Three-dimensional porous stent and preparation method and application thereof

A three-dimensional porous and porous technology, applied in medical science, prosthesis, additive processing, etc., to achieve precise controllability, good biocompatibility and biodegradability, and suitable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A method for preparing a three-dimensional porous scaffold, comprising:

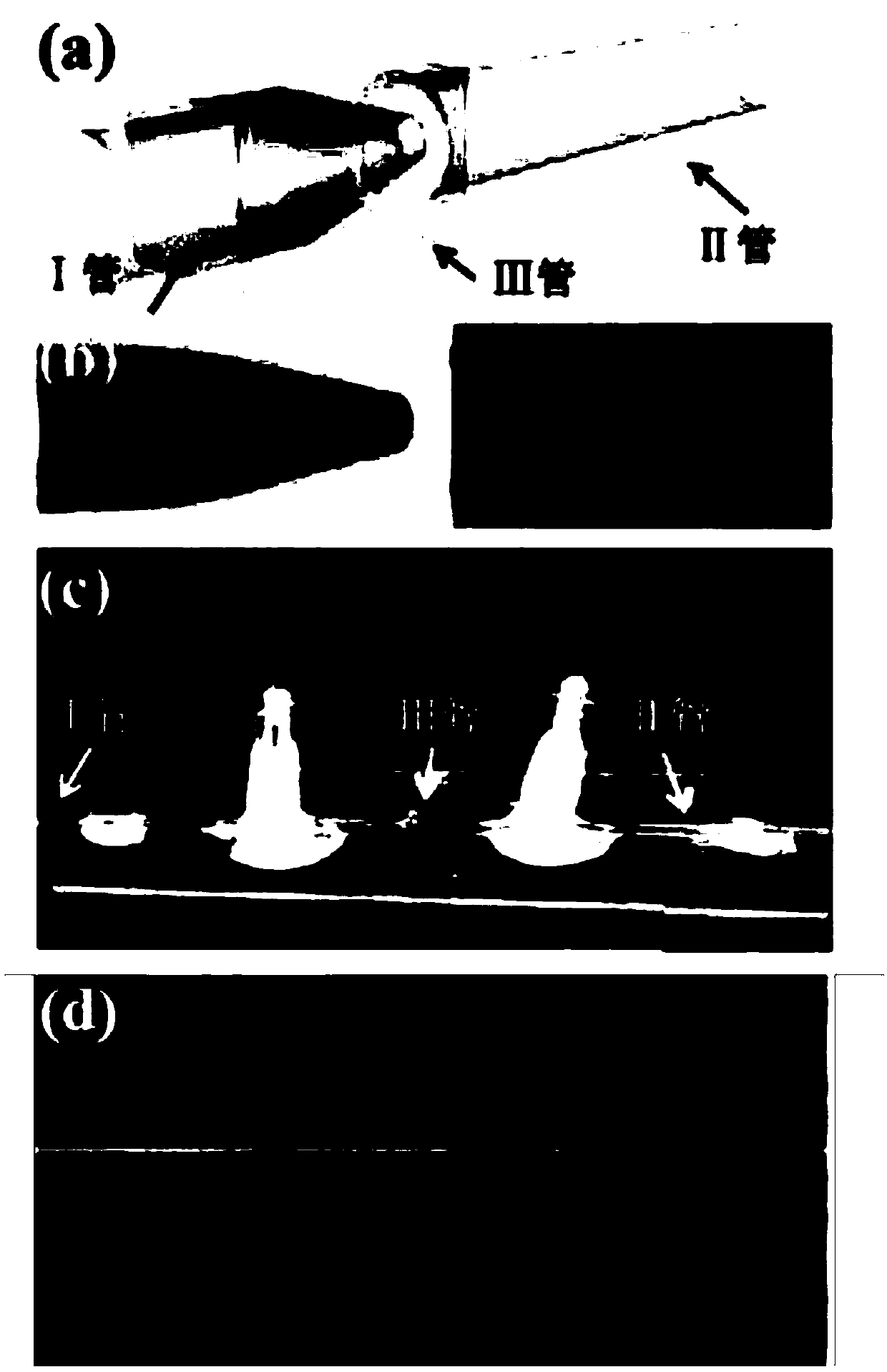

[0076] 1) Preparation steps of monodisperse emulsion droplets: using a microfluidic device, an external phase and an internal phase to prepare monodisperse emulsion droplets with a controllable particle size, and cleaning and collecting the monodisperse emulsion droplets;

[0077] Wherein, wherein, the external phase includes a composite composed of degradable natural biological materials and degradable synthetic polymer materials; the weight ratio of the degradable natural biological materials to the degradable synthetic polymer materials is 1:7.5 . The degradable natural biological material is sodium alginate. The artificially synthesized polymer material is polyethylene glycol diacrylate.

[0078] The internal phase is methyl silicone oil.

