Electrode plate for super capacitor and preparation method of electrode plate

A technology for supercapacitors and electrode sheets, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve problems such as complex processes, high energy consumption, and high production costs. Achieve the effect of overcoming complex process, high specific surface area and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step, the preparation of nanoporous copper by dealloying method

[0031] Take a Cu with a length of 8 cm, a thickness of 20 μm and a width of 2 mm 50 Zr 50 Amorphous metal thin strips are free to dealloy under 0.5M hydrofluoric acid for 15 minutes at room temperature to obtain nanoporous copper. After removing it, wash it with absolute ethanol, weigh it, and soak 0.0215g of nanoporous copper completely. in absolute ethanol;

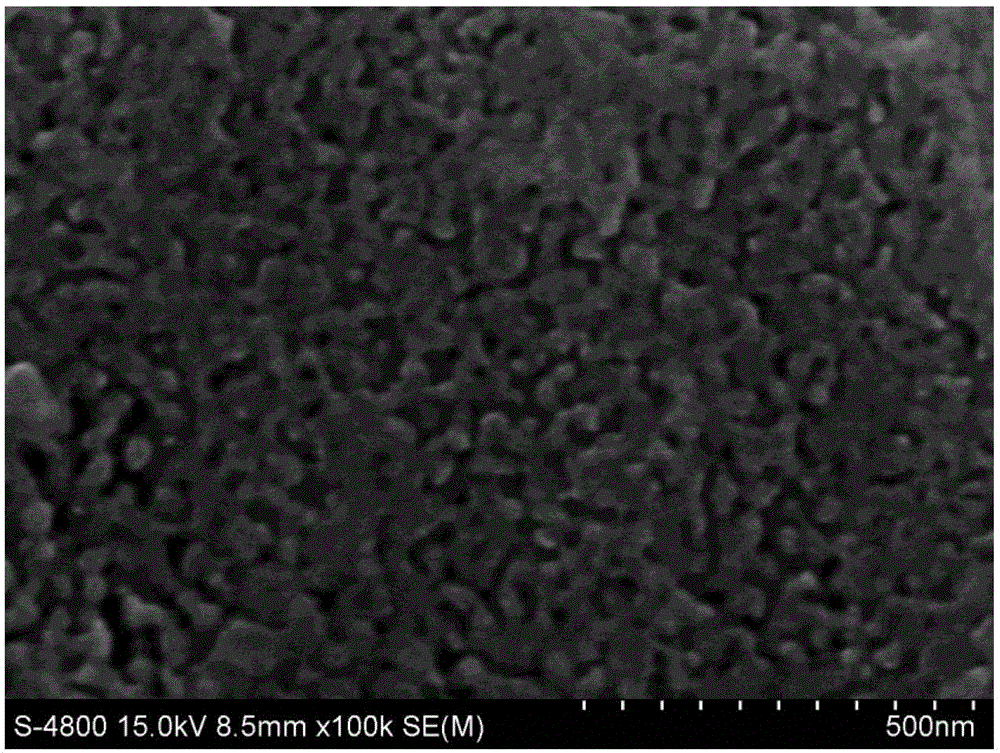

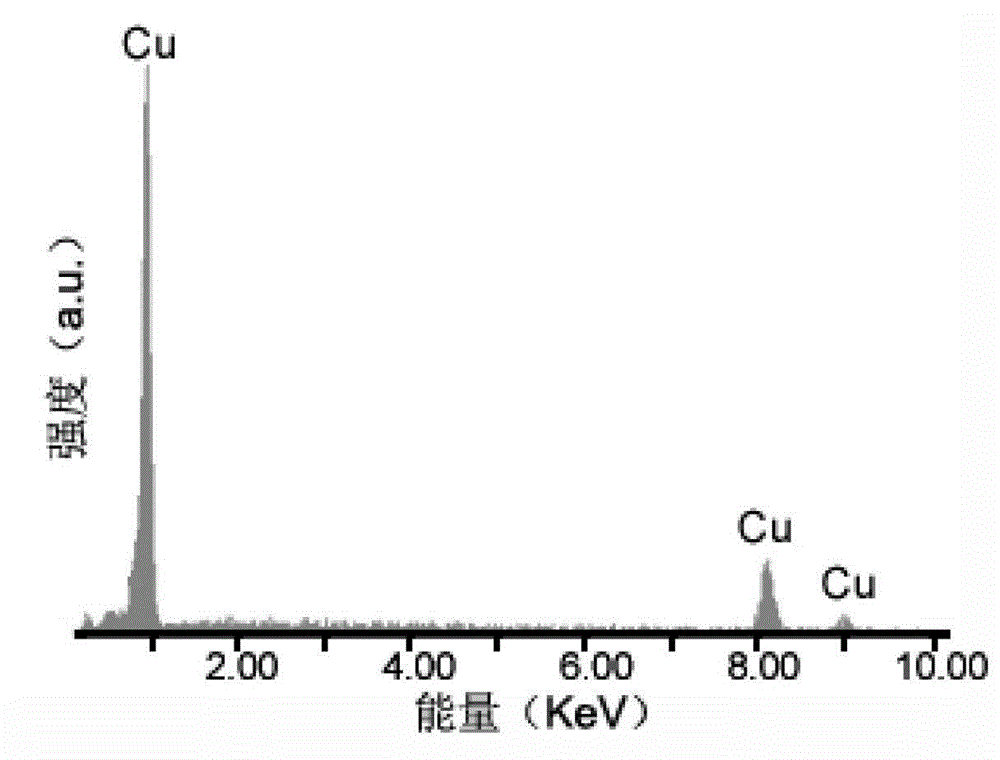

[0032] figure 1 The scanning electron micrograph of the nanoporous copper prepared in this example shows the morphology of the prepared nanoporous copper. from figure 2 The energy spectrum analysis (EDS analysis) figure confirms that Cu 50 Zr 50 After the amorphous metal strip is dealloyed, there is only Cu element in the strip, which is nanoporous copper.

[0033] The second step is to prepare nanoporous copper and manganese dioxide mixed powder

[0034] 7.41mL of 0.1mol / L KMnO 4 The solution is dripped into the absolute ethano...

Embodiment 2

[0043] The first step, the preparation of nanoporous copper by dealloying method

[0044] Take a Cu with a length of 11 cm, a thickness of 20 μm and a width of 2 mm 50 Zr 50 Amorphous metal thin strips are free to dealloy under 0.5M hydrofluoric acid for 15 minutes at room temperature to obtain nanoporous copper. After removing it, wash it with absolute ethanol, weigh it, and soak 0.0478g of nanoporous copper completely. in absolute ethanol;

