Novel die bag water filtering hole sewing machining and constructing method

A construction method and technology for water filtering holes, which are applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as large deviation, poor appearance quality, and large pore pressure of mold bags, so as to achieve no impact on construction efficiency and improve appearance quality. , to ensure the effect of filling thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 1 , 2 As shown, a novel mold bag filter hole sewing processing and construction method is characterized in that it includes the following steps:

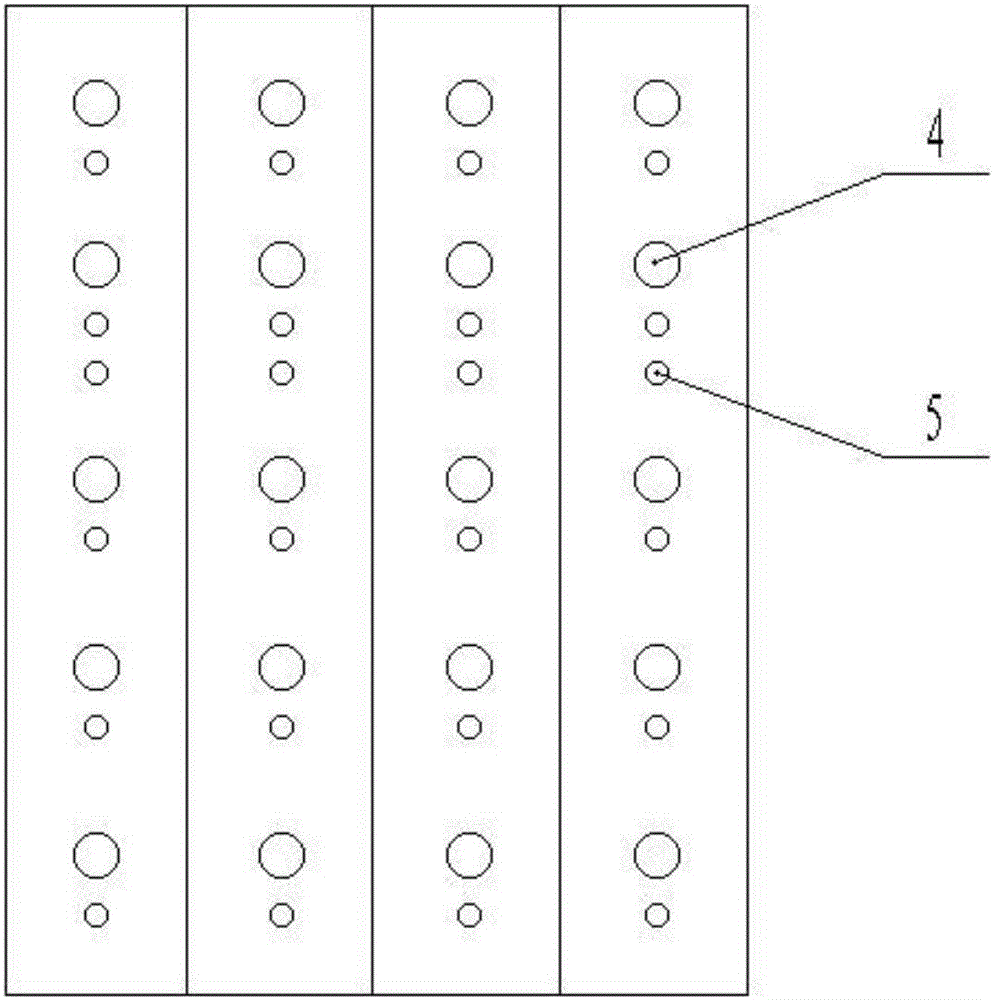

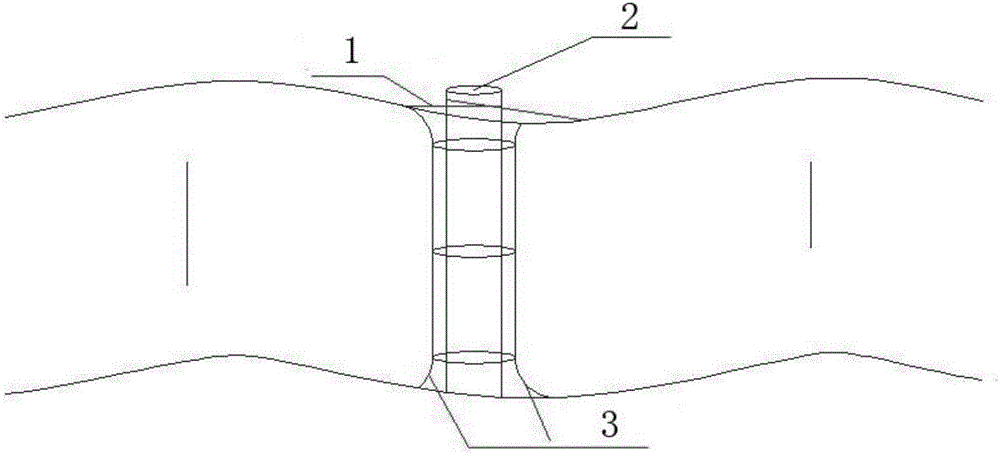

[0027] ①According to the design requirements of the mold bag sewing process, after the mold bag cloth is blanked and the initial sewing is completed, according to the hole position positioning and setting out, a hole with a diameter of 150mm is ironed at the predetermined position of each compartment as the water filter hole 5. Reserve two tethers 1 around the hole, and prefabricate the protective tube cloth 3 matching the diameter of the water filter hole 5, and use the overlock process to connect the upper and lower filter holes 5 of the mold bag through the protective tube cloth 3 to form a protective tube cloth 3 the filter hole 5;

[0028] ②After laying the mold bag, manually insert the PVC water filter pipe 2 with a length of 1m and a diameter of 120mm into the protective pipe cloth 3 of the water filte...

Embodiment 2

[0038] A new mold bag filter hole sewing processing and construction method, comprising the following steps:

[0039] ①According to the design requirements of the mold bag sewing process, after the mold bag cloth is blanked and the initial sewing is completed, according to the hole position positioning and setting out, a hole with a diameter of 150mm is ironed at the predetermined position of each compartment as the water filter hole 5. Reserve two tethers 1 around the hole, and prefabricate the protective tube cloth 3 matching the diameter of the water filter hole 5, and use the overlock process to connect the upper and lower filter holes 5 of the mold bag through the protective tube cloth 3 to form a protective tube cloth 3 the filter hole 5;

[0040] ②After laying the mold bag, manually insert the cut steel pipe with a length of 1m and a diameter of 120mm into the protective pipe cloth 3 of the water filter hole 5 of the mold bag, and use the tether 1 on the mold bag cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com