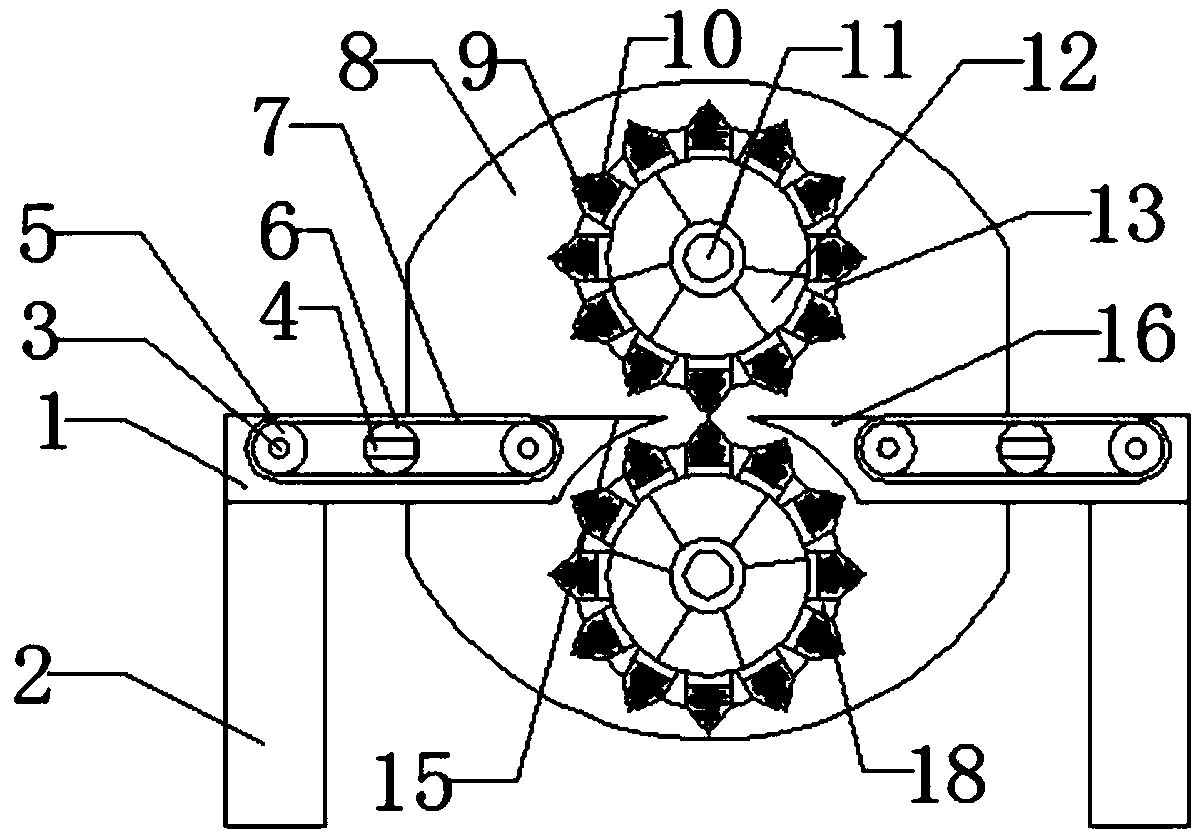

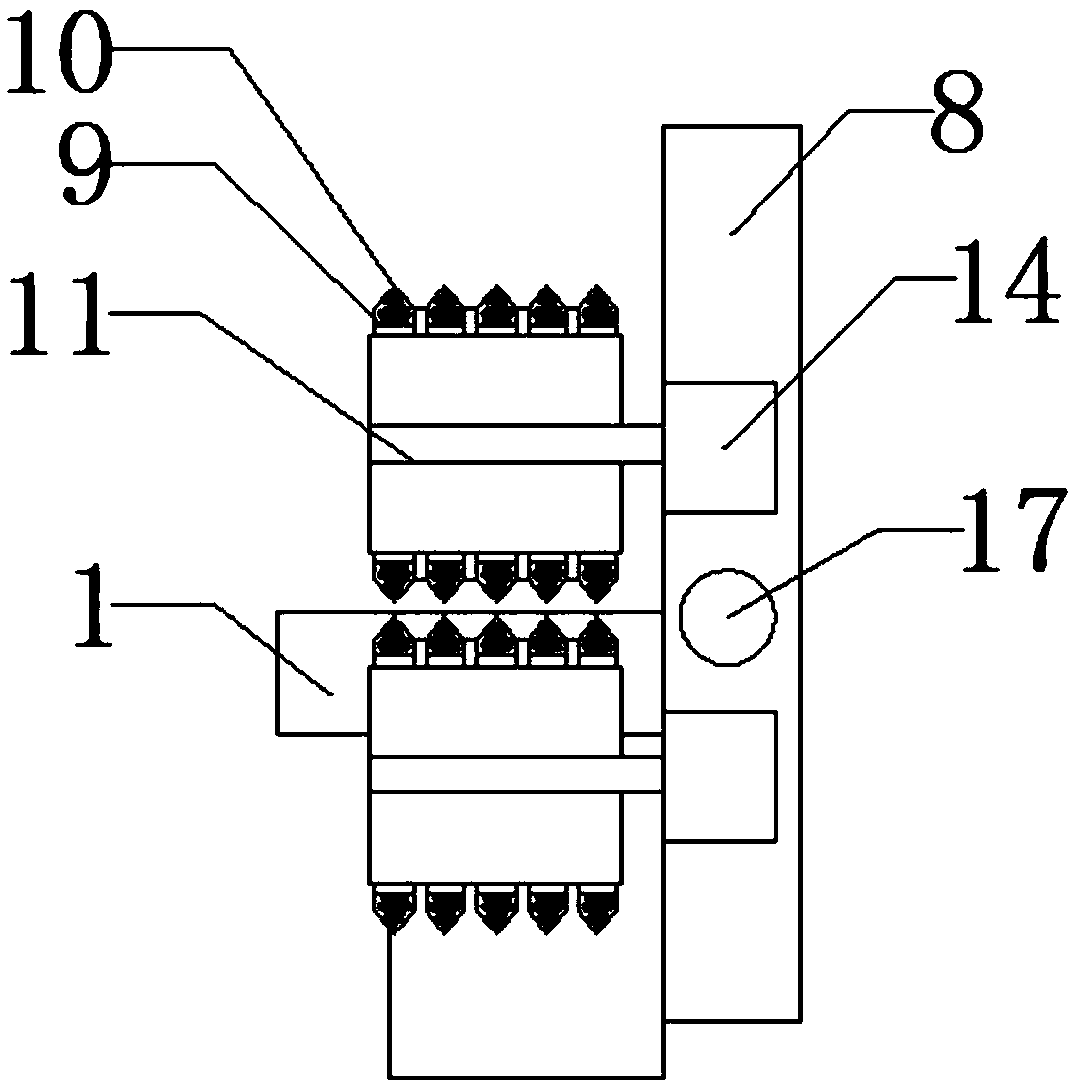

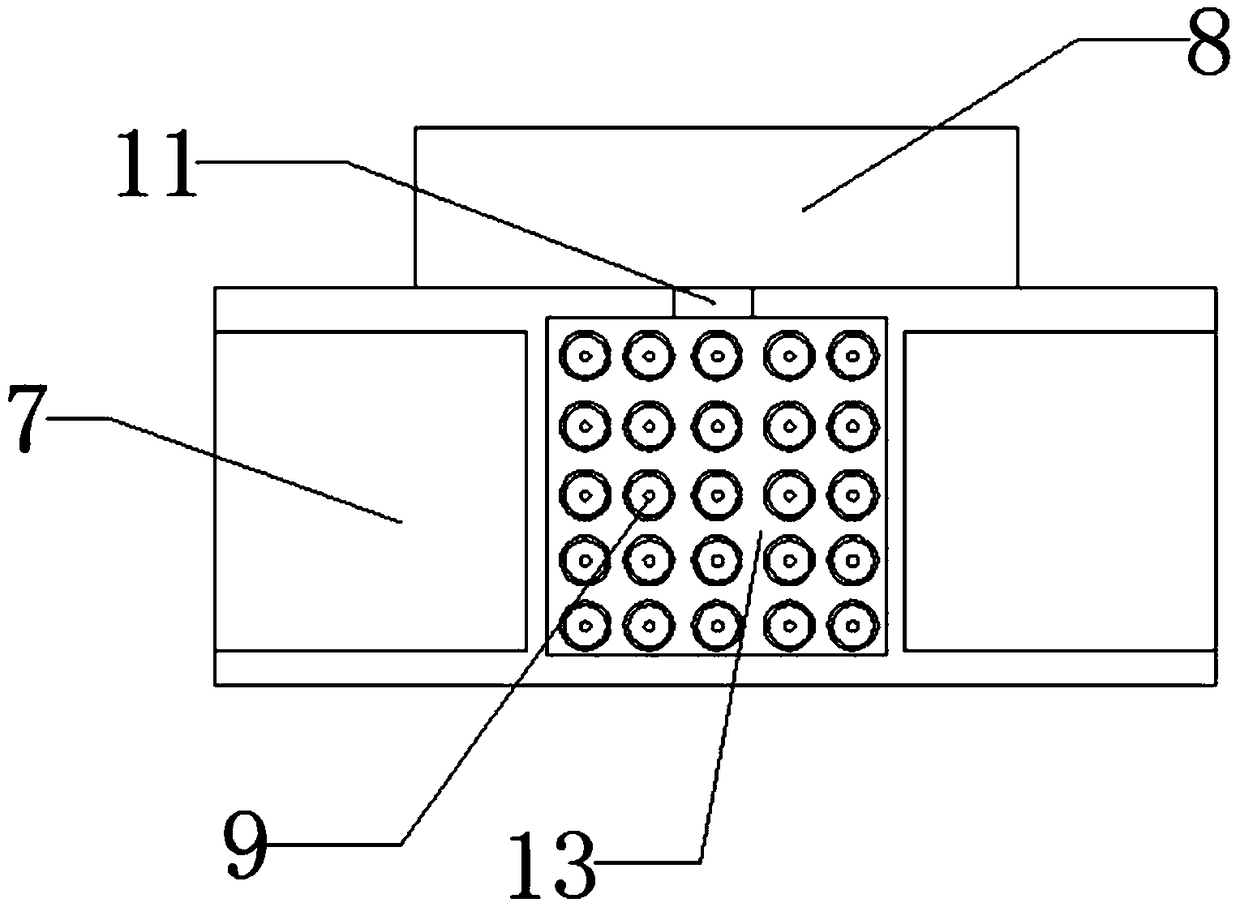

Automatic digging mechanism of intelligent construction tunneling machine

The invention discloses an automatic digging mechanism of an intelligent construction tunneling machine. The automatic digging mechanism comprises a first tunneling mechanism and a second tunneling mechanism, wherein the first tunneling mechanism is arranged on the second tunneling mechanism, a ring of synchronously telescopic and rotating first drill bits are arranged on the first tunneling mechanism, a first top pressing shaft is arranged at an end of each first drill bit, a first chain wheel is arranged at the end of each first top pressing shaft, a ring of synchronously telescopic and rotating second drill bits are arranged on the second tunneling mechanism, a fourth top pressing shaft is arranged at the end of each second drill bit, and a second chain disc is arranged at the end of each fourth top pressing shaft. The first drill bits and the second drill bits drill holes on a wall, so that the hole size on the wall can be unified, the problem of different hole sizes caused by manual drilling can be avoided, and the digging efficiency is improved greatly.

