Batch distillation-adsorption coupling method dehydration technology of trichloroacetaldehyde hydrate

A technology for hydrating chloral and chloral, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve problems such as corrosion of industrial equipment, consumption of large concentrated sulfuric acid, waste acid cannot be processed, etc., and achieve simple installation , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

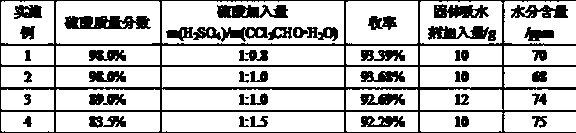

Embodiment 1

[0024] Take 100g of chloral hydrate to the distillation device, heat it to 57°C to make it into a molten state, start stirring and add 80g of concentrated sulfuric acid with a mass fraction of 98%, raise the temperature to 120°C, distill, collect 83.22g of fractions, and the yield is 93.39 %, add 10g load-type solid water-absorbing agent to the collected fractions for static adsorption, and vacuum filter after 24h to obtain anhydrous chloral with a moisture content of 70ppm.

Embodiment 2

[0026] Take 100g of chloral hydrate into the distillation device, heat to 57°C to make it into a molten state, start stirring and add 100g of concentrated sulfuric acid with a mass fraction of 98%, heat up to 120°C, distill, collect 82.15g of fractions, and the yield is 92.19 %, add 10g load-type solid water-absorbing agent to the collected fractions for static adsorption, and vacuum filter after 24h to obtain anhydrous chloral with a moisture content of 68ppm.

Embodiment 3

[0028] Take 100g of chloral hydrate to the distillation device, heat it to 57°C to make it into a molten state, start stirring and add 100g of concentrated sulfuric acid with a mass fraction of 89%, raise the temperature to 120°C, distill, collect 82.60g of fractions, and the yield is 92.69 %, add 12g load-type solid water-absorbing agent to the collected fractions for static adsorption, and vacuum filter after 24h to obtain anhydrous chloral with a moisture content of 74ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com