[0045] The second step is to prepare nanoporous copper and manganese dioxide mixed powder

[0046] 5.49mL of 0.1mol / L KMnO 4 The solution is dripped into the absolute ethanol completely immersed in the nanoporous copper obtained in the first step with a dropper, and the reaction equation is:

[0047] 4KMnO 4 +3CH 3 CH 2 OH=3CH 3 COOK+4MnO 2 ↓+KOH+4H 2 O,

[0048] Make the mass ratio=1:1 formed by the nanoporous copper and manganese dioxide formed, wherein the mass percentage of nanoporous copper is 50%, let stand for 3h, wash ...

Embodiment 3

[0054] The first step, the preparation of nanoporous copper by dealloying method

[0055] Take a Cu with a length of 14cm, a thickness of 20μm and a width of 2mm 50 Zr 50 Amorphous metal thin strips are free to dealloy under 0.5M hydrofluoric acid for 15 minutes at room temperature to obtain nanoporous copper. After removing it, wash it with absolute ethanol, weigh it, and soak 0.0624g of nanoporous copper completely. in absolute ethanol;

[0056] The second step is to prepare nanoporous copper and manganese dioxide mixed powder

[0057] 2.39mL of 0.1mol / L KMnO 4 The solution is dripped into the absolute ethanol completely immersed in the nanoporous copper obtained in the first step with a dropper, and the reaction equation is:

[0058] 4KMnO 4 +3CH 3 CH 2 OH=3CH 3 COOK+4MnO 2 ↓+KOH+4H 2 O,

[0059] Make the mass ratio=3:1 formed by the nanoporous copper and manganese dioxide formed, wherein the mass percentage of nanoporous copper is 75%, let stand for 3h, wash the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com