Method for effectively controlling ozone oxidation byproducts and pollutants in water treatment process

An ozone oxidation and treatment process technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low reaction rate, high pH adjustment cost, accelerated ozone decomposition, etc., and achieves the scope of application Extensive, highly maneuverable, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

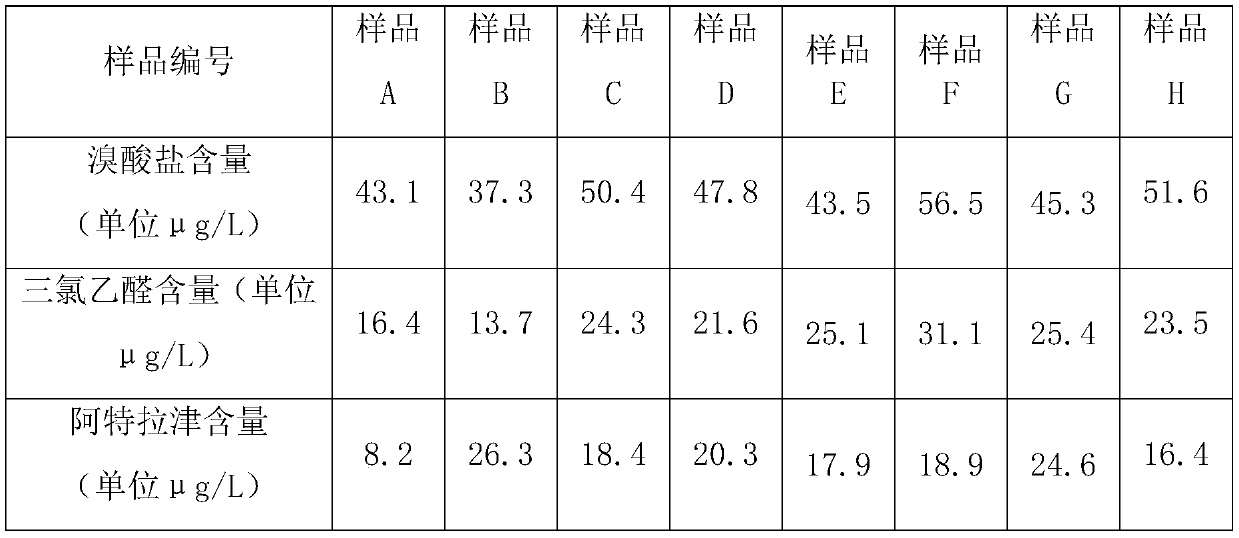

[0025] 1) Take 8L raw water sample, filter it with a filter membrane with a pore size of 0.45 μm, divide it into 8 equal parts (respectively named A, B, C, D, E, F, G, H), and add pollutants to them respectively Trazine, the weight-to-volume ratio (unit) that makes Atrazine (ATR) and raw water is 150.0 μ g / L;

[0026] 2) Perform the following treatments on the 8 samples (A, B, C, D, E, F, G, H) in step 1) respectively: Sample A: add 1 mg / L to sample A in step 1) Potassium permanganate + 5mg / L sodium bisulfite, and adjust the pH to 7 with NaOH solution or HCl solution; stir with a rotor, pre-oxidation treatment time 20min; sample B: add 2mg / L to sample B in step 1) Potassium permanganate + 5mg / L sodium bisulfite, and adjust the pH to 7 with NaOH solution or HCl solution; stir with a rotor, pre-oxidation treatment time 20min;

[0027] Sample C: sample C in step 1) is not subjected to pre-oxidation treatment;

[0028] Sample D: add 5 mg / L sodium bisulfite to the sample D in ste...

Embodiment 2

[0039] 1) Pre-oxidation pre-oxidation treatment: the amount of water entering the plant is 3000t / h, the dosage of potassium permanganate is 1mg / L, the dosage of sodium bisulfite is 5mg / L, and the pre-oxidation treatment time is 20min; After water sample;

[0040]2) Ozone pretreatment: add ozone to the water sample after preoxidation treatment in step 1), make the concentration control of ozone be 3mg / L, ozone contact time 3min, obtain the water sample after ozone pretreatment;

[0041] 3) Coagulation and precipitation: add 25mg / L polyaluminum chloride to the water sample after ozone pretreatment in step 2);

[0042] 4) Pre-sand filter: use a single layer of quartz sand filter material, particle size d10 = 0.9mm, unevenness coefficient k80 = 1.4, thickness 1.2m; the lower layer is provided with a coarse sand layer, thickness 50mm, particle size 2.0 ~ 4.0mm. The design scale of the pre-sand filter is 80,000 m 3 / d, the filter material adopts a V-type filter with air-water back...

Embodiment 3

[0048] 1) Pre-oxidant pre-oxidation treatment: the amount of water entering the plant is 3000t / h, the dosage of potassium permanganate is 2mg / L, the dosage of sodium bisulfite is 5mg / L, and the pre-oxidation treatment time is 20min; After water sample;

[0049] 2) Ozone pretreatment: add ozone to the water sample after preoxidation treatment in step 1), make the concentration control of ozone be 3mg / L, ozone contact time 3min, obtain the water sample after ozone pretreatment;

[0050] 3) Coagulation and precipitation: add 24mg / L polyaluminum chloride to the water sample after ozone pretreatment in step 2);

[0051] 4) Pre-sand filter: use a single layer of quartz sand filter material, particle size d10 = 0.9mm, unevenness coefficient k80 = 1.4, thickness 1.2m; the lower layer is provided with a coarse sand layer, thickness 50mm, particle size 2.0 ~ 4.0mm. The design scale of the pre-sand filter is 80,000 m 3 / d, the filter material adopts a V-type filter with air-water backw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com