Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Chloral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloral, also known as trichloroacetaldehyde or trichloroethanal, is the organic compound with the formula Cl₃CCHO. This aldehyde is a colourless oily liquid that is soluble in a wide range of solvents. It reacts with water to form chloral hydrate, a once widely used sedative and hypnotic substance.

Semi-bright nickel electroplating solution additive, semi-bright nickel electroplating solution and semi-bright nickel electroplating method

The invention provides a semi-bright nickel electroplating solution additive which comprises a brightener, a potential difference stabilizer, and a wetting agent; the potential difference stabilizer is chloral hydrate; the mass ratio of the brightener, the potential difference stabilizer, and the wetting agent is 5.3-123:1:0.7-35. The invention also provides a semi-bright nickel electroplating solution and a semi-bright nickel electroplating method. The semi-bright nickel electroplating solution additive of the invention provides stable potential difference environment for the electroplating solution, and is suitable for electroplating with high electroplating layer potential difference requirement and high workpiece corrosion resistance requirement.

Owner:HANGZHOU WIN WIN TECH CO LTD

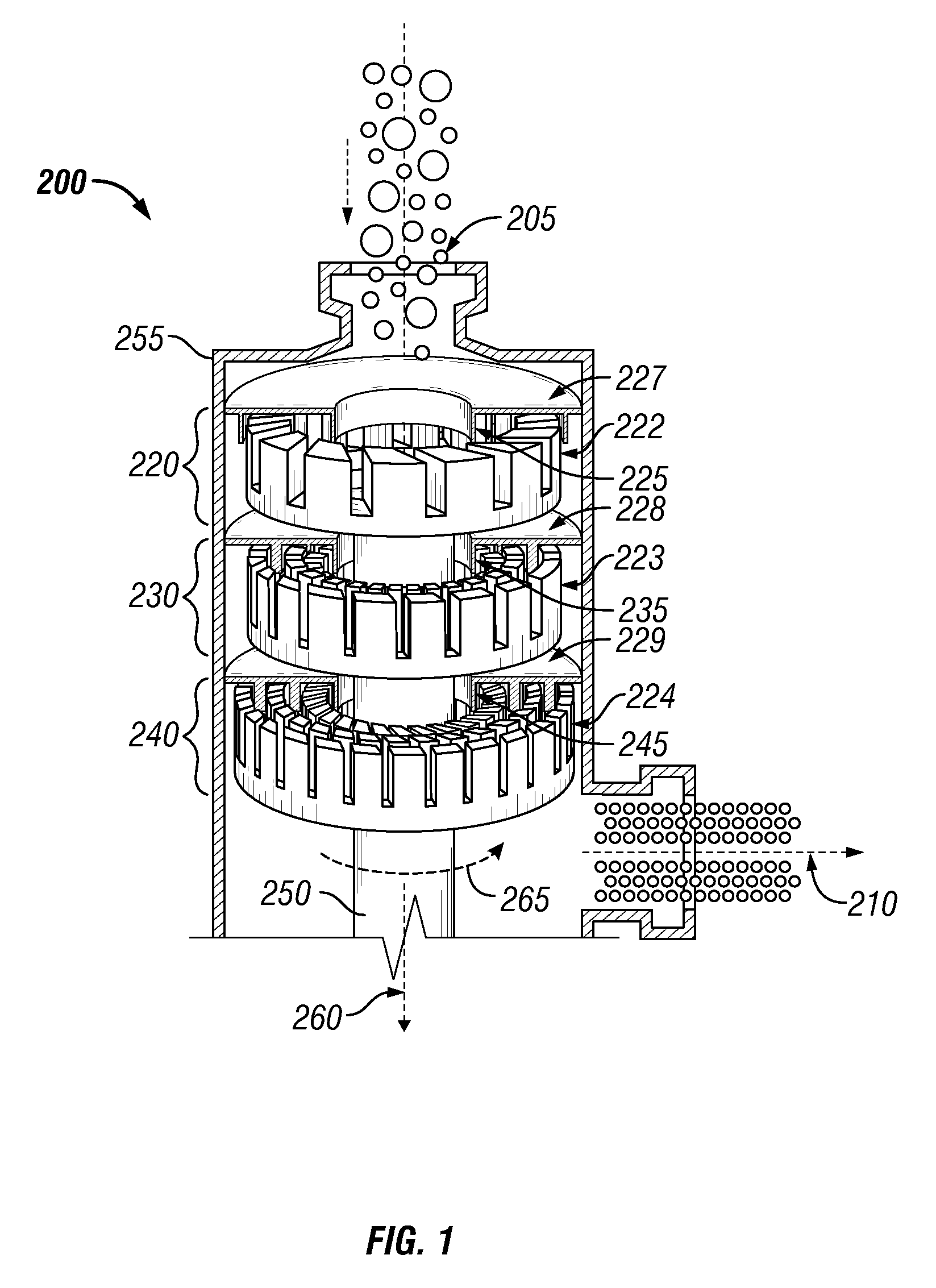

High shear process for the production of chloral

InactiveUS20090005604A1Increase ratingsReduced mass transfer limitationsOrganic compound preparationRotary stirring mixersProcess engineeringAcetaldehyde

Use of a high shear mechanical device incorporated into a process for the production of chloral as a reactor device is capable of decreasing mass transfer limitations, thereby enhancing the chloral production process. A system for the production of chloral from acetaldehyde and chlorine, the system comprising a reactor and an external high shear device the outlet of which is fluidly connected to the inlet of the reactor; the high shear device capable of providing a dispersion of chlorine gas bubbles within a liquid, the bubbles having an average bubble diameter of less than about 100 μm.

Owner:HRD CORP

New technology of producing trichloroaldehyde from chlorine oil

InactiveCN1868993AAlcohol consumption dropsReduce manufacturing costOrganic compound preparationCarbonyl compound preparation by oxidationAlcoholPhysical chemistry

A process for preparing trichloroacetaldehyde from alcohol or acetaldehyde includes such steps as reaction on Cl to generate chlorine oil, deacidifying or not, distilling or rectifying to obtain heavy component, medium-boiling compound and low-boiling compound, rejecting the heavy component, returning low-boiling component back to chlorinating system, and dewatering the medium-boiling compound (refined chlorine oil) to obtain target product.

Owner:王蒙

Dedevap continuous production method

InactiveCN1951944AReduce consumptionIncrease production capacityBiocideGroup 5/15 element organic compoundsBiochemical engineeringTrimethyl phosphite

The invention discloses a preparing method of continual manufacturing of atgard, which comprises the following steps: filling atgard base in the first grade reactor; adding trichloroacetaldehyde and trimethyl phosphite into the first grade reactor; controlling the temperature between 0 and 100 deg.c; flowing the reacting material from the first grade reactor to the second grade reactor; insulating at 0-100 deg.c.

Owner:荆州沙隆达控股有限公司

Synthetic method of stable isotope deuterium-labeled DDT

InactiveCN104557449AAvoid problemsAvoid abundance dilutionHalogenated hydrocarbon preparationChlorobenzeneDeuterium labeled

The invention relates to a synthetic method of stable isotope deuterium-labeled DDT. The synthetic method comprises the following steps: with stable isotope deuterium-labeled chlorobenzene as an isotope-labeled precursor, in the presence of a catalyst, carrying out dehydration synthesis on the isotope-labeled precursor and chloral to obtain the stable isotope deuterium-labeled DDT. Compared with the prior art, according to the synthetic method disclosed by the invention, after the stable isotope deuterium-labeled DDT is separated and purified, the isotope-labeled position is stable, so that the abundance of an isotope is prevented from diluting, the chemical purity achieves above 99.0 percent, the abundance of the isotope achieves above 99.0 percent atom, and the stable isotope deuterium-labeled DDT can fully meet the needs for residue detection in the food safety field.