Owner:同炎数智科技(重庆)有限公司

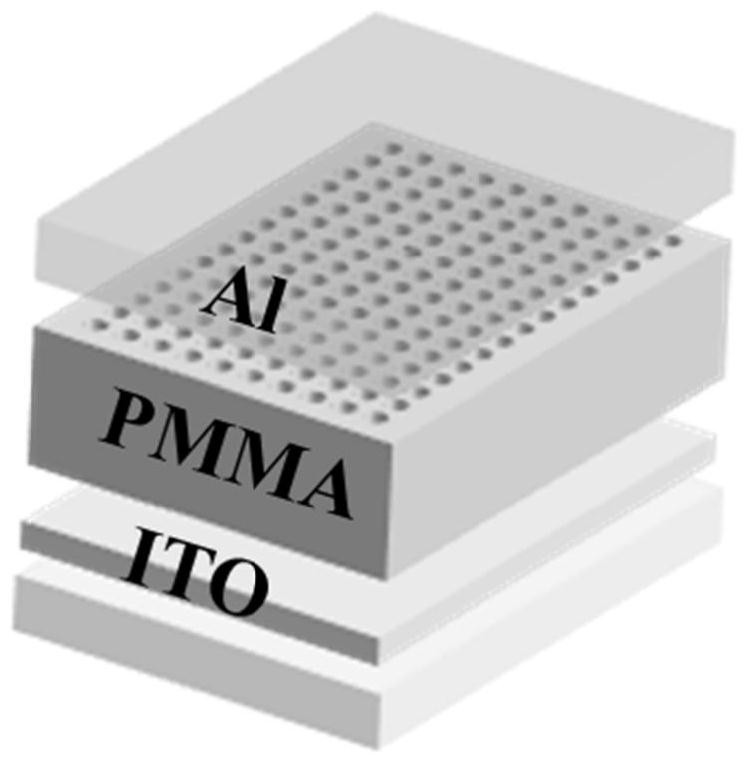

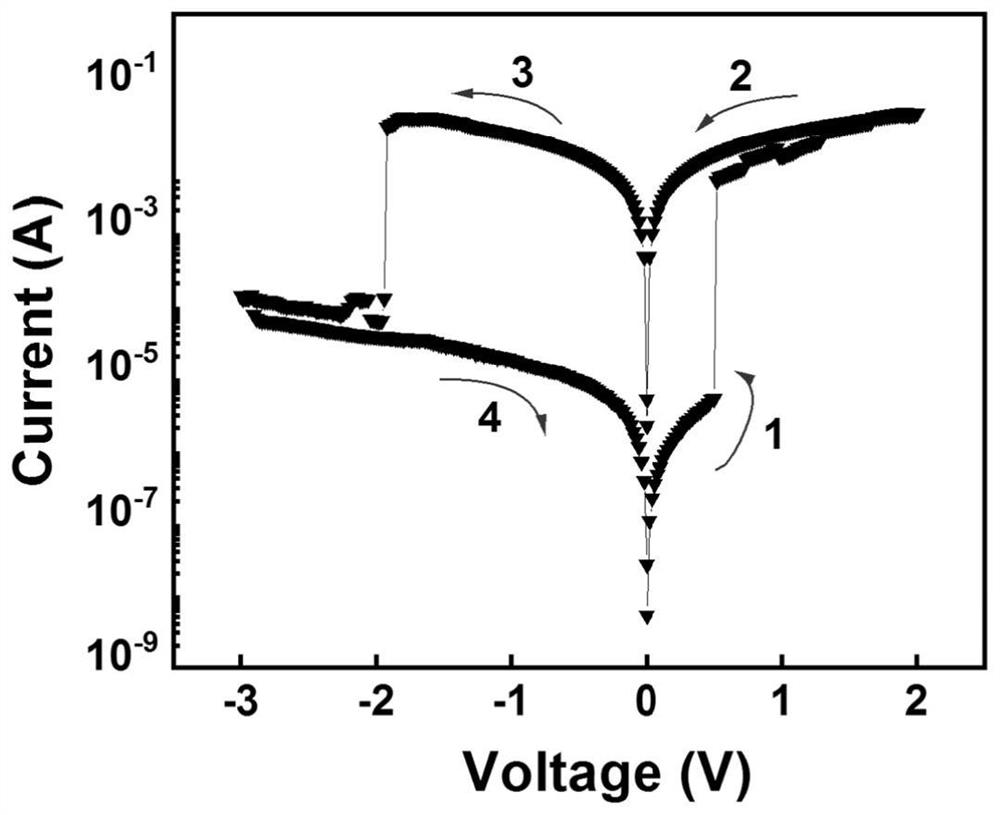

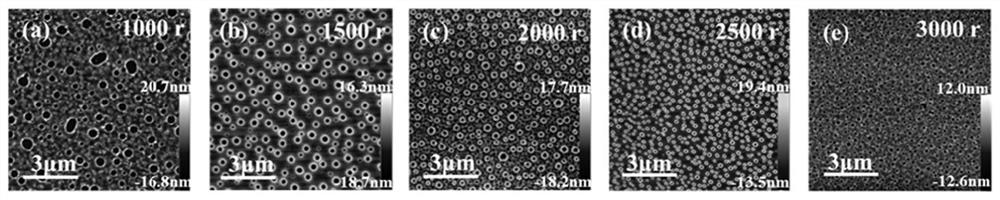

Nonvolatile resistive random access memory with adjustable write-in voltage and preparation method thereof

ActiveCN112382722AImplement storageRaw materials are easy to getElectrical apparatusEnergy efficient computingThin membraneEngineering

The invention discloses a nonvolatile resistive random access memory with an adjustable write-in voltage and a preparation method thereof, and belongs to the field of resistive random access memory devices. The memory device includes a substrate, a bottom electrode, a resistive function layer, and a top electrode. and the resistive function layer is an organic polymer film which is prepared by spin-coating a mixed solution of two polymers and contains nano-pores on the surface. By changing the spin-coating conditions of the mixed solution, the sizes of the thin film holes can be adjusted, andthen the accurate regulation and control of the device write-in voltage are achieved. The memory device provided by the invention is simple in structure and is easy to process, shows nonvolatile storage characteristics, can realize the accurate regulation and control on the write-in voltage, and has a wide application prospect in the field of information storage.