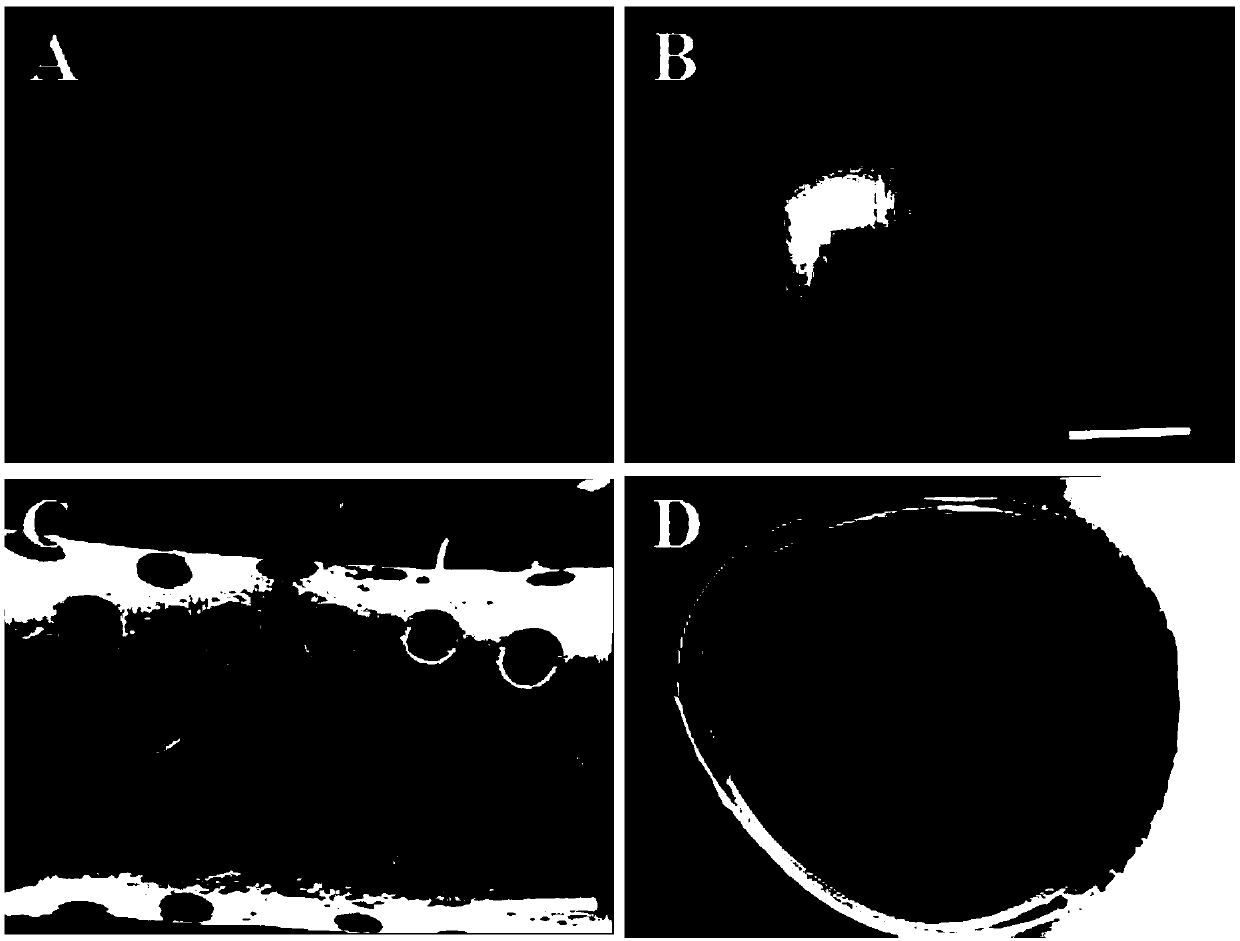

[0079] 2) The preparation steps of the emulsion droplet template: the collected monodisperse emulsion droplets are left to stand, the monodisperse emuls...

Embodiment 2

[0083] 1) Preparation steps of monodisperse emulsion droplets: using a microfluidic device, an external phase and an internal phase to prepare monodisperse emulsion droplets with a controllable particle size, and cleaning and collecting the monodisperse emulsion droplets;

[0084] Wherein, the outer phase 1 includes a composite composed of degradable natural biomaterials and degradable synthetic polymer materials; the weight ratio of the degradable natural biomaterials to the degradable synthetic biomaterials is 1:7.5. The degradable natural biological material is sodium alginate. The synthetic biomaterial is gelatin methacrylate (Gelma).

[0085] The internal phase is methyl silicone oil.

[0086] 2) The preparation steps of the emulsion droplet template: the collected monodisperse emulsion droplets are left to stand, the monodisperse emulsion droplets will self-assemble into a tightly packed structure, and finally form a uniform and neat emulsion droplet template; then the ...