Owner:SHANGHAI RES INST OF CHEM IND

Tower type continuous dehydration technique for trichloroacetaldehyde monohydrate

InactiveCN101215228AImprove mass transfer effectShort stayCarbonyl compound separation/purificationSmall footprintAcetaldehyde

Disclosed is a tower type continuous dewatering technology of chloral hydrate, technical characteristic of which is that dilute sulphuric acid is discharged out from the bottom of the tower, the chloral hydrate enters from a certain portion at the bottom of the tower, concentrated sulfuric acid enters from the top of the tower, and refined chloral is discharged out from the top of the tower. The whole process is the continuous dewatering operation and the technique is simple, fast and fluently, which realizes continuous dewatering of chloral hydrate with relatively less equipments and relatively low energy consumption. The technique can be controlled easily and operated relatively stably. Compared with other existing dewatering techniques, the invention not only can reduce investment of equipments, but also is small in area and low in energy consumption. Further, the invention can decrease dewatering cost of chloral hydrate obviously and improve product quality.

Owner:荆州沙隆达控股有限公司

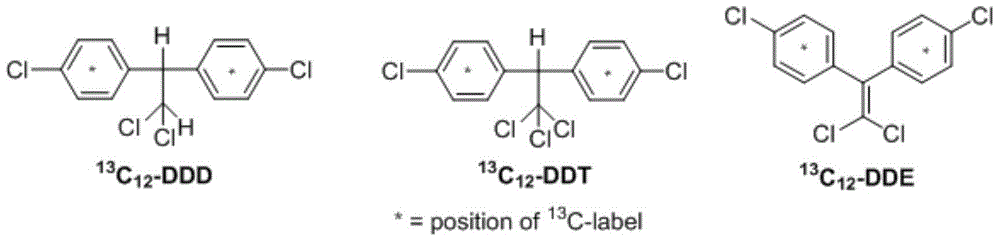

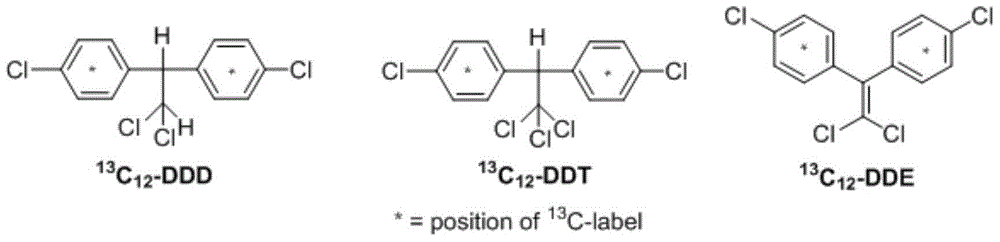

Synthesis method of C13-labelled DDT (Dichlorodiphenyl Trichloroethane), DDD (Dichlorodiphenyl Dichloroethane) and DDE (Dichlorodiphenyl Dichloroethene)

ActiveCN103601610AStable abundancePreparation by hydrogen halide split-offChlorobenzeneSynthesis methods

The invention discloses the technical field of synthesis of isotope labeled compounds and particularly relates to a synthesis method of C13-labelled DDT (Dichlorodiphenyl Trichloroethane), DDD (Dichlorodiphenyl Dichloroethane) and DDE (Dichlorodiphenyl Dichloroethene). The synthesis method comprises the following steps: with 13C6-benzene as a raw material, carrying out oxychlorination to obtain 12C6-chlorobenzene, carrying out acid catalytic condensation on the 12C6-chlorobenzene with a trichloracetic aldehyde hydrate and a dichloroacetaldehyde hydrate respectively to obtain 13C12-DDT and 13C12-DDD, and preparing 13C12-DDE by carrying out catalytic dehydrochlorination on 13C12-DDT by means of a phase transfer catalyst. A series of representations prove that the products are 13C12-DDT, 13C12-DDD and 13C12-DDE, and the chemical purity of the products reaches above 90 percent, and the stable isotope abundance is above 90 percent.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

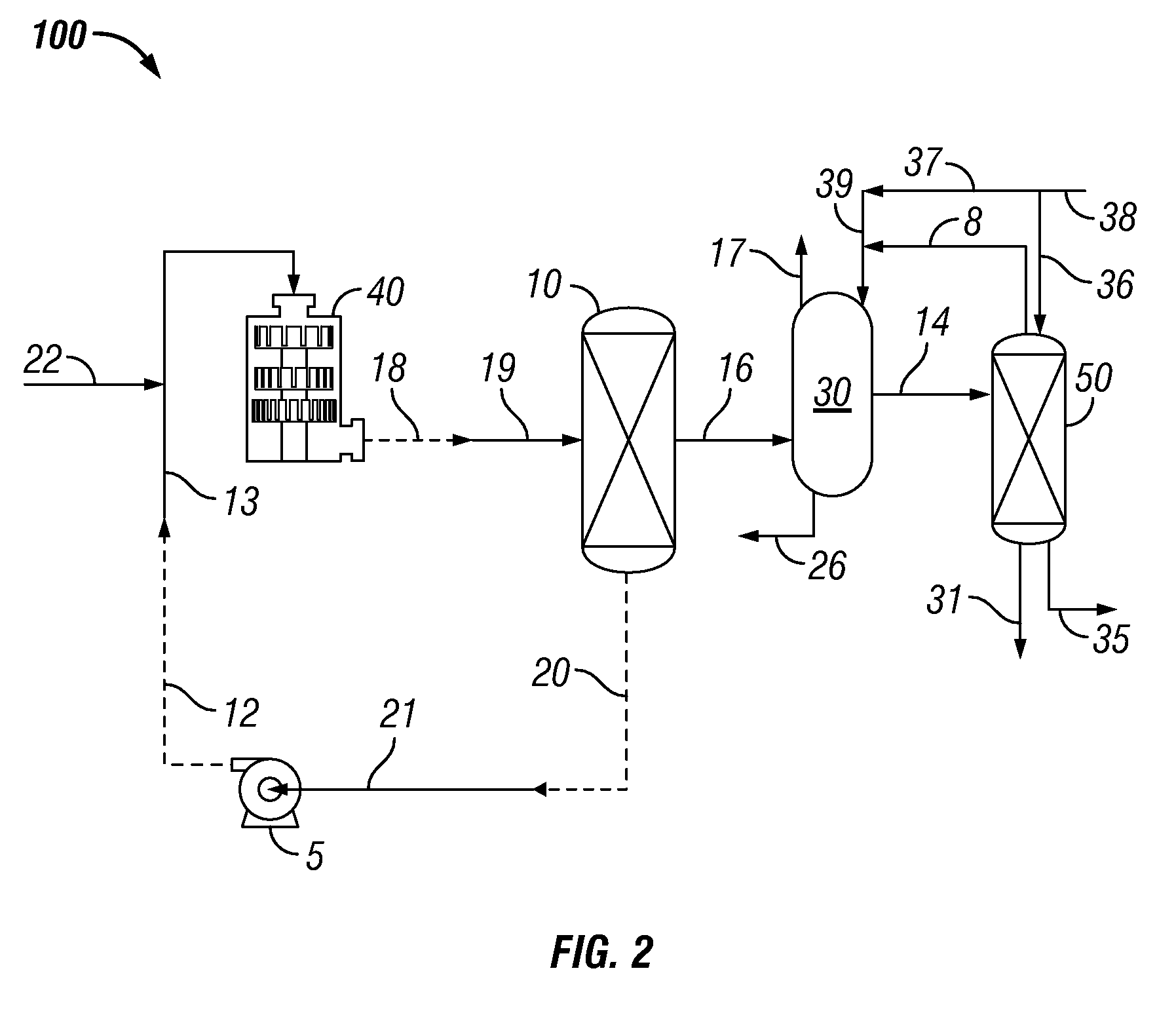

High shear process for the production of chloral

InactiveUS7652174B2Increase ratingsReduced mass transfer limitationsOrganic compound preparationTransportation and packagingProcess engineeringEngineering

Use of a high shear mechanical device incorporated into a process for the production of chloral as a reactor device is capable of decreasing mass transfer limitations, thereby enhancing the chloral production process. A system for the production of chloral from acetaldehyde and chlorine, the system comprising a reactor and an external high shear device the outlet of which is fluidly connected to the inlet of the reactor; the high shear device capable of providing a dispersion of chlorine gas bubbles within a liquid, the bubbles having an average bubble diameter of less than about 100 μm.