Owner:NANJING UNIV OF TECH

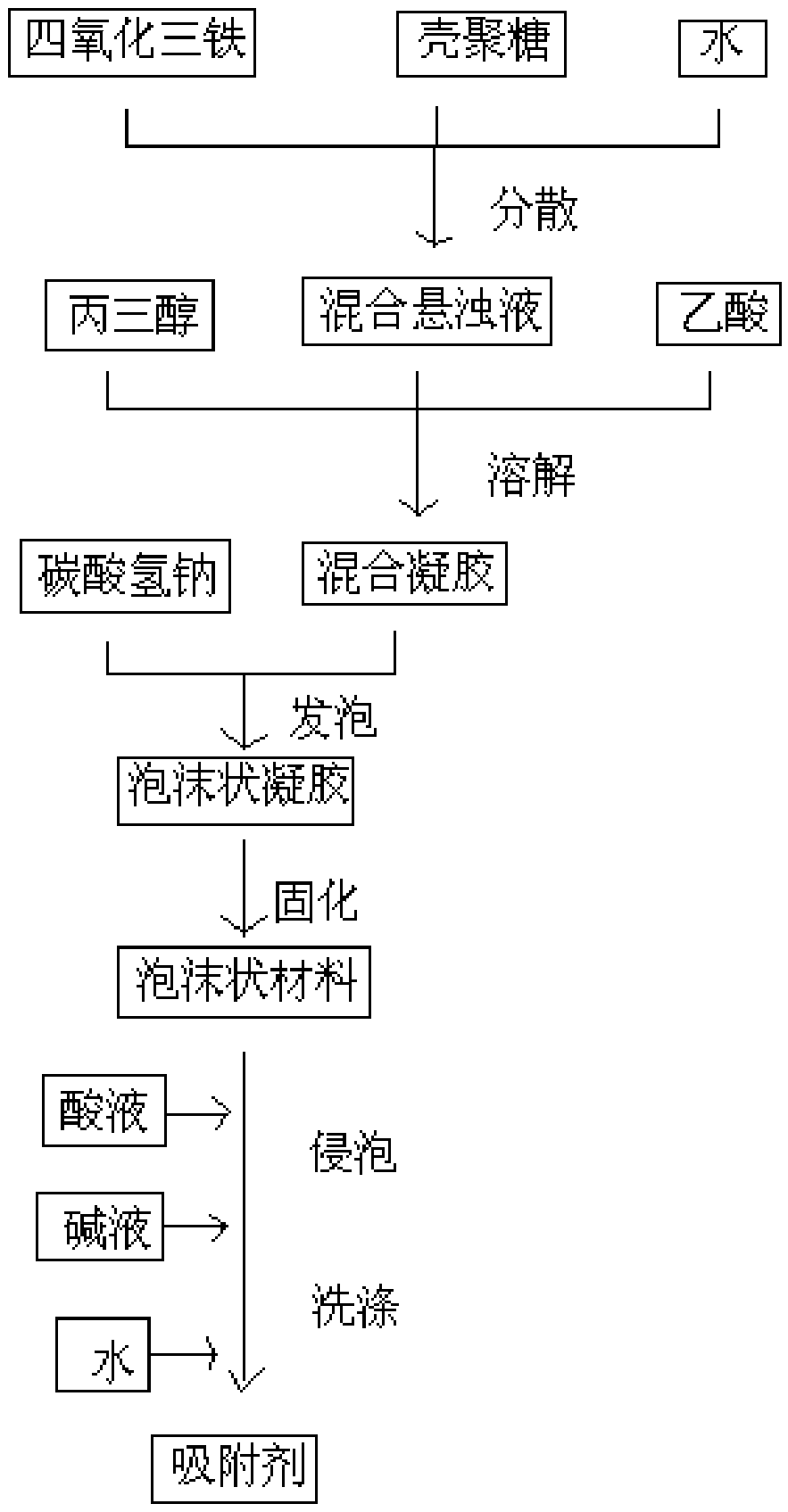

Foam-like magnetic chitosan adsorbent and preparation method thereof

ActiveCN108714414AImprove adsorption capacityEvenly distributedOther chemical processesWater contaminantsAcetic acidSodium bicarbonate

The invention discloses a foam-like magnetic chitosan adsorbent and a preparation method thereof. The foam adsorbent is foamed by carbon dioxide produced by the reaction of sodium bicarbonate and acetic acid, and is prepared under the aid and protection of glycerol, the size and distribution of pores in the foam adsorbent are uniform, and more active groups are retained on chitosan. Consequently,the foam-like magnetic chitosan adsorbent has the advantages of having adsorbability to metal ions, and being conducive to large-scale application of the foamed chitosan-based adsorbent in water treatment.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Preparation method of silicon nitride and silicon carbide combined niobium carbide foamed ceramic

The invention discloses a preparation method of silicon nitride and silicon carbide combined niobium carbide foamed ceramic. The preparation method is characterized by comprising the steps of uniformly mixing NbC, silica micro-powder, phenolic resin and a hydroxypropyl methyl cellulose solution to form ceramic slurry, immersing polyurethane foam in the ceramic slurry, drying, and firing in an nitrogen atmosphere to obtain the silicon nitride and silicon carbide combined niobium carbide foamed ceramic. The silicon nitride and silicon carbide combined niobium carbide foamed ceramic has a uniform microscopic structure, is high in strength and uniform in pore size and is free of residue of carbon and free silicon, and the strength, high-temperature resistance and thermal shock resistance of the foamed ceramic are improved substantially.

