Dedevap continuous production method

A technology of dichlorvos and temperature control, applied in the production field of dichlorvos, can solve the problems of poor production stability and safety, product quality and yield cannot reach a better level, low production efficiency, etc., and achieve stable product quality and reduce energy. The effect of consumption and improving the efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

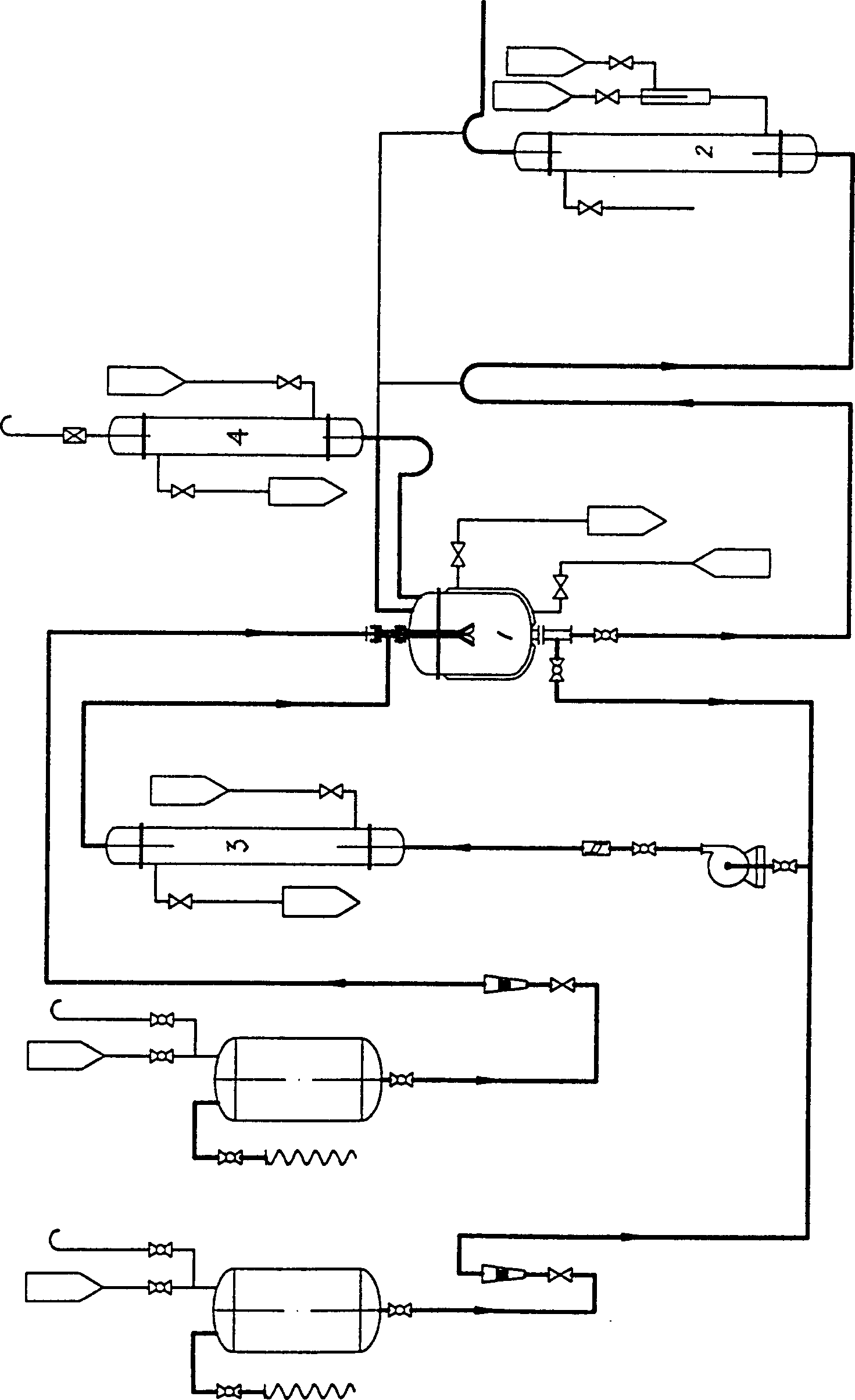

[0011] As shown in the schematic flow chart, first, 900kg of dichlorvos with a content of 91.5% is cast in the first stage reactor 1 as the bottom material of the reactor, and then two raw materials of chloral and trimethyl phosphite are added simultaneously through a flow meter and a circulating pump To the first stage reactor 1 to react, chloral and trimethyl phosphite add-on are respectively 573.5kg / h and 486kg / h, temperature is controlled at 65 ℃, and simultaneously make reaction material from the first stage reactor 1 flows out from the bottom, then overflows from the bottom of the second stage reactor 2 to the insulation reaction in the second stage reactor. There is primer 900kg), content 95.2%. The yield is 99.5% based on chloral and 99% based on trimethyl phosphite. Wherein the process flow includes a cooler 3, the material inlet of the cooler 3 is connected with the discharge port of the first stage reactor 1 by a pipeline, and the material outlet of the cooler 3 is...

Embodiment 2

[0013] First, throwing 900kg content in the first-stage reactor 1 is 91.5% dichlorvos as the reactor bottom material, and then simultaneously adding two kinds of raw materials of chloral and trimethyl phosphite to the first-stage reactor through a flow meter and a circulation pump Carry out the reaction, the addition of chloral and trimethyl phosphite is 573.5kg / h and 486kg / h respectively, and the temperature is controlled at 15°C, and the reaction material is flowed out from the bottom of the first-stage reactor at the same time, and then from the second-stage reactor. The bottom of the first-stage reactor overflowed into the second-stage reactor for heat preservation reaction, the temperature was controlled at 35°C, and the metering was stopped after 3 hours of continuous operation to obtain 1802kg of finished dichlorvos crude oil (900kg of base material still exists in the reactor), with a content of 95.2% . The yield is 99.5% based on chloral and 99% based on trimethyl pho...

Embodiment 3

[0015] First, 900kg content of 91.5% dichlorvos is used as the bottom material of the reactor in the first-stage reactor, and then two kinds of raw materials, chloral and trimethyl phosphite, are added to the first-stage reactor through a flow meter and a circulation pump at the same time. Reaction, the addition of chloral and trimethyl phosphite is 573.5kg / h and 486kg / h respectively, and the temperature is controlled at 65°C, and at the same time, the reaction material flows out from the bottom of the first-stage reactor, and then from the second-stage The bottom of the reactor overflowed to the second-stage reactor for heat preservation reaction, the temperature was controlled at 100°C, and the metering was stopped after 1.5 hours of continuous operation to obtain 1802kg of finished dichlorvos crude oil (900kg of base material still exists in the reactor), with a content of 95.2%. The yield is 99.5% based on chloral and 99% based on trimethyl phosphite. Wherein the process f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com