Owner:HRD CORP

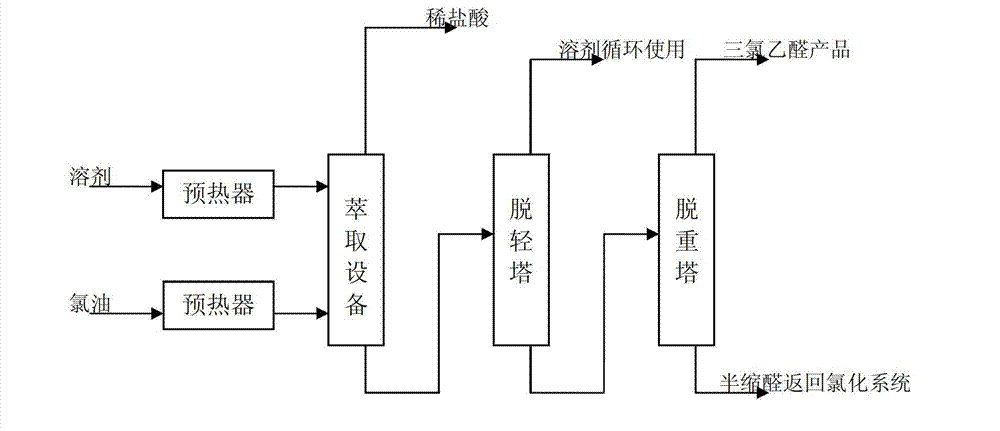

Novel technology for chloral industrial production

InactiveCN102924248AAvoid it happening againAvoid consumptionCarbonyl compound separation/purificationChemical industryOrganic solvent

The invention belongs to the field of chemical industry production technology, and relates to a novel technology for chloral industrial production. The chloro oil produced through the chlorination of technology-processed ethanol is extracted through organic solvent solution and separated into a diluted hydrochloric acid water phase and an organic phase, and the organic phase is used for producing high-content chloral through rectifying technology. As concentrated sulfuric acid is not used as dehydrating agent, waste sulfuric acid is prevented from being produced, the yield of chloral produced through the chloro oil amounts to more than 97%, and the components in the chloro oil as ethanol and hemiacetal are rectified and separated to return again to the chlorination reaction system, as a result, the utilization rate of raw material is further improved. The technology is environment-friendly, even though a small amount of organic solvent is consumed, a large amount of concentrated sulfuric acid is prevented from being used, and the steam consumption is barely increased, so that the product cost of the novel technology is the same as that of the existing technology.

Owner:SHANDONG DACHENG AGROCHEM

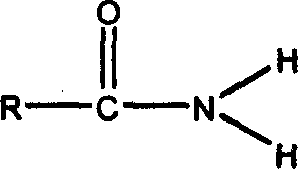

Acidamide derivative preparation method

InactiveCN1544416AAvoid corrosionEasy to operateOrganic compound preparationCarboxylic acid amides preparationStrong acids3-Bromobenzaldehyde

A process for preparing amide derivant, comprises reacting fatty group amide with aldehydes in methyl alcohol or carbon tetrachloride or benzene or methylbenzene or dioxane or acetonitrile with the presence of catalyst, and separating the reaction product, characterized in that the catalyst is type H strong acidic positive ion exchange resin, the aldehyde is selected from the groups of paraformaldehyde, acetaldehyde, propionaldehyde, chloral, bromal, glyoxylic acid, 4-bromobenzaldehyde, 3-bromobenzaldehyde, hydrosulfide acetaldehyde, p-nitrobenzaldehyde, and 4-hydroxybenzaldehyde. The formula of the fatty group amide is described in the specification, wherein R 2 is saturated or unsaturated fatty group having 2-12 carbon atoms, the type H strong acidic positive ion exchange resin is sulphonated coal, sulfonated phenylethene copolymer or sulfonated phenol formaldehyde resin.

Owner:OCEAN UNIV OF CHINA

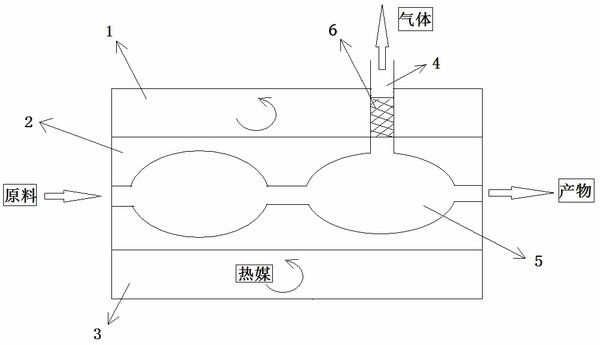

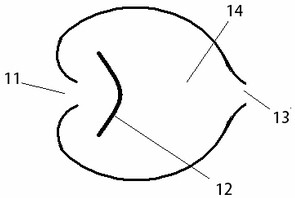

Micro-channel reactor and preparation method of high-content dichlorvos

ActiveCN111793084ATime consumingHigh energy consumptionGroup 5/15 element organic compoundsChemical industryPhosphorous acidDichlorvos

The invention discloses a micro-channel reactor. The micro-channel reactor is of a three-layer sandwich structure, wherein a flowing heating medium is arranged in the upper layer and the lower layer,and the middle layer is a reaction space of a multi-stage series heart-shaped structure; a vacuum pumping hole communicating with the middle-layer reaction space is locally reserved in the upper layer; and the hole is covered with a molecular sieve or a semipermeable membrane with a pore diameter of 0.6-0.7 nm. The micro-channel reactor is used for producing dichlorvos, the temperature of the heating medium is 40-50 DEG C, and the air pressure of the reaction space is minus 0.02 to minus 0.08 Mpa. According to the invention, when methyl chloride and water vapor volatilize, trimethyl phosphiteand trichloracetic aldehyde cannot be entrained, side reactions cannot be generated, trichloracetic aldehyde cannot form hydrate, and a reaction speed and a conversion rate are increased.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

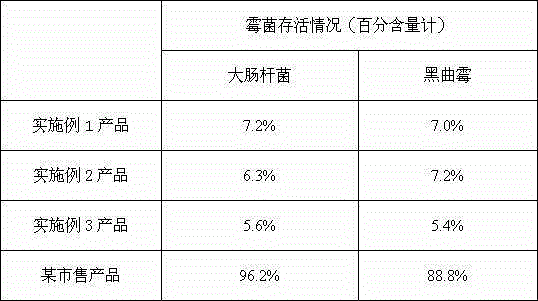

Garden seed sterilization mildew-proof treating agent

InactiveCN105123799AHelps growImprove survival ratePlant growth regulatorsBiocideSodium acetatePolythylene glycol

The invention relates to a garden seed sterilization mildew-proof treating agent. The treating agent is composed of the following ingredients, by weight, 28-32 parts of corn starch, 30-34 parts of red peppers, 26-30 parts of anhydrite mine, 30-34 parts of fly ash, 26-30 parts of clinoptilolite, 30-34 parts of vermiculite powder, 26-30 parts of santal, 32-36 parts of lysimachia foenum-graecum powder, 26-30 parts of zinc sulfate, 30-34 parts of dipterex, 26-30 parts of chloral hydrate, 30-34 parts of sodium diacetate, 26-30 parts of butyl hydroxyanisole, 30-34 parts of sodium dehydroacetate, 26-30 parts of polyglycerol, 30-34 parts of olive oil macrogol ester, 26-30 parts of nimbin, 30-34 parts of buprofezin, 26-30 parts of rare earth cerium oxide powder, 30-34 parts of butene-fipronil, 26-30 parts of agritol, 30-34 parts of Dupont curzate, 26-30 parts of thiacloprid and 1000-2000 parts of water. The treating agent has excellent sterilization and mildew-proof performances, and raises the garden seed survival rate.