Owner:SHANDONG UNIV OF TECH

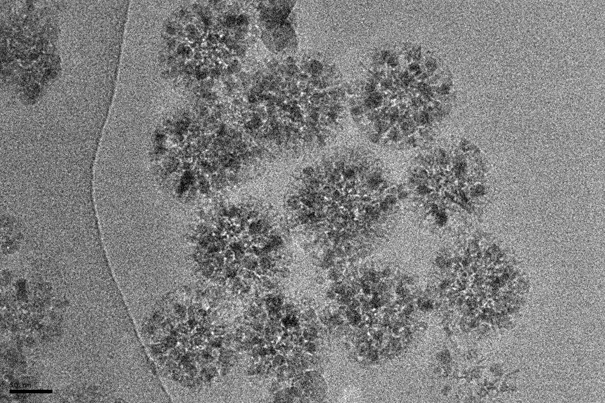

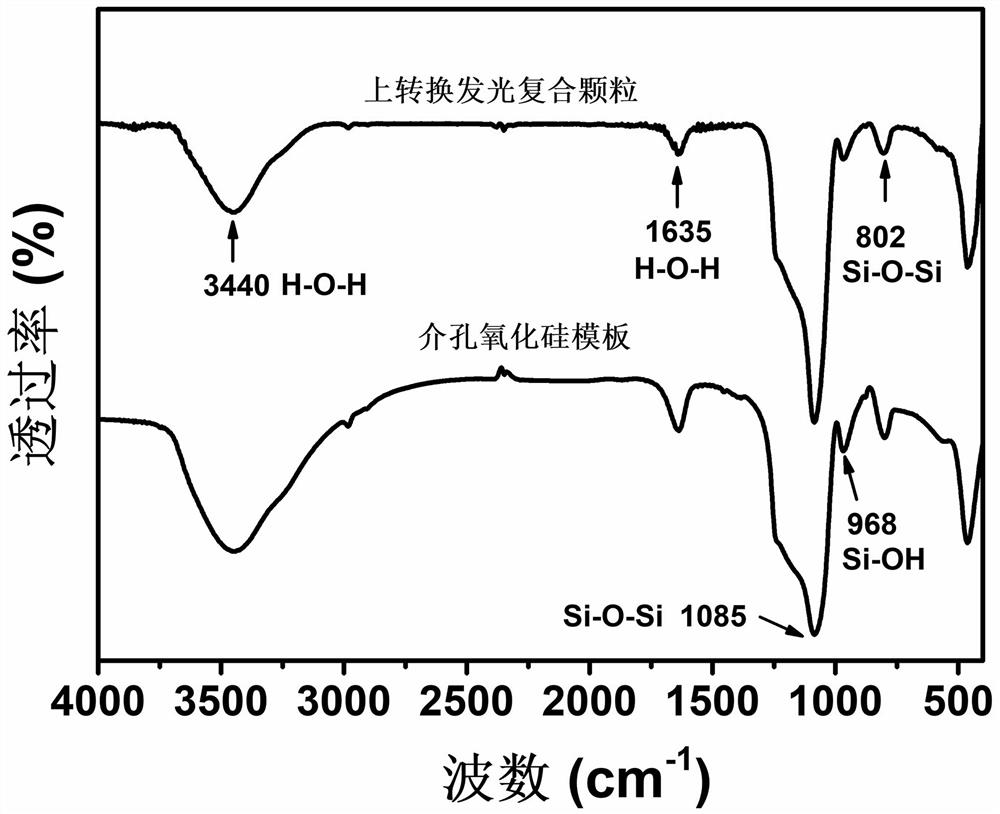

Preparation method of up-conversion luminescence coding nano-composite particle based on mesoporous silica and coding method

PendingCN113355084ARich coding methodLarge specific surface areaLuminescent compositionsRare-earth elementUpconversion luminescence

The invention discloses a preparation method of up-conversion luminescence coding nano composite particles based on mesoporous silica, which comprises the following steps: preparing metal fluoride precursor sol containing rare earth elements, stirring to enable the sol to enter pore channels of the mesoporous silica through a capillary effect, centrifuging at a low speed to remove a supernate, adding water, and carrying out soft vortex oscillation , and washing off the precursor sol on the surfaces of the particles, centrifugally collecting a sample at a low speed, drying the sample in a drying oven to form xerogel of metal fluoride in the pore channels of the mesoporous silica, and sintering the xerogel after drying to obtain the up-conversion luminescent mesoporous silica composite nanoparticles. According to the method, the up-conversion luminescent nanocrystals can only nucleate and grow in silicon oxide mesopores, the biotoxicity of the up-conversion luminescent nanocrystal encoding microspheres can be greatly reduced, and further modification of the encoding microspheres is facilitated; the invention also provides a corresponding coding method, so that the types or contents of rare earth elements contained in the up-conversion luminescent nanocrystals in different composite particle pore channels are different.

