Method for preparing high-purity calcite calcium carbonate micropowder through shell hydro-thermal treatment

A technology of calcium carbonate micropowder and hydrothermal treatment, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems that it is difficult to remove insoluble protein from shells and cannot obtain high-purity calcium carbonate micropowder, and achieve significant economic and social value and improve Effect of high hydrolysis reaction rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 10 grams of 150-mesh clam shell powder, add it to 50 milliliters of 0.5 mol / liter urea aqueous solution, mix well, pour it into a 200 milliliter autoclave, treat it at 200 ° C for 2 hours, and then remove the precipitate Separation, washing, drying, to obtain calcite calcium carbonate micropowder, its photo is as figure 1 (b) shown.

[0023] Take 10 grams of 150-mesh mussel shell powder, add it to 50 ml of sodium hydroxide aqueous solution with a concentration of 1 mol / L, mix well, pour it into a 200 ml autoclave, treat it at 250 ° C for 4 hours, and then carry out precipitation separated, washed with water, and dried to obtain calcite calcium carbonate micropowder, the photo of which is as follows figure 1 (c) shown.

[0024] and figure 1 (a) Compared with the yellow clam shell raw material, the powder treated with alkaline solution hydrothermal treatment is white, especially the shell powder treated with sodium hydroxide aqueous solution ( figure 1 (c)) has t...

Embodiment 2

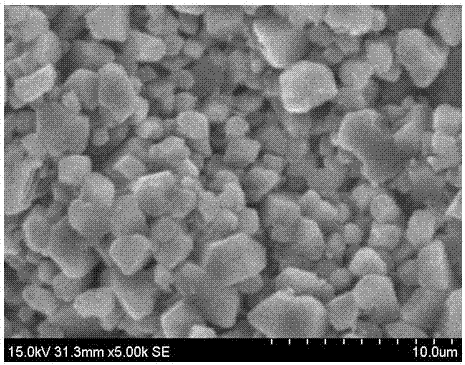

[0026] like figure 2 , image 3 As shown, X-ray structure analysis is carried out to the powder of sodium hydroxide aqueous solution hydrothermal treatment in embodiment 1, as figure 2 , indicating that the powder has completely transformed into a calcite structure. The scanning electron microscope photograph of the powder is as image 3 As shown, it can be seen that the powder is an equiaxed grain, and the grain size distribution is relatively uniform, ranging from 0.5 to 2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com