Owner:王璐

Method for preparing trichloroacetaldehyde

InactiveCN102108046AOrganic compound preparationCarbonyl compound preparationReaction temperatureAcetaldehyde

The invention discloses a method for preparing trichloroacetaldehyde through catalysis of aqueous solution of aldehyde. The aqueous solution of aldehyde is taken as a raw material, and the method comprises the following steps of: performing chlorination on aldehyde by controlling reaction temperature in the presence of a single or mixed catalyst; and after the reaction is finished, performing azeotropy dehydration through a latent solvent, and distilling a product to obtain high-purity trichloroacetaldehyde. The method has the advantages of high yield and light environmental pollution, and can be applied to preparation of a small amount of trichloroacetaldehyde in a laboratory and industrial production.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Berber fleece dyeing and finishing process

InactiveCN105386302AImprove mildew resistanceExcellent mothproofHeat resistant fibresGrip property fibresAntibacterial propertyDiethanolamide

The present invention discloses a berber fleece dyeing and finishing process, which comprises: 1) pre-treatment; 2) dyeing; and 3) finishing: sequentially pouring 1-2 parts by weight of coconut oil fatty acid diethanolamide, 0.7 part by weight of polyvinyl pyrrolidone, 0.3 part by weight of calcium carbonate, and 0.7 part by weight of chitosan to 21.3 parts by mass of deionized water, uniformly stirring, pouring 0.6 part by weight of an agent, 0.8 part by weight of fatty acid amide, 0.9 part by weight of chloral, and 0.7 part by weight of triethanolamine, continuously stirring until completely mixing to prepare a finishing solution, carrying out an immersing rolling treatment on a fabric in the finishing solution, taking out, and carrying out constant temperature drying. According to the present invention, with the process, the dyed and finished fabric has characteristics of excellent mildew resistance, excellent moth resistance, excellent antibacterial property, excellent fire retardation, excellent static electricity resistance, strong washing resistance, and soft hand feeling.

Owner:常熟市博凡针纺织有限公司

Aftertreatment method of chloral intermediate product synthesized by acetaldehyde aqueous solution

The invention discloses an aftertreatment method of a chloral intermediate product synthesized by an acetaldehyde aqueous solution. The method comprises the following steps of: in a system for preparing the chloral from the acetaldehyde aqueous solution, adding water-soluble inorganic salt into water in an amount differing according to the solubility of the inorganic salt in water; simultaneously, adding a water-insoluble organic solvent in an amount equal to the volume of the aqueous solution for extracting; and distilling under reduced pressure or normal pressure to obtain a mixture applied through target rectified chloral and an organic solvent.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Trichlorfon continuous production method and production device for method

PendingCN112266395AImprove product qualityHigh yieldGroup 5/15 element organic compoundsPhosphorous acidDimethyl phosphite

The invention provides a preparation method and production equipment for continuous production of trichlorfon, and effectively solves the problems of low production efficiency, poor production stability and safety, poor product quality and low yield of the existing production method. The continuous production method of trichlorfon comprises the following two stages of synthesis reactions for continuously preparing trichlorfon: (1) adding trichlorfon into a I-stage synthesis kettle as a synthesis kettle reaction mother liquor, then simultaneously dropwise adding trichloroacetaldehyde and dimethyl phosphite for reaction, and controlling the reaction temperature to be 75-85 DEG C; (2) enabling the reaction materials to enter a second-stage synthesis kettle from the first-stage synthesis kettle to continuously react, and controlling the reaction temperature to be 75 DEG C; and the product trichlorfon is obtained after the reaction in the I-stage synthesis kettle and the II-stage synthesiskettle.

Owner:漯河市新旺化工有限公司

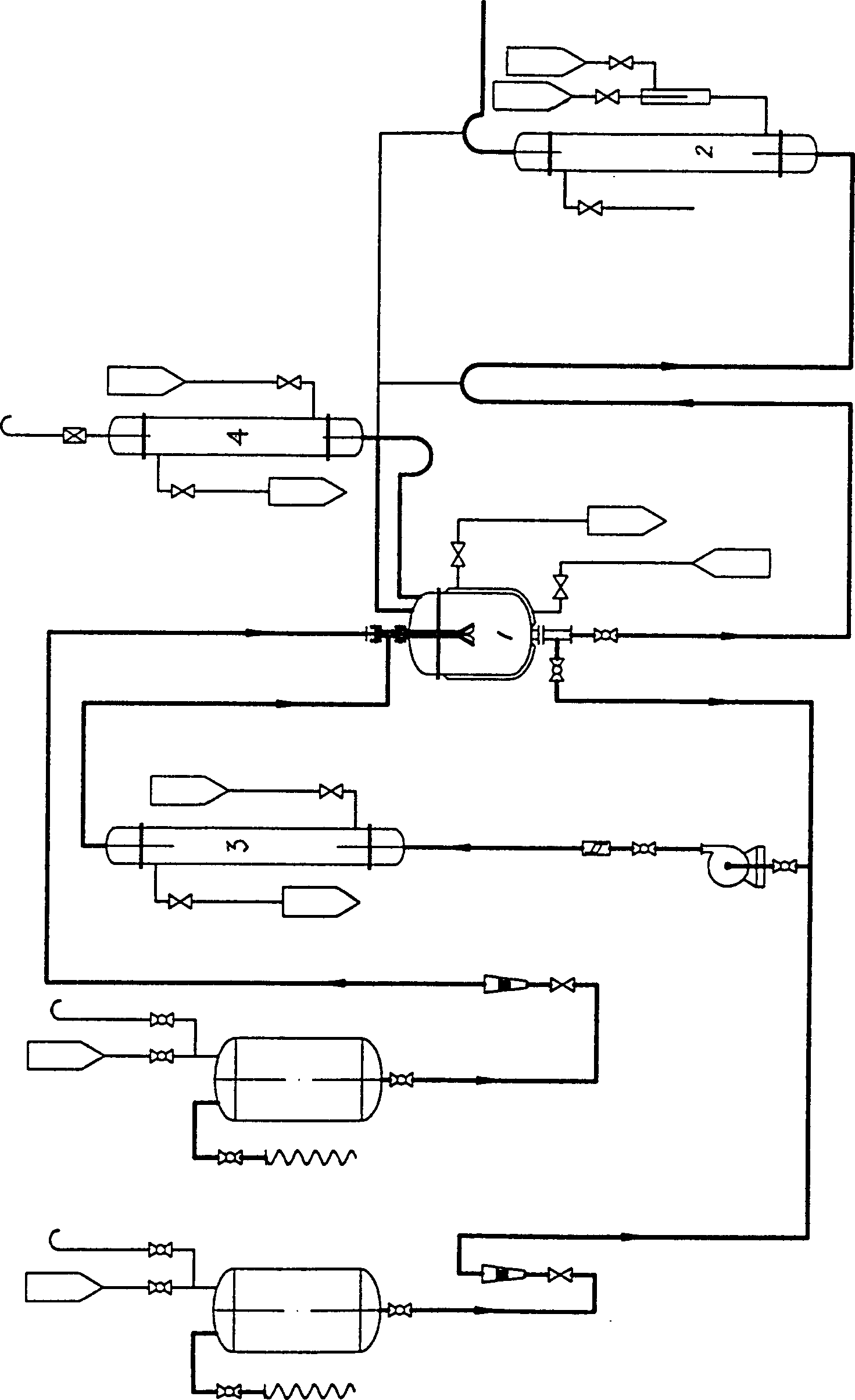

Method for continuously synthesizing trichloracetic aldehyde and device thereof

InactiveCN101805248BIncrease profitReduce generationCarbonyl compound preparation by oxidationPhysical chemistryChloroacetaldehyde

The invention discloses a method for continuously synthesizing trichloracetic aldehyde and a device thereof. Ethanol and chlorine gas react through countercurrent contact, a reaction vessel consists of three stages of loop reaction vessels and one stage of filling material reaction vessel or a plate type reaction vessel, the mol ratio of the chlorine gas to the ethanol is 3.5 to 4.5 / 1, and the mol ratio of water to the ethanol is 0.6 to 1.5 / 1. The first stage of the reaction vessel has the temperature between 10 and 30 DEG C, the second stage of the reaction vessel has the temperature between50 and 75 DEG C, the third stage of the reaction vessel has the temperature between 80 and 95 DEG C, and the third stage of the reaction vessel has the temperature between 80 and 110 DEG C. The chlorine gas is introduced through the bottom of the second stage, the third stage and the fourth stage of the reaction vessels, tail chlorine of the second stage, the third stage and the fourth stage of the reaction vessels enters the first stage of the reaction vessel after being merged, the ethanol is added from the first stage of the reaction vessel, intermediate products of the reaction sequentially flow into a next stage of the reaction vessel, and the water is respectively added at different heights of the fourth stage of the reaction vessel. The method and the device have the advantages that the reaction yield and the equipment utilization rate are high, and the invention has good industrial application prospects.