Owner:JIHUA LAB

Active NS-GAM gene scaffold for treating scalds and preparation method thereof

ActiveCN109529116AObvious wound repair effectReduce inflammationCapsule deliveryProsthesisArginineGene vector

The invention provides an active NS-GAM gene scaffold for treating scalds. According to the active gene scaffold, a crosslinked scaffold of carboxymethyl chitosan and sodium alginate carries an arginine-chitosan gene vector and the arginine-chitosan gene vector enwraps a target gene. The prepared NS-GAM has an obvious wound repairing effect on scalded skin of a rat, has relatively mild inflammatory reaction, can promote wound repairing by achieving effective in-vivo transfection, has a very significant function of promoting repairing of the skin suffering from deep second-degree scald, and cangenerate a relatively ideal benign repairing effect.

Owner:OCEAN UNIV OF CHINA

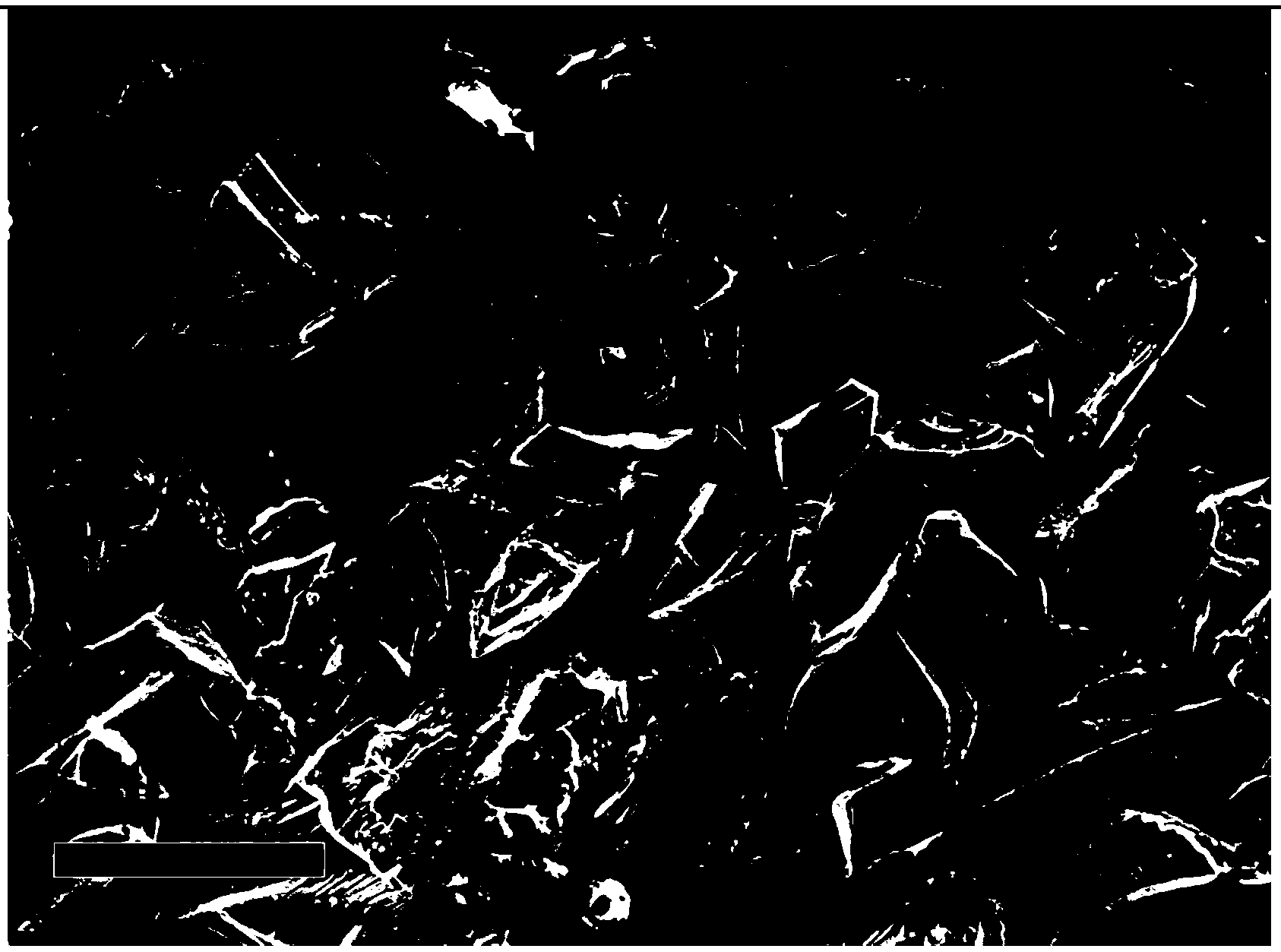

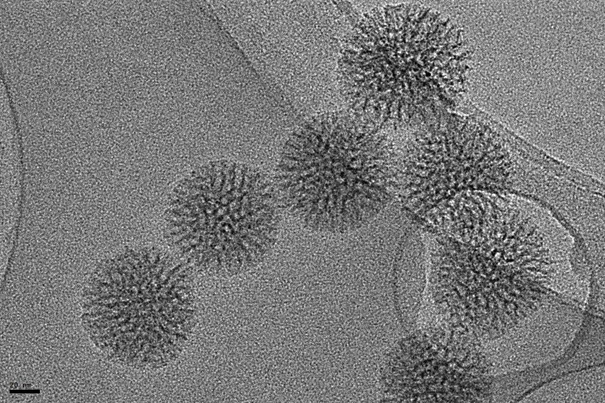

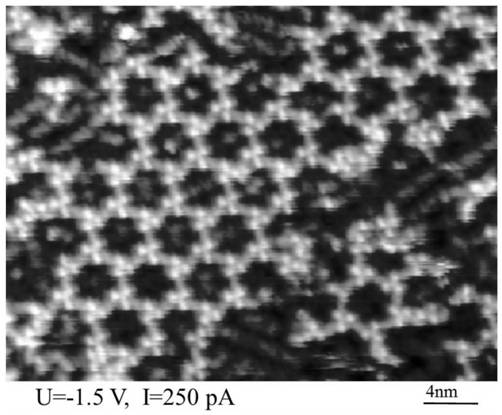

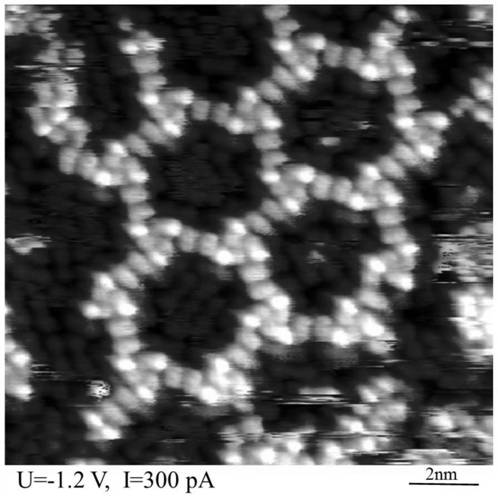

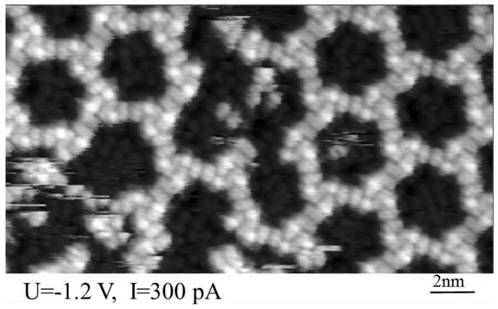

Method for preparing nano material layer by self-assembling diphenylacetylene on surface of metal single crystal

ActiveCN113136548AStructured orderUniform hole sizeVacuum evaporation coatingSputtering coatingSelf-assemblyComposite material

The invention provides a method for preparing a two-dimensional porous nano material based on diphenylacetylene molecule self-assembly. The method aims to prepare the two-dimensional nano material with a uniform porous structure on the surface of the single crystal by utilizing diphenylacetylene molecule self-assembly under an ultrahigh vacuum condition. The method comprises the following steps that 1, argon ion sputtering is carried out on a metal single crystal substrate, then annealing is carried out, and the sputtering and annealing processes are repeated; and 2, the metal single crystal treated in the step 1 is placed in an ultrahigh vacuum preparation cavity and heated to 50-53 DEG C, then diphenylacetylene molecules are deposited on the surface of the metal single crystal under the room temperature condition, the deposition time is 3-5 s, and the two-dimensional porous nanometer material is prepared. The method is simple in process, and the nanometer material with the uniform porous structure can be obtained. The pore size is 3.37 nm to 3.46 nm, the thickness of the pore wall is 0.7 nm to 1.2 nm, the height is 115 pm to 125 pm, and the coverage rate can reach 18% to 30%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

