Preparation method of up-conversion luminescence coding nano-composite particle based on mesoporous silica and coding method

A mesoporous silica and nanocomposite technology is applied in the field of preparation of upconversion luminescence coding microspheres, and can solve the problems of complex operation steps, high biological toxicity, difficult surface modification and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

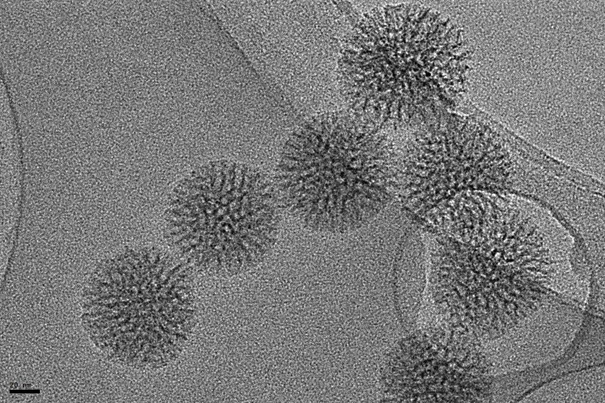

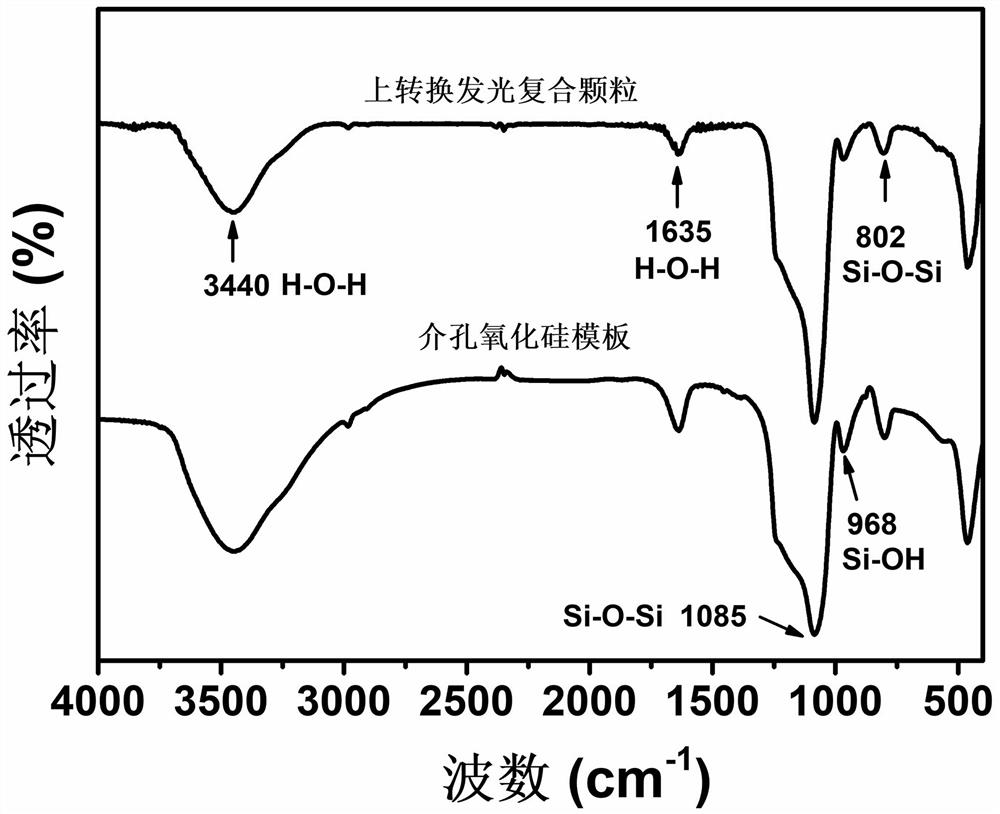

[0047] The mesoporous silica nanoparticle template with radial pore structure was prepared by microemulsion method: 100 mg CTAB was dissolved in 30 mL deionized water, and heated and stirred in an oil bath at 60 ℃ for 30 minutes. Then 25.5 mL of n-octane, 1.8 mL of styrene, 22 mg of lysine, 1 mL of TEOS and 46.3 mg of AIBA were added, and stirred at 350 rpm for 3 hours. The product was collected by ethanol washing and centrifugation for several times, dried in an oven at 80°C for 4 hours, and sintered at 550°C to remove the organic template. figure 1 The mesoporous silica template shown.

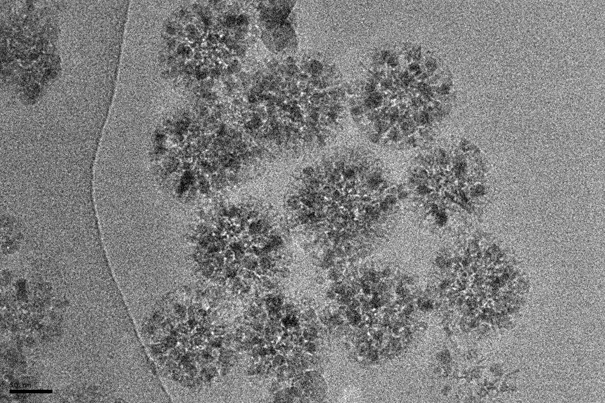

[0048] Preparation of calcium fluoride precursor sol co-doped with ytterbium and holmium: dissolve 5.2854 g of calcium acetate monohydrate in 68 mL of water, add 2.5334 g of ytterbium acetate and 0.2052 g of holmium acetate, that is, the rare earth doping ratio is Yb 3+ / Ho 3+ (20 / 2 mol%), adding 12 mL of trifluoroacetic acid and stirring at room temperature for 24 hours, a clear and trans...

Embodiment 2

[0055] The method of preparing zinc fluoride precursor sol co-doped with ytterbium and erbium by using metal alkoxide and rare earth alkoxide: Weigh 3.8238g of zinc methoxide and dissolve it in 68 mL of water, add 2.1018 g of ytterbium isopropoxide and 0.1034 g of erbium isopropoxide, That is, the rare earth doping ratio is Yb3+ / Er3+= 20 / 1 mol%, adding 12 mL of trifluoroacetic acid and stirring at room temperature for 24 hours, a clear and transparent up-conversion luminescence precursor solution is obtained. Add 100 mg of mesoporous silica with radial pore structure prepared in advance to 20 mL of the above precursor sol, and stir thoroughly at a constant temperature and low speed in a 40°C water bath for 12 hours. After centrifugation at 8000 rpm for 2 and a half minutes, the supernatant was discarded, and 200 μL of precursor sol was added again, and the adherent particles were redispersed by vortexing. After standing at room temperature for half an hour, add 20 mL of deioni...

Embodiment 3

[0057] Method for preparing lanthanum fluoride or cerium fluoride precursor sol co-doped with ytterbium and holmium by using trivalent metal acetate and rare earth acetate: Weigh 5.01 g of lanthanum (Ⅲ) acetate hydrate or 4.76 g of cerium (Ⅲ) acetate The hydrate was dissolved in 34 mL of water, and 1.2667 g of ytterbium acetate and 0.1026 g of holmium acetate were added, that is, the rare earth doping ratio was Yb 3+ / Ho 3+ (20 / 2 mol%), adding 6 mL of trifluoroacetic acid and stirring at room temperature for 24 hours, a total volume of 40 mL of ytterbium holmium co-doped LaF 3 or CeF 3 Precursor sol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com