Owner:XIANGTAN UNIV

Synthesis method of C13-labelled DDT (Dichlorodiphenyl Trichloroethane), DDD (Dichlorodiphenyl Dichloroethane) and DDE (Dichlorodiphenyl Dichloroethene)

ActiveCN103601610BStable abundancePreparation by hydrogen halide split-offChlorobenzenePtru catalyst

The invention discloses the technical field of synthesis of isotope labeled compounds and particularly relates to a synthesis method of C13-labelled DDT (Dichlorodiphenyl Trichloroethane), DDD (Dichlorodiphenyl Dichloroethane) and DDE (Dichlorodiphenyl Dichloroethene). The synthesis method comprises the following steps: with 13C6-benzene as a raw material, carrying out oxychlorination to obtain 12C6-chlorobenzene, carrying out acid catalytic condensation on the 12C6-chlorobenzene with a trichloracetic aldehyde hydrate and a dichloroacetaldehyde hydrate respectively to obtain 13C12-DDT and 13C12-DDD, and preparing 13C12-DDE by carrying out catalytic dehydrochlorination on 13C12-DDT by means of a phase transfer catalyst. A series of representations prove that the products are 13C12-DDT, 13C12-DDD and 13C12-DDE, and the chemical purity of the products reaches above 90 percent, and the stable isotope abundance is above 90 percent.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

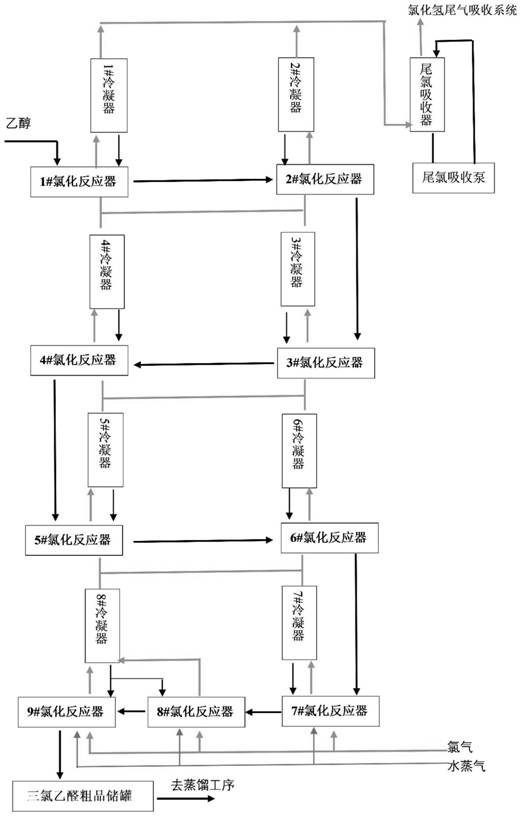

Continuous chlorination reaction device and method for producing trichloroacetaldehyde

PendingCN112624912AIncrease profitReduce consumptionOrganic compound preparationCarbonyl compound preparationReaction rateWater chlorination

The invention provides a continuous chlorination reaction device and method for producing trichloroacetaldehyde, and the provided continuous chlorination reaction device specifically comprises chlorination reactors 1 #-9 #, condensers 1 #-8 # matched with the chlorination reactors 1 #-9 #, a tail chlorine absorber, a tail chlorine absorption pump, a trichloroacetaldehyde crude product storage tank and a hydrogen chloride tail gas absorption system which are connected in sequence through pipelines, and the four-step nine-stage continuous chlorination reaction device is formed. When the device is used for producing trichloroacetaldehyde, reactant ethanol is added from the 1 # chlorination reactor in the top layer and continuously flows into the chlorination reactor from top to bottom; the reactant chlorine is continuously introduced into chlorination reactors 7 # to 9 # at the bottom layer from bottom to top according to a proper proportion and are subjected to countercurrent contact reaction with ethanol in the chlorination reactors, and water vapor participates in the reaction process. The reaction device disclosed by the invention can reduce the requirement on the height of a plant, is simple in structure and reaction condition, and is easy to realize industrialization; and the provided production method optimizes the kinetic control of the reaction process, and improves the reaction rate and the reaction yield.