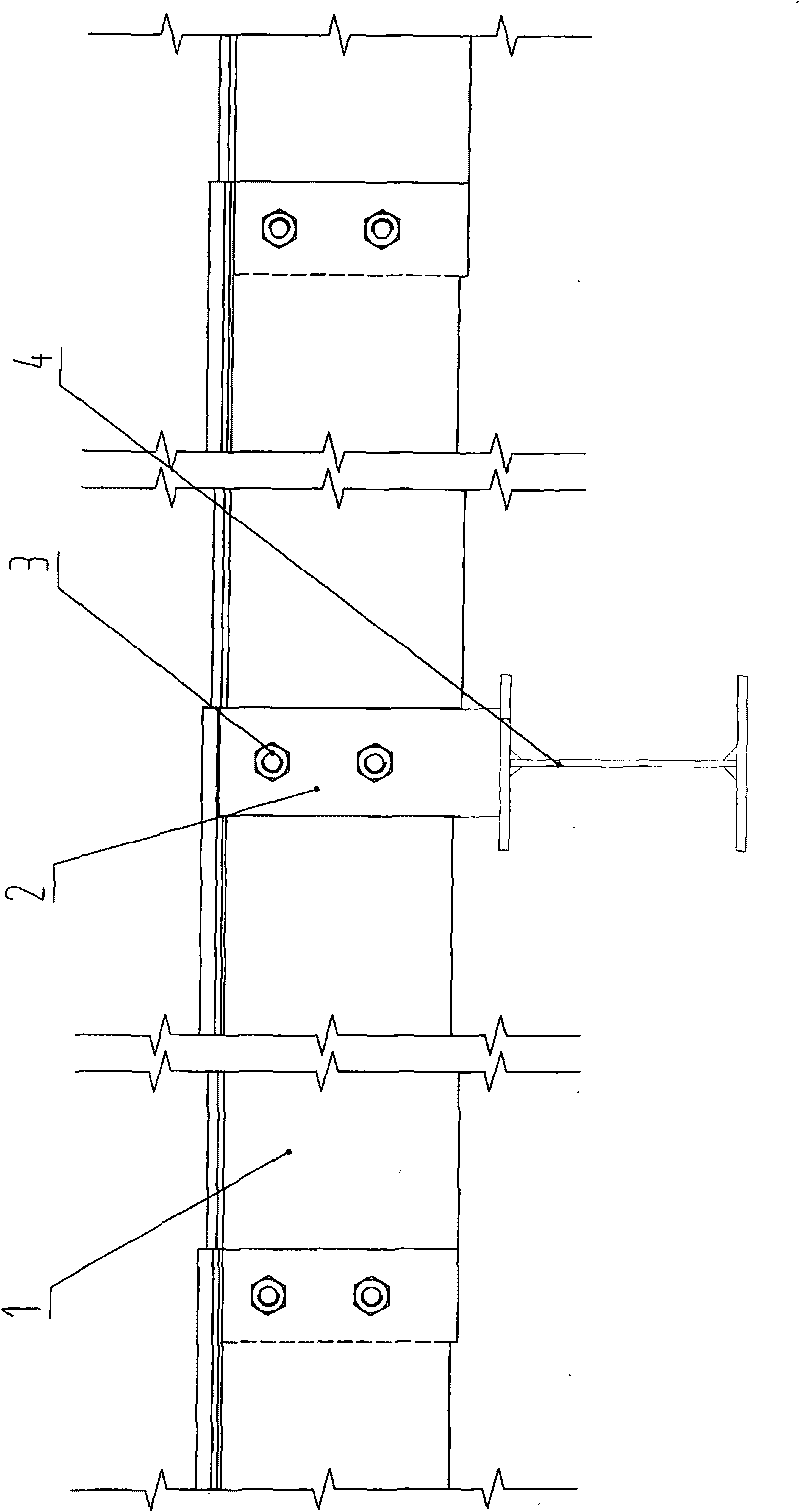

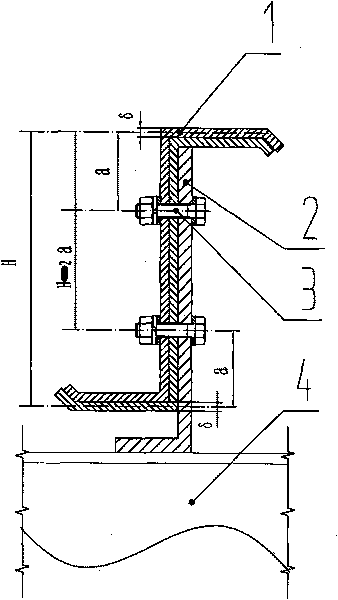

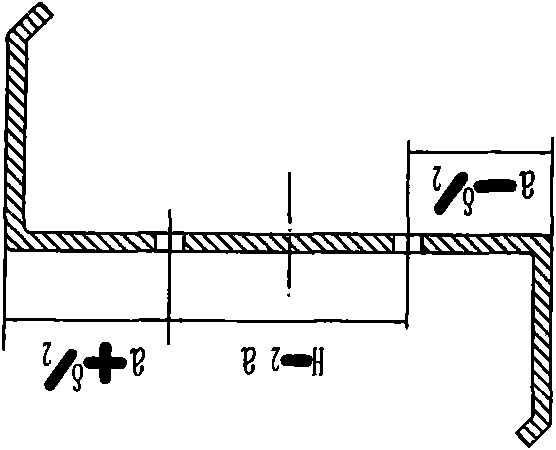

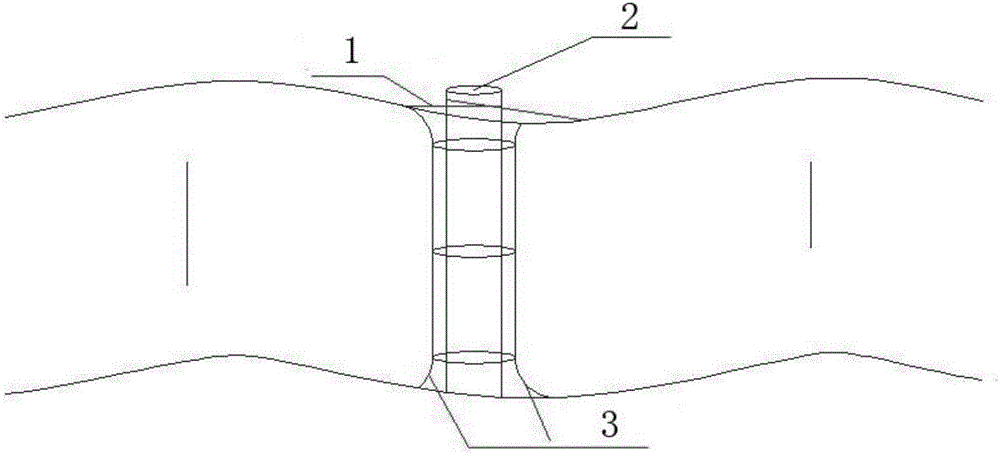

Z-shaped purline end part connecting process and method

InactiveCN101748803AImprove bearing strengthFirmly connectedBuilding constructionsMechanical engineeringIndustrial engineering

The invention discloses Z-shaped end part connecting process and method, relating to building construction. End parts of two purlines (1) are lapped together up and down and then are fixed by using bolt fastening assemblies (3), bolt holes are round holes, and bolts are in zero clearance fit with the bolt holes. The bolt holes are prepared by the following steps of: positioning the bolt holes of the upper purline, wherein the upper end face of the purline is used as a positioning reference surface, the distance between the center line of the upper line of bolt holes and the reference surface is equal to the distance between the center line of the lower line of bolt holes and the center line of the upper line of bolt holes and is equal to H-2a; and processing all bolt holes on the upper purline according to the positioning; the positioning method of the bolt holes of the lower purline comprises the steps that, the upper end face of the lower purline is used as a positioning reference surface, the distance between the center line of the upper line of bolt holes and the reference surface is equal to the distance between the center line of the lower line of bolt holes and the center line of the upper line of bolt holes and is equal to H-2a; and processing all bolt holes on the lower purline according to the positioning.

