Phosphorous-removing double-metal organic framework material and preparation method and application thereof

An organic framework and bimetallic technology, applied in the field of pollution control, can solve the problems of low efficiency of phosphorus removal by adsorption, low reusability, difficulty in meeting emission standards, etc., achieve excellent phosphorus removal effect, great practical application value, excellent The effect of reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

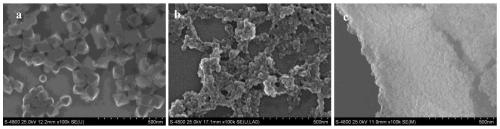

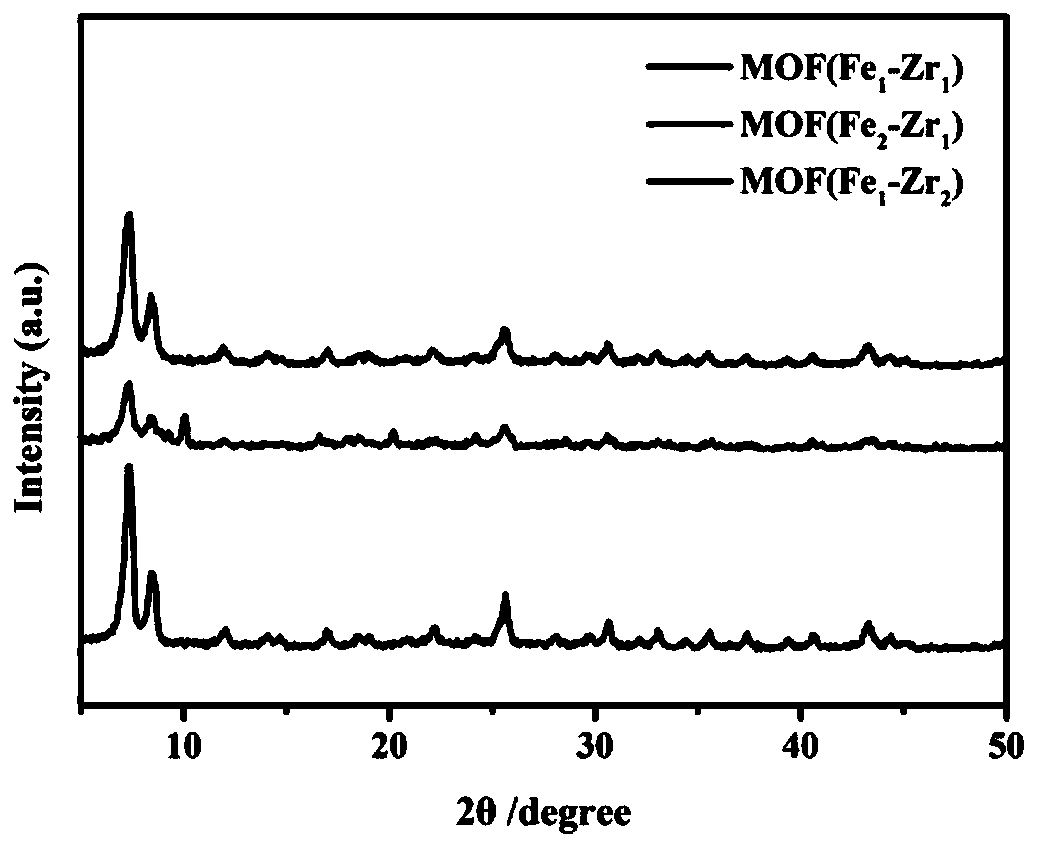

[0029] The synthesis of embodiment 1 bimetallic organic framework material

[0030] 1 mmol ferric chloride hexahydrate FeCl 3 ·6H 2 O (0.271g), 1mmol zirconium chloride ZrCl 4 (0.233g) and 2mmol (0.362g) 2-aminoterephthalic acid NH 2 Dissolve BDC in 40mL N,N'-dimethylformamide DMF, then add 0.2g PVP (K 30), stir until it is completely dissolved, and after ultrasonication for 30min, transfer the mixed solution to the reaction kettle and heat to 150 After reacting at ℃ for 24 hours, take it out and cool it down to room temperature, wash it alternately with DMF and ethanol for 3 times, and dry it in an oven at 90℃ for 12 hours to obtain a bimetallic framework material, which is denoted as MOF(Fe 1 -Zr 1 ). By changing the ratio of iron element content to zirconium element content to 2:1 and 1:2 respectively, and the total content of iron and zirconium to 2 mmol, the bimetallic frame material MOF (Fe 2 -Zr 1 ) and MOF (Fe 1 -Zr 2 ).

[0031] NH 2 - Synthesis of Fe-MOF: ...

Embodiment 2

[0038] Example 2 Study on Phosphorus Adsorption Properties of Bimetallic Organic Framework Materials

[0039] 1. MOF (Fe 1 -Zr 1 ), MOF(Fe 1 -Zr 2 ) and MOF (Fe 2 -Zr 1 ) Phosphorus adsorption efficiency

[0040] In addition to the above three materials, in order to further reflect the beneficial effects of bimetallic frame materials, we also set NH 2 -Fe-MOF, NH 2 -Zr-MOF two comparison groups, under the same conditions (pH=7, temperature 25°C, phosphate concentration 50mg / L, material dosage 2mg), oscillate at 180rpm for 24h in a shaker, the solution is subjected to 0.22 After filtering with a μm filter membrane, measure the phosphorus concentration and calculate the adsorption capacity. The results are as follows: Figure 4 shown. MOF(Fe 1 -Zr 1 ), MOF(Fe 2 -Zr 1 ), MOF(Fe 1 -Zr 2 ), NH 2 -Fe-MOF and NH 2 The adsorption capacities of the five materials of -Zr-MOF from high to low are 222.4mg / g, 199.9mg / g, 109.7mg / g, 107.1mg / g, 91.2mg / g.

[0041] For further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com