Owner:安道麦股份有限公司

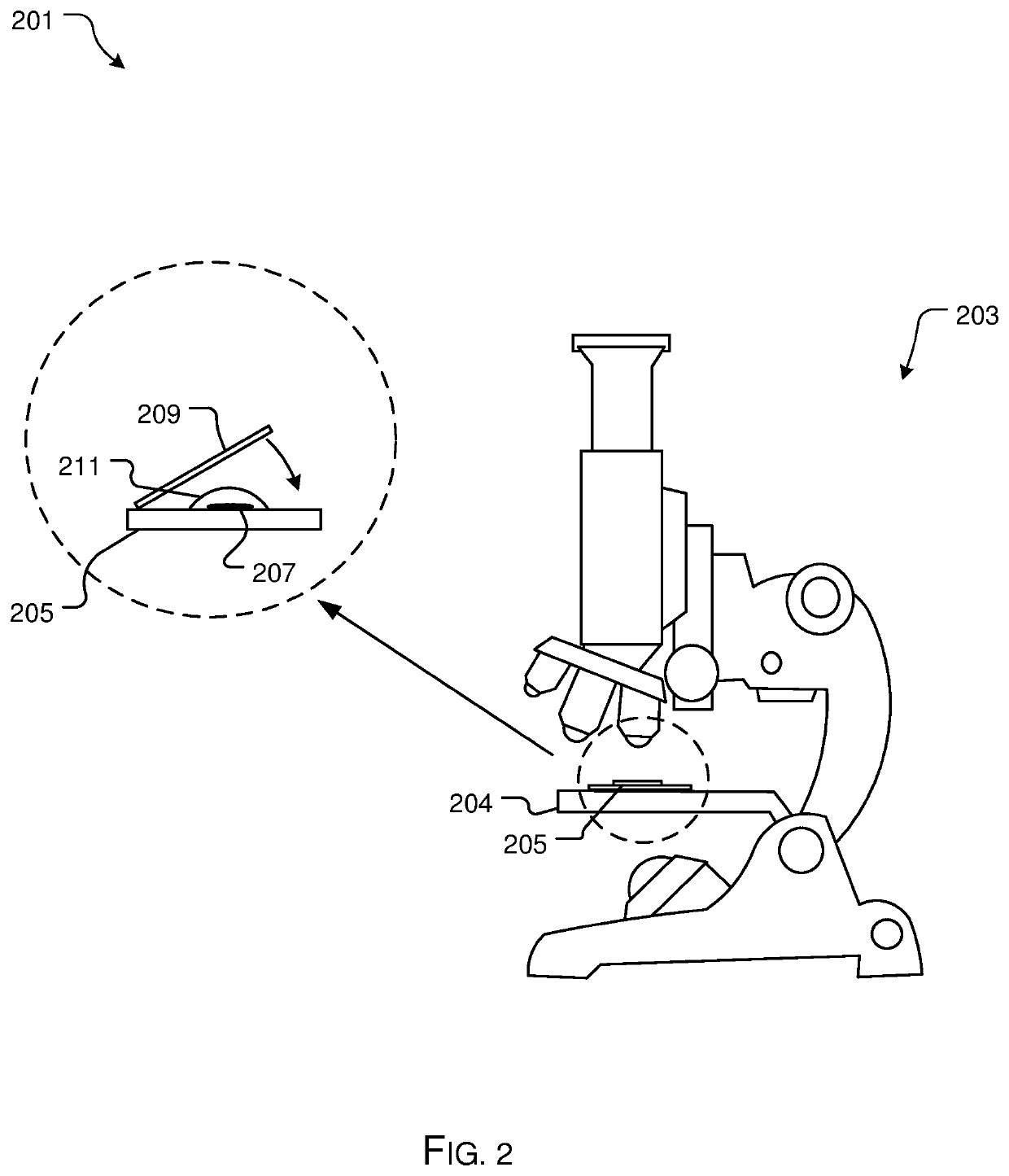

Microscope slide mounting system

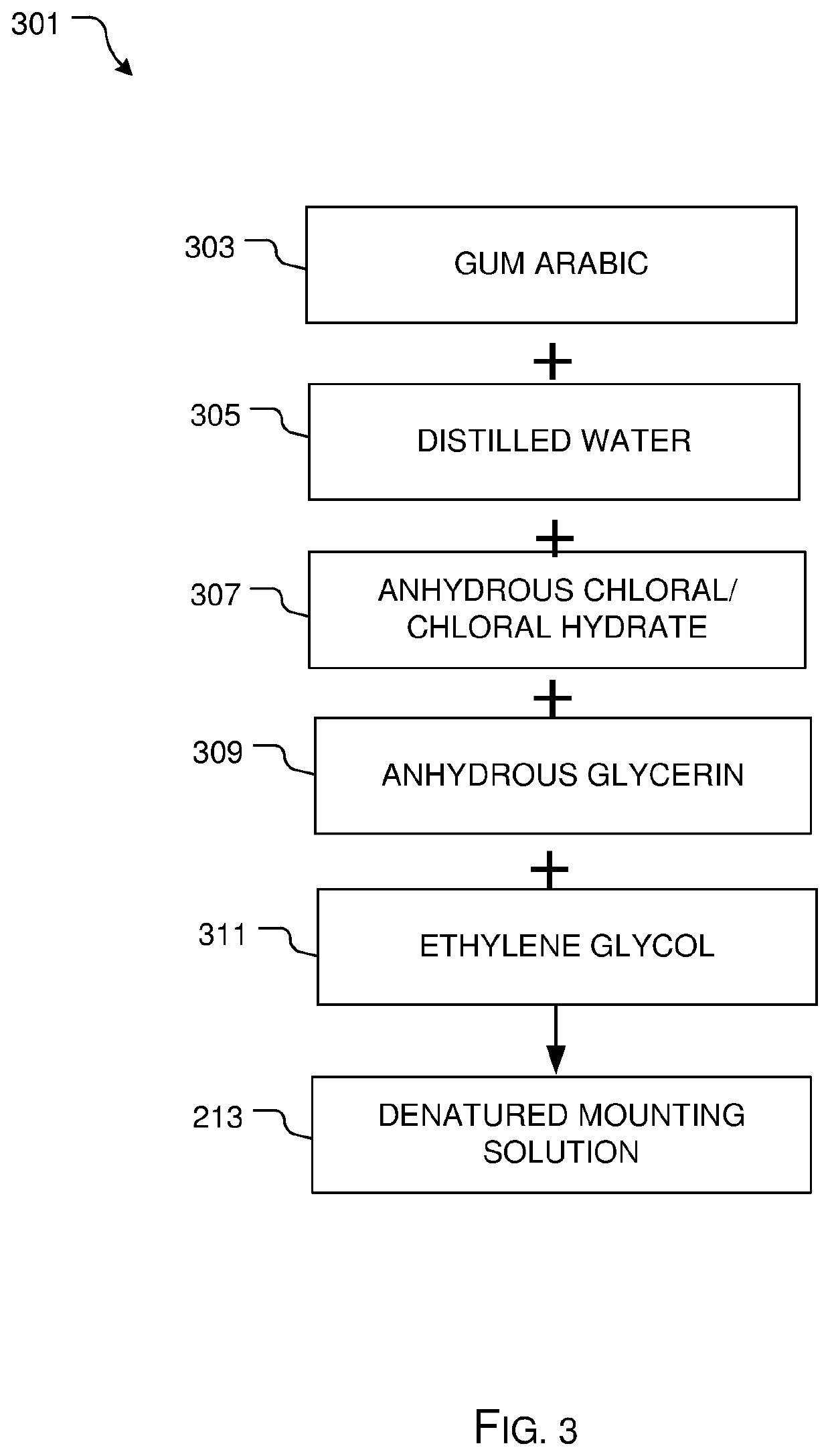

A microscope slide mounting system includes a slide mounting medium, with a predetermined weight of powdered gum arabic in a predetermined weight of distilled water; a predetermined weight of anhydrous chloral; a predetermined weight of anhydrous glycerin; and a predetermined percentage of ethylene glycol; the ethylene glycol acts as a denaturant in the mounting medium; and the ethylene glycol causes mild illness when ingested, thereby discouraging the use of the mounting medium as a sedative or recreational drug and prevents the crystallization of the medium.

Owner:HAYS THOMAS EDWARD

Method for effectively controlling ozone oxidation byproducts and pollutants in water treatment process

PendingCN111533316AEfficient removalSuppress generationTreatment involving filtrationMultistage water/sewage treatmentSodium hydrogen sulphiteSodium bisulfate

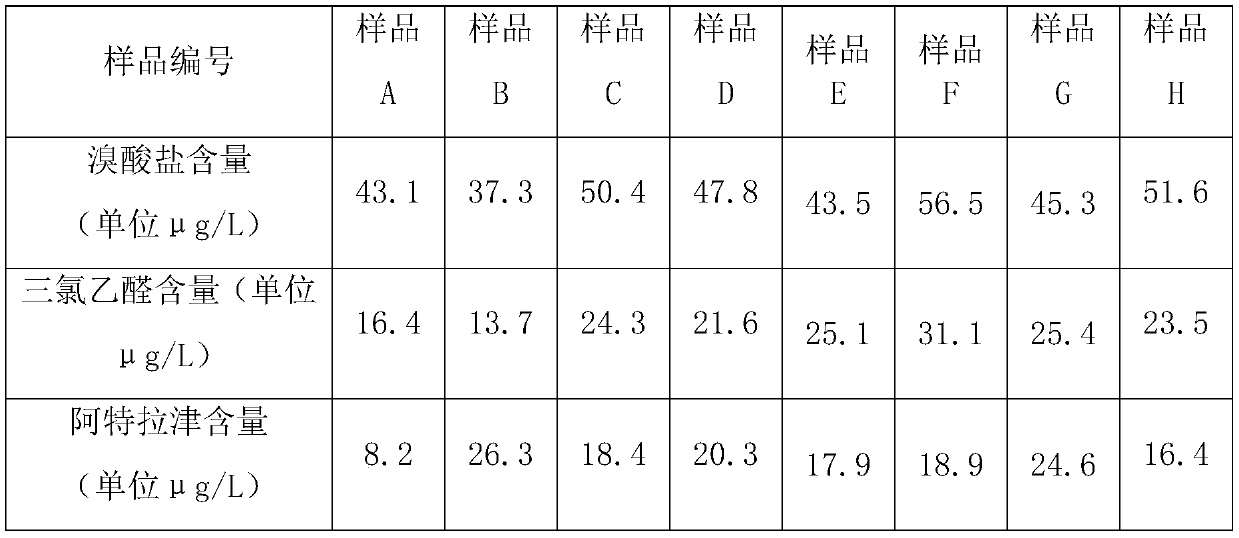

The invention relates to the technical field of water treatment, in particular to a method for effectively controlling ozone oxidation byproducts and pollutants in a water treatment process. A pre-oxidant potassium permanganate / sodium hydrogen sulfite is added for pre-oxidation treatment before an ozone reaction, atrazine ATR can be effectively removed, the generation of bromate and trichloroacetaldehyde can be effectively inhibited, the removal of organic matters is ensured while controlling byproducts, and the method is an effective method for controlling pollutants and ozonation byproducts.The method is low in cost, easy to implement, convenient to control, high in operability and wide in application range.

Owner:舟山市自来水有限公司

A kind of manufacturing method of high temperature resistant printing rotary screen

ActiveCN107447236BHigh temperature resistance hasGuaranteed molding effectElectroforming processesTextile printerProcess engineering

The invention discloses a manufacturing method of a high temperature resistant printing rotary screen. The manufacturing method sequentially comprises the following steps of (1) preparing a die; (2) plating for the first time, and manufacturing a single screen; (3) preparing an additive, wherein the new additive is prepared from chloral hydrate for replacing saccharin sodium salt, 1,4-butynediol and deionized pure water; (4) plating for the second time, and adding the additive in the step (3) to a plating bath plated for the second time; and (5) processing a finished product. The manufacturing method has the advantages of simple step and convenience in operation, and a bath solution and the new additive are matched, so that the forming effect of the printing rotary screen is guaranteed, and the printing rotary screen has the characteristics of high temperature resistance, high rigidity, good toughness and durability; in addition, the new additive is prepared from the chloral hydrate for replacing the saccharin sodium salt, so that the brightness of the printing rotary screen is reduced, a frosted effect is generated, when plate making is performed on the printing rotary screen, the sizing is easy, and the phenomena of sticking and the like cannot occur.