Owner:CHINA COAL NO 5 CONSTR

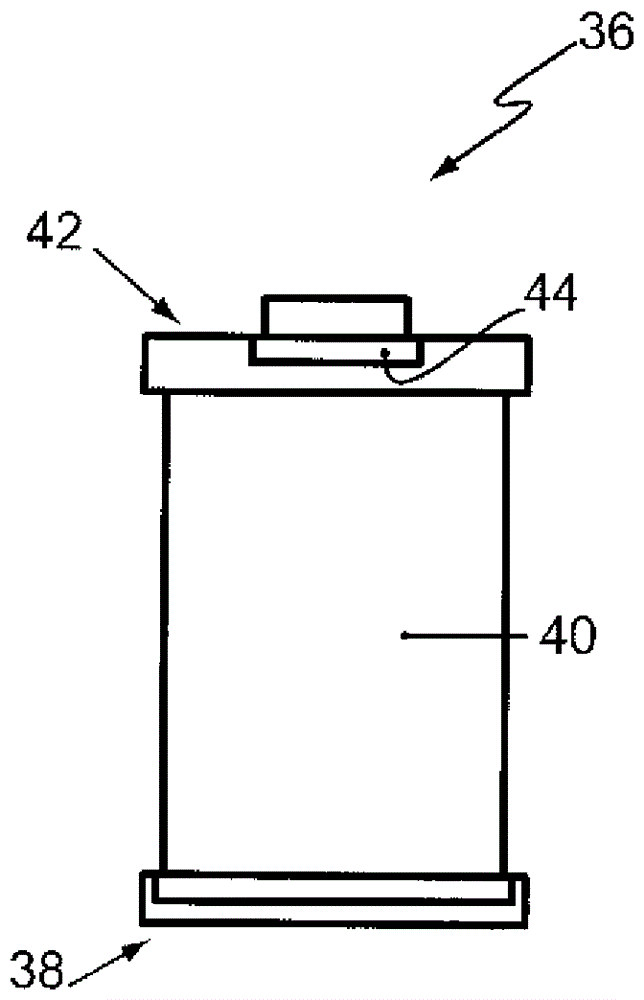

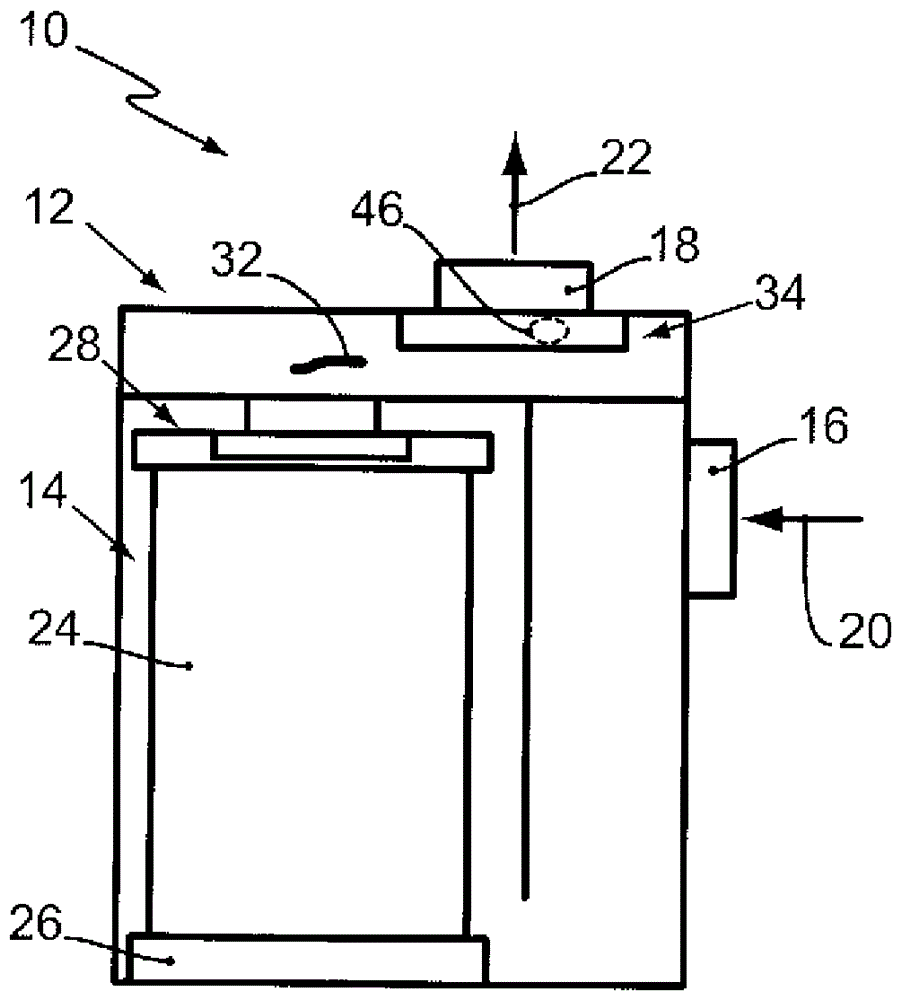

Filter system and filter element having a glass fiber filter medium and a sintered body

InactiveCN106457076AAvoid damageIncrease flow resistanceMembrane filtersLoose filtering material filtersGlass fiberFilter system

Owner:MANN HUMMEL GMBH

Preparation method of silicon nitride, silicon carbide and molybdenum carbide combined foam ceramic

The invention discloses a preparation method of silicon nitride, silicon carbide and molybdenum carbide combined foam ceramic. The preparation method is characterized by comprising the steps of uniformly mixing Mo2C, silica powder, phenolic resin and a hydroxypropyl methyl cellulose solution to prepare ceramic slurry; then, dipping the ceramic slurry on polyurethane foam, and drying; and next, firing at the nitrogen atmosphere to prepare the silicon nitride, silicon carbide and molybdenum carbide combined foam ceramic. The silicon nitride, silicon carbide and molybdenum carbide combined foam ceramic prepared by using the preparation method disclosed by the invention is uniform in microstructure, high in strength and uniform in pore size, and the residues of carbon and free silicon are avoided, so that the strength, high temperature resistance and thermal shock resistance of the silicon nitride, silicon carbide and molybdenum carbide combined foam ceramic are greatly improved.

Owner:SHANDONG UNIV OF TECH

A kind of preparation method of silicon nitride bonded silicon carbide foam ceramics

A method for preparing silicon nitride-bonded silicon carbide foam ceramics, characterized in that: SiC, silicon micropowder, phenolic resin and hydroxypropyl methylcellulose solution are uniformly mixed to form a ceramic slurry, and then the ceramic slurry is impregnated in On the polyurethane foam, after drying, it is fired in a nitrogen atmosphere to form silicon nitride bonded silicon carbide foam ceramics. The silicon nitride bonded silicon carbide foam ceramic prepared by the invention has uniform microstructure, high strength and uniform pore size, avoids the residue of carbon and free silicon, and greatly improves its strength, high temperature resistance and thermal shock resistance.

Owner:SHANDONG UNIV OF TECH

Novel die bag water filtering hole sewing machining and constructing method

InactiveCN106677128ASmall thickness deviationUniform hole sizeCoastlines protectionWater pipeFixed position

The invention discloses a novel die bag water filtering hole sewing machining and constructing method. After die bag cloth is discharged and primarily sewn, holes are formed in the fixed positions in a burning manner to serve as water filtering holes, pipe protection cloth matched with the holes in diameter is prefabricated, the upper holes and the lower holes of a die bag are connected through the pipe protection cloth through the overseam technology, the water filtering holes with the pipe protection cloth are formed, and water filtering pipes are then inserted in the pipe protection cloth of the die bag water filtering holes. The water filtering pipes are isolated from concrete through the pipe protection cloth, and the phenomenon that water filtering pipes slide down along with ash during concrete filling is effectively avoided; and meanwhile, the thickness of the die bag concrete at the water filtering hole parts is guaranteed, and the too large thickness deviation at the water filtering hole parts is greatly reduced. Due to the fact that the overseam technology is adopted in the pipe protection cloth, an upper-layer die bag body and a lower-layer die bag body, the hole forming size is uniform, and the die bag concrete appearance quality is greatly improved. Meanwhile, the reasonable concrete flushing and filling sequence is adopted, longer time can be reserved for filtering out of laitance in concrete while the construction efficiency is not influenced, and the die bag filling thickness is guaranteed.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY

Method for preparing impregnated cathode matrix

InactiveCN102024640BUniform hole sizeWell distributed holesThermionic cathode manufacturePrillMicrowave

The invention discloses a method for preparing an impregnated cathode matrix and relates to technology of microwave devices. The method is used for preparing a tungsten sponge matrix of an impregnated barium and tungsten cathode. Tungsten particles of different sizes are prepared into uniform spherical particles by particle spray drying powder treating technology, so that the flowability of tungsten powder is enhanced; and after being filled into a rubber sleeve, the treated tungsten powder can be beat, tamped or vibrated to form a close-packed structure, and then the close-packed structure is pressed and sintered to prepare the tungsten sponge matrix. The method is simple and practicable, the prepared impregnated cathode matrix has the advantages of uniform hole size, uniformly distributed holes, few closed holes and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

A kind of preparation method of silicon nitride, silicon carbide combined with zirconium boride foam ceramics

A method for preparing silicon nitride, silicon carbide and zirconium boride foam ceramics, characterized in that: ZrB2, silicon micropowder, phenolic resin and hydroxypropyl methylcellulose solution are uniformly mixed to form a ceramic slurry, and then the ceramic The slurry is impregnated on the polyurethane foam, and after drying, it is fired in a nitrogen atmosphere to form silicon nitride, silicon carbide and zirconium boride foam ceramics. The silicon nitride, silicon carbide and zirconium boride foam ceramics prepared by the present invention have uniform microstructure, high strength, and uniform pore size, avoiding the residue of carbon and free silicon, and greatly improving the strength, high temperature resistance, and thermal shock resistance. improve.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com