Embodiment 3

[0091] A method for preparing a drug-loaded three-dimensional porous scaffold: soak the three-dimensional porous scaffold described in Example 3 in a 75% alcohol solution overnight, then wash it repeatedly with sterile PBS (PH=7.4), and soak it in PBS for ultraviolet light Irradiate for 3h. Soak the porous scaffold in 100ug / mL bFGF solution to fully disperse the drug into the pores, take it out after 24 hours for later use, and obtain the drug-loaded three-dimensional porous scaffold.

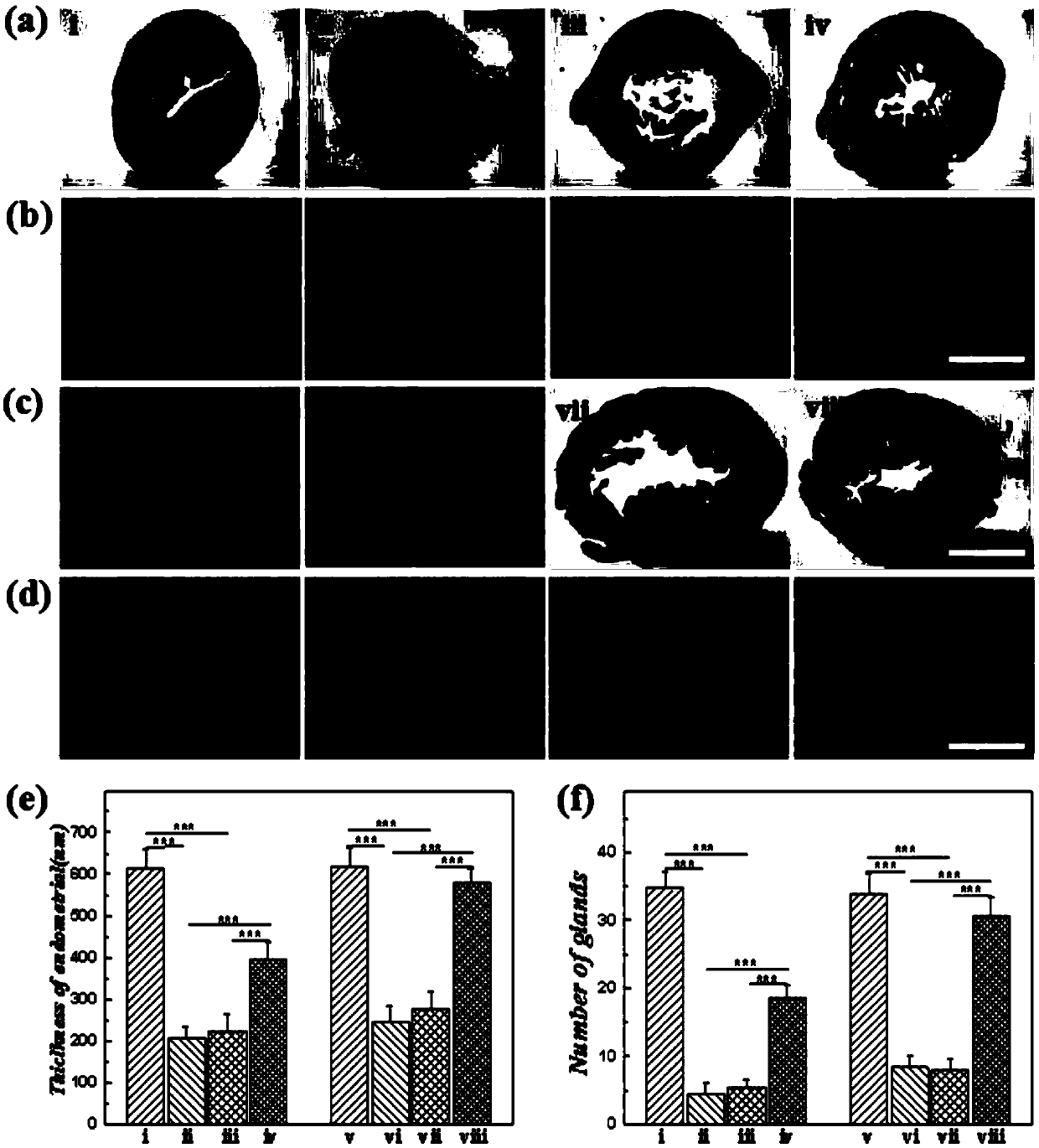

[0092] Application of drug-loaded three-dimensional porous scaffold in intrauterine adhesion rat model:

[0093] (1) Establishment of intrauterine adhesion model rats: the rats were anesthetized with 350 mg / kg 10% chloral hydrate, the lower abdomen was shaved and fixed in the supine position on the operating board, disinfected with iodine, and a long slit was made in the middle of the lower abdomen. A longitudinal incision of about 2-3 cm was made to enter the abdominal cavity to expose the ut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com