Owner:翟安民

Batch distillation-adsorption coupling method dehydration technology of trichloroacetaldehyde hydrate

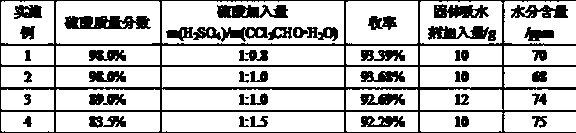

InactiveCN110922319AReduce moisture contentEasy to operateCarbonyl compound separation/purificationHydration reactionDistillation

The invention discloses a batch distillation-adsorption coupling method dehydration technology of trichloroacetaldehyde hydrate. The technology solves the problems of chemical reaction affection and device corrosion, caused by the water content of above 0.1% in conventional trichloroacetaldehyde hydrate dehydration methods. The technology comprises the following specific steps: heating trichloroacetaldehyde hydrate in a distillation condensation system to form a molten state, starting stirring, adding concentrated sulfuric acid, continuously performing heating distillation, collecting the obtained 97-99 DEG C fraction, carrying out static adsorption on the collected trichloroacetaldehyde through a supported solid water absorbent, and then performing filtering separation to obtain anhydroustrichloroacetaldehyde. The batch distillation-adsorption coupling method reduces the cost of the dehydration process of trichloroacetaldehyde hydrate, and makes the technology economical and environmentally friendly, the concentrated sulfuric acid and the solid adsorbent used in the process can be recycled and repeatedly used, and the moisture content of the anhydrous trichloroacetaldehyde is reduced to 100 ppm or below.

Owner:HUBEI HONGYUAN PHARMA

Electrolysis recovery method of nickel in waste water

ActiveCN102618882AHigh purityEasy to removePhotography auxillary processesWater/sewage treatmentHydration reactionPhosphorous acid

Disclosed is an electrolysis recovery method of nickel in waste water. The method includes steps of: firstly, selecting 1000-1500 parts of waste water containing nickel, using sodium hydroxide flakes to regulate PH in a range of 1-6; secondly, adding 0.01-0.05 parts of polyethylene glycol, 0.03-0.06 parts of thiourea, 0.01-0.015 parts of at least one of sodium dodecyl sulfate, chloral hydrate, para toluene sulfonamide and saccharin, maintaining a system temperature at 50-80 DEG C, controlling current to in a range of 1.0-5.0A and starting electrolysis with stirring, maintaining the PH the same as that in the first step through adding the sodium hydroxide flakes, and controlling electrolysis time in a range of 12-24 hours; and thirdly, using sodium hydroxide flakes again to regulate the PH in a range of 6-10, adding 0.15-0.3 parts of at least one of sodium monophosphate and gelatin, maintaining the system temperature continuously, controlling current to in a range of 1.0-5.0A and starting electrolysis with stirring, and controlling electrolysis time in a range of 8-16 hours. The electrolysis recovery method of the nickel in the waste water is high in applicability, simple and convenient, low in cost; and can obtain metallic nickel directly.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Flame retardant with good flowing property and for polyurethane foam product

The invention discloses a flame retardant with good flowing property and for a polyurethane foam product. A formula of the flame retardant comprises the following components in parts by weight: 2-3 parts of trichloroacetaldehyde, 10-15 parts of tris(1,3-dichloropropyl)phosphate, 4-6 parts of tributyl phosphate, 0.3-0.6 part of trioctyl phosphate, 8-10 parts of triisocyanate, 15-18 parts of hydrated alumina, 10-13 parts of expanded graphite, 5-9 parts of hydrated zinc borate, 0.1-0.3 part of molybdenum trioxide and 1-1.3 parts of tetrabromophthalic anhydride. According to the invention, hydrated alumina and expanded graphite are used as flame-retardant materials, triphosphate and molybdenum trioxide are mixed, and the characteristic of low viscosity of triphosphate is utilized, so the fluidity of hydrated alumina and expanded graphite is improved after triphosphate is mixed with hydrated alumina and expanded graphite; and thus, the fluidity of the whole flame retardant is further improved, and in the process of polyurethane foaming, hydrated alumina and expanded graphite can be quickly mixed in the polyurethane foaming raw material to allow the whole polyurethane foaming process tobe quicker.

Owner:宁波耀众模塑科技有限公司

A kind of synthetic method of 2,3,5-trichloropyridine

ActiveCN112159349BHigh yieldReduce pollutionOrganic chemistryChemical recyclingPtru catalystAcrylonitrile

The present invention relates to a kind of synthetic method of 2,3,5-trichloropyridine, it comprises the following steps: (1) under the condition that phase-transfer catalyst and polymerization inhibitor exist, chloral, acrylonitrile and catalyzer are in 60 Carry out chemical reaction at ~90°C to prepare the intermediate product 2,4,4-trichloro-4-formylbutyronitrile; (2) warm up the reaction solution obtained in step (1) to 60-100°C, and slowly pass Hydrogen chloride gas was added to carry out the ring closure reaction to prepare the target compound 2,3,5-trichloropyridine. By adopting the synthesis method of the present invention, the reaction conditions are mild and do not require harsh reaction conditions, such as high temperature, high pressure and reaction solvent, the catalyst can be recycled and used mechanically, the heavy metal pollution is less, the yield of the target product is high, reaching 80%, and the purity is high. 99%, the post-treatment of the product is simple, the cost is reduced, and it is suitable for industrial production.

Owner:常州沃腾化工科技有限公司

Application of fungicide comprising pseudomonas monteilii in purification of chlorine-containing waste gas

ActiveCN108624529AShort adaptation periodHigh efficiency of organic chlorine degradationBacteriaDispersed particle separationFungicideExhaust fumes

The invention belongs to the field of environmental governance, and particularly relates to application of fungicide comprising pseudomonas monteilii in purification of chlorine-containing waste gas.The pseudomonas monteilii is particularly Pseudomonas monteilii LW-1, the accession number is CGMCC No. 13748, the fungicide is used for treating organic-chlorine-containing waste gas generated in a pesticide waste water storage pond, gas flow is 100-5000 m<3> / h, residence time is 1.0-5.0 min, the temperature is 35-55 DEG C, the concentration of trichloracetic aldehyde is 5-100 mg / m<3>, and the degradation efficiency of the trichloracetic aldehyde can reach 75% or above.

Owner:DAJIANG ENVIRONMENT CORP +1

Synthetic method of 3-chlorine-5-aminopyridazines serving as medicine and pesticide intermediates

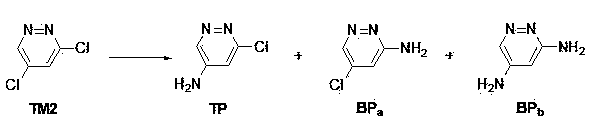

ActiveCN102838548BEmission reductionReduce usageOrganic chemistryReaction temperatureChloroacetaldehyde

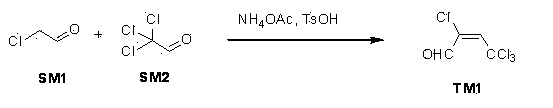

The invention relates to a synthetic method of 3-chlorine-5-aminopyridazines serving as medicine and pesticide intermediates. A process route comprises chloroacetaldehyde and trichloracetic aldehyde serving as initial raw materials, three steps of reactions including condensation, cyclization and amination are carried out to prepare the 3-chlorine-5-aminopyridazines. In order to further improve technical effects of the synthetic method, an inventor of the synthetic method conducts an optimization evaluation on process conditions such as using quantity proportion of the raw material, used solvent types and reaction temperature and time in each step. Total recovery of 3-chlorine-5-aminopyridazines products prepared by using optimized process conditions is improved from 29.2% to 36.5%.

