Porous silicon material and preparation method of porous silicon material

A technology for porous silicon and raw materials, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high production cost of porous silicon materials, polluting industrial production, complicated processes, etc., and achieves low production cost and uniform pore size. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

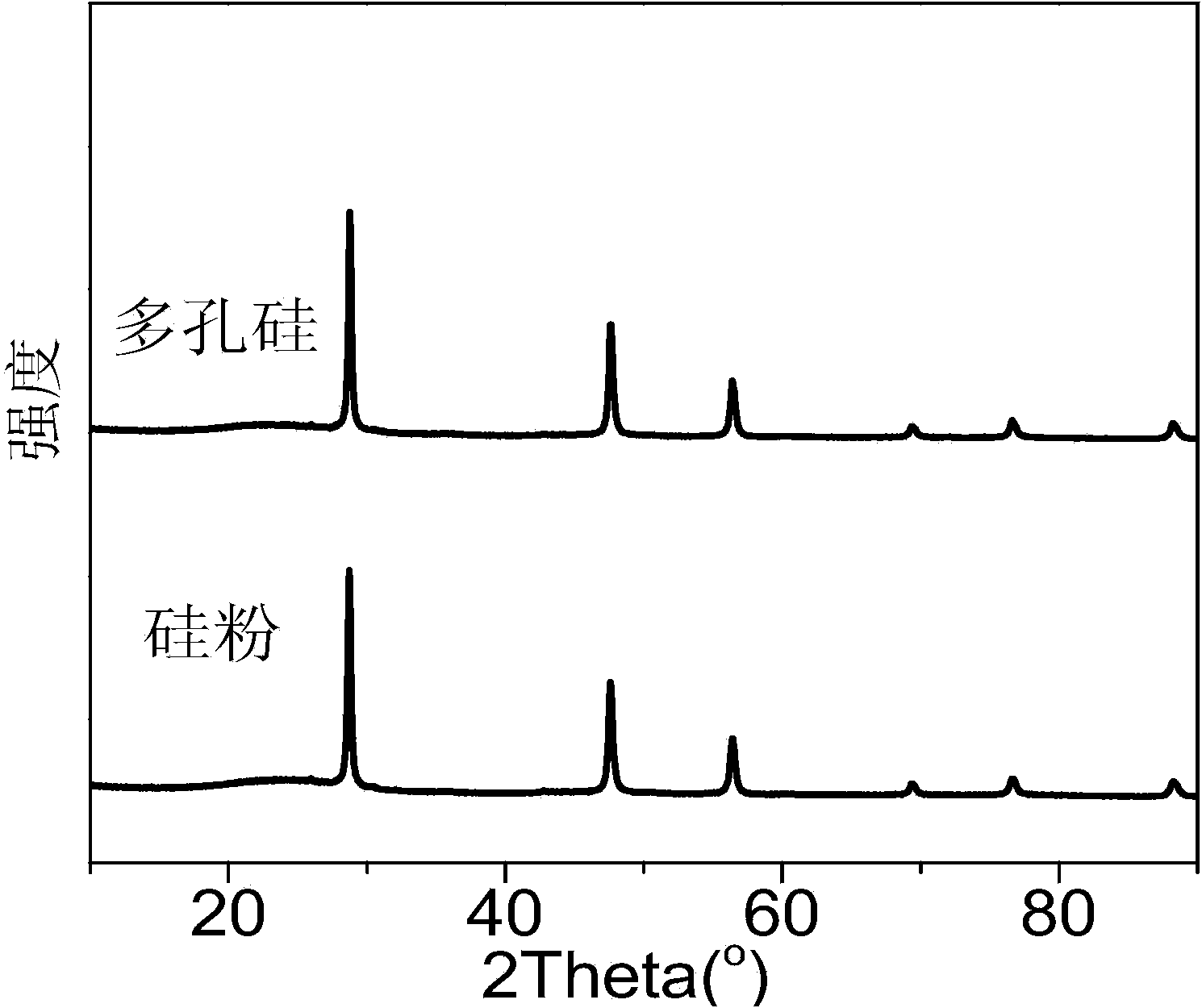

[0051] 10 grams of commercially purchased silicon fume raw materials (particle size range 10-100 microns) were mixed with commercially purchased powdered Cu 2 10 grams of O material (as a solid copper-based catalyst, particle size range 0.2-30 microns) is mixed and ground evenly, then put into a hydrothermal reaction kettle, add 40mL of ethanol, heat up to 120°C, and react for 18 hours, then cool to room temperature, the reaction process The gaseous products in the process become alkoxysilanes after condensation, which can be separated into chemicals by rectification in the later stage, and unreacted ethanol can be recycled. The solid residue after the reaction contains silicon and solid copper-based catalyst, sonicated in concentrated nitric acid at 90°C for 4 hours, washed repeatedly with deionized water 5 times to remove the copper-based catalyst, and then stirred and reacted in sodium hydroxide solution for 24 hours , repeatedly washed with deionized water 5 times to remov...

Embodiment 2

[0060] Mix and grind 10 grams of commercially purchased silicon powder raw materials (10-100 microns in particle size range) and 5 grams of commercially purchased powdered Cu (as a copper-based catalyst, 1-5 microns in particle size range) and put them into an autoclave, add 20mL of ethanol, heated to 320°C, reacted for 48 hours, then cooled to room temperature, the gaseous product in the reaction process will become alkoxysilane after condensation, which can be separated into chemicals by rectification in the later stage, and the unreacted ethanol can be recycled. The solid residue after the reaction contains silicon and solid copper-based catalyst, sonicated in concentrated nitric acid at 90°C for 4 hours, washed repeatedly with deionized water 5 times to remove the copper-based catalyst, and then stirred and reacted in sodium hydroxide solution for 24 hours , washed repeatedly with deionized water 5 times to remove the silicon dioxide on the surface of the porous silicon, an...

Embodiment 3

[0063] Mix 20 grams of commercially purchased silicon powder raw materials (1-20 microns in particle size range) with commercially purchased gelatinous Cu-Cu 2 3 grams of O-CuCl material (as a copper-based catalyst, particle size range 0.1-10.0 microns) is mixed and ground evenly and then loaded into a fixed-bed reactor, and the carrier gas high-purity nitrogen (gas velocity is 50mL / min) is passed into 100ml of ethanol Liquid bottle, bring ethanol gas into the fixed bed reactor, under normal pressure, after preheating, heat up to 300°C, react for 3 hours, cool to room temperature, the gaseous product in the reaction process will become alkoxysilane after condensation , which can be separated into chemicals by rectification in the later stage, and unreacted ethanol can be recycled. The solid residue after the reaction contains silicon and solid copper-based catalyst, sonicated in concentrated nitric acid at 90°C for 4 hours, washed repeatedly with deionized water 5 times to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com