Owner:JINAN TRIO PHARMATECH

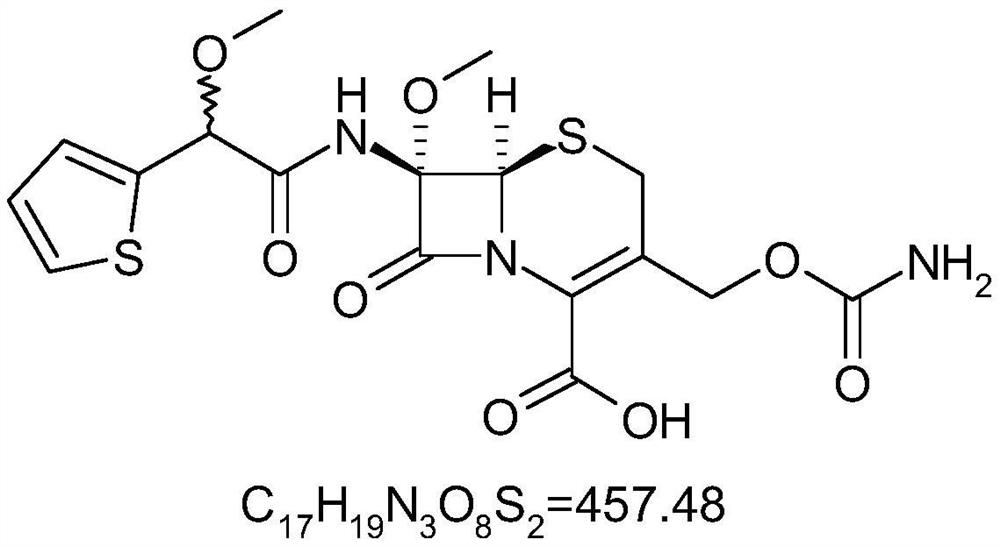

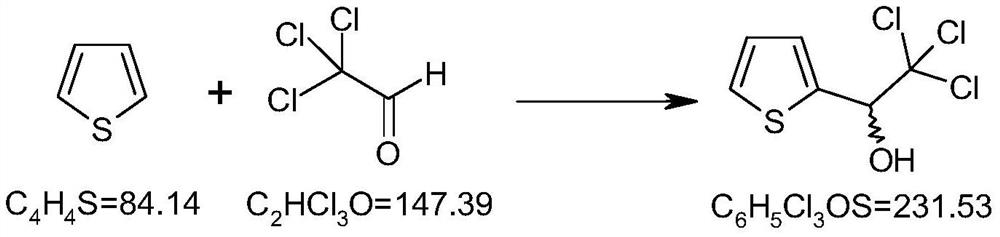

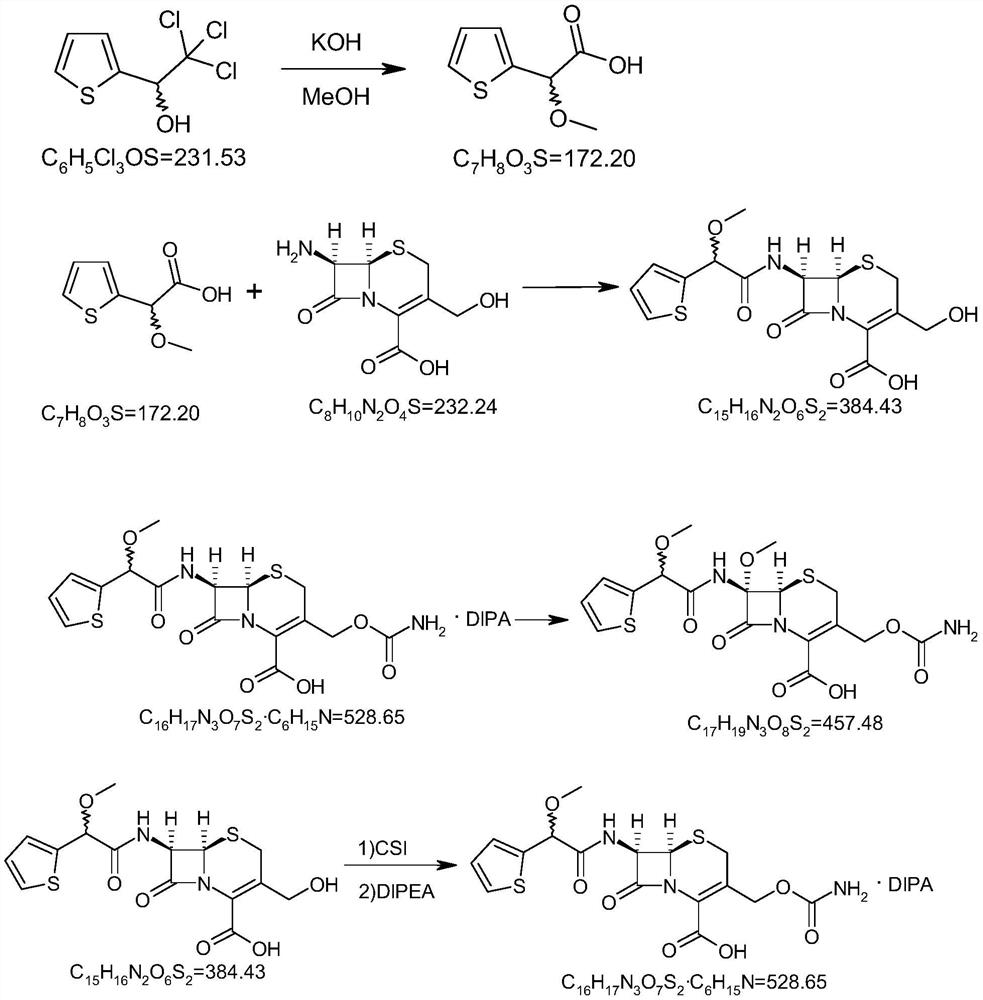

The preparation method of (rs)-methoxycefoxitin

The invention discloses a preparation method of (RS)-methoxy cefoxitin, which is characterized by comprising the following steps: (1) taking thiophene as an initial raw material, n-heptane as a reaction solvent, reacting with trichloroacetaldehyde, and distilling under reduced pressure after the reaction; (2) reacting the product of the step (1) with methanol in the presence of alkaline substancesto prepare (RS)-alpha-methoxy-2-thiophenephenylacetic acid; (3) dissolving the (RS)-alpha-methoxy-2-thiophenephenylacetic acid in an organic solvent, adding a first organic base, stirring and clarifying, and dripping methanesulfonyl chloride or pivaloyl chloride for later use; adding HACA and an organic solvent into another reaction vessel, adding a second organic base, and stirring the mixture until the mixture is clarified for later use; slowly dripping a solution B into a solution A at below -30 DEG C; then dropwise adding chlorosulfonyl isocyanate to react to obtain white-like crystallinepowder; and (4) reacting the white-like crystalline powder with sodium methoxide to obtain a product. The purity of the product is high.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

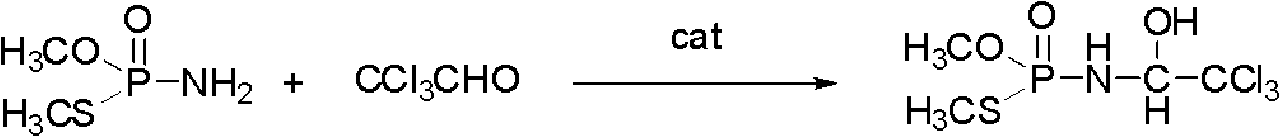

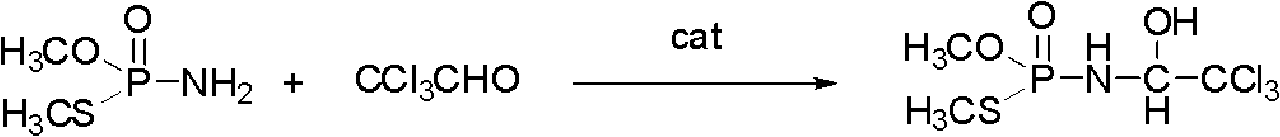

Chemical composite method for O, S-dimethyl-2, 2, 2-trichlorine-1-hydroxy ethyl amido phosphoric acid

InactiveCN101671360AReduce pollutionReduce usageGroup 5/15 element organic compoundsBenzeneChemical synthesis

The invention relates to a chemical composite method for O, S-dimethyl-2, 2, 2-trichlorine-1-hydroxy ethyl amido phosphoric acid, which is as follows: taking methylamine phosphine and chloral as mainraw materials, taking 1, 2-dichloroethane as organic solvent, reacting for 2-3 hours in the presence of a catalyzer Cu (OTf)2. As the chemical composite method uses 1, 2-dichloroethane with relativelysmaller toxicity for replacing benzene as organic solvent and the usage amount is greatly reduced; therefore, in the production process, the chemical composite method greatly reduces the pollution tothe environment and is worth to popularize.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com